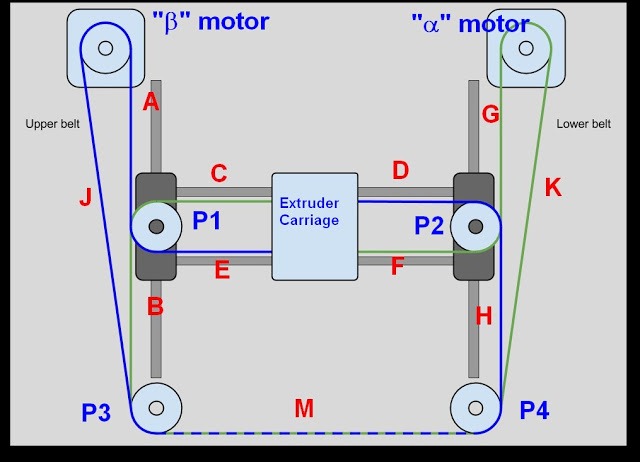

CoreXY belt pattern.

-

Mine is here https://somei3deas.wordpress.com/my-corexy-printer-build/. Essentially it's the "standard" stacked belt arrangement. What I do that is a bit different is that the belts to the X carriage run along the centre line of the carriage rails and attach to the centre of the X carriage, rather than either side of it (which can impart a twisting force). The motor mounts are slotted where the bolts attach them to the front rail but the other bolts fit into V-slot nuts. Tensioning is done by slackening the fixing bolts then there is a thumb screw arrangement so turning the screw in against the frame pushes the motor mount backwards. When the tension is set the fixing bolts are tightened and the thumbscrew locked.

