Nevermind, stupid me found the issue while posting up the codes. I've adjusted the F value but not the T value. It now does indeed work

Posts made by Danny Jay

-

RE: How to speed up bed leveling?posted in Tuning and tweaking

-

RE: Large 3D printer build! Hardware discussion and ideasposted in General Discussion

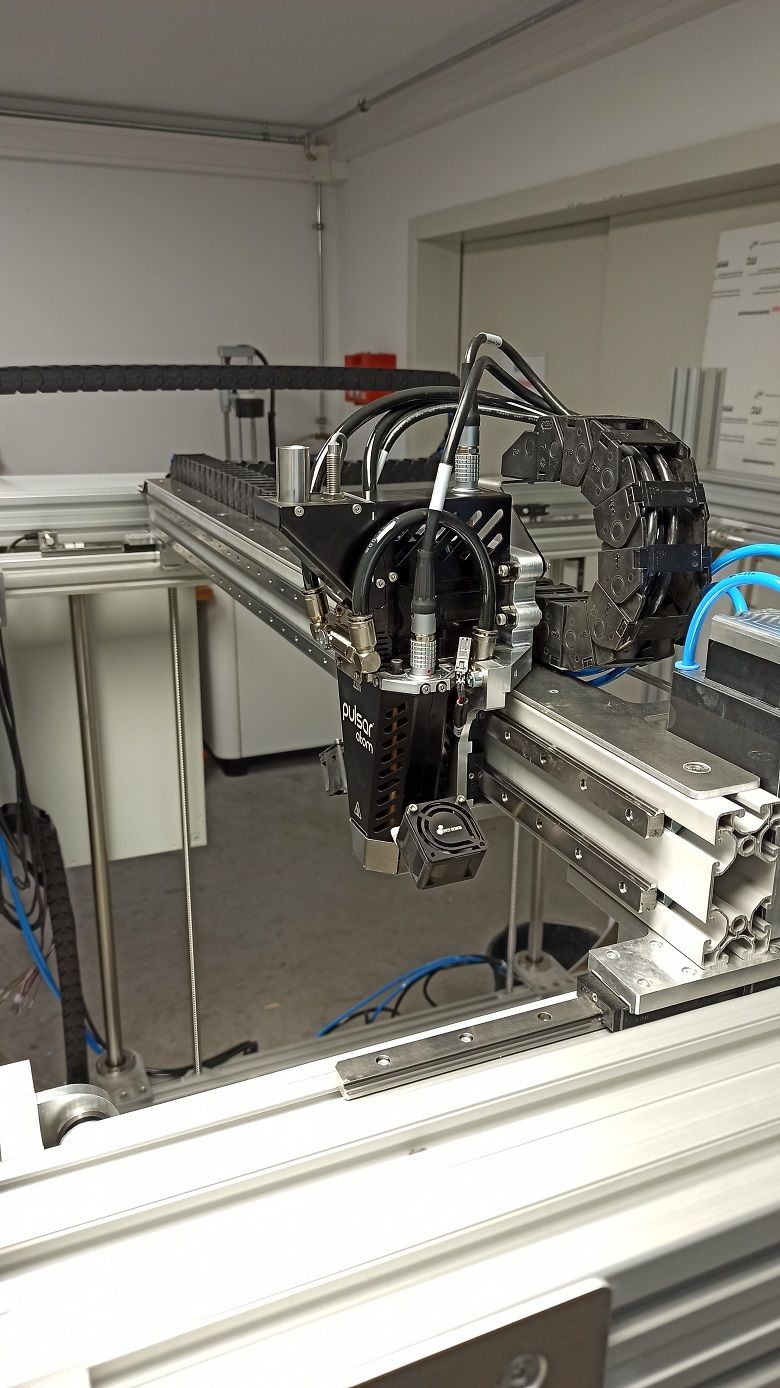

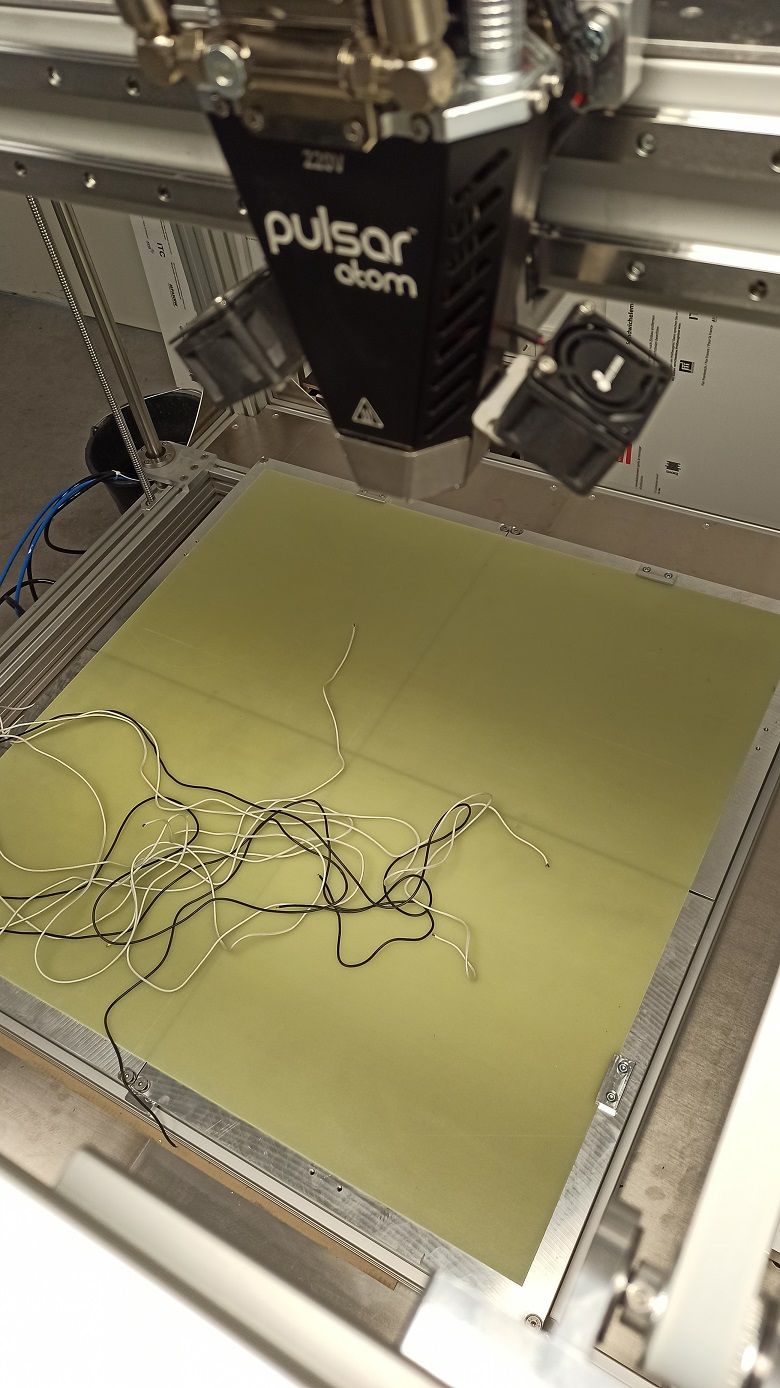

Status update,

The machine is now up and running, yet not completed but good for now running some experiments

Test move:

https://youtube.com/shorts/3CKMNepaWuw?si=1G-3YxQf6VK5LicsProbing:

https://youtube.com/shorts/EADCz_VwGls?si=ZgHFzYnbh_czCJaQ

-

RE: How to speed up bed leveling?posted in Tuning and tweaking

Hey Guys,

I'm struggling with the same issue, my maximum axis speed is set to 36000mm/min which equals 600mm/s, but no matter what I input as T value it's still traversing at 33.3 mm/s which is awfully slow for 90 points one a 1000*1000 build plate.

