please help me blv setting

-

@jay_s_uk M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable TelnetM669 K1 ; select CoreXY mode

; ======================= Endstops =========================M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on ZM575 P1 S1 B57600 ; Set things up for the PanelDue

; Filament sensorM591 D0 P1 C"e0stop" S1 ; Set Filament sensor Simple type (High) for extruder drive 0, connected to endstop input 3 (E0

; ======================= Drives ===========================M569 P0 S0 ; Drive 0 goes backwards blv: its was S1

M569 P1 S0 ; Drive 1 goes backwards blv: its was S1

M569 P2 S0 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes backwards WAS 0

M569 P4 S0 ; Drive 4 goes forwards

M584 X0 Y1 Z2:4 E3 ; set drive mapping; ===================== Drive Settings =====================M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X200.00 Y200.00 Z800 E714.36 ; Set steps per mm for orbiter

;M566 X600 Y600 Z800 E600 ; Set maximum instantaneous speed changes (Jerk) (mm/min)

M203 X20000 Y20000 Z600 E7200 ; Set maximum speeds (mm/min)

;M201 X1000 Y1000 Z100 E600 ; Set accelerations (mm/s^2)

M906 X1500 Y1500 Z1000 E500 I10 ; Set motor currents (mA) and motor idle factor in per cent

;M84 S30 ; Set idle timeout

M566 X600 Y600 Z800 E1200

M201 X1000 Y1000 Z800 E1200;M203 E3600 or E7200 ;max speed mm/min

;M566 E600 ;instantaneous speed change mm/min

;M201 E600 or E800 ;acceleration mm/s^2

;M906 E500 or E1200 I10 ;motor current mA idle current 10%

; ===================== Axis Limits ========================M208 X-23 Y0 Z0 S1 ; Set axis minima

M208 X320 Y320 Z350 S0 ; Set axis maxima; ======================== Z-Probe =========================M558 P1 C"^zprobe.in" H5 F200 T9000 I0 R0.5 ; Set Z probe type mini ir sensor

G31 P500 X-2.24 Y-20.81 Z1.300 ; Set Z probe trigger value, offset and trigger height

M557 X20:270 Y20:270 S240 ; Define mesh grid; ======================== Heaters =========================M308 S0 P"bed_temp" Y"thermistor" T100000 B3950 ; define bed temperature sensor

M950 H0 C"bed_heat" T0 ; heater 0 uses the bed_heat pin, sensor 0

M307 H0 R0.272 C388.6 D16.77 S1.00 V23.6 ; Heatbed PID

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B3950 ; define E0 temperature sensor

M950 H1 C"e0heat" T1 ; heater 1 uses the e0heat pin and sensor 1

M307 H1 R2.697 C168.9:154.1 D9.06 S1.00 V23.6 ; Hotend PID .4mm

M143 H1 S260 ; set temperature limit for heater 0 to 260C

M308 S2 P"mcu-temp" Y"mcu-temp" A"Duet Board" ; Configure MCU sensor; ======================== Tools ===========================M563 P0 S"T0" D0 H1 F1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; ========================= Fans ===========================;hotend fan/ hotend

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 C"hotend" T45 ; set fan 1 value. Thermostatic control is turned on 100% at 45deg;Tool Fan/ Layer Fan

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0.5 H-1 C"buse" ; set fan 0 value. Thermostatic control is turned off;MB cooling fan layer

M950 F2 C"fan2" Q250 ;H-1 ; create fan 2 on pin fan2 and set its frequency

M106 P2 S0.10 H-1 F250 C"AC alimentation" ; set fan 2 value. Thermostatic control is turned off; ===================== Custom settings ====================;M572 D0 S0.02 ;pressure advance - you may need to finetune it

;M207 S1.5 F3600 or F7200 Z0.2 ;firmware retraction

M572 D0 S0.01 ;pressure advance Set bowden extruder elasticity compensation for E0

M207 S1.5 F3600 Z0.01 ; Set firmware retraction parameters

M564 H0 ; Let the Jog buttons work blv: added to allow jog buttons; Scanner support (debug);M750

; Set up DHT sensor on channels 101-102;M305 P101 X405 S"DHT temperature" T11

;M305 P102 X455 S"DHT humidity [%]" T11; Automatic power savingM911 S21 R22 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss

; ====================== Miscellaneous =====================M501 ; load saved parameters from non-volatile memory

M500 ; save

T0 ; select first toolM575 P1 S1 B57600 ; enable support for PanelDue

;M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

@jay_s_uk

sorry some ask me to take a screenshot. -

@sgk said in please help me blv setting:

M563 P0 S"T0" D0 H1 F1

the fan defined here should be F0 not F1

nothing else looks out of place.

which bits do you have issues with?

and which firmware version are you running? M115 will tell you -

@jay_s_uk Board: Duet 2 WiFi (2WiFi)

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 3.3 (2021-06-15)

Duet WiFi Server Version: 1.26 -

@jay_s_uk said in please help me blv setting:

which bits do you have issues with?I do not understand

-

@sgk what problems are you having?