-

https://www.thingiverse.com/thing:2849355

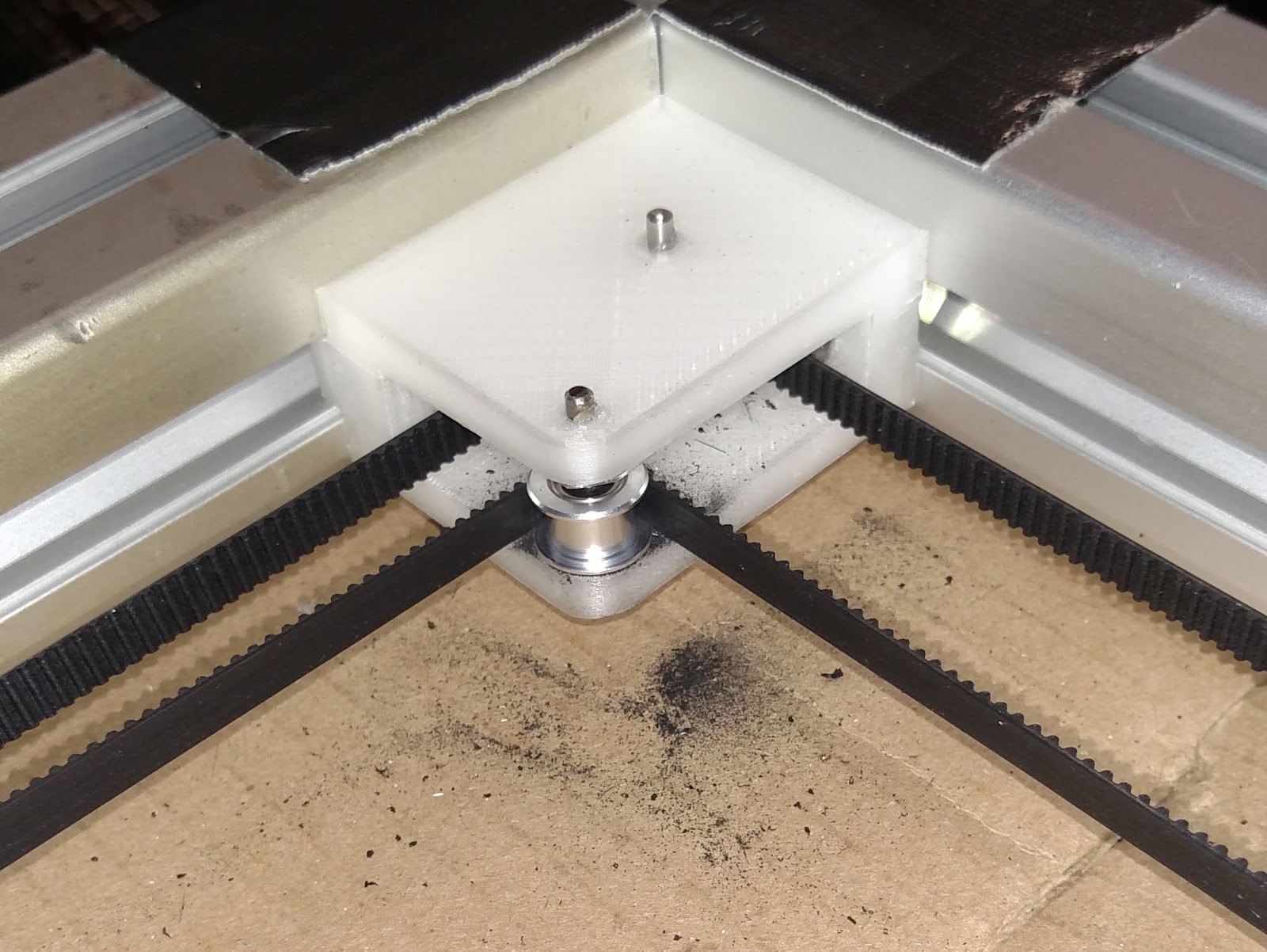

I use tensioner blocks that slot into the carriage itself. They use a bolt to tighten. As long as the belts are snug by adjusting the self locking block at one end, there is enough travel on the tensioning blocks to get nice even tension on both belts.

-

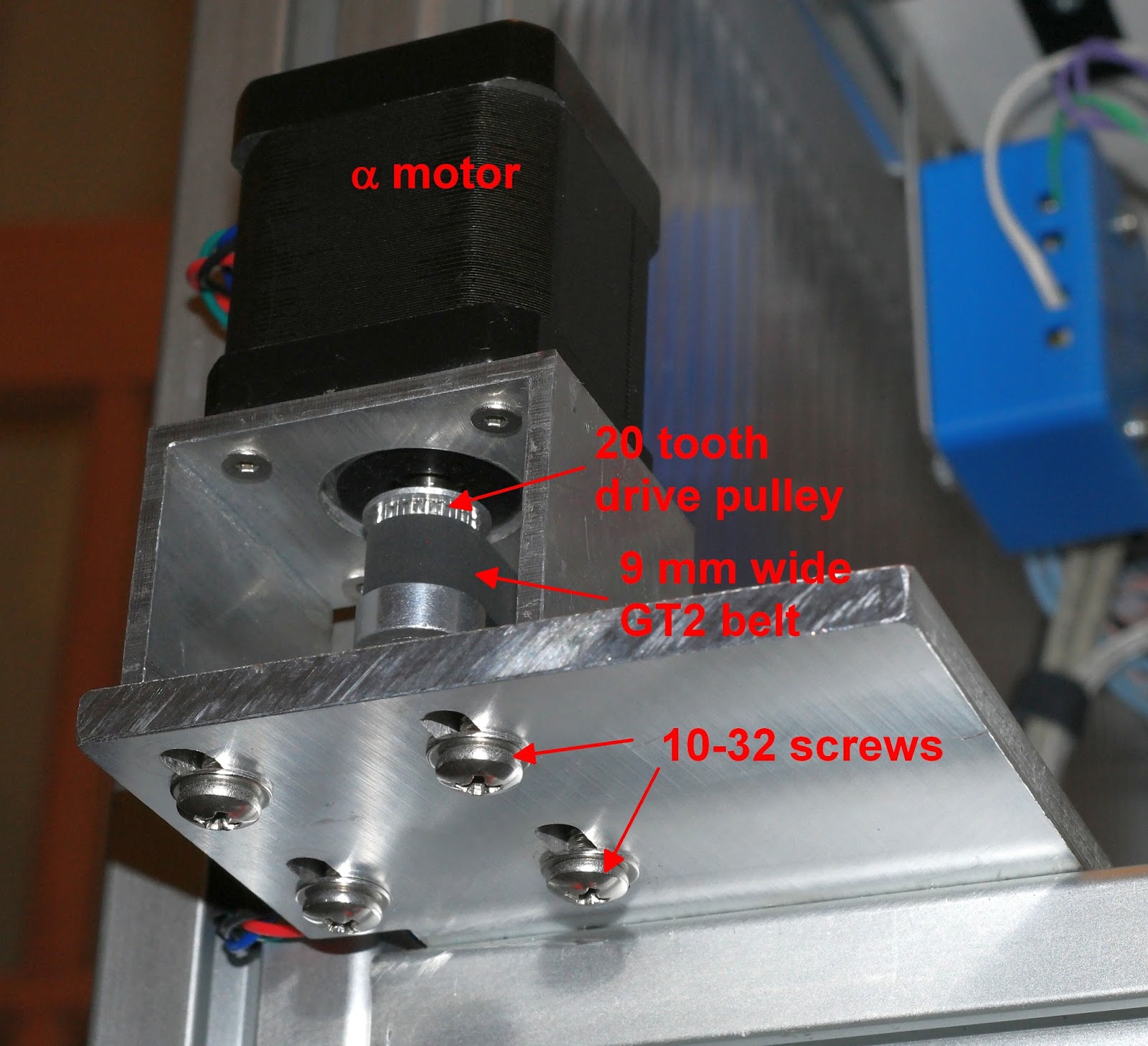

I made motor mounts from rectangular aluminum tubing, and I slide the mounts to tighten the belts:

-

I made mine with the motors at the back with the belt tensioner.

https://www.thingiverse.com/thing:3072219

-

Thanks guys for the info and the links

This is what I came up with, any comments appreciated.

Here is an ISO View.

