Yet another cast aluminum plate topic...

-

@TLeTourneau, you will find different opinions on that. I prefer to use a removable glass plate so that I can swap print beds easily. The main benefit is that if a print sticks too well to the bed, I can put the bed+print in the fridge or freezer to help it to come free. Also I can swap plates and start a new print after one has finished, without waiting for the bed to cool down (which can take a while if you are using a thick aluminium plate). Finally, I can experiment with different print surfaces (plain glass, PEI, PrintBite etc.) on top of the glass plates.

The disadvantages of using glass on top is that you need to have space at these margin for bed clips (which loses a little print area unless you included a margin in your bed design), and the temperature on top of the glass will be lower than on the aluminium by 5 to 10C.

If you do use glass then I suggest 4mm thick not quarter inch. Ordinary float glass is usually flatter than toughened glass.

-

Because you use cast aluminium there is no need for a glass on top in my opinion (that just increases the heat up time and weight)

-

@tletourneau You'll get dozens of different opinions on this. IMO, there is no right or wrong - it's just personal preference. Like DC42, I prefer the removable glass option and for the same reasons. I use 6mm thick float glass (1/4 inch) because my bed is on the large side, and it's fine. Just allow for the top surface of the glass to be about 2 deg C less than the aluminium under it.

Edit. Because aluminium is a soft metal, it's not too difficult to scratch or dent it. Especially if you print directly on to it and resort to using a scraper or some such to remove a part. So I'd highly recommend that you put something on top of it, whether that be semi-permanent of easily removable.

-

@deckingman

I will use a magnetic printbed like Ziflex or easy-peelzy (but they are not that good for ABS because of temperature resistance of the magnets)

I backed them back on kickstarter but didn't receive my item yet

EDIT: Ziflex can be heated up to 100°C before loosing its power. -

Well the plate and heater are installed, now to run a mesh and see what it looks like. Here are some pictures.

Here's the cast aluminum plate:

Here is a view of the frame I made to mount the plate:

Here is the front with the plate on the mount:

Here is a closer look at the front mount:

Here is the rear left mount:

And the rear right mount:

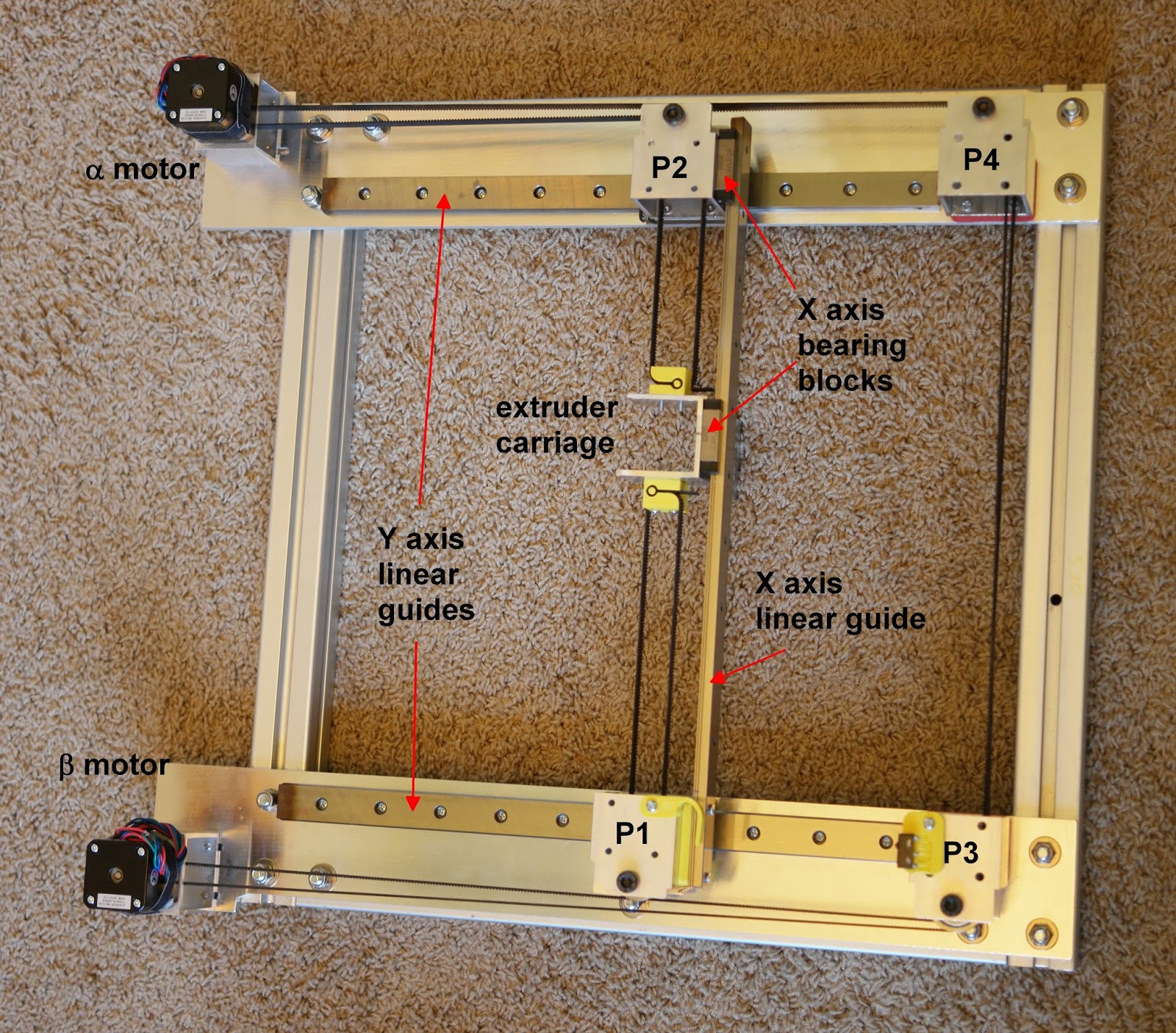

I also installed linear rails on the X and Y axis's:

I just thought I'd share.

-

@tletourneau run a detailed G29, let's see how flat that sucker is.

-

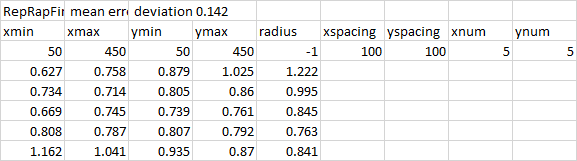

Well this is strange to me, any thoughts on how to adjust this?

Here is the CSV data:

RepRapFirmware height map file v2 mean error 0.847 deviation 0.142 xmin xmax ymin ymax radius xspacing yspacing xnum ynum 50 450 50 450 -1 100 100 5 5 0.627 0.758 0.879 1.025 1.222 0.734 0.714 0.805 0.86 0.995 0.669 0.745 0.739 0.761 0.845 0.808 0.787 0.807 0.792 0.763 1.162 1.041 0.935 0.87 0.841This is using a BLTouch, the Z-probe settings are:

; Z-Probe ; BLTouch M574 Z1 S2 ; Set endstops controlled by probe M307 H7 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch M558 P9 H5 F100 T6000 A10 R0.3 S0.01 B1 ; Set Z probe type to bltouch and the dive height + speeds G31 P25 X59 Y-12 Z.92 ; Set Z probe trigger value, offset and trigger height M557 X50:450 Y50:450 S150 ; Define mesh grid -

Did you remeasure your z offset and manually level the bed first?

-

Thanks for the reply! I did measure my Z offset using the method in the wiki. I thought I leveled my bed... I'll level it again to be sure and run it again.

-

@tletourneau

Dat thicc boiIs that 1/2 inch?

-

@wyvern said in Yet another cast aluminum plate topic...:

@tletourneau

Dat thicc boiIs that 1/2 inch?

Naw, it's only 3/8". When I started to think about a 500x500mm piece I figured that about 9.5mm thick should be rigid enough for a 3 point mount.

