@T3P3Tony V4 says "Filament Length:" at the bottom. V5 says "Material Length:" at the bottom

Best posts made by GeneRisi

-

RE: Simplify3d and Filament Timingsposted in General Discussion

-

RE: Dumbfounded ! Firmware bug in 3.4 beta 6?posted in Beta Firmware

@dc42 I found the problem.

When tool T1 was being returned, the Y "parking" coordinate was off by 1 mm. The tool parking location didn't budge but the firmware thought that the tool location was 1mm beyond where it actually was. The machine is a corexy (E3D), so even though only the Y coordinate was off, I suspect it affected both the x and y location from the the firmware's perspective.

-

RE: Best IDEX nozzle wipe mechanisms?posted in 3D Printing General Chat

@oliof I have the pebble wiper design installed and it works very well once you have it set up properly. Does it do more than any other purge and wipe tool? Maybe not.

I have an e3d tool changer with a couple of home made Orbiter / v6 hot end tools and a Hemera. The version I use is on a linear rail so that it can accommodate different size tools.

-

RE: Extruder parameter format questionposted in General Discussion

I just created SeqTest.g which contains this:

M584 X0

M350 X16

M584 Y1

M350 Y16It runs fine. Did it do the right thing? I don't know yet.

-

RE: Accelerometer Usageposted in Beta Firmware

FWIW, twisted pair wiring is designed to use both wires in the pair. The signals we are carryng are not differential, so try connecting the "other" wire in the pair to ground at both ends of the wiring. You might find that it cleans up the signal quite a bit. I am using CAT5 unshielded cable for both the accelerometer and the Paneldue serial link without any issues (as far as I can tell)

-

RE: PanelDue 3.4.0-pre2 releasedposted in PanelDue

@mfs12 Has anyone mentioned a problem on the 5i where using the extrusion control (with tool 1) the extrusion length and speed do not remain highlighted after being selected? What would I provide for you to check this out if it is a new issue? I am using 3.4.0 b4.

On another note, could DWC report which version of firmware the Paneldue is running? It would be nice to have.

-

RE: All of a sudden, my corexy steppers aren't workingposted in General Discussion

@generisi I found errors that make me wonder how it ever worked... It is fixed now - thank you!