-

RE: Large 3D printer build! Hardware discussion and ideasposted in General Discussion

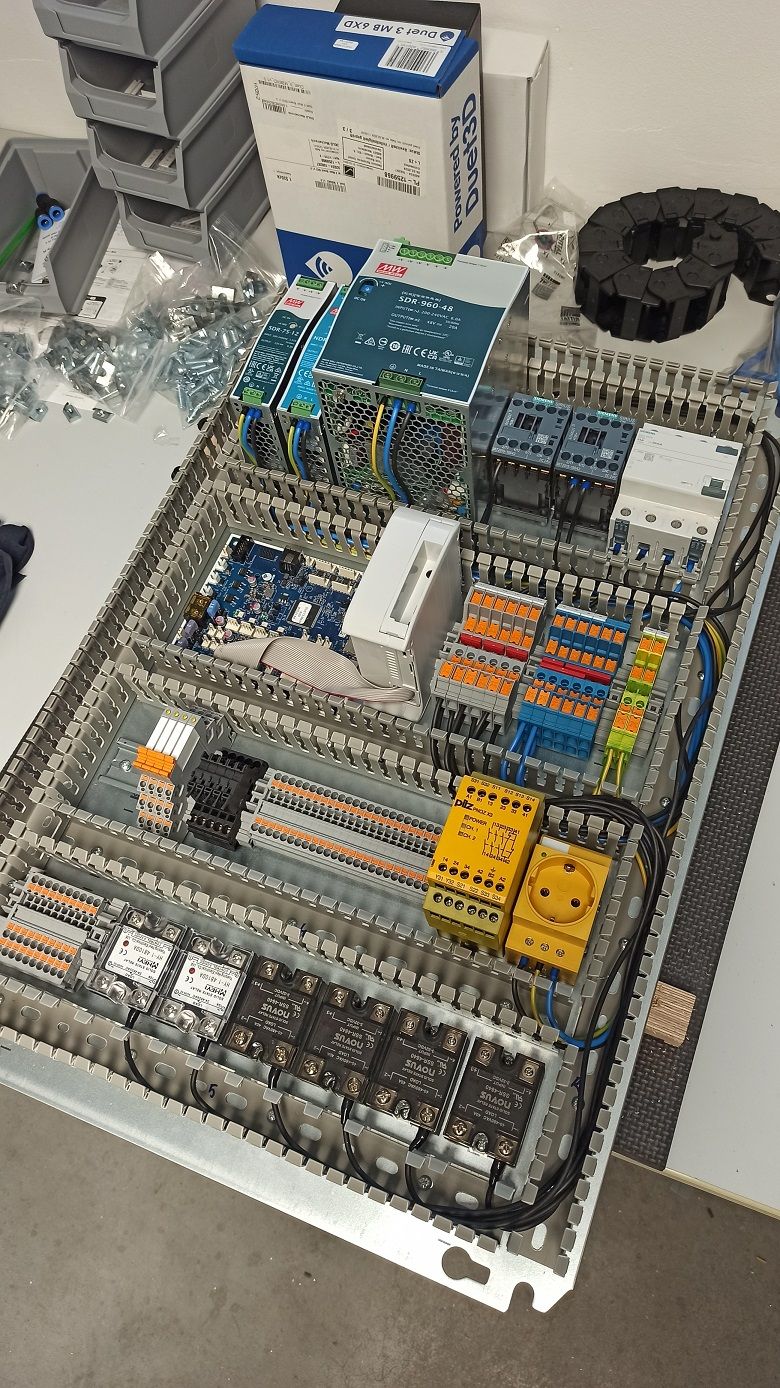

Hey guys!

