not able to get a good first layer using 3PL and bed mesh

-

This post is deleted! -

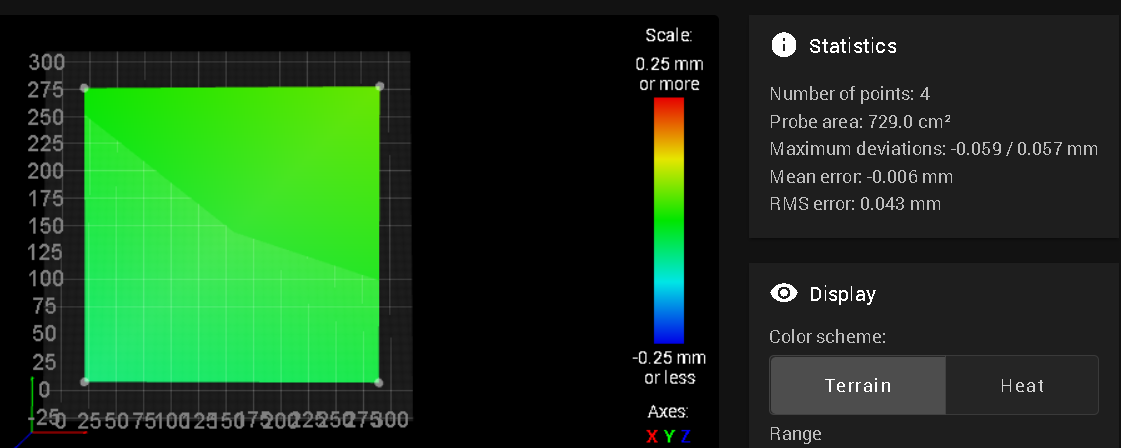

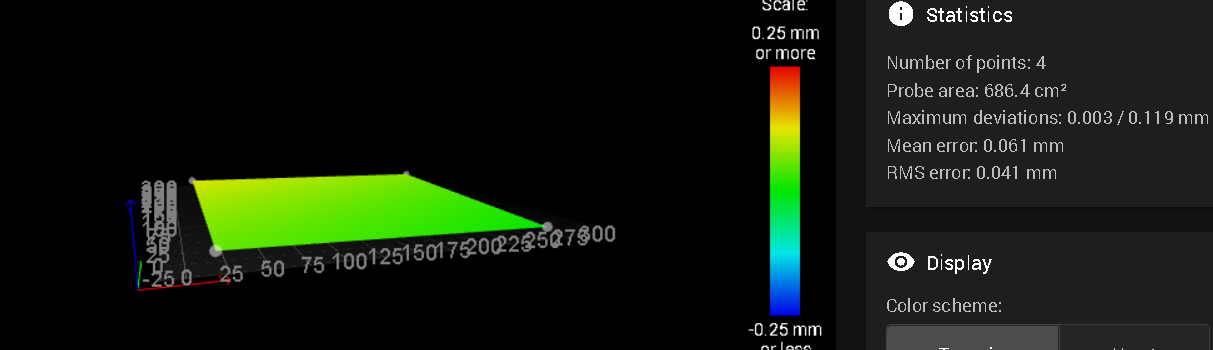

ok i can get a 4 point mesh to this

-

I would suggest loosening the bolts for the XY stage, checking with a square and retightening.

-

same result

same result -

@moth4017 i made changes to get the 4 point mesh this level

-

@moth4017 I just did a check to see if i could see my Z motors turning , i have a gear box's on the z axis so i should be able to see the steeper motor turning , but there is no movement

-

@moth4017 start G code befor a print

M104 S[first_layer_temperature] ; set extruder temp

M140 S[first_layer_bed_temperature] ; set bed temp

M190 S[first_layer_bed_temperature] ; wait for bed temp

M109 S[first_layer_temperature] ; wait for extruder temp

M561 ; clear any bed transform

G28 ; home all axes

G29 ; mesh bed -

Is the gearbox having backlash?

