please help me blv setting

-

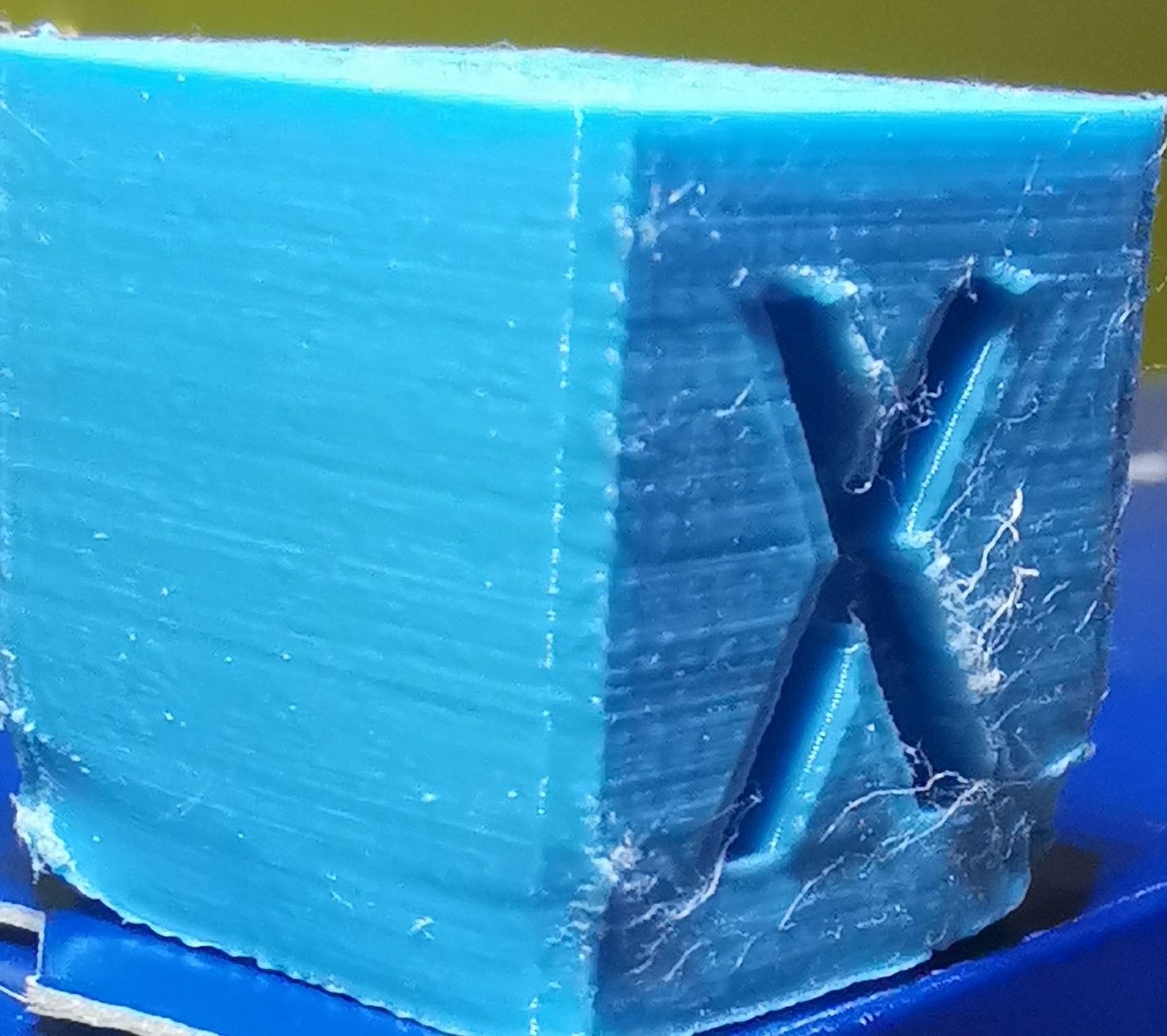

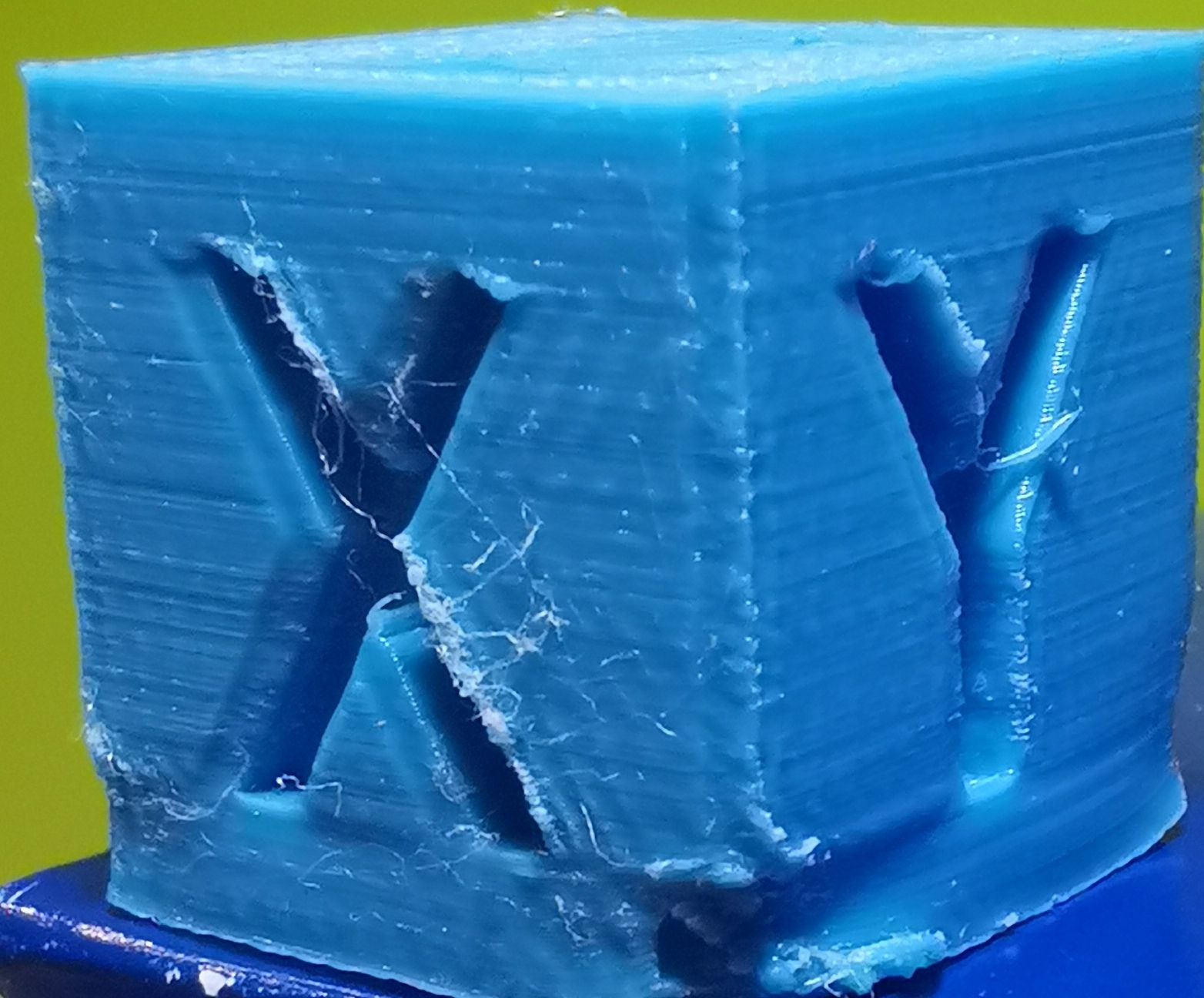

@jay_s_uk when I print my pieces where the cubes are of a really bad quality even with my cr10 which is not in good condition I have better impression. I have changed a lot of things on my blv and always a shit quality excused me word

-

@sgk well make the change i suggested here and then print another cube and see how that comes out

https://forum.duet3d.com/topic/26387/please-help-me-blv-setting/11 -

undefined jay_s_uk referenced this topic

undefined jay_s_uk referenced this topic

-

@jay_s_uk ok thank you sir jay

-

@sgk

-

@sgk

it’s the same if it’s not worse -

Looks like you need to to flow and temperature calibration. Here is a website which may help you with that https://teachingtechyt.github.io/calibration.html

-

@oliof

I have done plenty of times

-

@sgk you have massive deformation at the bottom of the cube which looks like the heated bed is way too hot, and the extrusion looks very uneven but not spotty/spidery, except for the stringing. Maybe share the gcode file with us (you can upload it) so we can take a look.

-

@oliof

the deformation is the fan -

-

@sgk what material is it that you are printing?

Looking at your gcode file you have set the bed to 90C. That is waaaaay too hot for PLA and I doubt your extruder temp of 195C would be correct if it was PETG or ABS.

Leads me to think that @oliof was right and the deformation at the bottom of the part is because it is too hot and the part is melting!

TYPE:Custom M104 S195; set extruder temp M140 S90 ; set bed temp M109 S195 ; wait for extruder temp M190 S90 ; wait for bed temp -

but if I have but not 90 it does not adhere to the bed.

pla -

@engikeneer

and as we see in the photo it is already peeling off on the corner -

@engikeneer I've been fighting for months, I've changed a lot of things but still the same I'm at the end of the line

-

@sgk what is your print surface?

-

@oliof 350x350mm

-

what material? painter's tape, PEI, Pertinax, Buildtak,....?

-

@oliof pei

-

@sgk make sure there is no protective sleeve still on the PEI. Then clean it with Isopropyl Alcohol. Then give it a scuff with steel wool.

For PEI the right temperature for PLA is 55-65C. If that doesn't stick there is another issue you will need to fix. 90C is definitely wrong.

-

@oliof I put a new pei plate it may be the same because the aluminum plate is 10mm