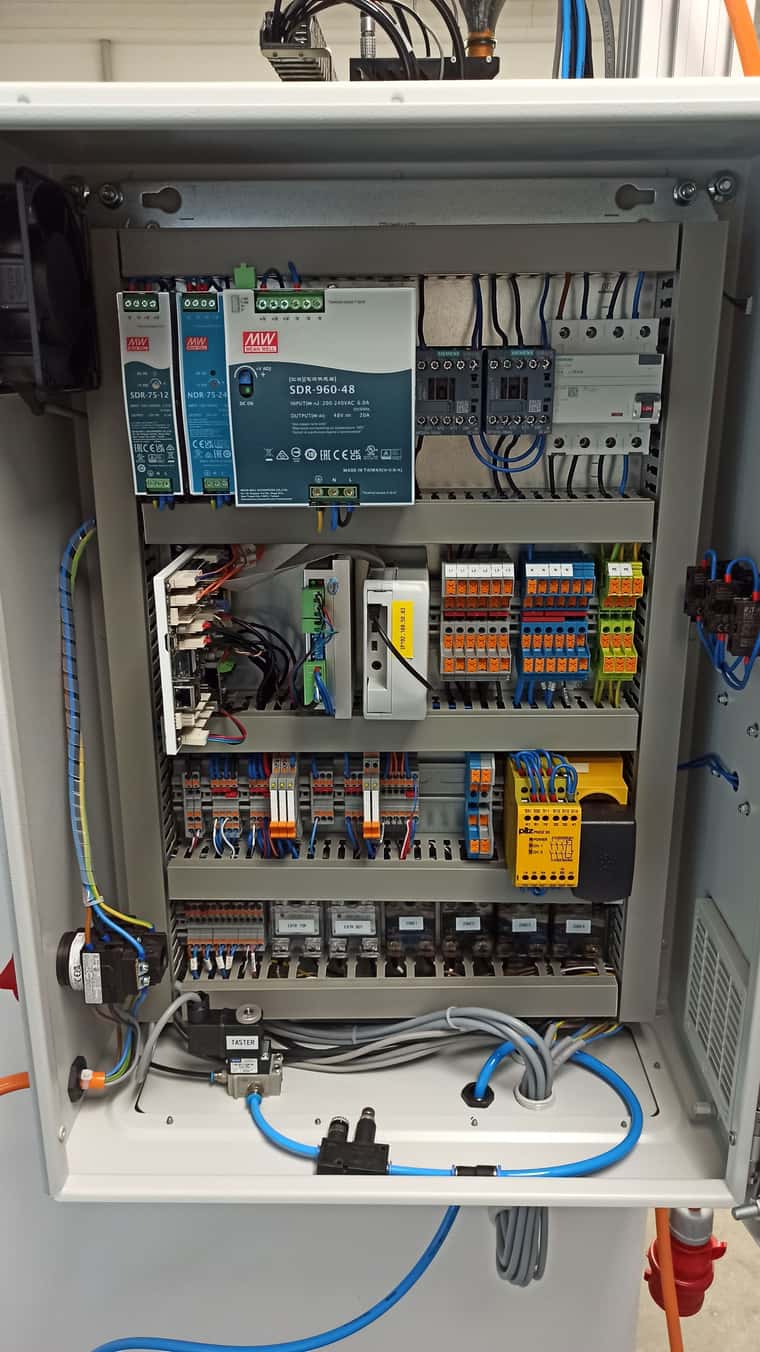

Jumping right in to post some update pictures of the current state, it's pretty close to the final wiring ( yuck!)

Does anybody know how far the Duet inductive bed probe does travel in terms of distance to a metal surface?

-

RE: Large 3D printer build! Hardware discussion and ideasposted in General Discussion

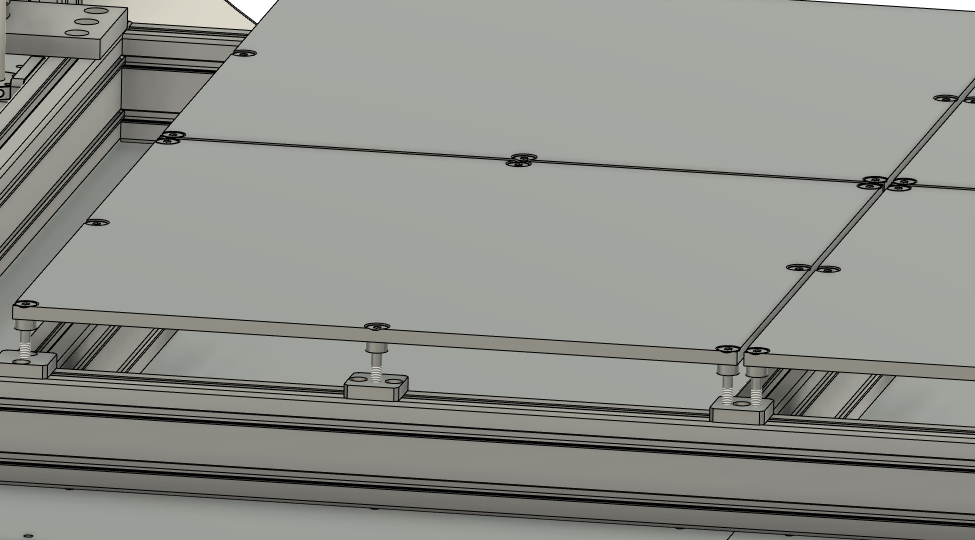

@mrehorstdmd I'm gonna implement that, quite adaptable to the current design. The plates are 530mm, 10 thick, quite large actually.

