Posts made by bulka

-

RE: RepRapFirmware 3.0 is released!posted in Firmware installation

This is the config;

; Endstops

M574 X2 S1 P"xstop" ; Set active high endstops

M574 Y2 S1 P"ystop"

M574 Z2 S1 P"zstop"; Z-Probe

M558 P5 C"zstop" R0.4 H1 F120 T6000 ; Set Z probe type to effector and the dive height + speeds

G31 P100 X0 Y0 Z-0.252 ; Set Z probe trigger value, offset and trigger height

M557 R85 S20 ; Define mesh grid; Heaters

M308 S0 P"bed_temp" Y"thermistor" T100000 B4138 C0 R4700 ;

M950 H0 C"bed_heat" T0 ; heater 0 uses the bed_heat pin, sensor 0

M308 S1 P"spi.cs1" Y"rtd-max31865" ; define E0 temperature sensor

M950 H1 C"e0_heat" T1 ; heater 1 uses the e0_heat pin and sensor 1; Fans

M950 F0 C"fan0" ;

M106 P0 S0 Q500 H-1 ;

M950 F1 C"fan1" ;

M106 P1 S1 Q500 H1 T45 ;

M950 F2 C"fan2" ;

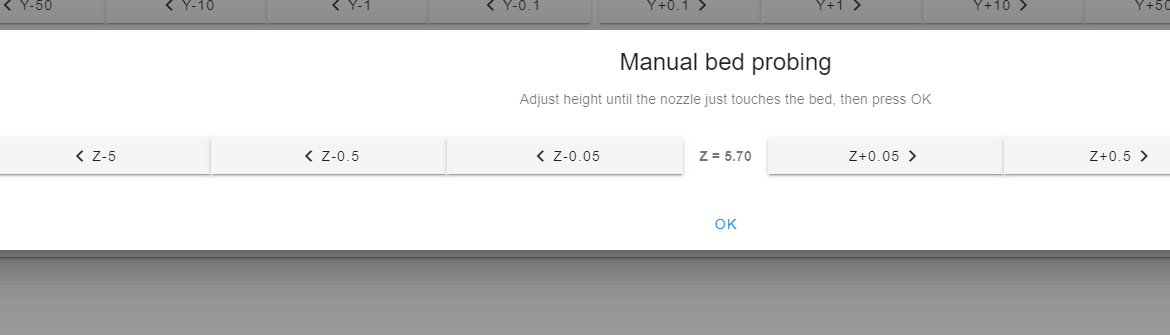

M106 P2 S1 Q500 H1 ;added the bold part as you suggest but if try to run Delta calibration start on Manual calibration

-

RE: RepRapFirmware 3.0 is released!posted in Firmware installation

My questions are about z-probe and bed leveling.

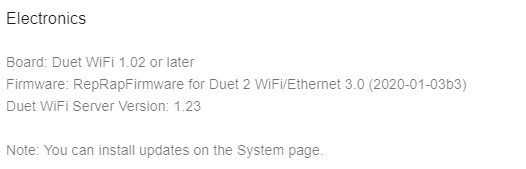

I updated my Duet wifi 1.02 with these new firmware.

z-probe: if I understood correctly there are no g-code modification if I'm using Smart Effector ...it's true? ( I'm talking about gcode for zprobe)

bed leveling: the automatic leveling was removed? I tried to run the leveling from web interface and started with a manual leveling.

Thanks

Giulio

-

RE: Printing Settings problemposted in General Discussion

@dc42 ok . I calibrated my extruder steps/mm to extrude exactly the amount requested but i want to fix the gumming produced. There is something else ( parameter ) to fix to reduce that ? Or is something that with PETG is normal and impossible to go to 0 ?

-

RE: Printing Settings problemposted in General Discussion

@phaedrux I tried to lower the extrusion factor from 100 to 96% and seems better....but I've to lower again...there is some value ( lower value ) that we don't have to reach?

-

RE: Printing Settings problemposted in General Discussion

Printed some object with some "error":

I tried to start the first layer with 245/85 and the other layers with 230/60.

Retraction setting with 3mm .I need to change something else to fix this errors...

-

RE: Printing Settings problemposted in General Discussion

240-245/85 ....seems perfect....I'll try another run to see the result

-

RE: Printing Settings problemposted in General Discussion

I'm reading :

This material doesn’t need to be squeezed onto your heated bed, you want to leave a slightly larger gap on the Z axis to allow more room for the plastic to lay down. If the extruder nozzle is too close to the bed, or previous layer it will skim and create stringing and build-up around your nozzle. We recommend starting off moving your nozzle away from the bed in 0.02mm increments, until there is no skimming when printing.How can I set on config.g to increments the height?

-

RE: Printing Settings problemposted in General Discussion

I tried to change bed temperature to higher...from 70 to 80 ..

changed first layer and layer height to 0.4

tried with higher hotend temperature from 220 to 230

PET-G seems not stick to the bed...

another problem....If I extrude 100m at 5mm/s ..or try continuous extrusion...homed....I hear a motor clicking(extruder)....

-

Printing Settings problemposted in General Discussion

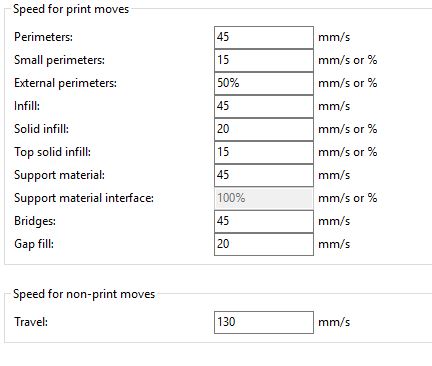

I started printing my first object: a case cover for duet.

I stopped because I seen some errors:

I thought that I needed to fix the hotend temperature for PETG ( from 230 to 220) and to fix the retraction settings ( from 1mm to 3mm)

something changed...

but there are again (the same) or something else to change....that I'm not understanding....

any suggestion?

Regards,

Giulio

-

RE: Printing faultposted in Tuning and tweaking

installed and configured....works perfectly!

thx for the help

-

RE: Printing faultposted in Tuning and tweaking

@hergonoway

not with cold extrusion....I fixed the temperature of the hotend to 180 to unlock the extrusion and unplugged the ptfe tube...and started to measure as you say -

Printing faultposted in Tuning and tweaking

I started to print ( hotend on 230C ...I'm using PETG ..and it's enough ) .

I sliced with Slic3r to convert a .stl to gcode and that is the result:

after 10 seconds of printing...or less..

and forced to stop everything...

I calibrated the motor "E" : M92 X160 Y160 Z160 E98

I used 98 after some try to extrude 100mm of filament at 5mm/s of feedrate...in order to get 100mm of filament out.

I don't know what I did wrong....

....it's possible that I sliced wrong and created a wrong file (with bad parameters?)?