Hi, I can't get consistent trigger heights for my delta printer and it throws up constant errors when auto-calibrating and auto-bed levelling. It does not print a consistent first layer.

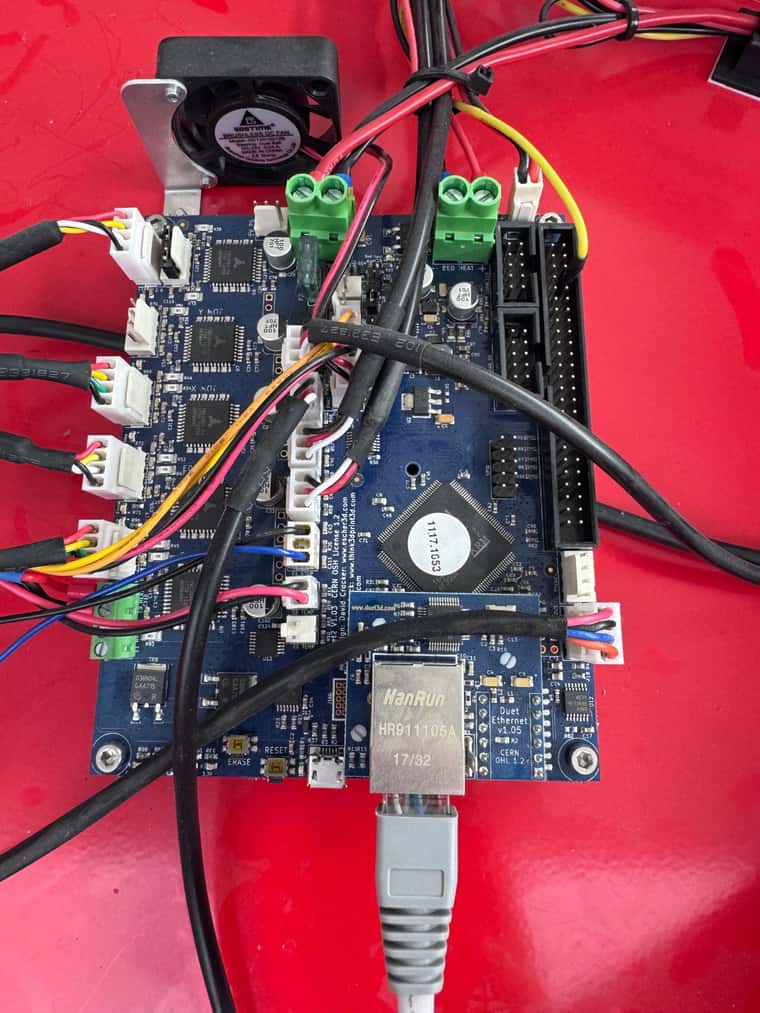

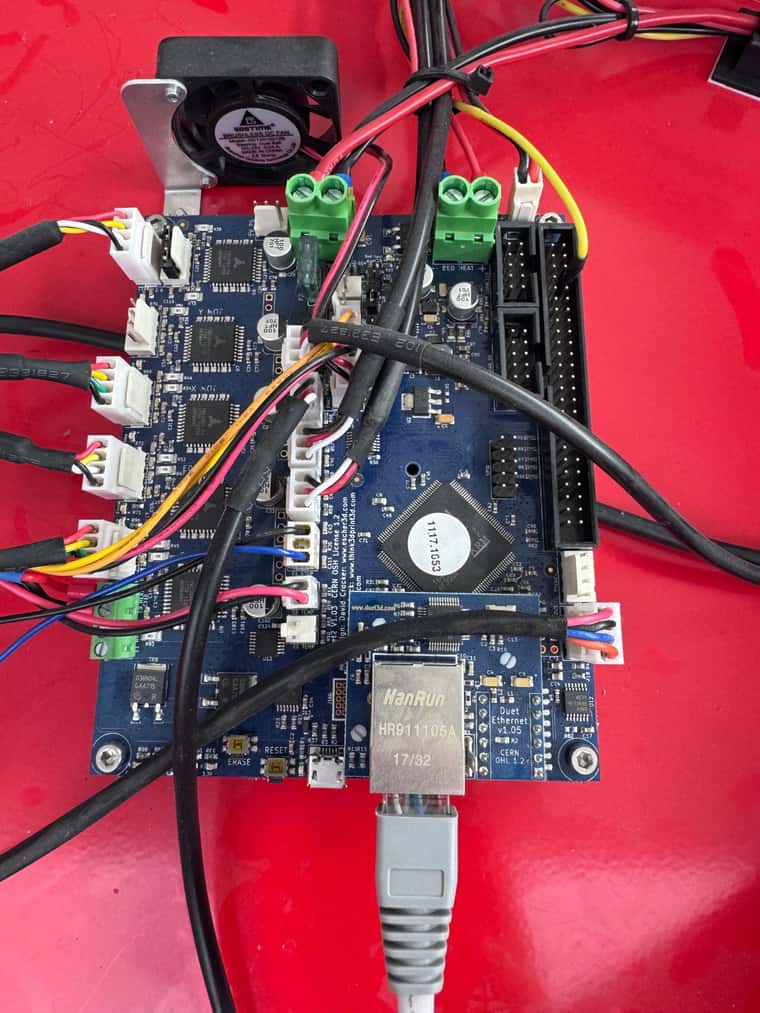

Printer: Tractus t1250 delta printer

Firmware:

Hardware:

I was following the calibration guide for delta printers and got to the auto-calibration step. When I got to the step to find the z-trigger height I could not get a consistent reading. I am not sure if this is hardware-related or software-related.

I have a range of measurements from -0.283mm to - 0.471mm. But each reading is different and a random number in this rang

e.

I am not sure what to do and what to check. So far I have:

-

Tried doing it hot and cold and I got the same inconsistencies.

-

Checked that the carriage wheels move freely.

-

I am not sure how to check the motor current.

But it could be due to how the bed probe system is set up, I am not entirely sure how it works. It uses the nozzle so I assume it is a pressure sensor as it is a glass bed.

I am not sure how to check if this is working properly and what I would need to do to fix it. I have attached some pictures of the printer and the bed.

Is there anything I can do with the software to reduce this inconsistency? I am really stuck and not sure what to do.

Any help would be much appreciated. Thanks

; Configuration file for RepRapFirmware on Duet 2 Ethernet

