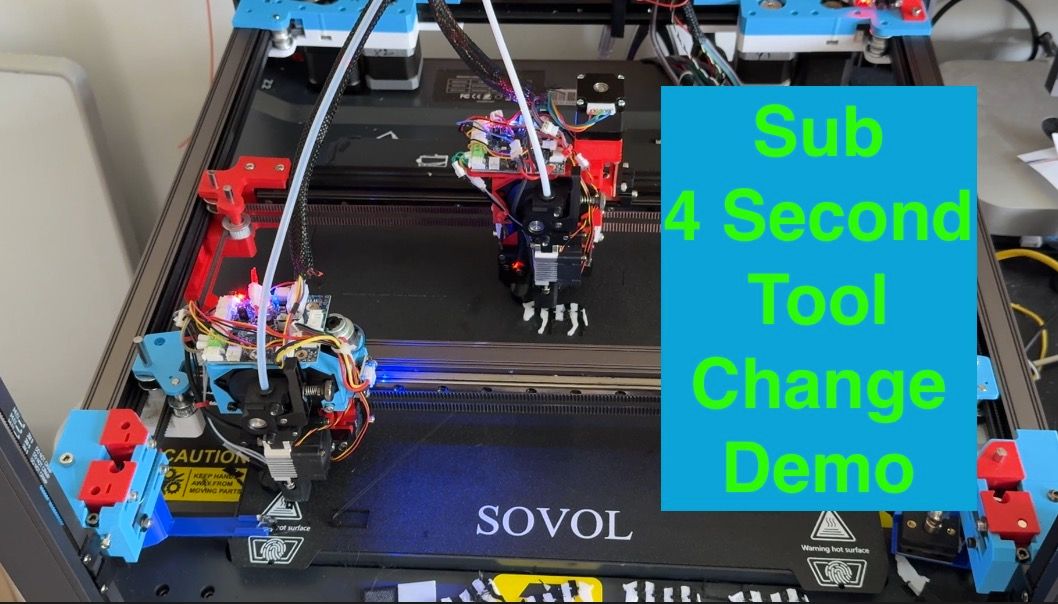

Sovol SV08 Multiple Motion System Upgrade.

