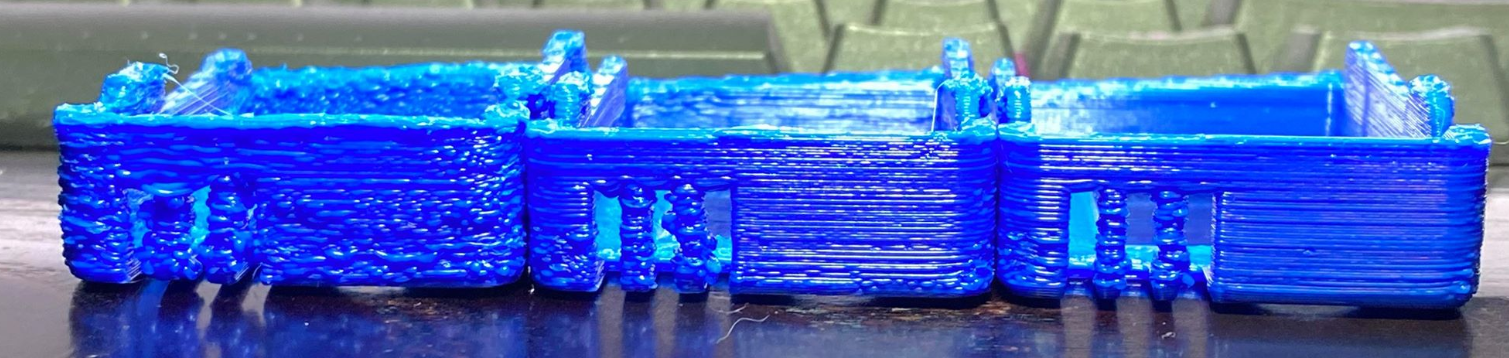

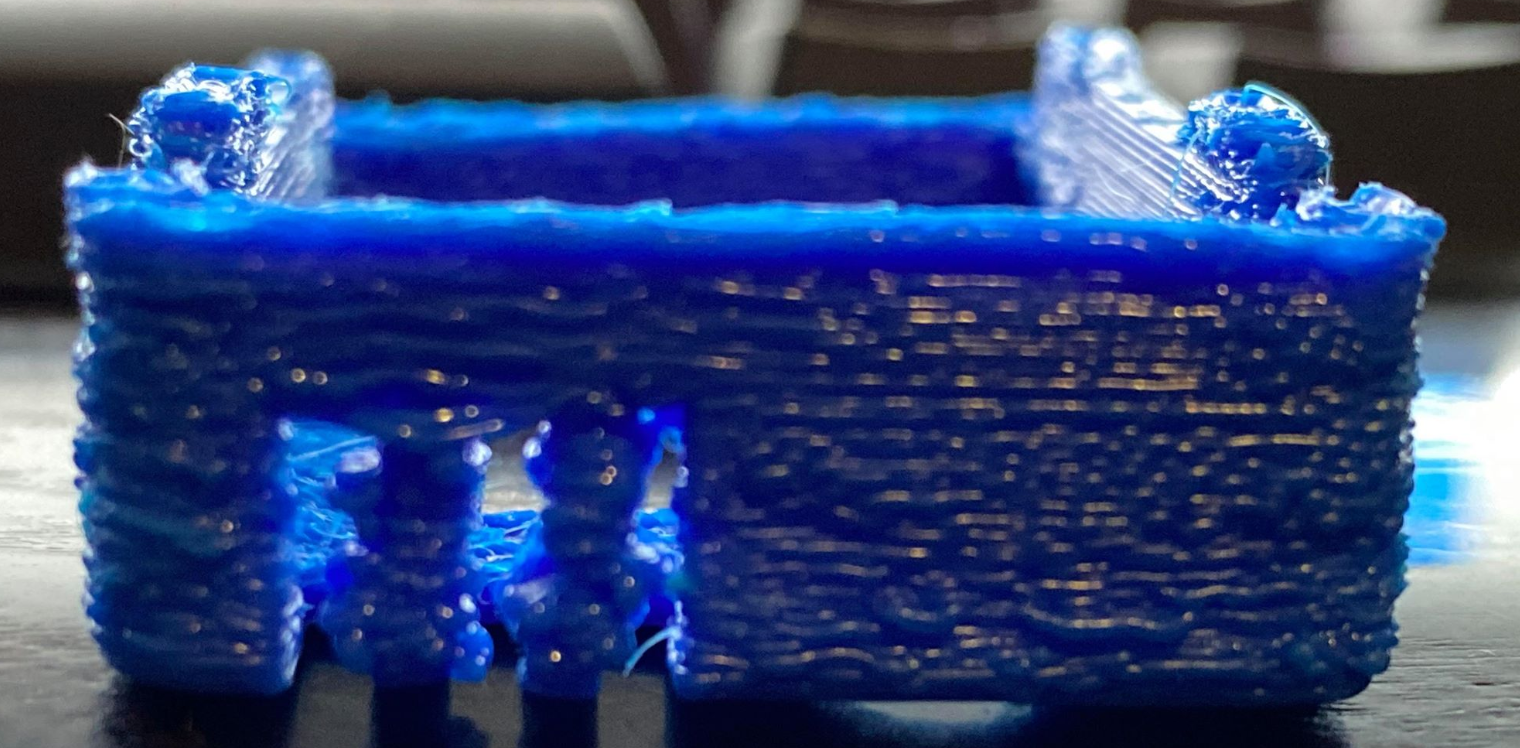

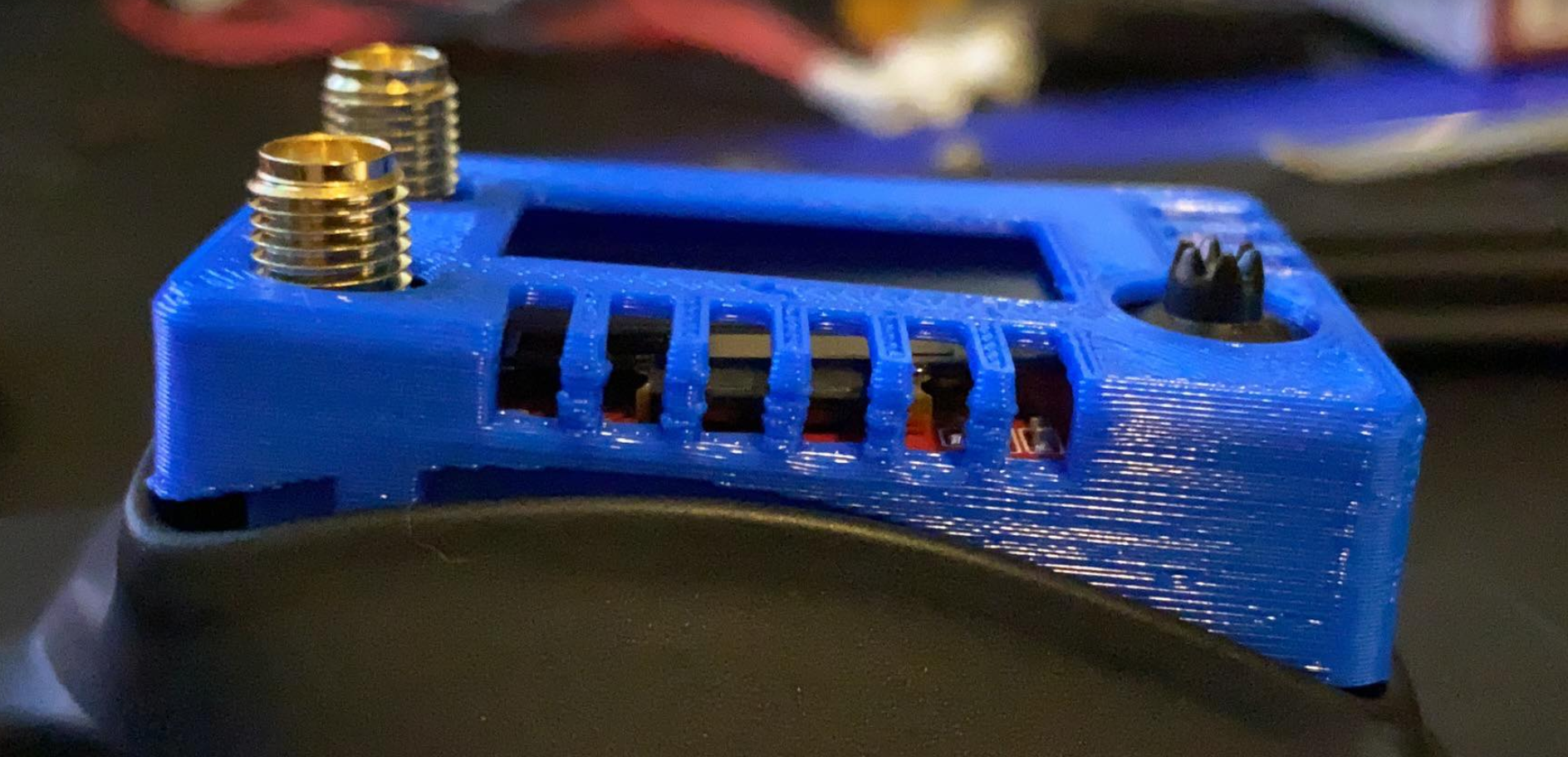

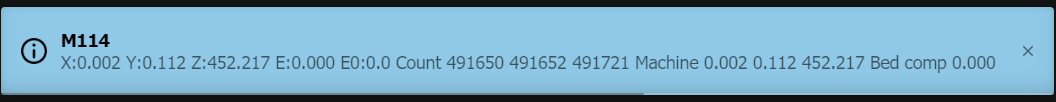

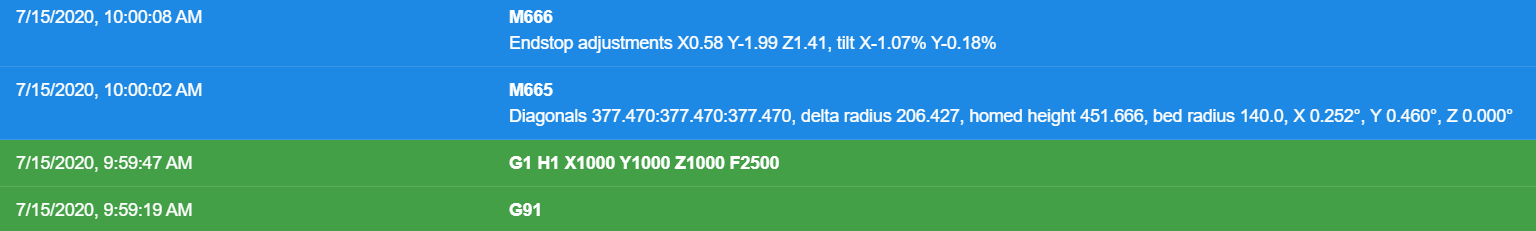