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.5.4 on Fri Aug 16 2024 12:20:56 GMT+0100 (British Summer Time)

; General

G90 ; absolute positioning

M83 ; relative extruder moves

M550 P"T1250" ; set hostname

; Accessories

M575 P1 S0 B57600 ; configure PanelDue support

; Network

M552 P0.0.0.0 S1 ; configure Ethernet adapter

M586 P0 S1 ; configure HTTP

; Smart Drivers

M569 P0 S1 D2 ; driver 0 goes forwards (extruder 0)

M569 P2 S0 D2 ; driver 2 goes backwards (X axis)

M569 P3 S0 D2 ; driver 3 goes backwards (Z axis)

M569 P4 S0 D2 ; driver 4 goes backwards (Y axis)

; Motor Idle Current Reduction

M906 I40 ; set motor current idle factor

M84 S30 ; set motor current idle timeout

; Axes

M584 X2 Y4 Z3 ; set axis mapping

M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation

M906 X1700 Y1700 Z1700 ; set axis driver currents

M92 X160 Y160 Z160 ; configure steps per mm

M566 X30000 Y30000 Z30000 ; set maximum instantaneous speed changes (mm/min)

M203 X36000 Y36000 Z36000 ; set maximum speeds (mm/min)

M201 X4000 Y4000 Z4000 ; set accelerations (mm/s^2)

; Extruders

M584 E0 ; set extruder mapping

M350 E16 I1 ; configure microstepping with interpolation

M906 E1100 ; set extruder driver currents

M92 E357.14286 ; configure steps per mm

M566 E18000 ; set maximum instantaneous speed changes (mm/min)

M203 E18000 ; set maximum speeds (mm/min)

M201 E4000 ; set accelerations (mm/s^2)

; Kinematics

M665 L457.600 R267.126 B175 H679.885 ; set delta radius, diagonal rod length, printable radius and homed height