@dc42 Thanks, the chamber may go up to 80° C. My current sensors are rated up to 50 deg. Of course I could just use simple clicky switches. But that's pretty basic

-

RE: Large 3D printer build! Hardware discussion and ideasposted in General Discussion

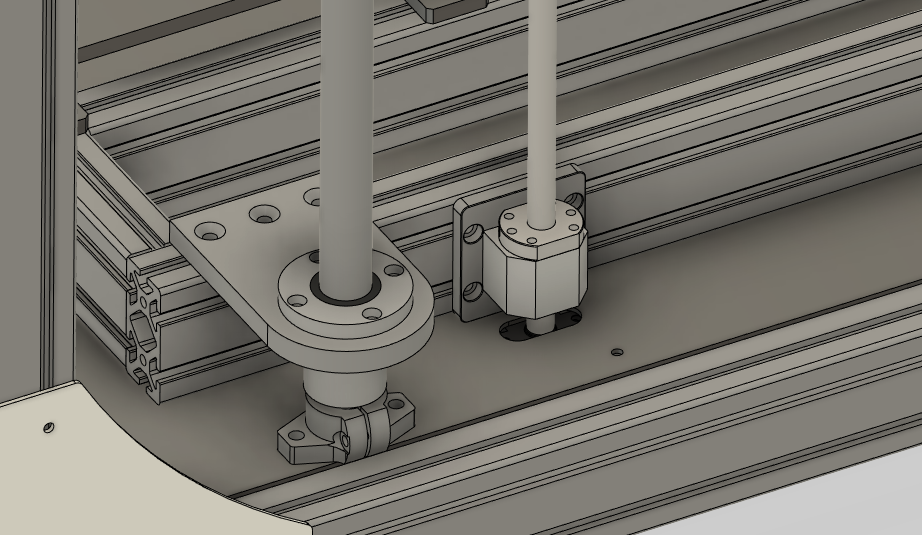

@mrehorstdmd Well I've used the term `flexible´ as kind of a stretch. They're stainless M8 shanked bolts which, considering how far they stick out, provide some radial give for the few tenths of expansion whilst being stiff in Z direction. At least that seems theoretically plausible. I'll need to check for flatness when everything's heated up properly. In the end, when everythings chambered in and heated equally, there should be little concern of parts binding up. Yet, I haven't worked with such material lengths and amounts before to be eventually an 'oven' (stretch) in the end.

Could anyone provide an insight, if sensorless homing is an option on Duet paired with Duet closed loop steppers?

That way I don't need to look out for endstop sensors that can cope with higher temps! -

RE: Large 3D printer build! Hardware discussion and ideasposted in General Discussion

I kinda did, firstly because I'm lazy and belts solve a lot of points at once with little parts count. On the other hand, I wasn't too sure about flex, and temperature expansion, considering possibly very heavy prints to an extend. So I went with the ´missionary´-way of things, haha. Just works that way.

Do you have any pictures of your design ?

-

RE: Large 3D printer build! Hardware discussion and ideasposted in General Discussion

That's why I split up the bed into 4 zones; And installed them on comparably ´flexible´studs, which also allow for a precise first leveling. There will be nuts down at the thread to secure them once set.

Your method of installation seems very appealing to me!

-

RE: Large 3D printer build! Hardware discussion and ideasposted in General Discussion

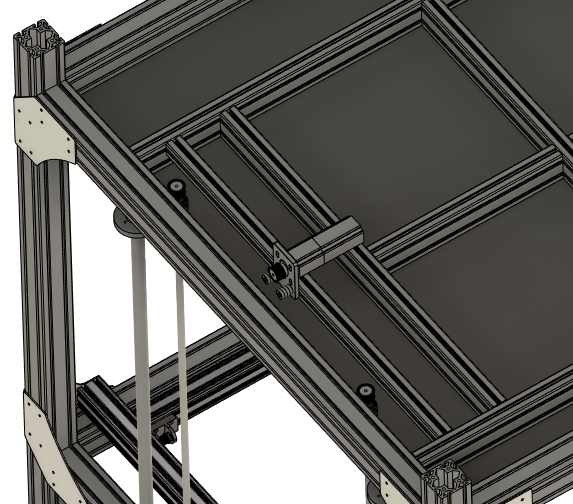

Hi there,

Thanks for the replies! I'm going to add a bottom view picture of the Z drive :