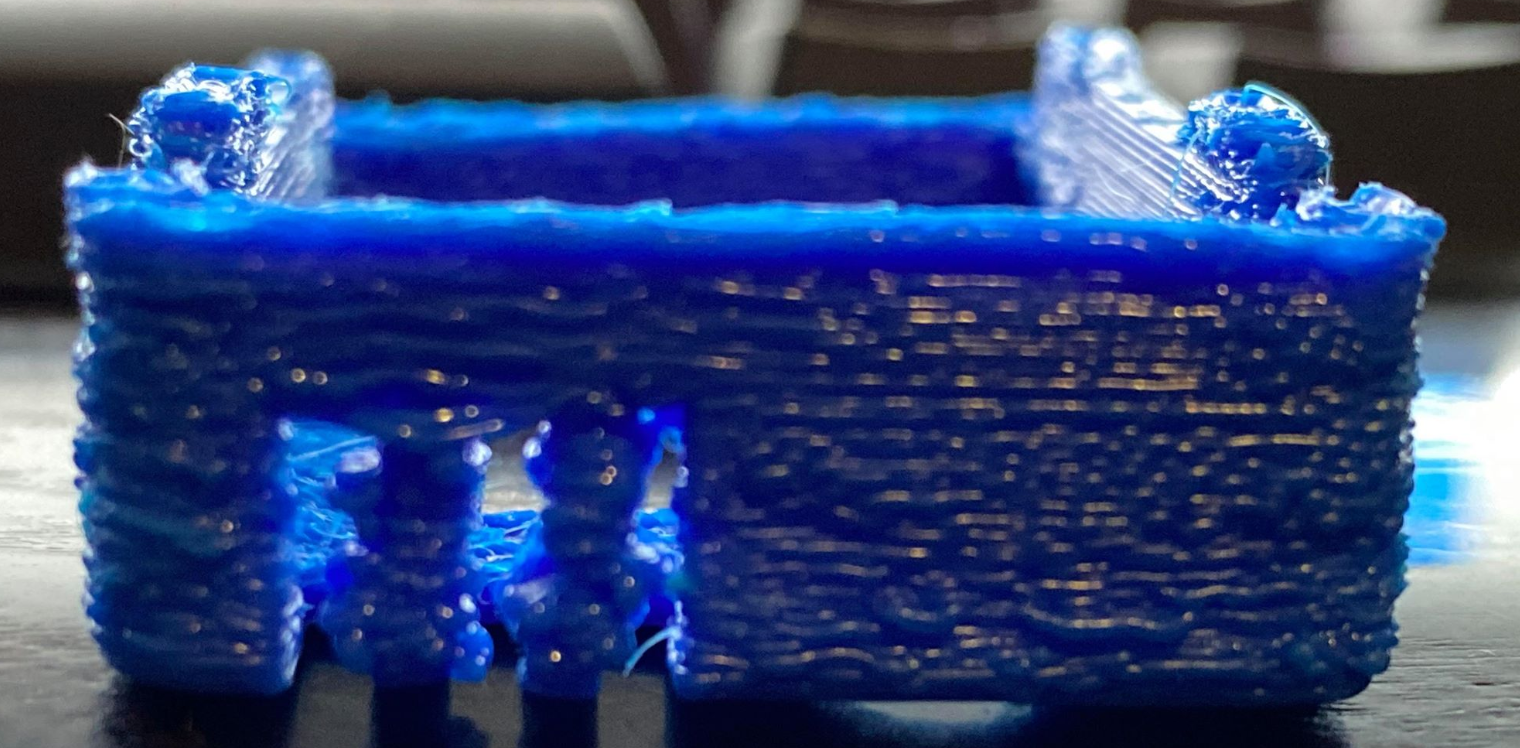

For example I had gcode I printed on 1.21rc3 and it printed perfectly fine, but since upgrading to 3.11 it printed like hot garbage. I don't know if its over extruding or what, but the prints are terrible.

This is on a D300vs Delta, it has an e3d titan on it and up until a few days ago it printed perfect.

That is with GCode that printed this same exact piece

Same GCode different results.

I was thinking it was a partial clogged nozzle, but I've done cold pulls and the end is coming out clean so I am at a complete loss.