-

RE: Dumbfounded ! Firmware bug in 3.4 beta 6?posted in Beta Firmware

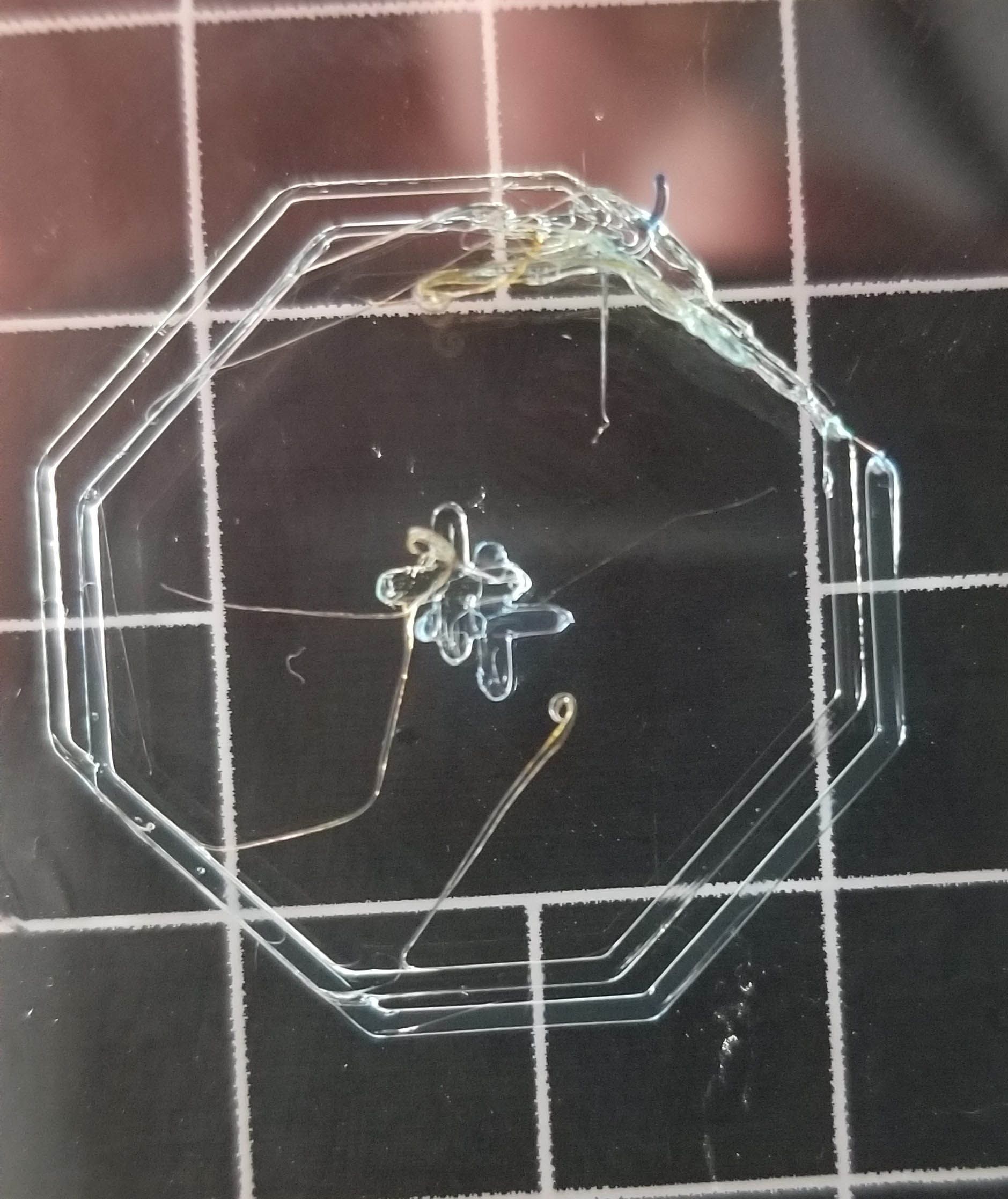

@t3p3tony Here is a simple print file that demonstrates T1,T0,T1,T0:

G90 M83 M117 Preheat & Level G28 G10 P0 S242 R200; set extruder 0 active and standby temps G10 P1 S242 R200; set extruder 1 active and standby temps M190 S85 ; wait for bed temperature ;mesh gcode G29 Q0 T1 G1 E-0.8000 F3000 ; feature skirt ; tool H0.200 W0.400 G1 Z0.200 F360 G1 X145.575 Y112.700 F9000 G1 E0.8000 F3000 G1 X139.600 Y106.725 E0.2810 F90 G1 X137.300 Y104.425 E0.1082 G1 X137.300 Y95.575 E0.2944 G1 X145.575 Y87.300 E0.3892 G1 X154.425 Y87.300 E0.2944 G1 X156.725 Y89.600 E0.1082 G1 X162.700 Y95.575 E0.2810 G1 X162.700 Y104.425 E0.2944 G1 X154.425 Y112.700 E0.3892 G1 X145.575 Y112.700 E0.2944 G1 E-0.8000 F3000 ; feature cross - external single extrusion ; tool H0.200 W0.400 G1 Z0.400 F360 G1 X147.738 Y100.000 F9000 G1 Z0.200 F360 G1 E0.8000 F3000 G1 X149.641 Y100.000 E0.0633 F45 G1 X150.000 Y99.641 F9000 G1 X150.000 Y97.738 E0.0633 F45 G1 E-0.8000 F3000 G1 Z0.400 F360 G1 X152.262 Y100.000 F9000 G1 Z0.200 F360 G1 E0.8000 F3000 G1 X150.279 Y100.000 E0.0659 F45 G1 X150.200 Y100.000 E0.0026 ; tool H0.200 W0.416 G1 X150.117 Y100.000 E0.0029 ; tool H0.200 W0.499 G1 X150.000 Y100.000 E0.0049 G1 X150.000 Y100.117 E0.0049 ; tool H0.200 W0.416 G1 X150.000 Y100.200 E0.0029 ; tool H0.200 W0.400 G1 X150.000 Y100.279 E0.0026 G1 X150.000 Y102.262 E0.0659 G1 E-0.8000 F3000 ; layer end T0; G1 E-0.8000 F3000 ; feature skirt ; tool H0.200 W0.400 G1 Z0.200 F360 G1 X145.575 Y112.700 F9000 G1 E0.8000 F3000 G1 X139.600 Y106.725 E0.2810 F90 G1 X137.300 Y104.425 E0.1082 G1 X137.300 Y95.575 E0.2944 G1 X145.575 Y87.300 E0.3892 G1 X154.425 Y87.300 E0.2944 G1 X156.725 Y89.600 E0.1082 G1 X162.700 Y95.575 E0.2810 G1 X162.700 Y104.425 E0.2944 G1 X154.425 Y112.700 E0.3892 G1 X145.575 Y112.700 E0.2944 G1 E-0.8000 F3000 ; feature cross - external single extrusion ; tool H0.200 W0.400 G1 Z0.400 F360 G1 X147.738 Y100.000 F9000 G1 Z0.200 F360 G1 E0.8000 F3000 G1 X149.641 Y100.000 E0.0633 F45 G1 X150.000 Y99.641 F9000 G1 X150.000 Y97.738 E0.0633 F45 G1 E-0.8000 F3000 G1 Z0.400 F360 G1 X152.262 Y100.000 F9000 G1 Z0.200 F360 G1 E0.8000 F3000 G1 X150.279 Y100.000 E0.0659 F45 G1 X150.200 Y100.000 E0.0026 ; tool H0.200 W0.416 G1 X150.117 Y100.000 E0.0029 ; tool H0.200 W0.499 G1 X150.000 Y100.000 E0.0049 G1 X150.000 Y100.117 E0.0049 ; tool H0.200 W0.416 G1 X150.000 Y100.200 E0.0029 ; tool H0.200 W0.400 G1 X150.000 Y100.279 E0.0026 G1 X150.000 Y102.262 E0.0659 G1 E-0.8000 F3000 ; layer end ; pass 2 T1 G1 E-0.8000 F3000 ; feature skirt ; tool H0.200 W0.400 G1 Z0.200 F360 G1 X145.575 Y112.700 F9000 G1 E0.8000 F3000 G1 X139.600 Y106.725 E0.2810 F90 G1 X137.300 Y104.425 E0.1082 G1 X137.300 Y95.575 E0.2944 G1 X145.575 Y87.300 E0.3892 G1 X154.425 Y87.300 E0.2944 G1 X156.725 Y89.600 E0.1082 G1 X162.700 Y95.575 E0.2810 G1 X162.700 Y104.425 E0.2944 G1 X154.425 Y112.700 E0.3892 G1 X145.575 Y112.700 E0.2944 G1 E-0.8000 F3000 ; feature cross - external single extrusion ; tool H0.200 W0.400 G1 Z0.400 F360 G1 X147.738 Y100.000 F9000 G1 Z0.200 F360 G1 E0.8000 F3000 G1 X149.641 Y100.000 E0.0633 F45 G1 X150.000 Y99.641 F9000 G1 X150.000 Y97.738 E0.0633 F45 G1 E-0.8000 F3000 G1 Z0.400 F360 G1 X152.262 Y100.000 F9000 G1 Z0.200 F360 G1 E0.8000 F3000 G1 X150.279 Y100.000 E0.0659 F45 G1 X150.200 Y100.000 E0.0026 ; tool H0.200 W0.416 G1 X150.117 Y100.000 E0.0029 ; tool H0.200 W0.499 G1 X150.000 Y100.000 E0.0049 G1 X150.000 Y100.117 E0.0049 ; tool H0.200 W0.416 G1 X150.000 Y100.200 E0.0029 ; tool H0.200 W0.400 G1 X150.000 Y100.279 E0.0026 G1 X150.000 Y102.262 E0.0659 G1 E-0.8000 F3000 ; layer end T0; G1 E-0.8000 F3000 ; feature skirt ; tool H0.200 W0.400 G1 Z0.200 F360 G1 X145.575 Y112.700 F9000 G1 E0.8000 F3000 G1 X139.600 Y106.725 E0.2810 F90 G1 X137.300 Y104.425 E0.1082 G1 X137.300 Y95.575 E0.2944 G1 X145.575 Y87.300 E0.3892 G1 X154.425 Y87.300 E0.2944 G1 X156.725 Y89.600 E0.1082 G1 X162.700 Y95.575 E0.2810 G1 X162.700 Y104.425 E0.2944 G1 X154.425 Y112.700 E0.3892 G1 X145.575 Y112.700 E0.2944 G1 E-0.8000 F3000 ; feature cross - external single extrusion ; tool H0.200 W0.400 G1 Z0.400 F360 G1 X147.738 Y100.000 F9000 G1 Z0.200 F360 G1 E0.8000 F3000 G1 X149.641 Y100.000 E0.0633 F45 G1 X150.000 Y99.641 F9000 G1 X150.000 Y97.738 E0.0633 F45 G1 E-0.8000 F3000 G1 Z0.400 F360 G1 X152.262 Y100.000 F9000 G1 Z0.200 F360 G1 E0.8000 F3000 G1 X150.279 Y100.000 E0.0659 F45 G1 X150.200 Y100.000 E0.0026 ; tool H0.200 W0.416 G1 X150.117 Y100.000 E0.0029 ; tool H0.200 W0.499 G1 X150.000 Y100.000 E0.0049 G1 X150.000 Y100.117 E0.0049 ; tool H0.200 W0.416 G1 X150.000 Y100.200 E0.0029 ; tool H0.200 W0.400 G1 X150.000 Y100.279 E0.0026 G1 X150.000 Y102.262 E0.0659 G1 E-0.8000 F3000 ; layer end M117 Print Complete ! T-1 M999