There will be a GT belt synchronizing two ballscrews, with the motor sideways (twisted belt) to accomodate this chonker down there. I wanted to keep them at the bottom, because I'm already going to have to deal with proper cooling of the XY drives up in the chamber. This way they can mind their own business down there at room temperature

The slots at the base plate allow for belt tensioning. Don't mind the rudimentary axial roller installation too much; it'll be neatly cnc'ed once it's confirmed working (i'll swear

)

)Dan

-

RE: Large 3D printer build! Hardware discussion and ideasposted in General Discussion

@T3P3Tony said in Large 3D printer build! Hardware discussion and ideas:

@Danny-Jay said in Large 3D printer build! Hardware discussion and ideas:

My first nagging question would be, how I could possibly manage the four heating zones via the Duet, of course each one gets his own feed via SSR and each has it's own temp. probe (and fuse of course)

its is possible to setup multiple heated beds using M140 P0 H0, M140 P1 H1 etc up to 4. The UI (DWC) has the option to group these beds into one "logical" bed to make it easier for the user. That is not the case on PanelDue though.

That sounds like we're in the right ballpark so I'm kinda relieved

Thanks

-

RE: Large 3D printer build! Hardware discussion and ideasposted in General Discussion

Hi,

Thanks for the replies already! I'll try to answer your points in order.

@soare0 said in Large 3D printer build! Hardware discussion and ideas:

- I would say that bed temperature would be the smallest problem of yours right now, but hey...!

To answer your question, unless you have 4 heating heating pads, each one with its own thermistor, why would you want to control separately each of them, and not wire them to the same SSR for power, and use just one thermistor?

Even with 4 thermistors, factory mounted for each pad, you have two solutions: use only one of them, or group them, 2 parallel groups in series. One of these ways would spare many thermistor inputs...

I would say that many heating zones on the bed may be useful, but not in the manner you indicated in the picture, but with some outer ring and inner core, and even then, you may run into troubles, as I am not sure that RRF can manage something wich need such control complexity (fuzzy control, zone correlation, so on). Still, it may be doable with Duet, just not sure, but anyway, you have my 2c already.- I did group the bed into 4, because a) most of the time we're only gonna use the size of one, or two at a time, no need for the remaining area to waste the energy and b) I don't want to use one large sheet of metal to avoid the worst warping that may occur.

So I just place the part in the slicer according to the heated area, and select the zones on the machine manually (doesn't even need to be automated)

- I would suggest to use 4 motors for this area, with only 2 axial bearing rods. Mine is only 600x600 and it is very useful to have 4 motors. You will only need for a CAN board for extruder, in this case, as 6XD will be ... full .

- I'm using 4 rods and even then I think it may be the wrong approach, the bed will be HEAVY even empty, plus considering a THICK part on it, and I'm worried about ballscrew wobble and to keep it properly oriented in XY directions.

I considered 4 motors actually, to make proper use of bed tramming, but I figured it's just a luxury at this point. May add later but since we're building rough parts with large nozzles I don't worry atm

Still, probably it depends of the rigidity of your bed, but I would not be worried about it, at these dimensions.

3. Why use CAN for motors when have 6XD? You only need some external drivers for motors, these being more fast accurate and not prone to eventual CAN errors.- because the Duet motors offer that feature plus internal drivers, and it's a good way to cut down on wiring chaos

- On Y, you want two rails, and 2 belts, driven from the same motor preferably, via a shaft. The motor can be fitted on the backplane of the printer (interior wall). Having two motors is possible, using two drivers controlled by the same signal (wich can be done for Z too, but you will loose the automated leveling possibility). Still, with two motors, even paralleled through drivers, well ... pray for luck (if not closed loop).