-

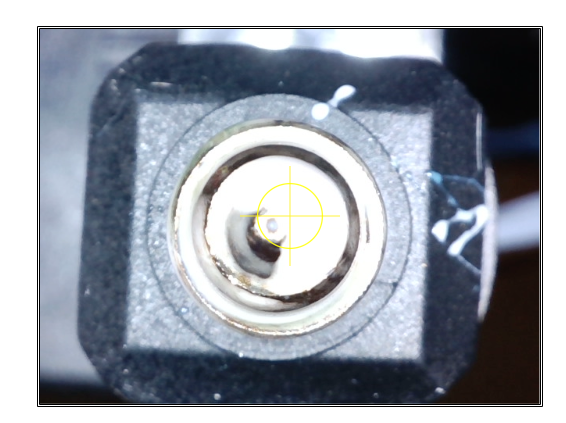

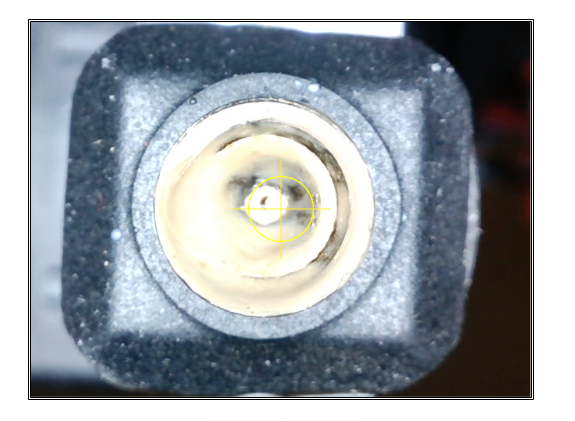

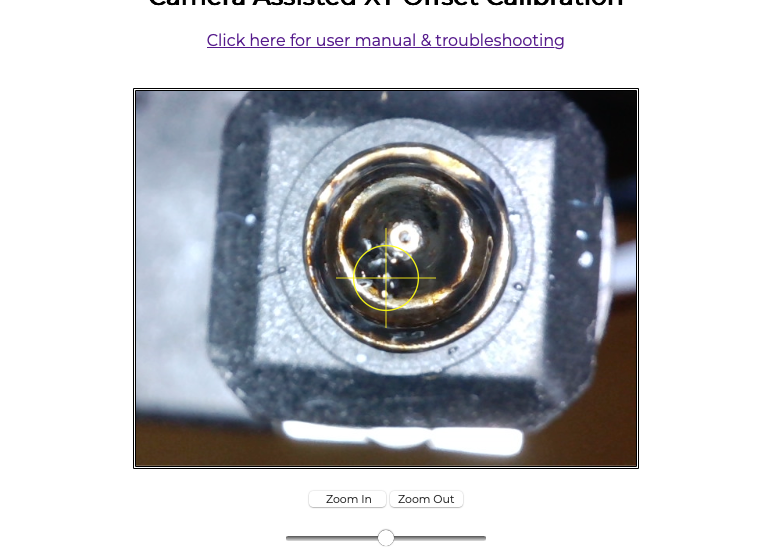

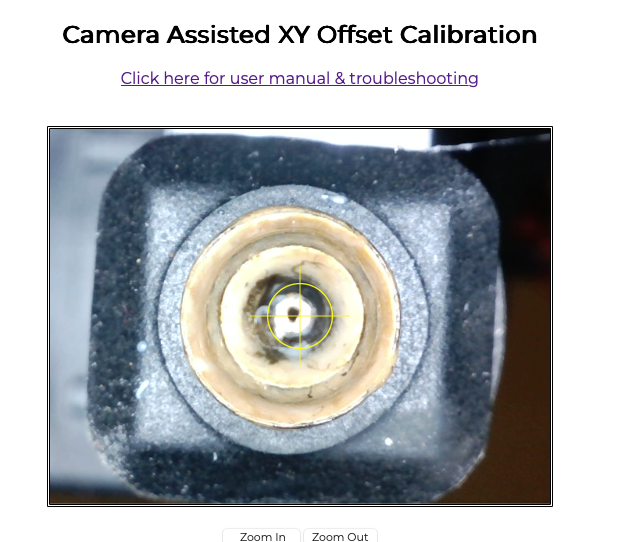

Ball probe Auto Alignment getting fairly good.

Images of nozzle as was found by printer with no manual adjustment or head movements.

The alignment isn't perfectly on the centre of the nozzles in the camera because I can't guarantee the XY offset between the camera and ball probe - due to the swing out movement based on a servo - which might be a slightly different angle every time.

Checking with the camera I am getting a 0.1mm variation in the X/U axis, and 0.7mm in the Y/V axis.

Not sure if this a consistent difference or whether it varies.Not sure if this is dirty nozzles, nozzle shape irregularity or RRF Ball Probe macros' or just the sort of error you might get with a ball probe vs camera.

My XY Axis is still on sensorless end stops - so will be interesting to see what difference it makes swapping between sensorless and optical end stops in keeping alignment across reboots.

-

I think I just had a bright moment regarding z-hop: Re-purposing Rc-car servo savers could be the answer to more torque and accuracy, whilst still be backlash-free.

I tried to find a good picture to show how they work and came up with this:

Twisting the servo arm while the output-side is fixed to the tool head would be translated to vertical lift (or drop if you want to use gravity to your advance).

They usually come with an adjustable spring which isn't shown here. -

@o_lampe said in Sovol SV08 Multiple Motion System Upgrade.:

Rc-car servo savers

Thanks - are you suggesting having this attached to a non geared stepper motor, or a servo or somehow attaching it to the lead screw to translate big linear movements into smaller more powerful ones?

The final Nema8 I ordered just arrived and its a non lead screw 34 high vs most of the others which were 24 - so hopefully a bit more powerful.

The Lead Screw Nema 11 still seems to be working quite well in my probing and Z offset tests - but haven't actually tried doing some proper printing with lots of Z Hopping yet. It is noticeably quicker than the tiny linear stepper that I had on the other axis - and I think will end up being quicker the geared belt driven Z Axis of the SV08

The good news with my current 3 rather than 4 headed next step is at least it means one less Z hopper motor to buy.

Shame I bought the 4th Extruder/ 1LC board and 2nd Mini5 - as I think I might be able to get away with the 16 drivers available on the 6HC, Mini5+, plus 3x1LC

Glad I haven't done to termination removal drill out on the Mini5+ board yet.

-

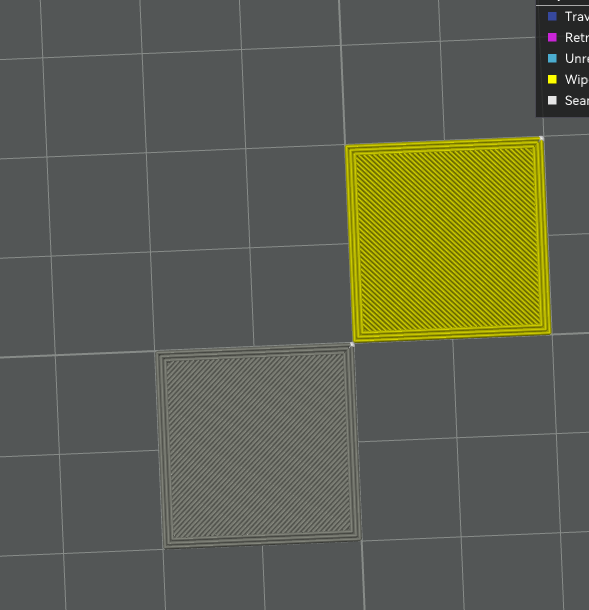

Work progressing on dual colour printing - example of auto alignment (it looked fairly good on the camera so I didn't adjust it at all).

Also made an extremely useful discovery about pre-heating - Orca Slicer (and probably PrusaSlicer and Bambu Studio supports it).

Example below with 2 seconds specified. - see 5th line down.

