@droftarts So, all bypass jumpers should be in place, and all toolboards should be wired to pins 3 and 4 on each T0-T3 connector. Pin 3 Low and Pin 4 High.

Posts made by j.pickens

-

RE: Duet 3 Mini 5+ with Canbus boards.posted in Duet Hardware and wiring

-

RE: Duet 3 Mini 5+ with Canbus boards.posted in Duet Hardware and wiring

@droftarts How's your drawing coming? It looks to me like the only way to get the 2 wire signal from the T0 to T1 connector and so on is to use the bypass jumpers. To get T0 pins 1 and 2 to T1 pins 3 and 4. Or remove the jumpers? Not sure. I'll Ohm out these pins and see what is connected with the jumpers in and out.

-

RE: Duet 3 Mini 5+ with Canbus boards.posted in Duet Hardware and wiring

@droftarts This is excellent. Of course, I need the 2 wire Can-FD, so tomorrow it is! I'll attempt a diagram tonight to see how close I get.

-

RE: Duet 3 Mini 5+ with Canbus boards.posted in Duet Hardware and wiring

@droftarts Thank you very much for this response. Looking forward to the wiring diagram.

-

RE: Duet 3 Mini 5+ with Canbus boards.posted in Duet Hardware and wiring

@droftarts Here is a screengrab closeup of the disconnected canbus connector on the toolboard.

I measured it, it is 0.2mm out. Might need a better connector for this.

-

RE: Duet 3 Mini 5+ with Canbus boards.posted in Duet Hardware and wiring

@droftarts I found the problem, the Roto Toolboard connector was approx. 0.2mm out of the socket. You can see in the video how very slightly it was out. This killed the L connection, the H was still made. Perhaps a locking Molex plug like the other connectors on this board is called for. Hot glue for the win.

I am still requesting a wiring diagram of the main board/canbus expansion/and 1, 2, 3, or 4 tool board options, with wiring diagrams, bypass jumper, and terminator jumper setups for all 4 options. ANYBODY purchasing your boards who is not familiar with Canbus FD will need this documentation. Thanks.

-

RE: Duet 3 Mini 5+ with Canbus boards.posted in Duet Hardware and wiring

@droftarts I wired it as shown.

Here is a video:

https://youtu.be/Q99Rn5CfPhk -

RE: Duet 3 Mini 5+ with Canbus boards.posted in Duet Hardware and wiring

@droftarts said in Duet 3 Mini 5+ with Canbus boards.:

Try connecting the CAN wires the other way around. Probably easiest to switch them at the Mini 5+ end.

Wow, really? Perhaps a wiring diagram for the whole setup? Am I asking too much?