- That's what I tried to avoid, so I'm using one motor, two belts, two rails and synced via a shaft. Our ISEL mill works that way, so I just copied it

- I do not understand exactly why do you want to use brake motors for Z, as it is almost impossible, given the right diameter for screws and the size of the motors. This will only complicate things, unless... well, unless you know why.

- brakes are an absolute necessity on this scale, the bed will crash down no matter what as soon as power is cut to the motors. From my understanding, they are controlled via CAN as well, so they don't even need extra wires. The motors are mounted sideways, so the belt just needs to be twisted 90°, and space is no longer an issue

- Use polycarbonate removable for the to upper lateral sections. You will need this.

- Yes, the plan is to make the upper section removable and see-thru, but no solid plans on how to execute best atm.

7.Let PI4 for after the rest of your printer will work flawlessly. Do it standalone for beginning.

- For sure

-

On the top, you will want 1-2 removable panels/hinged doors, with polycarbonate window. Now, of course that the front door will be polycarbonate too, and probably sectioned.

-

If you want to work up to 80C at this volume, you may want some insulation on the inside. Still, depending on what you want to do, sometimes, especially because on insulation, you may also want a cooling duct/fan, wich be thermostatic controlled. Also, consider from start excellent quality belts, maybe rated to 120C, and the same for all bearings.

- I want to use 16mm isolated panels for the enclosure, sidewalls and on top; the large doors at the front probably use the same material plus isolated glass windows

- My 600x600 is working on glass bed, while I must admit that this is a real pain many times. Your choice may be better, but I do not know how it will fare with expansion. I am still curious why would want to work with FR4 and 80C inside (for PC maybe?), as PC needs even 130C for bed, and FR4 or such, it is not such a great ideea to work with, at these temperatures, for long time, even the HT versions (not the yellow one, anycase).

- I just thought I'd give it a shot, cause it works great on my smaller printers up to 80° C on a regular basis with no issues and it's relatively stiff/cheap so even If it gets messed up. And the surface texture may help greatly with adhesion.

The large glass bed on DrD-Flo's large printer (diy on youtube) shattered from the material warping

You will need anyway some smart ways to fix the build plate, to ensure planeity for such area. On my glass, I have up to 0.35mm differences... As it is for big stuff, it does not really matters, but even so, babysteps comes handy many times.

*** my idea was to push it underneath recessed blocks at the back and on the left, and bolt recessed blocks to the right and to the front after installation to hold it in position**

- You forgot the power supply for PI. I would not use the 6XD for that, even if possible. The 12V PSU may be useful for some fans, I used it for some water cooling pump, as the 12V PSU on 6XD is ... for Tinkerbell like stuff.

- I just didn't mention it, I bought one of course

Being in your place, I would have bought a large DoWell printer (wich in fact I did), and send electronics on the bin (except motor drivers and cables), replacing belts and bearings (as they are junk). Eventually one not enclosed, as this would be cheaper, depending on version. But as you already have bought much, maybe it is better to follow ... the hard way you are following now.

- Actually considered many routes, for what makes the most sense. Thing is, you never know what you'll get with the chinese stuff; you can't check it out beforehand, etc.. plus adding all the shipping and taxes and customs, plus the extra modification time and cost, is it really making sense. Plus, my design already existed from years ago, I just had to get back to it. And my boss prefers building stuff, I'm fine with that

Note: if you are not experienced in hardware and coding, just do not do it, buy one. The project is not for .... faint of heart. I already saw on the forum, at least two ... lost cases with such builds, because it was a ... too far strech for them.

Still, if you have already built smaller 3d printers, and got your nose into marlin/klipper, you may be safe. I would wish you luck, but as this only depends on your skills... I wish you skills!- skills are mostly there my man

I'm years into marlin and 3D printing stuff at home, geeking out on all things tech, fixing cars, RC airplane stuff for decades... I'm just diving into python, just all that Duet stuff is new for me. But I rather chose that platform instead of going full industry standard drives, because I would have a lot to chew with those that's for sure.

I'm years into marlin and 3D printing stuff at home, geeking out on all things tech, fixing cars, RC airplane stuff for decades... I'm just diving into python, just all that Duet stuff is new for me. But I rather chose that platform instead of going full industry standard drives, because I would have a lot to chew with those that's for sure.