This will be very useful - because I can fairly easily change the G10 Pre-heats to be a macro call with a post processor - which can they do:

- More intelligent pre-heating based on the actual amount the inactive extruder has cooled - perhaps with some feedback to see how long it actually takes to reheat.

- Do the priming in parallel - so that as soon as in this example T0 has completed T1 can then start immediately printing - with hopefully almost no delay.

G1 X131.54 Y141.994 E.34619 G1 X131.54 Y142.652 E.02497 M73 P23 R1 G1 X137.336 Y148.448 E.31089 G10 S220 P1 ; preheat T1 time: 2s G1 X136.677 Y148.448 E.02497 G1 X131.54 Y143.31 E.27558 G1 X131.54 Y143.968 E.02497 G1 X136.019 Y148.448 E.24028 G1 X135.361 Y148.448 E.02497 G1 X131.54 Y144.627 E.20497 M73 P24 R1 G1 X131.54 Y145.285 E.02497 G1 X134.703 Y148.448 E.16966 G1 X134.044 Y148.448 E.02497 G1 X131.54 Y145.943 E.13436 G1 X131.54 Y146.601 E.02497 G1 X133.386 Y148.448 E.09905 G1 X132.728 Y148.448 E.02497 M73 P25 R1 G1 X131.54 Y147.259 E.06375 G1 X131.54 Y147.918 E.02497 G1 X132.275 Y148.654 E.03947 ; stop printing object Cube id:0 copy 0 ; printing object Cube id:1 copy 0 ; stop printing object Cube id:1 copy 0 G10 ; retract ; filament end gcode M106 P3 S0 G10 S215 P0 ; set nozzle temperature ;cooldown ;M98 P"0:/macros/changeFilament.g" A previous_extruder B new_filament_temp L layer_num N next_extruder F first_layer_temperature1 M98 P"0:/macros/changeFilament.g" A0 B220 L0 N1 F220 M106 S0 T1 ; Filament gcode G10 S220 P1 ; set nozzle temperature -

Simple post processing script created

#!/usr/bin/python3 # preheat - simple script to change all G10 & G11 commands to .1 versions - so that they run a Macro in RRF # Based on example from Bobs Notebook. - https://projects.ttlexceeded.com/3dprinting_prusaslicer_post-processing.html import sys import re import os sourceFile=sys.argv[1] # Read the ENTIRE g-code file into memory with open(sourceFile, "r") as f: lines = f.readlines() destFile = sourceFile os.rename(sourceFile,sourceFile+".preheat.bak") count = 0 with open(destFile, "w") as of: for lIndex in range(len(lines)): oline = lines[lIndex] # Parse gcode line if oline.startswith("G10 ") and "X0 " not in oline: oline = oline.replace("G10 ","G10.1 ") if "preheat" in oline: oline = oline.replace("G10.1 ","G10.1 Q1 ") count += 1 of.write(oline); elif oline.startswith("G11 "): oline = oline.replace("G11 ","G11.1 ") count += 1 of.write(oline); else: # Write original line of.write(oline) of.write(";****\n;****preheat " + str(count) + " lines changed\n") of.close() f.close()

Results - changing G10's all to G10.1 (except G10's with lots of AXIS parameters in).

M73 P23 R1 G1 X137.336 Y148.448 E.31089 G10.1 Q1 S220 P1 ; preheat T1 time: 2s G1 X136.677 Y148.448 E.02497 G1 X131.54 Y143.31 E.27558 G1 X131.54 Y143.968 E.02497 G1 X136.019 Y148.448 E.24028 G1 X135.361 Y148.448 E.02497 G1 X131.54 Y144.627 E.20497 M73 P24 R1 G1 X131.54 Y145.285 E.02497 G1 X134.703 Y148.448 E.16966 G1 X134.044 Y148.448 E.02497 G1 X131.54 Y145.943 E.13436 G1 X131.54 Y146.601 E.02497 G1 X133.386 Y148.448 E.09905 G1 X132.728 Y148.448 E.02497 M73 P25 R1 G1 X131.54 Y147.259 E.06375 G1 X131.54 Y147.918 E.02497 G1 X132.275 Y148.654 E.03947 ; stop printing object Cube id:0 copy 0 ; printing object Cube id:1 copy 0 ; stop printing object Cube id:1 copy 0 G10.1 ; retract ; filament end gcode M106 P3 S0 G10.1 S215 P0 ; set nozzle temperature ;cooldown ;M98 P"0:/macros/changeFilament.g" A previous_extruder B new_filament_temp L layer_num N next_extruder F first_layer_temperature1 M98 P"0:/macros/changeFilament.g" A0 B220 L0 N1 F220 M106 S0 T1 ; Filament gcode .... ;****preheat 21 lines changedNow I just need to write the G10.1.g macro - to do the preheating and parallel priming.

-

Parallel colour changes more or less working.

I used Orca Slicer to send 17 second pre-heating G10's

The preheat G10 comes in the opposite motion system to the one that needs the colour change to kick off.

So I used a loop within the next motion system to wait for the target temperature to change.- by checking heat.heaters[].active, and checking for temperature reached by looping around and checking sensors.analog[].lastReading.