-

There's not much to comment on other than the lines you drew to represent the belts look about right. The trick is in positioning the pulleys to actually put the belts along those paths, and to build it so that the belt tension doesn't cause the pulleys to tilt under belt tension force.

Are you planning to use BLDC motors for the XY drive? How will you control them? How will you get adequate resolution?

-

I would suggest you go with a fabtotum style belt pattern, that way there will be no twisting or crossing of belts.

-

@Surgikill I am stacking the belts to avoid the twisting. Fabtotum style dose look simpler. My goal is to make the XY belt path in such a way that the brackets for the pulley can be easily machined. As this will be a all metal machine, trying to avoid plastic as much as possible.

@mrehorstdmd hope you don't mind me using your photo as reference.

So do the position of the idlers P1/P2/P3/P4 have effect on the precision of the XY Motion?

For the BLDC motor I will be using odrive to drive the two motors.

Think ill be going with D5065 270kv Motor and a CUI AMT102 "8196 CPR capacitive encoder", haven't decide on the motor type 100%. -

You can change the position of the idlers as long as you keep this to be true:

The most important thing in any coreXY implementation is that the belt segments (a segment being the belt between two pulleys or between the extruder carriage and the end pulleys) whose length varies (labeled A-H in the diagram below), must be kept parallel to their respective guide rails.

from https://drmrehorst.blogspot.com/2018/08/corexy-mechanism-layout-and-belt.html

-

@OG3D I actually just made a corexy machine. It went through about 10 revisions before I was happy with it. Only issue is machining the the pulley mounts on mine would cost a shit load of money. I can post some pictures here if you want. The pulley pieces were over engineered so there should be no issue whatsoever using plastic for them.

-

@og3d Interesting. How does odrive interface to the Duet controller?

Will you be able to get sufficient resolution and low speed torque using BLDCs?

-

After Several revision, I think I'm happy with this design.

Thanks for the help at @mrehorstdmd and @Surgikill -

@mrehorstdmd odrive supports the step/dir interface. I'm not sure if I will have enough torque at low speeds so this will be like an experiment for me. I know the odrive creator had good results using odrive to control his Pick and Place Machine link text.

The reason for leaning toward BLDC motors is to decrease the tool change time during the printing as this printer will have a tool changer similar to E3Ds approach.

-

@og3d I think you're going to find that the upper pulleys on the ends of the X axis will tilt when you apply tension to the belts, and that will cause the belt to ride hard against the pulley flanges and will quickly wear the edge(s) of the belt.

How many steps per rev will that BLDC driver and motor give you? A stepper motor is a brushless DC motor, but unlike the airplane motors, they are designed to provide many steps per rev instead of maximizing rpm. In a high precision positioning mechanism like a 3D printer, you really want a high steps/rev count.

-

@mrehorstdmd yes I knew its gonna happen but didn't thick it would be bad for the belt.

For BLDC motor I'm still figuring how much steeps per revolution I could get out of it.

If you'll watch this Youtube video link text

It looks there are issues when traveling at low speed with resonance frequency but he claimed that it could be solved in firmware update. This is all new to me so I'm learning as I go. -

@og3d This is what happened when I put a 180 degree twist in a couple 1m long segments of belt in my sand table. The twist was forcing the belts to ride on the pulley flanges which were grinding away the edges of the belts.

-

I use a 180 twist on my DBot to keep the smooth side of the belt on the smooth idlers at the back corners and haven't noticed anything like that. Mind you it uses two flanged bearings rather than a rimmed idler like that.

-

@brunofporto said in CoreXY belt pattern.:

I made mine with the motors at the back with the belt tensioner.

https://www.thingiverse.com/thing:3072219This is a very elegant design, I like it more than the HEVO's tension screws on the X carriage.

-

Does being able to tension each of the belt ends on HEVO provide any advantage compared to this one? (I think Scott mentioned it in one of his videos).

-

This design adds 3 more idlers per belt. Any down side?

-

Do you think this approach will work with the steppers left at the front. That is, a rear passive tensioner with 3 (or 2?) idlers?

Thanks,

Z. -

-

@phaedrux I started out with cables, then switched to belts and flanged pulleys on one level. The belts started riding on top of the pulley flanges, so I switched to the wider flanged pulleys and finally to stacked belts to eliminate the twists and grinding. It may be the super long length (about 6m each) of the belts in the sand table made them a little too stretchy.

It always best to keep the belts and pulley axles square.

-

@zapta Thank you!

-

The only thing that tension each end does is provide a longer travel for adjustment, there is no difference if tension the belt from one end or another. Also, The main reason for using another approach is because it was very difficult to fix and calibrate the belts and also they were prone to lose adjustment due to vibration.

-

They add drag and due to more tight curves can reduce the belt life span. But it it is not noticeable

-

They are not only tensioners - a CoreXY needs a precisely calibrated belts loop relative length. If they have slightly different length then the parts will not have correct dimensions and "squareness" along the entire print area. You can have passive tensioners for sure, even integrated into this system but you will still need to adjust the relative length of the belts. (check this: https://www.thingiverse.com/thing:3306430)

You are welcome!

-