Solved, I soldered the 4-wire connections of the Duet and it works, thank you very much for the help GREETINGS.

Posts made by CHARLI55

-

RE: PanelDue will not display temperatureposted in General Discussion

-

RE: PanelDue will not display temperatureposted in General Discussion

Yes, it's okay, I tried another cable from the other Duet and it does the same thing to me, however it works on one duet and on another it doesn't, the one that works seems to connect to something because the connection ip appears on a screen.

Could it be that the Duet is faulty?

-

RE: PanelDue will not display temperatureposted in General Discussion

FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 3.4.0 ELECTRONICS: Duet WiFi 1.02 or later + DueX5 FIRMWARE_DATE: 2022-03-15 18:58:33

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat Apr 10 2021 17:47:01 GMT+0200 (hora de verano de Europa central); General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"My Printer" ; set printer name

M669 K1 ; select CoreXY mode PONIA K1; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive X goes forwards P0 S0

M569 P1 S1 ; physical drive Y goes forwards P0

M569 P2 S1 ; physical drive Z goes forwards

M569 P3 S1 ; physical drive E0 goes forwards

;M569 P4 S1 ; physical drive E1 goes forwards

M569 P5 S1 ; physical drive Z goes forwards

M569 P6 S1 ; physical drive Z goes forwards

M584 X0 Y1 Z2:5:6 E3 ; set drive mapping

M671 X182:320:30 Y65:320:320 S15 ;M671 X181:30:320 Y65:320:320 S1 ; leadscrews at rear left, front middle and rear right

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E420.00:420.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X320 Y320 Z400 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M950 S0 C"duex.pwm1" ;M950 S0 C"!exp.heater6" ;M950 S2 C"exp.heater5" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H10 F320 T6000 ; set Z probe type to bltouch and the dive height + speeds

M574 Z1 S2 ; set endstop controlled by probed

G31 P500 X0 Y0 Z6.5 ;PONIA G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

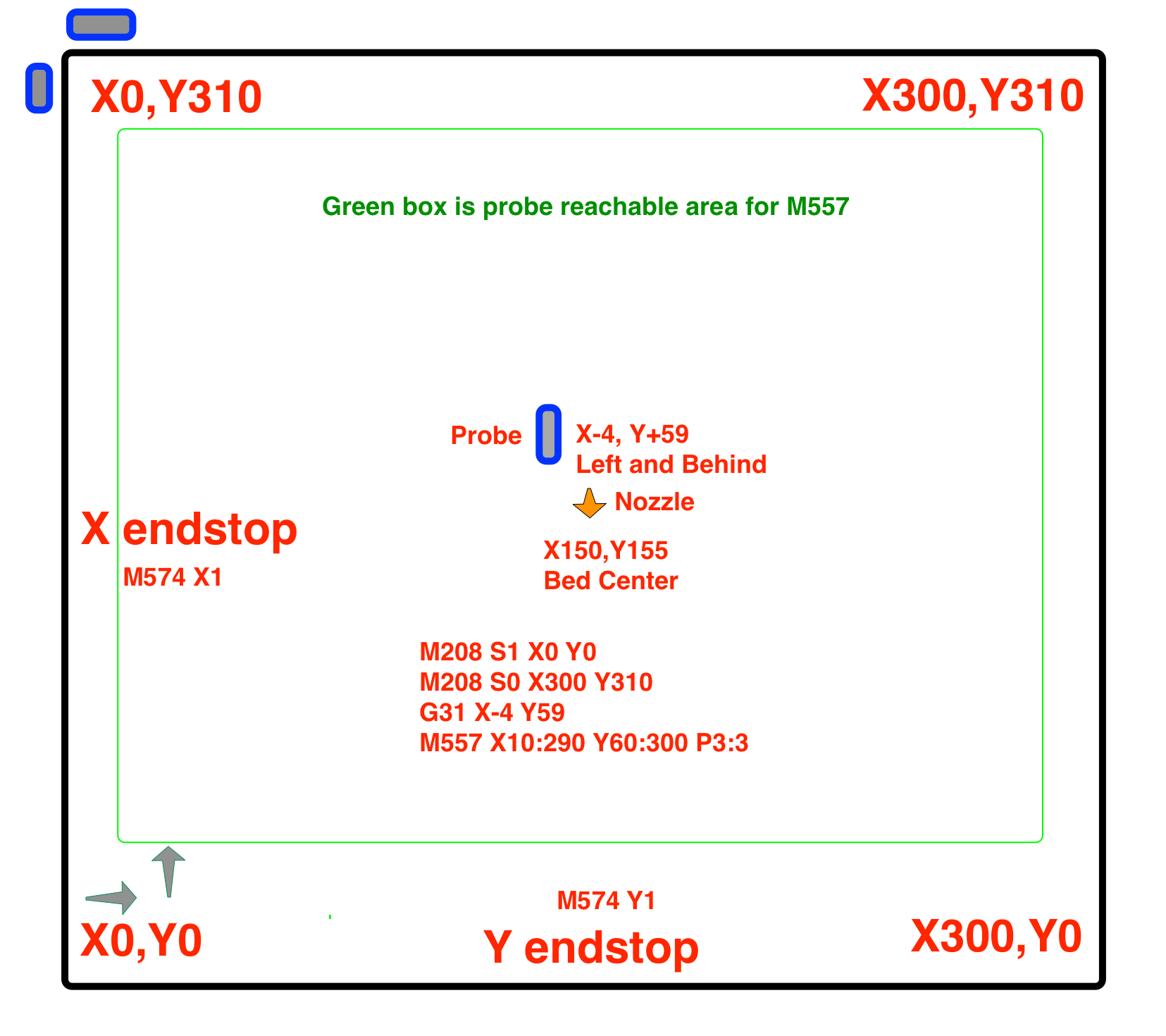

M557 X15:215 Y15:195 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M308 S2 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H2 C"e1heat" T2 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 D1 H2 F0 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined; Miscellaneous

M501

Connection from Paneldue to Duet Wifi 4 cables.