Then once temperature reached I kicked off the priming, and then have a M598 just after the priming, but before the printing - so that the printer waits until the other motion system has finished it's work - before starting with the new colour.

The eventual aim would be to tune the preheat, and introduce a precisely timed delay so that the priming of the next colour finishes exactly when the other colour finishes.

For the SV08 heaters will need a longer preheat period - and will change the preheat to a tiny amount - so that I can pick up the change.

Will then depending on the current temperature either wait a bit, or kick of preheating straight away - with the heat up time calculated to leave exactly enough time for priming to be completed at exactly the same time as the other colour finishes printing.,

so that ideally the M598 at the end is pretty much instant.NB/. This way of working is only for small multi colour / multi material models. For bigger objects, where there is room on the print bed for both print heads to be printing at the same time, much more use of the RRF Multi Motion System capabilities will be made.

Short demo video here

https://youtu.be/Qn1SG_vc8X8

-

Better demo of parallel colour/material changes - some changes as quick as 2 seconds.

Still more work to do - but synchronisation getting closer.

Using preheat G10's to kicking off the Pre Heat, delay, final heat, priming, tool change.

Demo here.

Tool change macro getting pretty complicated....

;changeFilament.g ;M98 P"0:/macros/changeFilament.g" A{previous_extruder} B{new_filament_temp} L{layer_num} F{first_layer_temperature} N{next_extruder} H{first_layer_height} echo {state.thisInput},"changeFilament" if exists(global.primeLayer) == false global primeLayer = {-2,-2} ;if exists(param.A) && param.A == 0 ; M98.1 A"parkXY.g" ;if exists(param.A) && param.A == 1 ; M98.1 A"parkUV.g" if exists(param.H) G1 Z{param.H} F500 if exists(param.N) && param.N == 0 M596.1 P1 T0 echo {state.thisInput},"step 0 - wait for 200",{sensors.analog[param.N+1].lastReading} while heat.heaters[1].active < 200 G4 P500 ;echo {state.thisInput},"step 0 - wait for 200",{sensors.analog[param.N+1].lastReading} ;echo {state.thisInput},"M116 P1 from ",{sensors.analog[param.N+1].lastReading}," to 200" ;var start = state.upTime ;M116 P{param.N} ;echo {state.thisInput},"step 1 heat up time",{floor(state.upTime-var.start)},"s" ;**** Calculate delay var delayT = global.preHeatT echo {state.thisInput},"delayT initial",var.delayT if exists(param.L) && param.L <= 0 if global.primeLayer[param.N] < param.L set var.delayT = var.delayT - global.primeTime0*2 if exists(param.L) && param.L > 0 && global.primeLayer[param.N] < param.L set var.delayT = var.delayT - global.primeTime0 echo {state.thisInput},"delayT with prime",var.delayT ; post delay heatup var lastR = sensors.analog[param.N+1].lastReading if var.lastR < 200 set var.delayT = var.delayT - ((220-200)/global.degSec) if (200-var.lastR)/global.degSec > var.delayT set var.delayT = var.delayT - ((200-var.lastR)/global.degSec - var.delayT) echo {state.thisInput},"delayT with heatup",var.delayT ;set var.delayT = var.delayT - 1 if var.delayT <= 0 echo {state.thisInput},"SYNC not enough time to parallel tool change",floor(-var.delayT*10+0.5)/10,"secs short" else if heat.heaters[2].active < 200 echo {state.thisInput},"SYNC - other motion system not active - so no need to wait" else echo {state.thisInput},"SYNC - wait for",floor(var.delayT*10+0.5)/10,"secs" G4 P{floor(var.delayT*1000)} M568 P0 S220 R220 ;echo {state.thisInput},"heat up step2" var start = state.upTime+state.msUpTime/1000 var startReading = sensors.analog[param.N+1].lastReading echo {state.thisInput},"M116 P0 from ",{sensors.analog[param.N+1].lastReading}," to 220" M116 P0 var delayFurther = false if heat.heaters[2].active > 199 set var.delayFurther = true while sensors.analog[param.N+1].lastReading < 219 M568 P0 S220 R220 G4 P500 echo {state.thisInput},"step2 heat up