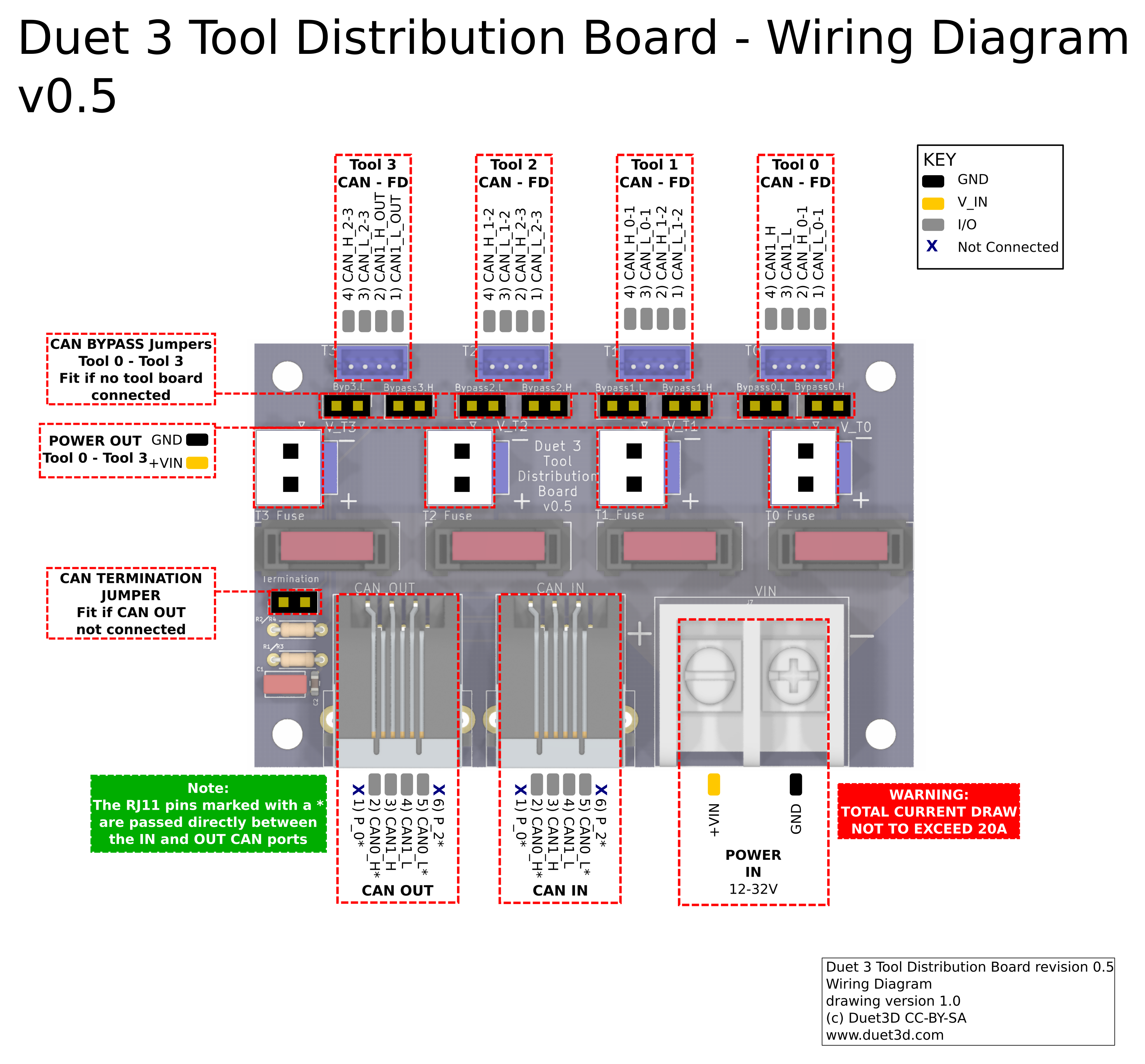

I saw absolutely nothing in your documentation about wiring High to Low."The Tool Distribution board isn't hard to understand; CAN1_H and CAN1_L connect to the TDB from CAN IN to, initially, Tool 0 connector. It goes out to a toolboard using the Tool 1 pins 3 and 4, and comes back in on pins 1 and 2. These are named CAN_H_0-1 and CAN_L_0-1, to show they connect from tool 0 to tool 1. This is done internally, to pins 4 and 3 of the Tool 1 connector. And so on, to Tool 2 and 3, and to CAN OUT. This keeps the CAN wires as a continuous bus, without the CAN_L or CAN_H wires crossing over, except at the ends of the bus, where it's terminated. You can see this in the wiring schematic:"

If you can parse this into a functional wiring setup, that's great. I, however, cannot. My head is spinning.

Schematic of the wiring, please. I really don't think this is an unreasonable request. Look at what LGO and Bigtreetech are doing with their Type C connector toolboards. If you don't get your setup documented better, they will eat your lunch.

I talked to about 20 people at MRRF about Canbus, they all said it was a pain. Bill Steele, who is a very talented engineer said the only way he could get his working was with an oscilloscope. He told me not only was the i/o and address setup a problem, but that the boards he used had different i/o speeds, which he only detected with the oscilloscope. These were your boards.

-

RE: Duet 3 Mini 5+ with Canbus boards.posted in Duet Hardware and wiring

@dc42 Here is the response from: M122 B121

CAN response timeout: board 121, req type 6024, RID 22I am currently wired Can H to Can H and Can L to Can L with a twisted pair between the CAN header on the Mini 5+ and the first Revo Roto Toolboard. The power to the Toolboard is on, the red activity light is blinking fast, not in sync withe the Mini 5+, and the termination jumper is installed on the Toolboard.

-

RE: Duet 3 Mini 5+ with Canbus boards.posted in Duet Hardware and wiring

@dc42 You see, here is a big problem with Duet and Canbus.

You just told me to use M122 B121 to get a full Canbus report.

There is nowhere on your search pages, even the Duet Reprapfirmware GCode dictionary to find these codes.

If I hit the search bar while in the dictionary, and I search "Can" "Can-FD" or "Canbus" I get only 2 links to the Gcode dictionary. Now since you told me to use M122, I can search for it. But not knowing the Canbus codes, how am I supposed to find them?The two hits come up as M952 and M953. There appears to be no guide to Canbus here with a technical outline of how to set up and program these boards. Your documentation says things like:

"Typically, the CAN bus is wired in a daisy-chain-style between boards. At one end will be the mainboard, with the CAN bus connecting to each subseqent board."

Nothing specific for your products with pinouts and wiring diagrams for the Main Board/Distribution Board/Multiple Tool Boards. I still have absolutely no idea how to wire your distribution board based upon the cryptic pin labels in your diagram up top of my post, which termination jumpers are needed, and which bypass jumpers to use.

