Cost effective dissolvable support

-

I am looking into printing with support. I normally pay around $20/kg for filament but it seems PVA ends up around $100/kg - a bit of a shock to the system. Hips dissoluble filament is a lot cheaper but requires chemicals.

I would appreciate getting input about PVA vs HIPS dissoluble support filament. Is there a less expensive way for supporting a print that is liquid dissoluble? When considering the cost of supplies, chemicals and disposal of waste, is HIPS or PVA more cost effective? What do you use and why?

Thanks in advance for your thoughts. -

I've seen before that you can use PVA as the interface layer only, greatly saving on material usage. If that was workable with your model and printer capabilities I would think that would be the preferable way to go.

-

HIPS is a great breakaway support, and while there is a lot of discussion online (and most of it is older) regarding dissolving HIPS, I don't think that is a common workflow nowadays. Limonene can be fairly nasty to work with, and can attack the build material as well (example - HIPS is very often used as a support for ABS, ABS can be negatively impacted by limonene).

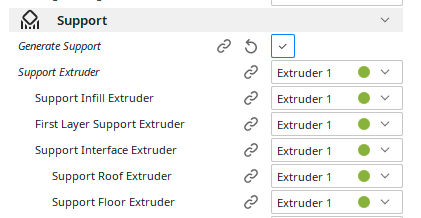

Printing only the support interface material with your soluble support (PVA, BVOH, any other) results in a cost effective workflow. Exact settings to choose vary per slicer. Example Cura options below - if I were to use soluble support only on the support interface layers, I would change the 'Support Interface Extruder' to my support nozzle/extruder.

-

Sounds like I don't want to get involved with HIPS .... and just making the interface the only area to use PVA in sounds like a good solution but that brings up a different question .... suppose you want to print a cube with one open side (ie, it has the four sides and bottom but no top). Now suppose you wanted to be difficult and print it with the open side on the build plate. You would have the center support section, a layer of PVA as interface and then the actual model. This would result in a 0.2 mm layer of PVA between the two parts of PLA (hope that makes sense) .... how well would the PVA dissolve in that case? Would I not need to make the PVA layer much thicker in order to allow water to get in there to do it's thing to dissolve the PVA?

It still sounds like PVA is the way to go but I am curious how well a single interface layer would work. -

@jens55 said in Cost effective dissolvable support:

Would I not need to make the PVA layer much thicker in order to allow water to get in there to do it's thing to dissolve the PVA?

If you make the PVA layer thicker, there will be more to dissolve. How would making it thicker let more water get in?

-

@jens55

The PLA supportstructure you'd print wouldn't be solid, but the interface layer is solid. There are plenty of gaps to flush away the interface material. -

@o_lampe, while the support structure itself would not be solid, I would likely want the last PLA layer and the PVA layer to be solid so that the upper PLA layer surface is nice and smooth ...

I currently print a solid layer, then a gap and then the supported layer itself is usually solid.Mind you, I could indeed try printing a 50% layer underneath the solid separation PVA.

I think it is most certainly worth a try so I will look for a source for some PVA.

Thanks everyone!

-

@phaedrux said in Cost effective dissolvable support:

If you make the PVA layer thicker, there will be more to dissolve. How would making it thicker let more water get in?

The thought was that the PVA would be dissolved from the edges in and the wider gap would give the water a better chance to circulate.

-

@jens55 if you don't need dissolvable supports but just a good interface layer, you can use PLA as supports for PETG and the other way round.

-

PVA is as cost effective as it will get. Using PVA only on interfaces could work, but you have to be able to get the leftover support chunks out. So you can't do inaccessible areas with that technique. But, using all-PVA supports is easier than some people lead us to believe.

PVA does take a while to dissolve, especially the special formulations like PolyDissolve S1. So, if you can easily access the support areas, breakaway support is faster, cheaper, and provides equivalently good surface finish.

I've tried PETG+PLA for supports, but did not enjoy the experience. Polymaker's PolySupport breakway support material is wonderful and half the cost of PVA.

-

@oliof, I am aware of that but thanks for pointing it out. In the project I have in mind, I need to dissolve the support.

-

@bot, thanks for that!