M208 Z0 S1 ; set minimum Z

M666 X0 Y-0 Z-0 A0 B0 ; endstop adjustments and XY tilt, can be determined using auto calibration as well

; Probes

M558 K0 P5 C"e0stop" H5 F120 T18000 R0.2 A3 ; configure digital probe via slot #0

M558 H5 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved

G31 P500 X0 Y0 Z-0.555 ; set Z probe trigger value, offset and trigger height

;Bed Mesh

M557 R150 S50 ;bed probe grid

; Endstops

M574 X2 P"xstop" S1 ; configure X axis endstop

M574 Y2 P"ystop" S1 ; configure Y axis endstop

M574 Z2 P"zstop" S1 ; configure Z axis endstop

; Sensors

M308 S0 P"bedtemp" Y"thermistor" A"Heated Bed" T100000 B4725 C7.06e-8 ; configure sensor #0

M308 S1 P"e0temp" Y"thermistor" A"Nozzle" T100000 B4267 C7.06e-8 ; configure sensor #1

; Heaters

M950 H0 C"bedheat" T0 ; create heater #0 (bed)

M143 H0 P0 T0 C0 S140 A0 ; configure heater monitor #0 for heater #0

M307 H0 R0.337 K0.353:0.000 D2.69 E1.35 S1.00 B0 ; configure model of heater #0

M950 H1 C"e0heat" T1 ; create heater #1 (Nozzle)

M143 H1 P0 T1 C0 S285 A0 ; configure heater monitor #0 for heater #1

M307 H1 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #1

; Heated beds

M140 P0 H0 ; configure heated bed #0

; Fans

M950 F0 C"fan0" ; create fan #0

M106 P0 S0 L0 X1 B0.1 ; configure fan #0

M950 F1 C"fan1" ; create fan #1

M106 P1 S0 B0.1 H1 T50 ; configure fan #1

M950 F2 C"fan2" ; create fan #2

M106 P2 S1 L0 X0.6 B0.1 ; configure fan #2

; Tools

M563 P0 D0 H1 F0 ; create tool #0

M568 P0 R0 S0 ; set initial tool #0 active and standby temperatures to 0C

; bed.g

; called to perform automatic delta calibration

;

; generated by RepRapFirmware Configuration Tool v3.5.4 on Fri Aug 16 2024 12:20:56 GMT+0100 (British Summer Time)

G28 ; home the towers first

; Probe the bed at 12 peripheral and 6 halfway points, and perform 6-factor auto compensation

; Before running this, you should have set up your Z-probe trigger height to suit your build, in the G31 command in config.g.

G30 P0 X0 Y84.9 H0 Z-99999

G30 P1 X42.45 Y73.53 H0 Z-99999

G30 P2 X73.53 Y42.45 H0 Z-99999

G30 P3 X84.9 Y0 H0 Z-99999

G30 P4 X73.53 Y-42.45 H0 Z-99999

G30 P5 X42.45 Y-73.53 H0 Z-99999

G30 P6 X0 Y-84.9 H0 Z-99999

G30 P7 X-42.45 Y-73.53 H0 Z-99999

G30 P8 X-73.53 Y-42.45 H0 Z-99999

G30 P9 X-84.9 Y0 H0 Z-99999

G30 P10 X-73.53 Y42.45 H0 Z-99999

G30 P11 X-42.45 Y73.53 H0 Z-99999

G30 P12 X0 Y42.4 H0 Z-99999

G30 P13 X36.72 Y21.2 H0 Z-99999

G30 P14 X36.72 Y-21.2 H0 Z-99999

G30 P15 X0 Y-42.4 H0 Z-99999

G30 P16 X-36.72 Y-21.2 H0 Z-99999

G30 P17 X-36.72 Y21.2 H0 Z-99999

G30 P18 X0 Y0 H0 Z-99999 S6

; Use S-1 for measurements only, without calculations. Use S4 for endstop heights and Z-height only. Use S6 for full 6 factors

; If your Z probe has significantly different trigger heights depending on XY position, adjust the H parameters in the G30 commands accordingly. The value of each H parameter should be (trigger height at that XY position) - (trigger height at centre of bed)