Scalable extra prime

-

hey lovely community,

I found the old plug-in for cura which is calling ´´scalable extra prime´´ for cura. Sadly it´s a bit old and not in the toolbox anymore.

Is here somebody who knows to install it in a other way to cura 5?

I really need this plug-in for my big nozzles and rec petg. I´m sure I need it.

Thanks a lot to everybodyhttps://github.com/Pheneeny/CuraPlugin-ScalableExtraPrime

KR. Richard

-

-

I would think the plugin would need to be updated. So you may be limited to the older version of Cura. Ping the plugin author? Or check the Ultimaker Cura forums?

-

@index4d I've replied in one of your other threads on how to do this using firmware retraction which is built into the firmware.

-

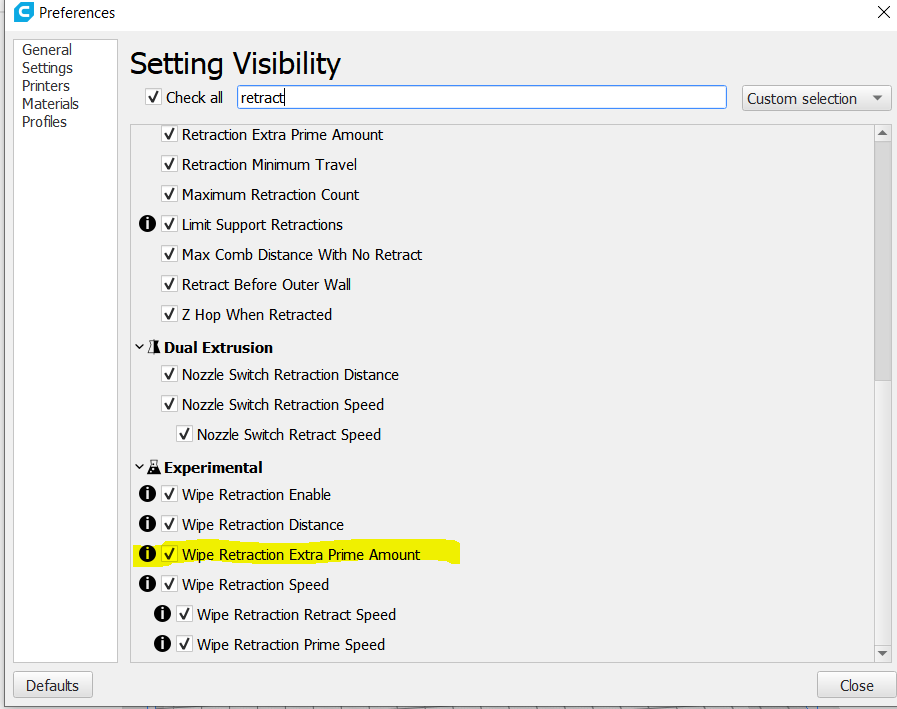

My version of Cura (not old, but not latest) seems to have an experimental feature for this:

-

@hebigt

I'm looking for a flexibel prime amount which is based on the length or better based on the time the printer needs to travel (max 1200mm). But I'll take a look about these options.Option 1 is the scalable prime amount and the plug-in.

Option 2 is individual jerk and accelerations for the extruder depending on the direction.

Best would be a combination of both I think.

Thanks for the fast answer

Richard -

@index4d I used that plug in a few years ago and found it didn't seem to work particularly well. I never dug into the reasons why.

Large nozzles can be difficult to tune compared to small nozzles. the plastic seems to behave differently when the nozzle is large. Maybe there's less pressure build up in the hot end. As you have noticed, you will frequently gets gaps at the start of lines after a travel move, and the longer the travel move, the bigger the gap. I don't know what happens to the plastic in the hot end during the travel move- it almost seems to back up into the nozzle.

I wonder if it wouldn't be prudent to put a couple o-rings that fit tightly on the filament inside the cold end of the heat-break, sealing it air tight. That might keep molten filament from moving.

-

@mrehorstdmd

I think the filament in the hot end gets hotter which results in lower pressure at the beginning of a line. Sometimes I can see a little overextruding after having this hole in the start of the line. I think pressure advance ONLY for the start of a line would be nice or something similar... to give the filament a bit of time to come out properly and is fast enough there where it should be. Stringing and oozing are not a problem in my case.Another Idea would be to print a small overalp like the cura setting "outer wall wipe distanze " BUT with extruding filament, which is not the case when wiping.

I don´t want to build a new slicer but is there a way to implement python in any ways into Duet to so something like this? @Phaedrux @HebigT @deckingmanWe´re gonna print and design furniture, so that we as Index4D must fix this Issue.

thanks for our replies !

KR RG -

Short of writing a new slicer, maybe you could rebuild the plugin you linked and make it better suit your needs? The readme on that github pages seems to suggest that it post processes the gcode by referencing the existing travel moves. You should be able to do this with a standalone python script. Or, If you're familiar with prusa slicer/super slicer, it has the same post-processing functionailty. You just have to point it to your script and I think it will allow you to save gcode normally.

Maybe one benefit of the original Cura plugin was that it offered buttons and fillable fields in the settings list.