-

Large 3D printer build! Hardware discussion and ideasposted in General Discussion

Good day Duet fam!

I'm currently in the design and purchasing phase of my large scale printer, that's gonna be used in our small company to print thermoforming plugs to their net shape, to be finish milled afterwards.

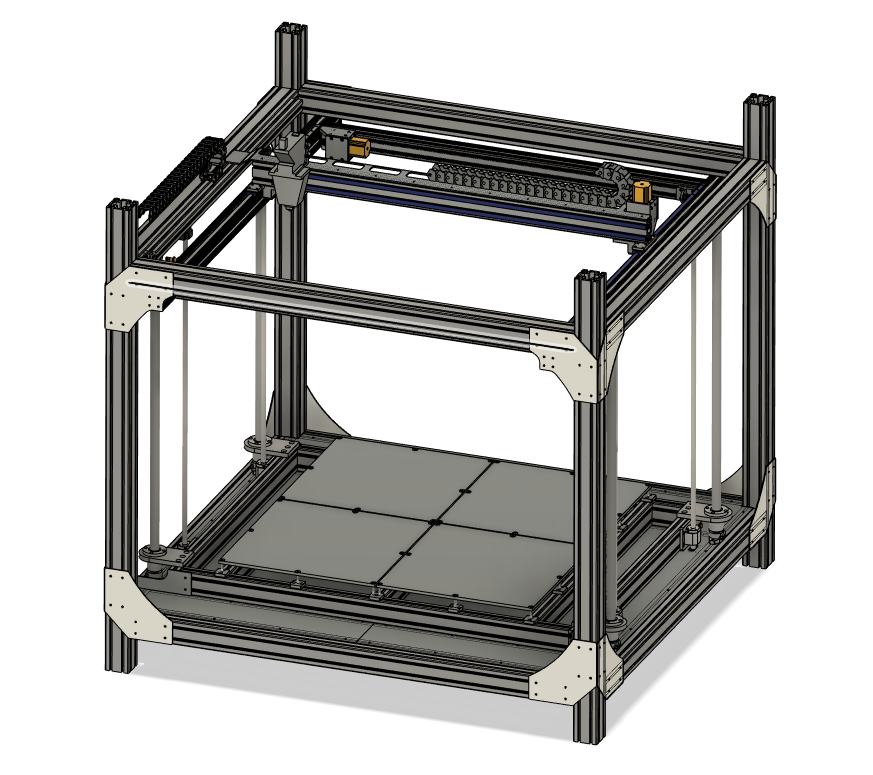

To give you an idea of where I'm currently at:

- roughly 1 cubic meter of build volume ( I don't care if 100 to 200 mm get shed off here or there )

- belt driven gantry at the top, bed moving up/down on four ballscrews

- 4 heating zones for the bed

- removable fiberglass build plate

- dyze atom pellet extruder (watercooled)

- Inductive limit sensors for X, Y

- two Duet closed loop motors on Z (brake)

- one Duet closed loop motor for each X and Y (water cooled)

- Duet bed leveling probe

- isolated enclosure, it's planned to be heated up in the future to possibly 80° C

It is going to be my first build this size; and also my first time using Duet hardware altogether. So I (surely) might run into issues regarding choice of components and their correct usage.

So far I purchased:

- Duet3 6XD board

- PanelDue 7 inch

- Raspberry Pi 4 (which I MIGHT need?)

- Duet 3 Bed Probe sensor (inductive)

- Duet closed loop steppers

- Limit switches

- 48V power supply 20 amps (one for all of the drives ?)

- 24V power supply 3,2 amps (for the board and IO´s

- 12V power supply 6,3 amps (because why not)

- 6 SSR´s for the heating systems

- one steel enclosure 700x500x250 mm

- safety components for power distribution and such

My first nagging question would be, how I could possibly manage the four heating zones via the Duet, of course each one gets his own feed via SSR and each has it's own temp. probe (and fuse of course)

but I may need further expansion boards, and if so, which ones.

The motors shall be running on CAN, daisy-chained would be a charm; the extruder motor has it's separate driver module from dyze. If my assumptions are correct, two limit switches for homing X and Y should do the trick?What are your opinions on this, would you do things differently ?

I'll try to get a picture of the current design state attached down here.

Thanks in advance,

Daniel