-

I'd like to print the hotend adapter with anycubics tough resin. Do you have a link to the .stl file, please?

-

@o_lampe

Sure

https://www.thingiverse.com/search?q=Dragon+hotend+adapter+to+Duet+Smart+Effector&page=1&type=things&sort=relevantI have the on i middle, but be aware of that this construction is not optimal as regards the M12 thread that easily snaps. So be careful when tightening the nut!

The one i use now is printed in ABS CF

-

@tecno The print went well, but the thread is fine-pitch. The nylon nuts I got with a smart effector don't fit.

It's no problem since the three outer screws are good enough. -

@o_lampe

Threads is std M12x1. You will need a tap and die to make parts perfekt and not too tight = snap risk. -

@tecno I may have older SE-heatsinks and nuts, but the thread is different in my case.

With resin prints there is no need for designing parts with the typical "FDM fudge factor".

E.g. a 3mm hole is exactly 3mm wide and cylindric. Same goes for internal threads.

I usually don't need to print a hole and tap a thread, I just print the thread and it fits. -

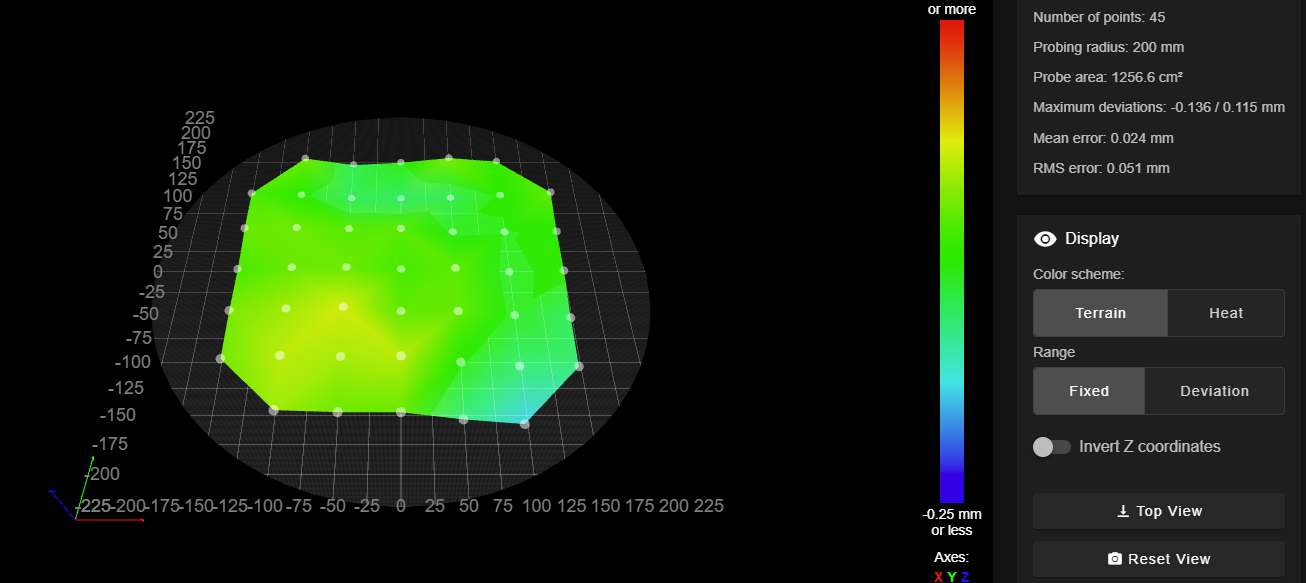

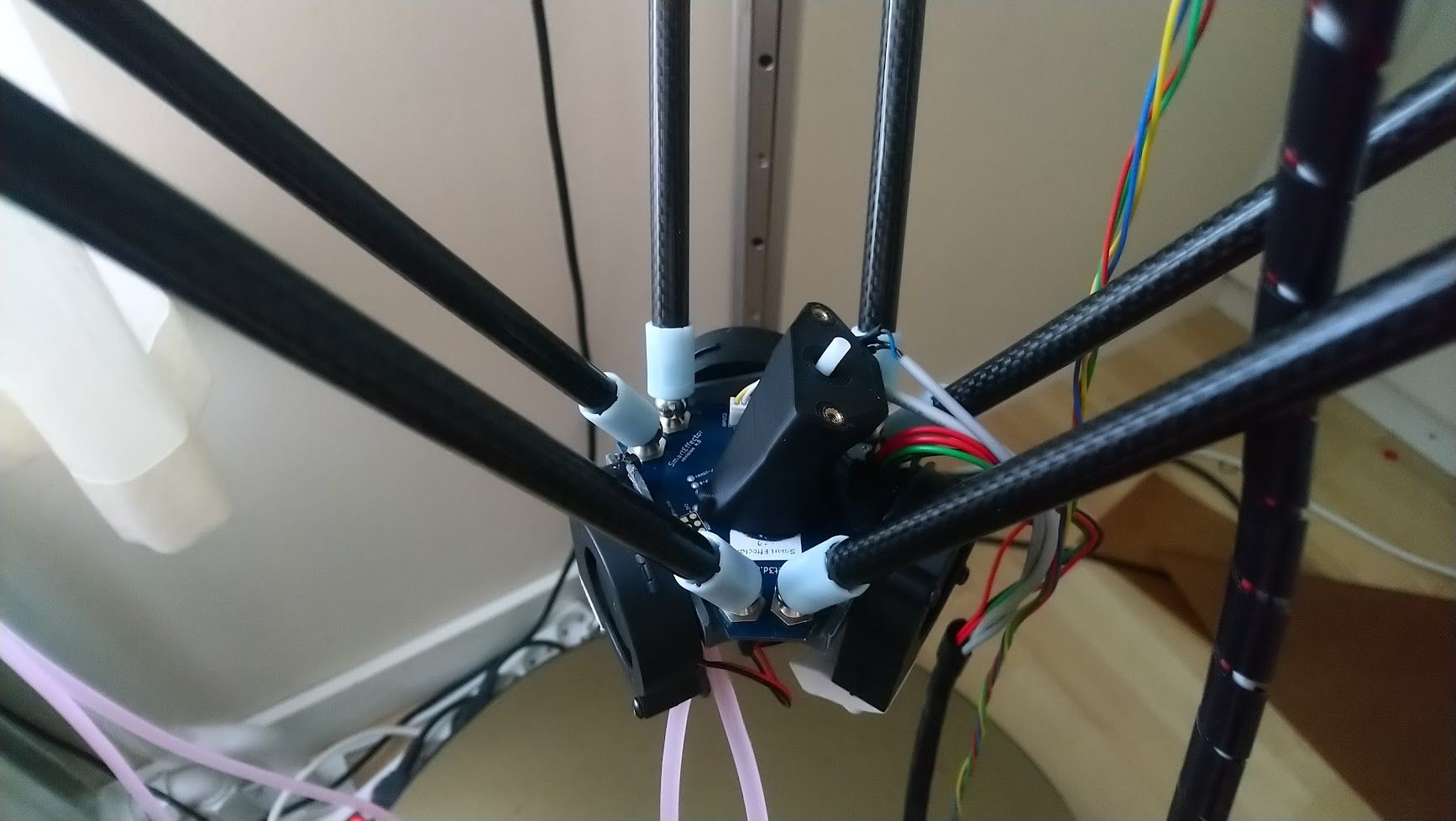

At last I now have bed mesh working, it took almost a year to know I had a faulty Smart Effector board!

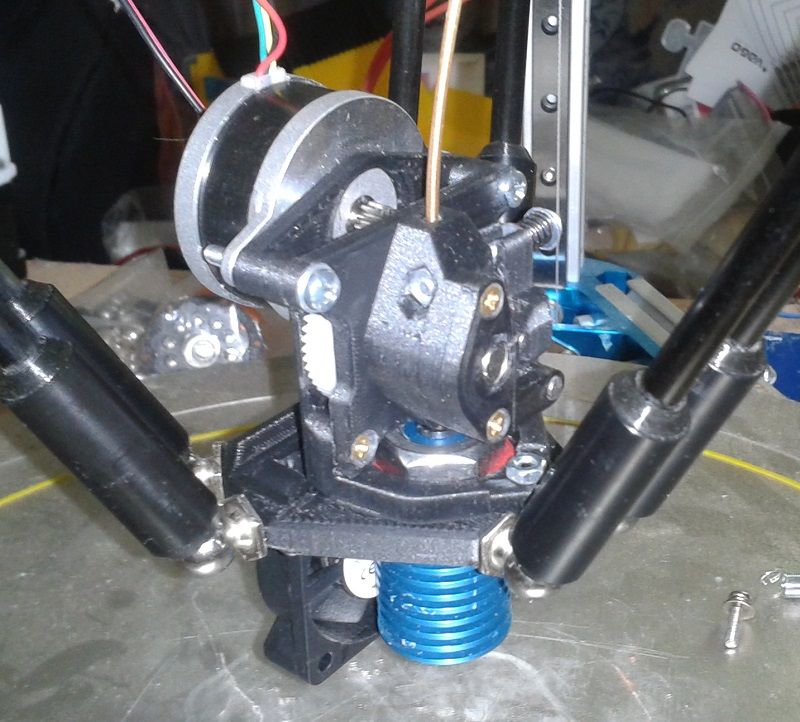

So next I have to redesign the foot for Orbiter V2 as it is now it is bit too tight corners or I go bowden.

So what is the general opinion DD or Bowden?

Just realised I have already done the mod and took an old part from the spareparts bin

So back to DD we go.