But if I put the same panel in another Duet 2wifi .....

-

PanelDue will not display temperatureposted in General Discussion

PanelDue does not show temperature or extruder everything else if any solution?

-

RE: Bed levelling using multiple independent Z motorsposted in General Discussion

@charli55 said in Bed levelling using multiple independent Z motors:

Thanks, it's already solved. Spindle adjustments made: -0.287 -0.128 -0.303, points used 3, (mean, deviation) before (-0.238, 0.079) after (0.000, 0.000

your dive height isn't high enough to accomodate the bed skew

-

RE: Bed levelling using multiple independent Z motorsposted in General Discussion

Thanks, it's already solved. Spindle adjustments made: -0.287 -0.128 -0.303, points used 3, (mean, deviation) before (-0.238, 0.079) after (0.000, 0.000

-

RE: Bed levelling using multiple independent Z motorsposted in General Discussion

But I don't know what happens if the bed almost touches the IR

-

RE: Bed levelling using multiple independent Z motorsposted in General Discussion

@charli55

If it is true that it is not activated in the first spindle, the red IR LED does not turn on -

RE: Bed levelling using multiple independent Z motorsposted in General Discussion

@jay_s_uk Error: Compensation or calibration cancelled due to probing errors

13/4/2021 20:28:34 g32

Error: Z probe was not triggered during probing move -

RE: Bed levelling using multiple independent Z motorsposted in General Discussion

@jay_s_uk M671 X176:305:46 Y3:285:285 S1.0

The engines still do not move

Z -

RE: Bed levelling using multiple independent Z motorsposted in General Discussion

@nuramori M584 X0 Y1 Z2:5:6 E3:4

I have duet wifi + duex5 -

RE: Bed levelling using multiple independent Z motorsposted in General Discussion

I change it, try and comment, thank you.

-

Bed levelling using multiple independent Z motorsposted in General Discussion

- Hello, I have a problem with a BLV MGN with Duet Wifi and RepRapFirmware 3, "Leveling the bed with several independent Z motors",

I have done everything that says the page https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors, but still when I send a G32 the extruder goes to the screws and when the bed is finished, no solution is leveled?

I attach my data from config.g and bed.g.

I'm very sorry for the bad translation from Spanish to English. Thanks.

; config.g ; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat Apr 10 2021 17:47:01 GMT+0200 (hora de verano de Europa central) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"My Printer" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive X goes forwards M569 P1 S1 ; physical drive Y goes forwards M569 P2 S1 ; physical drive Z goes forwards M569 P3 S1 ; physical drive E0 goes forwards M569 P4 S1 ; physical drive E1 goes forwards M569 P5 S1 ; physical drive Z goes forwards M569 P6 S1 ; physical drive Z goes forwards M584 X0 Y1 Z2:5:6 E3:4 ; set drive mapping M671 X176:305:46 Y3:285:285 S0.5 ; leadscrews at rear left, front middle and rear right M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E420.00:420.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00:1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X320 Y320 Z400 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S2 C"exp.heater5" ; create servo pin 0 for BLTouch M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds M574 Z1 S2 ; set endstop controlled by probed G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C M308 S2 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H2 C"e1heat" T2 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 D1 H2 F0 ; define tool 1 G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat Apr 10 2021 17:47:01 GMT+0200 (hora de verano de Europa central) M561 ; clear any bed transform G28 ; home M401 ; deploy Z probe (omit if using bltouch) G30 P0 X176 Y3 Z-99999 ; probe near a leadscrew G30 P1 X305 Y285 Z-99999 ; probe near a leadscrew G30 P2 X46 Y285 Z-99999 S3 ; probe near a leadscrew and calibrate 3 motors M402 ; retract probe (omit if using bltouch) - Hello, I have a problem with a BLV MGN with Duet Wifi and RepRapFirmware 3, "Leveling the bed with several independent Z motors",

-

RE: Problemas al hacer Homeposted in Duet Hardware and wiring

This is what I have set in config.g,

; Endstops

M574 X1 Y2 S1do I have to change it to ?

M574 Y2 S1 P"ystop" -

RE: Problemas al hacer Homeposted in Duet Hardware and wiring

This is the position of the endstop, I don't know if it's okay or the Y-axis endstop has to be on the left front end. -

RE: Problemas al hacer Homeposted in Duet Hardware and wiring

Si en eso estoy de acuerdo pero los ejes X Y tenian que poner 0?

-

RE: Problemas al hacer Homeposted in Duet Hardware and wiring

Gracias con el configurador tampoco se soluciona.

-

RE: Problemas al hacer Homeposted in Duet Hardware and wiring

Nada no va, ahora al cambiar el Y2 por el Y1 en M574 X1 Y1 S1 el eje Y empieza a dar saltos (mal funcionamiento)