time",{(state.upTime+state.msUpTime/1000-var.start)},"s",{sensors.analog[param.N+1].lastReading},"temp",{(sensors.analog[param.N+1].lastReading-var.startReading)/(state.upTime+state.msUpTime/1000-var.start)},"deg/sec" if exists(param.L) && param.L <= 0 if global.primeLayer[param.N] < param.L M98.1 A"clean T0" M801 X40 Y5 T0 S10 ; Prime M801 X40 Y5 T0 S10 ; Prime set global.primeLayer[param.N] = param.L if exists(param.L) && param.L > 0 && global.primeLayer[param.N] < param.L M801 X40 Y5 T0 S10 ; Prime set global.primeLayer[param.N] = param.L set global.T0Clean = false var timeC = state.upTime+state.msUpTime/1000 while global.uvParked = false ; move.axes[4].machinePosition <290 G4 P500 M400 echo {state.thisInput},"Waited for uv to be parked ",{state.upTime+state.msUpTime/1000-var.timeC},"secs" set global.xyParked = false echo {state.thisInput},"finished changeFilament" if exists(param.N) && param.N == 1 M596.1 P0 T1 echo {state.thisInput},"step 0 - wait for 200",{sensors.analog[param.N+1].lastReading} while heat.heaters[2].active < 200 G4 P500 ;echo {state.thisInput},"step 0 - wait for 200",{sensors.analog[param.N+1].lastReading} ;echo {state.thisInput},"M116 P1 from ",{sensors.analog[param.N+1].lastReading}," to 200" ;var start = state.upTime ;M116 P{param.N} ;echo {state.thisInput},"step 1 heat up time",{floor(state.upTime-var.start)},"s" ;**** Calculate delay var delayT = global.preHeatT echo {state.thisInput},"delayT initial",var.delayT if exists(param.L) && param.L <= 0 if global.primeLayer[param.N] < param.L set var.delayT = var.delayT - global.primeTime1*2 if exists(param.L) && param.L > 0 && global.primeLayer[param.N] < param.L set var.delayT = var.delayT - global.primeTime1 echo {state.thisInput},"delayT with prime",var.delayT ; post delay heatup var lastR = sensors.analog[param.N+1].lastReading if var.lastR < 200 set var.delayT = var.delayT - ((220-200)/global.degSec) if (200-var.lastR)/global.degSec > var.delayT set var.delayT = var.delayT - ((200-var.lastR)/global.degSec - var.delayT) echo {state.thisInput},"delayT with heatup",var.delayT ;set var.delayT = var.delayT - 1 if var.delayT <= 0 echo {state.thisInput},"SYNC not enough time to parallel tool change",-var.delayT,"secs short" else if heat.heaters[2].active < 200 echo {state.thisInput},"SYNC - other motion system not active - so no need to wait" else echo {state.thisInput},"SYNC - wait for",var.delayT,"secs" G4 P{floor(var.delayT*1000)} M568 P1 S220 R220 ;echo {state.thisInput},"heat up step2" var start = state.upTime+state.msUpTime/1000 var startReading = sensors.analog[param.N+1].lastReading echo {state.thisInput},"M116 P1 from ",{sensors.analog[param.N+1].lastReading}," to 220" M116 P1 while sensors.analog[param.N+1].lastReading < 220 M568 P1 S220 R220 G4 P500 echo {state.thisInput},"step2 heat up time",{(state.upTime+state.msUpTime/1000-var.start)},"s",{sensors.analog[param.N+1].lastReading},"temp",{(sensors.analog[param.N+1].lastReading-var.startReading)/(state.upTime+state.msUpTime/1000-var.start)},"deg/sec" var delayFurther = false if heat.heaters[1].active > 199 set var.delayFurther = true if exists(param.L) && param.L <= 0 if global.primeLayer[param.N] < param.L M98.1 A"clean T1" T1 M801 U50 V315 T1 S10 ; Prime M801 U50 V315 T1 S10 ; Prime set global.primeLayer[param.N] = param.L if exists(param.L) && param.L > 0 && global.primeLayer[param.N] < param.L M801 U50 V315 T1 S10 ; Prime set global.primeLayer[param.N] = param.L set global.T1Clean = false var timeC = state.upTime+state.msUpTime/1000 ;echo {state.thisInput},"M598 started" ;M598 ;M400 ;echo {state.thisInput},"M598 waited for ",{state.upTime+state.msUpTime/1000-var.timeC},"secs" set var.timeC = state.upTime+state.msUpTime/1000 while global.xyParked = false ; move.axes[1].machinePosition > 25 G4 P500 M400 echo {state.thisInput},"waited for xy to be parked ",{state.upTime+state.msUpTime/1000-var.timeC},"secs" set global.uvParked = false echo {state.thisInput},"finished changeFilament" -