You can send M122 to check if mesh is active. If you have G29 in your slicer start gcode it should be. Do you have a mesh.g file?

-

@Phaedrux no back lash gear box belt driven ,

M122 === Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.4.5 (2022-11-30 19:41:16) running on Duet 3 Mini5plus WiFi (standalone mode) Board ID: 3R9YY-6T9RL-D65J0-40KMN-2UW2Z-RHYT0 Used output buffers: 1 of 40 (18 max) === RTOS === Static ram: 103652 Dynamic ram: 111396 of which 124 recycled Never used RAM 23492, free system stack 126 words Tasks: NETWORK(notifyWait,13.9%,237) HEAT(notifyWait,0.0%,320) Move(notifyWait,0.1%,265) CanReceiv(notifyWait,0.0%,942) CanSender(notifyWait,0.0%,328) CanClock(delaying,0.0%,339) TMC(notifyWait,1.2%,82) MAIN(running,83.9%,347) IDLE(ready,0.0%,30) AIN(delaying,0.8%,263), total 100.0% Owned mutexes: WiFi(NETWORK) === Platform === Last reset 00:49:54 ago, cause: software Last software reset at 2022-12-11 09:53, reason: User, GCodes spinning, available RAM 23540, slot 1 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 MCU revision 3, ADC conversions started 2994886, completed 2994886, timed out 0, errs 0 Step timer max interval 1476 MCU temperature: min 34.9, current 38.4, max 41.7 Supply voltage: min 23.6, current 23.9, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/11, heap memory allocated/used/recyclable 2048/1652/1440, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min 0, read errors 0, write errors 0, ifcnt 7, reads 9988, writes 68, timeouts 0, DMA errors 0, CC errors 0 Driver 1: standstill, SG min 0, read errors 0, write errors 0, ifcnt 9, reads 9986, writes 69, timeouts 0, DMA errors 0, CC errors 0 Driver 2: standstill, SG min 0, read errors 0, write errors 0, ifcnt 79, reads 10050, writes 6, timeouts 0, DMA errors 0, CC errors 0 Driver 3: standstill, SG min 0, read errors 0, write errors 0, ifcnt 104, reads 10042, writes 14, timeouts 0, DMA errors 0, CC errors 0 Driver 4: standstill, SG min 0, read errors 0, write errors 0, ifcnt 252, reads 10024, writes 32, timeouts 0, DMA errors 0, CC errors 0 Driver 5: standstill, SG min 0, read errors 0, write errors 0, ifcnt 251, reads 10023, writes 33, timeouts 0, DMA errors 0, CC errors 0 Driver 6: standstill, SG min 0, read errors 0, write errors 0, ifcnt 245, reads 10024, writes 32, timeouts 0, DMA errors 0, CC errors 0 Date/time: 2022-12-11 10:43:08 Cache data hit count 4294967295 Slowest loop: 68.52ms; fastest: 0.10ms === Storage === Free file entries: 10 SD card 0 detected, interface speed: 22.5MBytes/sec SD card longest read time 4.9ms, write time 3.0ms, max retries 0 === Move === DMs created 83, segments created 8, maxWait 173411ms, bed compensation in use: mesh, comp offset -0.065 === MainDDARing === Scheduled moves 560, completed 560, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 2], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1, chamber heaters 2 -1 -1 -1, ordering errs 0 Heater 0 is on, I-accum = 0.1 Heater 1 is on, I-accum = 0.3 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === Filament sensors === Extruder 0 sensor: ok === CAN === Messages queued 26948, received 0, lost 0, boc 0 Longest wait 0ms for reply type 0, peak Tx sync delay 0, free buffers 18 (min 18), ts 14971/0/0 Tx timeouts 0,0,14971,0,0,11976 last cancelled message type 4514 dest 127 === Network === Slowest loop: 74.73ms; fastest: 0.00ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 = WiFi = Network state is active WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 0 WiFi firmware version 1.27 WiFi MAC address f0:08:d1:02:a1:0b WiFi Vcc 3.34, reset reason Power up WiFi flash size 2097152, free heap 26440 WiFi IP address 192.168.0.19 WiFi signal strength -54dBm, mode 802.11n, reconnections 0, sleep mode modem Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0;mesh.g echo "mesh.g" M561 M98 P"/macros/ProbePickUp" ; probe pick up; absolute positioning G29 S0 M98 P"/macros/ProbeDropOff" ; probe pick up; absolute positioning -