-

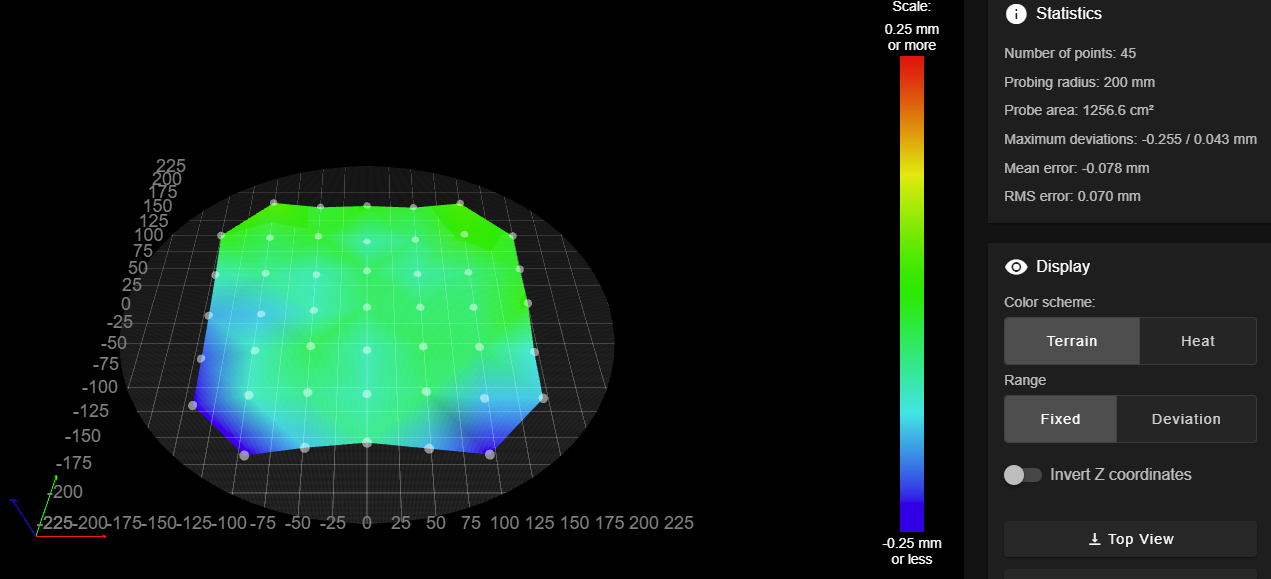

Now with the Orbiter V2 mounted I get a bit different mesh.

This must be due to weight high up from the effector, so I have to think what I will do. Leave it as is and see the results ormake chanes for Bowden drive.

-

@tecno I asked my crystal bowl and I see that smart effectors with a touch probe are a dying species.

Everyone will use a scanning z-probe soon.

With that in mind, it would be no problem to move the hole for the effector offcenter, as I did on my own effector.

That allows you to put a sherpa mini directly on the effector. Advantages:- the sherpa mini is smaller and lighter than the orbiter

- the effector is less top heavy, because it fits without adapter

- all the above allows you to print as fast as the sherpa allows (80-100mm/s with 0.4mm nozzle and 0.33mm layer)

The orbiter is stronger, but the weight- and COG penalty keeps you from printing fast. (bigger nozzle and thicker layer is another story, tho )

I admit, my opinion is biased but IMHO it's the best compromise. That's why I don't even consider bowden drive. -

Everyone will use a scanning z-probe soon.

Probes offset from the nozzle are a bad idea for delta printers, because it's very hard to eliminate very slight changes in tilt as the effector moves in the XY plane. Those changes in tilt alter the relative heights of the probe and the nozzle, which messes up auto calibration (as well as mesh bed compensation).

I also doubt that the existing inductive scanning Z probes would be accurate enough for delta calibration.

A well-built delta like mine does not require mesh bed compensation, just auto calibration. It's also possible to build Cartesian printers that don't need mesh bed compensation - ask @deckingman.

-

-

Another issue with scanning probes: they measure the aluminum plate, and not the glue/magnet/steel sheet/glue/print surface material stack on top of it. Inductive probes have a similar limitation. Thats why Id love to see the modified IR sensor, because I can choose a working surface for that.

-

@oliof @deckingman Sorry, I pulled the thread a bit offtopic.

A delta would need some sort of probe, no matter how good the build is.

In my case it's an 18mm capacitive probe, which doesn't care about surface material, as long as it's the same stack of materials it probes. (no hidden screw heads or magnets at some points).My main intention was to vote for DD extruder instead of Bowden. (and promote my idea of an offset-effector)

-

@o_lampe can you get a round stepper motor with a hollow shaft? I was thinking that you could mount it on top of something like a Sherpa, and use bevel gears to transmit the power to the hobbed inserts. That would centralise the mass and shape of the extruder drive. There would have to be a small bend in the filament paths after the stepper motor, to avoid the shaft, but I don’t think it would be that extreme.

Ian

-

@droftarts I'm always open for new ideas

I tried to picture how to combine the beveled gears with dual drive gears. It would need a two stage drivetrain to avoid offset.

I'll try to draw a sketch (and post it in a new thread)Sorry again for OT

Olaf -

@droftarts speaking of hollow shaft extruders, you have seen this, right? https://www.youtube.com/watch?v=YTADdWiFQnI

-

Taking about these lightweight delta extruders, have you seen this:

https://www.youtube.com/watch?v=eI0tD69wD18 -

Nice solution there but it is also top-heavy.