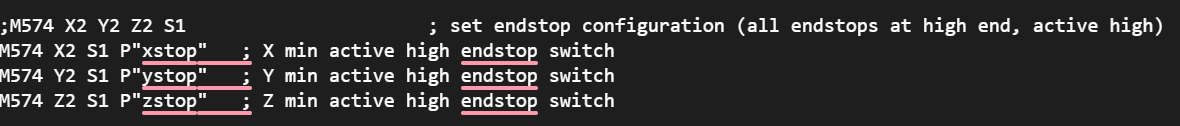

Here is my Config.G

; Configuration file for UltiBots D300 V-Slot 3D Printer

; version 1.0 for firmware version 3.0

; Communication and general

M111 S0 ; Debug off

M550 PVader ; Machine name and Netbios name (can be anything you like)

M551 XXXXX ; Machine password (used for FTP)

;*** If you have more than one Duet on your network, they must all have different MAC addresses, so change the last digits

;*** Wifi Networking

M552 S1 ; Enable WiFi

;M587 S"Epcot" I"192.168.1.102"

M555 P2 ; Set output to look like Marlin

M575 P1 S1 B57600 ; Communication parameters for the PanelDue

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

; Axis and motor configuration

M569 P0 S0 ; Drive 0 goes forwards (X tower)

M569 P1 S0 ; Drive 1 goes forwards (Y tower)

M569 P2 S0 ; Drive 2 goes forwards (Z tower)

M569 P3 S1 ; Drive 3 goes forwards (extruder 1)

;M574 X2 Y2 Z2 S1 ; set endstop configuration (all endstops at high end, active high)

M574 X2 S1 P"xstop" ; X min active high endstop switch

M574 Y2 S1 P"ystop" ; Y min active high endstop switch

M574 Z2 S1 P"zstop" ; Z min active high endstop switch

;*** The homed height is deliberately set too high in the following - you will adjust it during calibration

M665 L376.890 R209.421 H437.21 B140.0 X 0.125, Y 0.281, Z 0.000 ; set delta radius, diagonal rod length L380.31, printable radius and homed height

M666 X-0.44 Y-1.37 Z1.81 ; put your endstop adjustments here, or let auto calibration find them

M584 X0 Y1 Z2 E3 ; Set drive mapping

M350 X64 Y64 Z64 E16 I1 ; Set microstepping to 32 for X, Y and Z and 16 for extruder stepper with interpolation

M92 X640 Y640 Z640 ; Set axis steps/mm

M906 X1000 Y1000 Z1000 E500 ; Set motor currents (mA)

M201 X1000 Y1000 Z1000 E1000 ; Accelerations (mm/s^2)

M203 X20000 Y20000 Z20000 E3600 ; Maximum speeds (mm/min)

M566 X1200 Y1200 Z1200 E300 ; Maximum instant speed changes mm/minute

; Axis Limits

M208 Z-0.2 S1

; Fans

M950 F2 C"fan2"

M950 F1 C"fan1" ; This fan is the Heatsink Fan

M106 P1 T50 S255 H1 ; Set hotend heatsink FAN1 thermostatic control at 50°C

; Thermistors

M308 S0 P"bed_temp" Y"thermistor" T100000 B3950 ; define bed temperature sensor

M308 S1 P"e0_temp" Y"thermistor" T100000 B4725 C7.06e-8 ; define E0 temperature sensor

M950 H0 C"bed_heat" T0 ; heater 0 uses the bed_heat pin, sensor 0

M950 H1 C"e0_heat" T1 ; heater 1 uses the e0_heat pin and sensor 1

; Heater configuration

M140 H0

; Tool definitions

M563 P0 D0 H1 ; Define tool 0, the extruder

G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures

;M92 E415 ; Bondtech BMG steps per mm

M92 E822 ; Titan Aero steps per mm old: 837

; Z probe and compensation definition

; Change "H25" to "H3" AFTER commissioning your printer

M558 P5 C"!e0stop" X0 Y0 Z0 H5 F600 ; FSRs with JohnSL board Z probe behaves as a switch and is not used for homing any axes

;G31 X0 Y0 Z-0.15 P500 ; More (-) Z is less smooshed, more (+) Z is more smooshed

G31 X0 Y0 Z-0.75 P500 ; More (-) Z is less smooshed, more (+) Z is more smooshed

T0 ; Select tool 0, the hot end

M501 ; Load config-override.g

Thank you.