@moth4017 said in not able to get a good first layer using 3PL and bed mesh:

bed compensation in use: mesh

Were you using your detailed mesh or the simplified 4 point? The movement could be incredibly hard to see with a mean error of -0.006mm

-

@Phaedrux hi i was using the 4 point mesh , but the difference in nozel height from the bed was bad enough for the left hand side not to stick to the bed and the right hand side had a nice squish , see photo

above -

@moth4017, 1 step on my stepper motor moves the bed 0.025mm, using 1.8deg steppers

-

@moth4017 said in not able to get a good first layer using 3PL and bed mesh:

@moth4017, 1 step on my stepper motor moves the bed 0.025mm, using 1.8deg steppers

If your single step distance is 0.025mm and the mesh points have a difference of ~0.006mm you would be depending on microstepping for position. Perhaps between that and the gear box there isn't enough actual movement happening?

Regardless, I still think there is an issue with skew.

-

@moth4017

if i do a height check G30 s-1

results

12/11/2022, 11:04:22 AM Stopped at height 9.786 mm

Cen

ProbeDropOff

12/11/2022, 11:04:19 AM Stopped at height 10.011 mm

RL

12/11/2022, 11:04:15 AM Stopped at height 9.952 mm

RR

12/11/2022, 11:04:11 AM Stopped at height 9.898 mm

FR

12/11/2022, 11:04:08 AM Stopped at height 9.877 mm

FL

looking at the height map the rear left (RL)corner is highest, if i look at the probe height for RL 10.011 is that the correct?

-

@moth4017 if i measure the thickness of the first layer at each corner ,

layer height requested 0.3mm, nozzel dia 0.8mm

FL 0.35

FR 0.19

RR 0.33

RL 0.44 -

@moth4017

You've presented 3 or 4 heightmaps now and they are all different, why?

I guess it's a mechanical issue or you readjusted the frame?Anyway, 0.3 layer with a 0.8 nozzle should stick without mesh levelling, if temp parameters are correct. (and printsurface is OK with type of filament)

Did you check bed temp for consistency at all corners? Maybe the bed gets cold air on one side? -

@o_lampe hi , i readjusted the frame , removed the stepper motor extuder etc and just fitted a probe only , got all the tramming done , got a good 3 point leveling and a good flat level bed mesh which was repeatable.

reinstalled the extruder stepper motor re did the 3PL and bed mesh noticed the mesh was flat but tilted , it was the cable loom to the tool head causing the tilt, re did the cable loom.

3PL and mesh again flat and level again, did a print 300 x300 first layer as above but the result was the same right hand side was a good squish but the left hand side was the same as before barly attached to the bed..

i have tried printing on a cold bed too same result

-

@moth4017

Could it be overcompensation?

Did you tune the Z-axis steps/mm?

No one counts teeth of a belted gearbox, right? We just assume, the vendor did...

But sometimes they round up or down... -

@o_lampe i wish it was that easy , i check each z axis with a dial gauge just to make sure they were all moving the correct amount.. but i like your thinking ,

im not sure what else i can do , i even looked if i could manually adjust each motor with a offset just as a test ...

-

@moth4017 said in not able to get a good first layer using 3PL and bed mesh:

i even looked if i could manually adjust each motor with a offset just as a test ...

Been there, done it

IIRC, you could edit the heightmap or put a sheet of paper on the right side while mesh-probing.

But best practice is to find the cause for it. (stiffen up a sagging gantry or placing the filament spool elsewhere had helped me in the past)