Test post

<table>

<thead>

<tr>

<th>Header</th>

<th>Another Header</th>

</tr>

</thead>

<tbody>

<tr>

<td>field 1</td>

<td>value one</td>

</tr>

</tbody>

</table># *

bolded text -

@dwuk3d You can't do html tables in the forum, but you can do markdown tables, eg the following text:

| Column 1 | Column 2 | | ------------- | ------------- | | Cell 1, Row 1 | Cell 2, Row 1 | | Cell 1, Row 2 | Cell 1, Row 2 |creates this:

Column 1 Column 2 Cell 1, Row 1 Cell 2, Row 1 Cell 1, Row 2 Cell 1, Row 2 Ian

-

@droftarts Great thanks - couldn't find that in the documentation.

That makes things really easy - as I can just copy a table over from the TeachingTech discourse where I have started to build it up- might put this in a separate thread - but I am trying to build up a list of different colour changer options - mainly to compare them with my solution.

Re my Dual Gantry timings - I think if I change the polling frequency down from about 0.05 seconds, and kick off my tool move within about 0.06 seconds of the parking move of the other tool then I can get my tool changes down to about 0.1 secs.

Multi Colour/Filament Solution Comparison

Tool Timing Link Waste Reliability (DW view) Colours Multi Material Base printer speed (DW view) Parent Mosaic Palette 2/3 ~ 90 s 2020 H L 4-8 1 None X1C AMS + Flush into object ~ 120 s 2023 L H 4-16 7 MMU2 X1C AMS - off bed flushing ~ 90 s 2023 H H 4-16 8 MMU2 X1C AMS no prime tower ~90 s 2023 H M 4-16 8 MMU2 A1 AMS Lite- off bed flushing ~90 s 2023 H H 4 7 MMU1 Creality K2plus CFS ~90 s 2025 H M 4-16 9 AMS Other X1C AMS clones ~90 s 2025 H M 4-16 AMS Box Turtle ~ 75 s 2024 H M 4 AMS Klipper OpenAMS - BL AMS electronics upgrade ~90 s 2024 H M 4 AMS ERCF ~ 80 s 2023 H L 4-16 8 MMU2 TriColourMendel 10s - 60s 2013 L M 3 3 1 None Prusa MMU1 ~70 s 2016 H L 4 4 None Prusa MMU2 ~70 s 2018 H L 5 4 MMU1 Ryper MMU2 Clone ~70s 2022 H L 10 6 MMU2 Prusa MMU3 ~70 s 2023 H M 5 6 MMU2 PICO MMU ~70 s 2024 H M 4 6 MMU2 CoPrint Chroma AMS Lite Type Addon ~60 s 2024 H M 4-16 AMS Lite 3d Chameleon AMS Lite type add-on ~ 60s 2023 H M 4+ MMU2 Other 3rd party AMS/3rd party offerings ~90s H L AMS Filament Star rotating toolchanger ~60 s 2023 H L 4+ Y TeachingTech SV08 Stealth changer ~ 60 s 2025 L M 6-8 Y 8 E3D Misschanger Stealthchanger ~ 40 s 2025 L M 6-8 Y E3D H2D AMS2 pro ~ 90 s 2025 H H 4-28 2 8 AMS H2D between nozzles ~ 26 s 2025 L H 4-28 2 8 AMS + DualX E3D toolchanger ~ 30 s 2021 L M 2-5 Y None Prusa XL ~ 14 s 2024 L H 2-5 Y 6 E3D Nozzle changer (engineers grow) ~ 20 s 2024 L M 2-10 Y XL + Swapper3d Nozzle changer (Matti / @mvaar) ~ 20 s 2024 L M 2-10 Y XL + Swapper3d Virtual Colours Hueforge etc Any 2020 2022 2023 L H 20+ N/A Any Lithopane PolyDye - That inkjet colouring thing you featured on an ender printer. ~? s 2024 L M infinite 3 Flashforge CJ270 Full Colour Resin Printer ~?s 2024 2026 L H Infinite N/A 7 - 2.5mm/hour EufyMake E1 UV printer ~?s 2025 L H Infinite N/A 5mm Max Height Bigbrains3d Swapper3d nozzle changer ~ 90 s 2023 H M 2-20 Y 3 MMU2 Bondtech INDX 12-17 s 2025 L H 2-10+ Y XL + Swapper3d Conventional IDEX (with and without preheat) ~ 10 s - 60s 2018 L H 2 2 5 Conventional IDEX with box turtle on each toolhead (or ratrig IDEX/RMMU) ~10s - 90s 2021 H M 5-8 2 Ratrig Toolshift IDEX - without priming <1 s - 10s 2024 L M 2 2 8 IDEX Nathan Builds Robots 4 headed rotary printer < 10s 2024 L M 4 Y 15+ ukdw3d SV08 - Dual Gantry RRF parallel Bondtech INDX e < 0.5s - 17s 2026 L M 11+ Y 15+ INDX ukdw3d SV08 - Dual gantry/dual IDEX RRF <0.5 s - 10s 2025 L M 4 Y 15+ IDEX + Dueling Zero -

Been dusting off some maths knowledge today to try and more accurately position my print head over the top of the camera after auto aligning with the ball probe.

Firstly used a few captured nozzle probe and manually aligned readings, plus some measurements of the distance of the probe and camera from the servo pivot point to try and work out the XY coordinates of the servo pivot point.

With a bit of trial and error I found some numbers that worked

Then wrote this macro to calculate the camera position from ball probed UV coordinates - really please to see SIN/COS/ASIN/ACOS functions available...

