please help me blv setting

-

@jay_s_uk

sorry some ask me to take a screenshot. -

@sgk said in please help me blv setting:

M563 P0 S"T0" D0 H1 F1

the fan defined here should be F0 not F1

nothing else looks out of place.

which bits do you have issues with?

and which firmware version are you running? M115 will tell you -

@jay_s_uk Board: Duet 2 WiFi (2WiFi)

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 3.3 (2021-06-15)

Duet WiFi Server Version: 1.26 -

@jay_s_uk said in please help me blv setting:

which bits do you have issues with?I do not understand

-

@sgk what problems are you having?

-

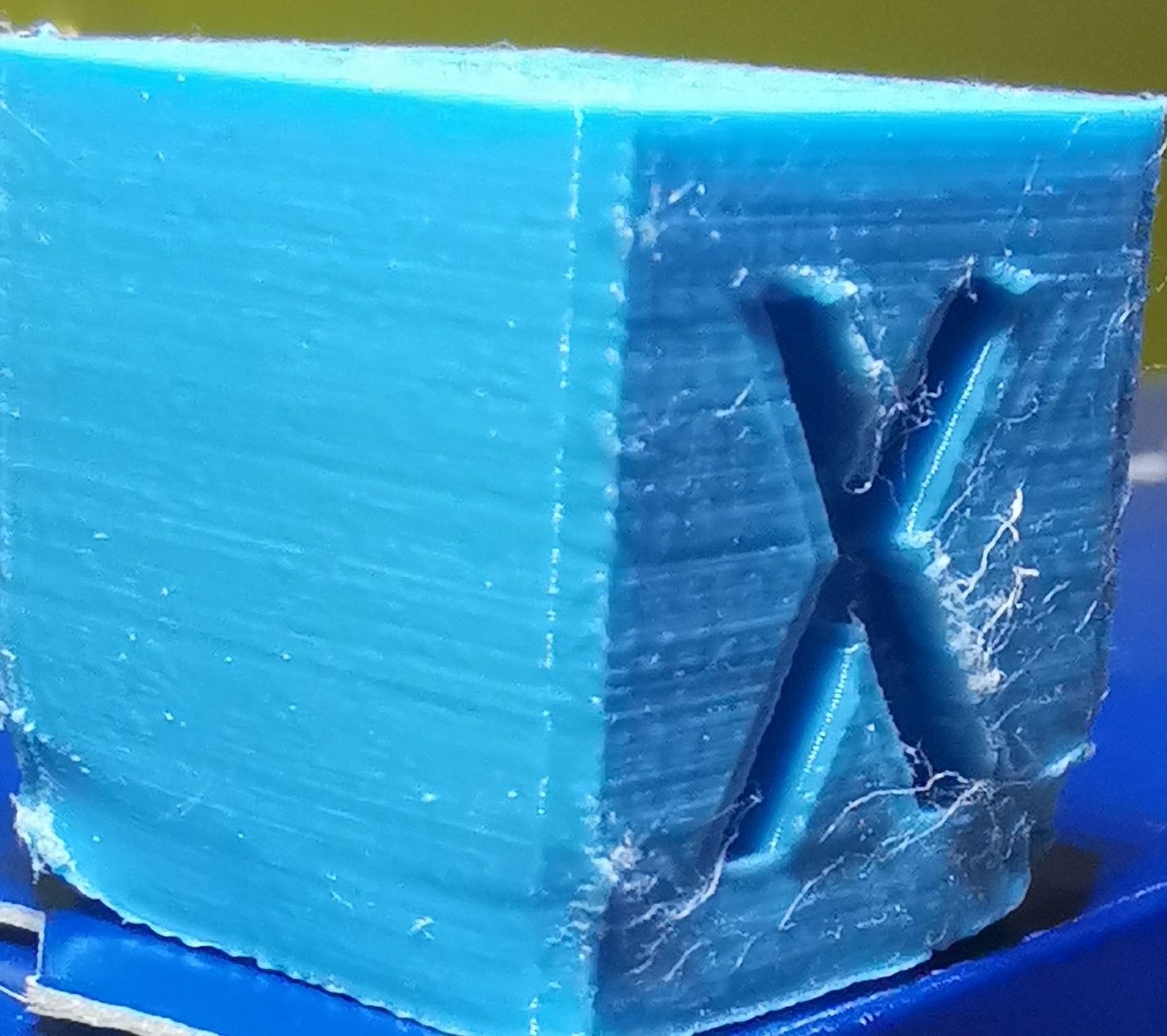

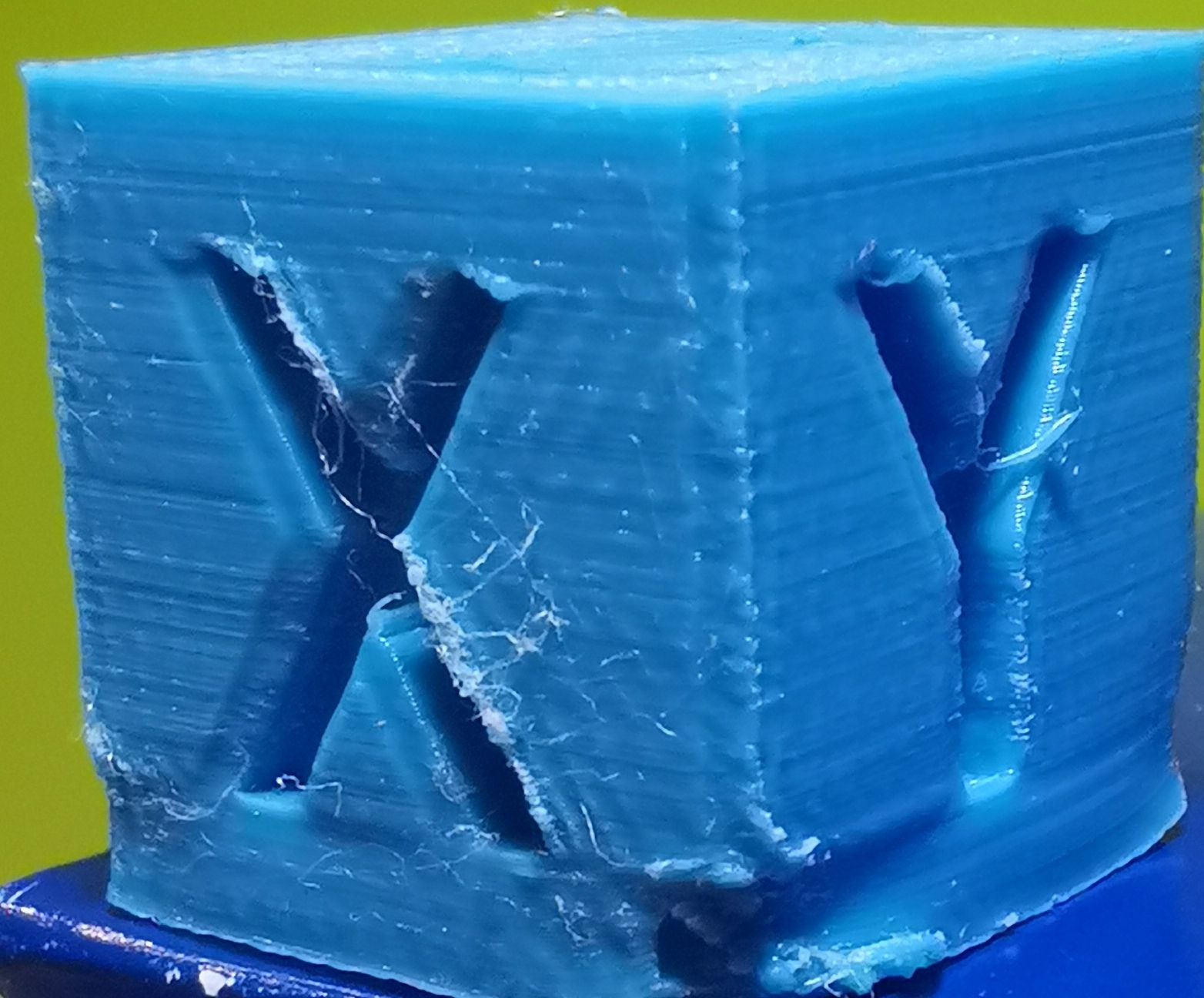

@jay_s_uk when I print my pieces where the cubes are of a really bad quality even with my cr10 which is not in good condition I have better impression. I have changed a lot of things on my blv and always a shit quality excused me word

-

@sgk well make the change i suggested here and then print another cube and see how that comes out

https://forum.duet3d.com/topic/26387/please-help-me-blv-setting/11 -

undefined jay_s_uk referenced this topic

undefined jay_s_uk referenced this topic

-

@jay_s_uk ok thank you sir jay

-

@sgk

-

@sgk

it’s the same if it’s not worse -

Looks like you need to to flow and temperature calibration. Here is a website which may help you with that https://teachingtechyt.github.io/calibration.html

-

@oliof

I have done plenty of times

-

@sgk you have massive deformation at the bottom of the cube which looks like the heated bed is way too hot, and the extrusion looks very uneven but not spotty/spidery, except for the stringing. Maybe share the gcode file with us (you can upload it) so we can take a look.

-

@oliof

the deformation is the fan -

-

@sgk what material is it that you are printing?

Looking at your gcode file you have set the bed to 90C. That is waaaaay too hot for PLA and I doubt your extruder temp of 195C would be correct if it was PETG or ABS.

Leads me to think that @oliof was right and the deformation at the bottom of the part is because it is too hot and the part is melting!

TYPE:Custom M104 S195; set extruder temp M140 S90 ; set bed temp M109 S195 ; wait for extruder temp M190 S90 ; wait for bed temp -

but if I have but not 90 it does not adhere to the bed.

pla -

@engikeneer

and as we see in the photo it is already peeling off on the corner -

@engikeneer I've been fighting for months, I've changed a lot of things but still the same I'm at the end of the line

-

@sgk what is your print surface?