-

[Feature request] add sort options to file listposted in PanelDue

@mfs12 It would be great to have an option in setup where the file name sorting could be specified. I would like "sort by date, most recent first" because I do a lot of test runs and find myself wanting to use the web interface to start the job because I can have it sort the files names by date. Thanks for considering my suggestion!

-

RE: different milling results dispite same G10 Offsetposted in General Discussion

@cmp I wish I had better insight to help you out... what firmware version are you running? If the experiments below don't provide insight, would you please post the Tool1 and Tool4 pre,.g , post.g and free.g macros?

Please try typing M999 (this will force the firmware to do a reset) just before you start your print. Make sure that you don't execute any additional gcode before starting your print. See if running the normal "print, then mill" sequence a couple of times give the same offsets or different offsets.

Another variation of this experiment is to home the machine, then pick up the milling tool, then put it back, then pick up the print tool, then print the object, then return the print tool, pick up the milling tool and then mill the object. Try this sequence at least twice to see if the offsets are the same or different.

One more variation: Print the object, then pick up the milling tool but don't use it, then put the milling tool back, then pick up the printing tool and add layers on top. Do the additional layers line up with the original layers?

-

RE: Slicer shuts off hotend fan.posted in Using Duet Controllers

@luka1952 I think you might have the fans swapped. The hotend fan (which cools the hotend) does not have a control in the web interface. The print cooling fan, which cools the filament just after it has extruded, can be controlled from web interface.

-

RE: Beta testers for multiple motion system supportposted in Beta Firmware

@dc42 is the memory space too limited with the duet2s ?

-

RE: Damn Layer Shift!, time to go Closed Loop?posted in General Discussion

@adamfilip I can think of a few more things to ask about and one thing to try (FWIW).

- Is the layer shift always happening in the same direction? (I am wondering if it is always associated with a particular stepper?).

2.) When I had this problem with my previous printer, the nozzle was getting hung up on a protruding piece of plastic ( Z hop would often help but wasn't a reliable solution for me). This would happen when either:

-

the layers would start to curl up which was due to insufficient cooling (which sometimes just meant that the layer time was so brief that the previous layer had not sufficiently cooled when the next layer was extruded on top of it

-

or plastic built up on the nozzle and at some point the glob would stick to the print ( less likely with PLA because any PLA building up on the nozzle should melt vs for example a PET-G which is more like a gel when extruded)

-

or I was using some PLA filament that wasn't well suited for 3d printers.

You didn't sat what brand filament you are using, but if you are in the US, try eSun PLA+. You will want to run it at a higher temperature. It is not very expensive and very consistent roll to roll. I have thrown away almost full rolls of some PLAs because I couldn't count on them to behave in a predictable fashion.

All of the other points that folks have brought up are also great ideas to chase down.

Good luck hunting down the problem!