-

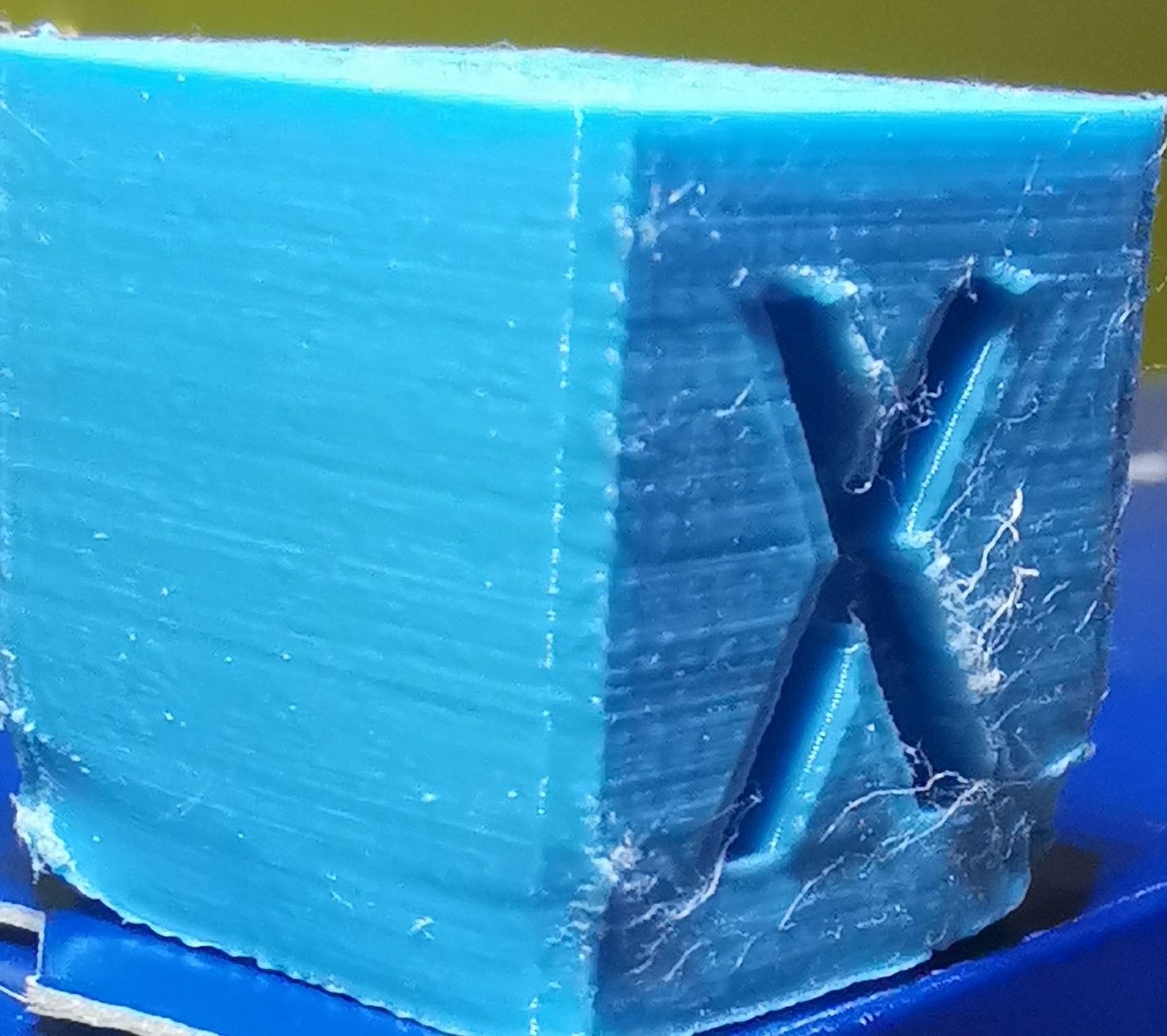

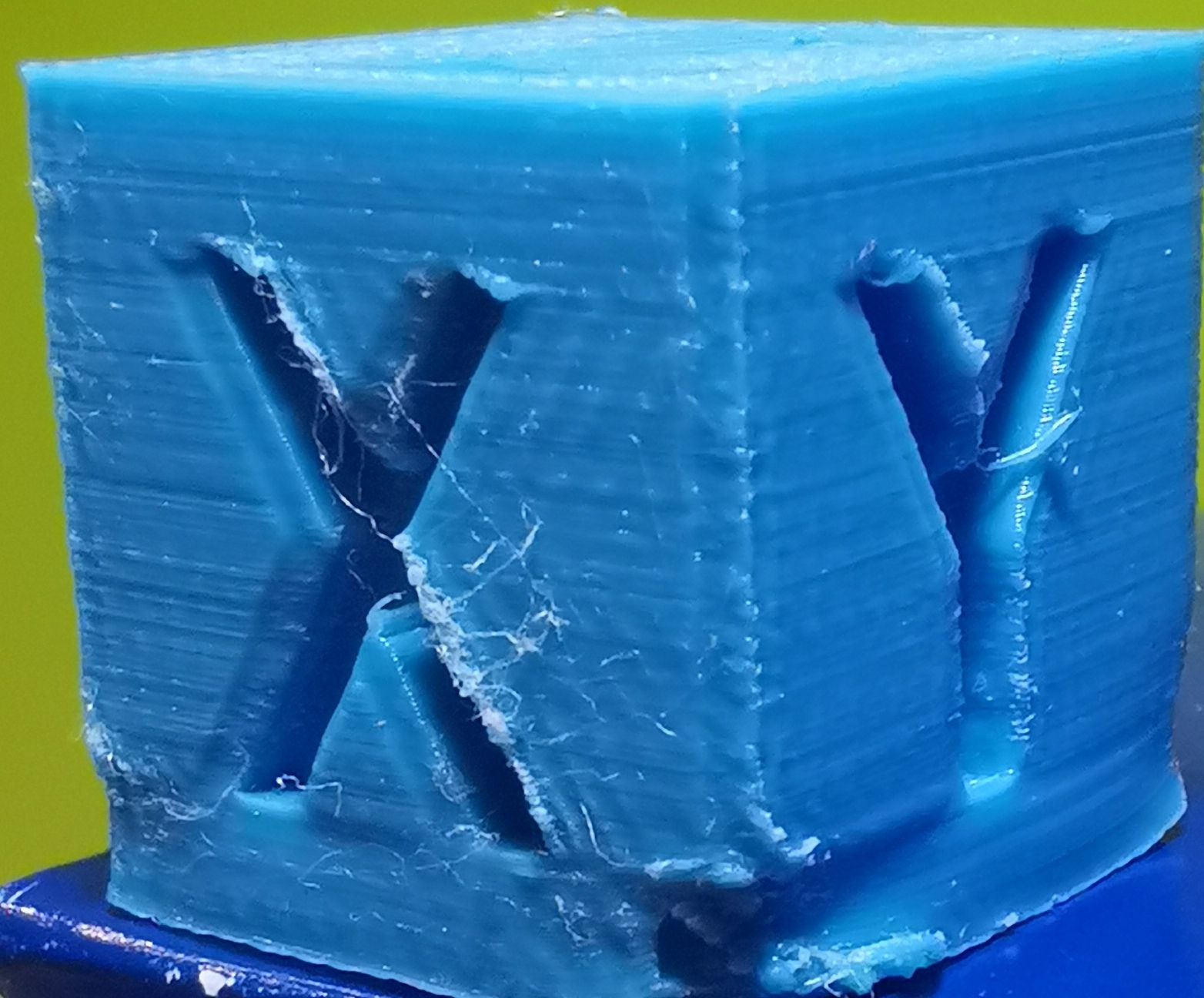

@jay_s_uk when I print my pieces where the cubes are of a really bad quality even with my cr10 which is not in good condition I have better impression. I have changed a lot of things on my blv and always a shit quality excused me word

-

@sgk well make the change i suggested here and then print another cube and see how that comes out

https://forum.duet3d.com/topic/26387/please-help-me-blv-setting/11 -

undefined jay_s_uk referenced this topic

undefined jay_s_uk referenced this topic

-

@jay_s_uk ok thank you sir jay

-

@sgk

-

@sgk

it’s the same if it’s not worse -

Looks like you need to to flow and temperature calibration. Here is a website which may help you with that https://teachingtechyt.github.io/calibration.html

-

@oliof

I have done plenty of times

-

@sgk you have massive deformation at the bottom of the cube which looks like the heated bed is way too hot, and the extrusion looks very uneven but not spotty/spidery, except for the stringing. Maybe share the gcode file with us (you can upload it) so we can take a look.

-

@oliof

the deformation is the fan -

-

@sgk what material is it that you are printing?

Looking at your gcode file you have set the bed to 90C. That is waaaaay too hot for PLA and I doubt your extruder temp of 195C would be correct if it was PETG or ABS.

Leads me to think that @oliof was right and the deformation at the bottom of the part is because it is too hot and the part is melting!

TYPE:Custom M104 S195; set extruder temp M140 S90 ; set bed temp M109 S195 ; wait for extruder temp M190 S90 ; wait for bed temp -

but if I have but not 90 it does not adhere to the bed.

pla -

@engikeneer

and as we see in the photo it is already peeling off on the corner -

@engikeneer I've been fighting for months, I've changed a lot of things but still the same I'm at the end of the line