;cameraFromUV.g M98 P"0:/macros/ParkXY.g" ;probe U 251.3187 offset U -13.6500092 probe V 202.1375 offset V 41.20003 ;probe U 251.0562 offset U -14.2998352 probe V 199.4344 offset V 41.00005 ;probe U 250.8687 offset U -14.7497253 probe V 197.4219 offset V 40.84999 ;probe U 250.8938 offset U -14.6997528 probe V 197.5125 offset V 40.85002 ;probe U 250.8000 offset U -15.0500336 probe V 196.2250 offset V 40.80002 ;probe U 250.9875 offset U -14.4999847 probe V 198.0063 offset V 40.89999 ; ;G1 U251.4 V202.8 F10000 var uPos = global.ballProbeU+14.5 var vPos = global.ballProbeV-40.9 var servoX = 427.9 var servoY = 188.3 var probePosRadius = 177 var cameraPosRadius = 165 var cameraOffsetAngle = 14 var probeAngle = degrees(asin((global.ballProbeV-var.servoY)/var.probePosRadius)) if var.probeAngle < 90 set var.probeAngle = 180 - var.probeAngle var cameraX = var.servoX + var.cameraPosRadius * cos(radians(var.probeAngle+var.cameraOffsetAngle)) var cameraY = var.servoY + var.cameraPosRadius * sin(radians(var.probeAngle+var.cameraOffsetAngle)) echo "U",global.ballProbeU,"V",global.ballProbeV,"angle",var.probeAngle,"cX",var.cameraX,"cY",var.cameraY if var.cameraX > 200 && var.cameraX < 300 && var.cameraY > 140 && var.cameraY < 200 set var.uPos = var.cameraX set var.vPos = var.cameraY else abort "cameraFromUV.g - suspect camera calculations" if exists(global.savedU) == false global savedU = -1 global savedV = -1 set global.savedU = var.uPos set global.savedV = var.vPos G1 U{var.uPos} V{var.vPos} F10000 if exists(global.servo5Off) && global.servo5Off > 0 set global.servo5Off = state.upTime + 120 if exists(global.magnetOff) && global.magnetOff > 0 set global.magnetOff = state.upTime + 120results pretty good - all photos are auto alignment and direct move to the camera

Notice the benefits of a camera over a ball probe in first photo - where the ball probe misaligned due to dirty nozzle.

UV

XY after cleaning

-

-

@dwuk3d As long as the belts along the crossbeam aren't aligned properly you won't see accurate positions anywhere else on the bed.

But it's good to have the theory behind alignement solved. -

@o_lampe yes - probably need to properly align belts in next stage.

I'm also thinking of trying the probe at some different angles to see whether the alignments of the two gantries are the same with the probe at different places on the bed.

I quite like the look of the new BambuLab H2D special alignment print bed - using camera's on the print head to read tiny qr codes at pre determined places.

-

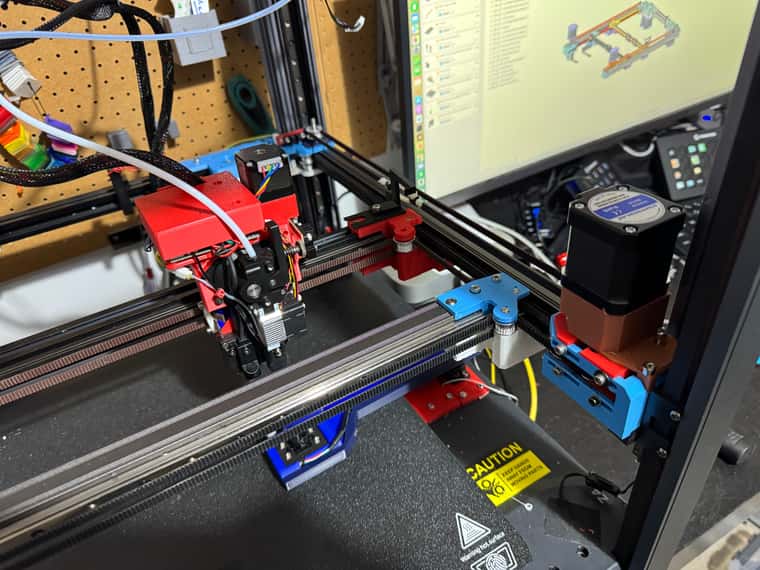

Made a start on IDEX motor and pulley mount (above side gantry supports) - will hold the idler at the back from the top took and introduce a tensioning system.

Zip Ties just temporary until I have the new top of gantry belt coupling.

Will have a mirror of the motor mount and idler on the other side.

The new motors at the front on each side will take over the Y axis movement - with the existing X & Y used for one print head each on the rear gantry.

Also tidied up extruders a bit and created top cover for 1LC boards.

-

starting to think about my occasionally moving bed phase.

My original idea for an occasionally moving bed was to allow for the printing of longer thin objects.

But my experience of even printing fairly small object is that the area where both print heads can access without hitting each other is quite restricted - so I think even the current size 350x350 bed moving maybe only 150mm would give some quite big benefits with very little overhang outside of the main printer body.