-

@tletourneau

Crazy, my 1/4 300x300 should be here tomorrow, I just did 12mm Z rod/motor upgrade and .9 extruder upgrade, took the wimpy 8mm bars and reinforced some of the frame.Been a busy last few days.

Since my platform is only ACM I need to go the 4 point route to prevent platform bow, but I can always add some 2020 on the underside if it clears the Z axis drive-train.

Putting PEI on top, never used it, but I finally am getting good results with glass, I found some magic hairspray!

-

@wyvern I stuck with the 8mm lead screw but changed it to a single start 2mm lead from a four start 8mm lead which helped prevent bed drop, I am also using derlin anti-backlash nuts. I already had 12mm linear guide rods on the Z axis so I changed the bearings on them to a longer LMF12 to help control wobble which seemed to help. I figured that if I have issues I can always change the lead screws to 12mm/2mm but that would require me rebuilding the plate they, and the linear rods and bed, mount to so I thought I would try this first. If I have to change the mounting plates I'll likely add a Duex5 and go with three Z motors to enhance the auto bed leveling.

-

I have 4 start leads but I also have 2:1 gearing, so I'm hoping the extra 3 pounds won't matter, I only have one larger .9 stepper

What has helped tremendously as far as bed drop is the use of anti-backlash nuts, they have a little pre-load and pushing down on the platform doesn't seem to make the axis go down.

I mostly am doing the bed upgrade so I do not have to rely on glass or auto-leveling, the less components and configuration I need, the better.

-

For your mesh grid, there's less than 0.5mm of warp measured, that is the difference in values from the high corners (1.222mm and 1.162mm and the centre at 0.739mm makes for a n average difference of 0.453mm.) This is really difficult to see with the naked eye, and the levelling report will exaggerate this.

First things first, I'd check with a machinist straight edge that this warp actually exists. Measuring corner to corner, and assuming that this is accurate; you should see a very nearly straight measurement one way, and a slight gap in the center the other way.

If indeed the plate is warped that way, you will want to see if this is from it being mounted down to the bed frame. It doesn't appear that it should be, but it's worth investigating. It may be that your machined flat plate has somehow become warped, perhaps in shipping, and maybe as an effect of the bed heater. 3/8" thick should be capable of maintaining flatness over that size, and your 3 point mount seems reasonable. Is it possible that this was machined to one side good, and you put the heater on the guaranteed flat side? It may be possible to have a local machine shop mill it flat, shouldn't be too unreasonably expensive, though it shouldn't need to be done for a piece that you bought specifically to be flat.

-

@tletourneau A 3/8" cast plate will not have warped in shipping or any other way short of driving a fork lift over it, and if that had happened, it would be obvious from damage to the plate.

It looks to me like your Y axis guide rails are skewed in the YZ plane.

-

@gtj0 Care to share what your mounting system looks like?

-

@mrehorstdmd said in Yet another cast aluminum plate topic...:

@tletourneau A 3/8" cast plate will not have warped in shipping or any other way short of driving a fork lift over it, and if that had happened, it would be obvious from damage to the plate.

It looks to me like your Y axis guide rails are skewed in the YZ plane.

LOL.

Yeah, I had to step away from the keyboard for a bit before I could finish.

If the plate is not warped, as verified by the machinist's straight edge, then what's warped is your print head movement, in which case you either want to fix that, or keep/use the mesh compensation to keep your prints flat relative to the bed. Usually if there is a sag in the rails, you'll see what looks like a hump in the center, instead of a dish like this. It doesn't appear to be in just the X or Y axis, but as a combination of both, almost exactly at 45 degrees.

This could be a misalignment of the 2 Y linear rails, introducing a twist in the gantry movement. Like I said earlier, the amount is small, less than 0.5mm. (Well, maybe the misalignment is more like 0.6mm at the one end.)

-

I use printed alignment tools for all linear rails just for this reason.

-

I mounted the Y axis rails on 1/4" MIC6 plates bolted to a 40mm square t-slot frame. That whole assembly then bolted into the printer's frame:

My original intention with this was to make a couple different height printer frames into which I could just drop this assembly. I didn't end up doing that, but it does seem to keep the rails parallel to each other.