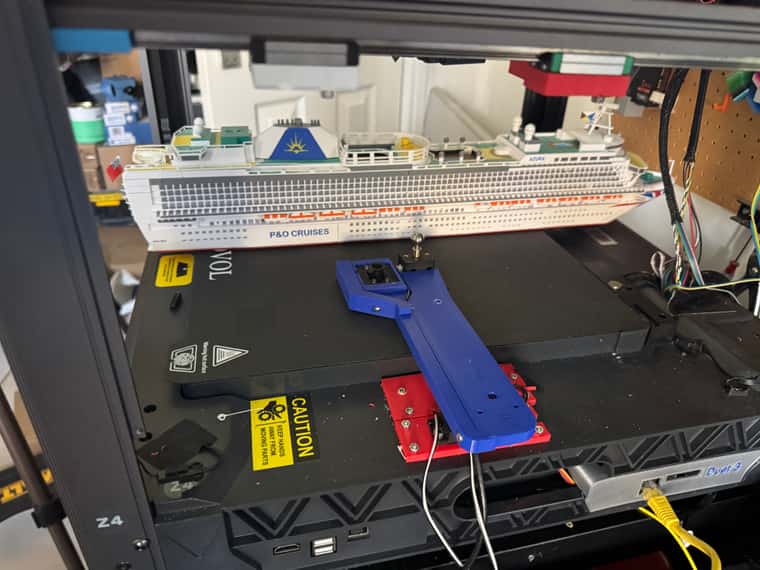

I think though that I want to go to 350 x 500 or even 350 x 550 - so that when parked the bed still fits nicely within the main printer size - but also allows for ships like the one shown (at 1:500 scale model) to be printed in one go.

Another interesting concept when thinking about ships - is the bow - which overhangs - that doesn't need a build plate under it - so would be an interesting concept having a print going completely beyond the build surface.

-

@dwuk3d In the end we'll see a conveyor belt bed with dozends of tools heads zipping around simultaneously...

But seriously: you could do the same split_the object_trick in a big scale manner.- Build two independent printers with 4 heads each

- place them above the looong conveyor belt with a certain gap

- print parts 1 + 3

- move the belt and print part 2 + 4

- move back and repeat

-

My response to Advantages and disadvantages of Dual Gantry over IDEX and Tool changers as asked by @MostlyMessingAbout

Advantages of Dual Gantry over IDEX

- Additional degree of freedom in Y Axis - allows for parallel printing of different shaped parts or whole objects (if independent Z hopping also available). - up to doubling print speeds.

- Allows Parallel priming and wiping during tool changes - which can push tool change times from >10 seconds down to <1 second

- Only having one head on each gantry means faster speeds possible in the Y direction in particular - which can be an issue with IDEX

- When used in combination with IDEX can allow up to 4 toolheads which can all print in parallel for some parts of large prints. - which could increase print speeds by over 50% more.

- Print head can access the whole X axis

Disadvantages of Dual Gantry over IDEX

- Increased complexity of belt routing

- Slicers don’t currently support parallel printing - so post processing of GCODE required

- Print heads cannot individually access the whole Y axis

- The front gantry and print head can block the view of the rear gantry.

Advantages of Dual Gantry over Tool changing

- Parallel printing - up to doubling print speeds.

- Allows Parallel priming and wiping during gantry or tool changes - which can push tool change times from >17 seconds down to <1 second

- When used in combination with IDEX can allow up to 4 toolheads which can all print in parallel for some parts of large prints. - which could increase print speeds by over 50% more.

- When used in combination with tool changing would allow extremely fast tool changes if the tool changes occur between the two gantries

- Less equipment sitting around not being used 90% of the time.

Disadvantages of Dual Gantry over Tool changing

- Increased complexity of belt routing

- More motors if using a Nozzle changer tool changer

- Slicers don’t currently support parallel printing - so post processing of GCODE required

- Print heads cannot individually access the whole Y axis

- The front gantry and print head can block the view of the rear gantry.

In response to question from @JavierHernandez-bj5hz asking where the Quad head design will be CoreXYUVAB

The current 2 head dual gantry implementation is already CoreXYUV, with AB added on for independent Z lifting.

When I move to 4 head IDEX I will be changing the kinematics of each Gantry over from CoreXY to Dual Markforged - So I guess it will be something like Double , Dual Markforged, Might be Better to call it Quad Markforged I suppose/

In terms of AXIS it will have Z0, X1,Z1,Y,X2,Z2, U1,Z3,V,U2,Z4.

Which in RRF will be XYZUVABCDEF.Then just to add to the complication - the next phase after IDEX is 'occasionally moving bed' - which will add a additional larger Y axis movement capability - so will then be

Z0, X1,Z1,Y,X2,Z2, U1,Z3,V,U2,Z4, Y2 , Which in RRF will be XYZUVABCDEFG -

@o_lampe If you look at some of my earlier video's you might see something like that.

Interestingly if I do end up with a fairly long bed - maybe 600 or 700 mm - then I might have to consider getting a 2nd SV08 and bolting it on the front - which as you said could have 4 heads of its own.

Might get out of hand though.

I think I will probably stop at 3 heads for a while - so that I can see how beneficial adding the 3rd IDEX head really is in real life situations.

I would though really think something like an Orangestorm Giga (with the 1m x 1m x 1m). Could really benefit from 3 gantries with 2 or 3 heads on each, or maybe even 4 gantries with 2-4 heads on each.

There was a good example in this video of printing a coffee table - where the 4 legs could be printed in parallel quite easily.

-

@dwuk3d said in Sovol SV08 Multiple Motion System Upgrade.:

Z0, X1,Z1,Y,X2,Z2, U1,Z3,V,U2,Z4, Y2 , Which in RRF will be XYZUVABCDEFG

Just call it Alphabet kinematics , because there aren't many unused letters left