This is getting very frustrating.

-

RE: Duet 3 Mini 5+ with Canbus boards.posted in Duet Hardware and wiring

@dc42 I attached my toolboard CAN lines directly to the Mini5+. The red LED on the toolboard flashes slowly in sync with the main board, so it appears to be communicating. How do I interrogate the bus to show the address of the toolboard? I assume that its address is the default 121, but I tried to set my config.g to assign Tool 0 to P121 and it does not seem to find it. I get error codes for not finding Canbus devices as shown:

6/23/2024, 11:27:22 AM CAN response timeout: board 61, req type 6042, RID 10

CAN response timeout: board 62, req type 6042, RID 11

CAN response timeout: board 63, req type 6042, RID 12

6/23/2024, 11:27:19 AM CAN response timeout: board 50, req type 6042, RID 8

CAN response timeout: board 51, req type 6042, RID 9

6/23/2024, 11:27:17 AM CAN response timeout: board 51, req type 6043, RID 6

CAN response timeout: board 50, req type 6043, RID 7

6/23/2024, 11:27:15 AM CAN response timeout: board 50, req type 6042, RID 4

CAN response timeout: board 51, req type 6042, RID 5

6/23/2024, 11:27:13 AM CAN response timeout: board 50, req type 6042, RID 2

CAN response timeout: board 51, req type 6042, RID 3 -

Duet 3 Mini 5+ with Canbus boards.posted in Duet Hardware and wiring

My setup is:

Duet 3 Mini 5+

Duet 3 Tool Distribution Board

Duet 3 Roto Toolboard (X2 for two tools as of now)I connected the Can 1 H and Can 1 L from the two center pins on the distribution board IN RJ11 plug to

the Can L and Can H pins of the CanFD pins on the Mini 5+I connected two pins of the Tool0 4 pin connector on the Distribution board to the two pins on the roto toolboard (started with only one board to hopefully get it working first)

The pins I used were the confusingly named pins 3 and 4 of connector V-T0

They are labeled as Can1_H (Pin 4) and Can 1_L (Pin 3)I am trying to get my head around the labels on these connectors, and which bypass jumpers to install or remove.

Could someone please explain what these labels mean, which to use, and which jumpers to install for a two tool setup?

Do I have to worry about Can addresses? If so, what is the procedure and recommended addresses?

Do I need to update the firmware on either the Distribution board or the Tool board?

If so, how to check them?A wiring diagram would be helpful for all three components and their CAN FD details. It is hard to determine which pins to connect to corresponding pins on the other boards from the pinout diagrams provided.

Thanks,

JohnP.S. I'm attempting this upgrade while at MRRF2024

-

RE: External 5V supply for SBC Raspberry Pi 4 and Duet 3 Mini 5+posted in Duet Hardware and wiring

@droftarts Thanks, I'm running it with the onboard power for the Duet3 and separate 5V power to the Pi. Running with NO jumpers, which I think is correct. Does this sound like the correct combo?

-

External 5V supply for SBC Raspberry Pi 4 and Duet 3 Mini 5+posted in Duet Hardware and wiring

I am confused by the jumper diagrams for the 5V SBC jumpers.

I have a 24V to USBC power supply for the raspberry pi 4, as the documents say the Duet 3 may not have enough power.

My supply should be sufficient to power both the Pi and the Mini.Can I power the Duet 3 Mini from the Pi via USBC on the Pi and the 26 pin ribbon between them?

If so, what jumper settings should I use? One says 5V ext, the other says 5V SBC.Alternately, I can use the internal Duet 3 Mini power, and power the Pi with the USBC on the pi.

In this scenario which jumpers to use? I'm thinking no jumpers installed, but I am confused.The section on powering the SBC says there are 4 ways to go, but there are 3 diagrams and no linkage between the 4 ways described and the diagrams.

Perhaps a diagram with wiring and jumper examples is called for here.

Help is appreciated.

-

RE: Scanning Sensor Mount for a Roto with Toolboardposted in Duet Hardware and wiring

@DeadNewbie Yes, this. I have not found anything either. Might have to fire up OpenScad and roll my own.

-

RE: Recommended Canbus E3D Toolchanger Cable Managementposted in Duet Hardware and wiring

@dc42 I'm not using the metal bands. They get kinked, at least in my experience. I'm planning to use long 5mm plastic cable ties.

Anyone know what the clothlike Prusa style cable covers are? Tried searching and Google failed me

-

RE: Scanning Z Probe giving erratic Z valuesposted in Duet Hardware and wiring

@droftarts That's funny, I have the same Tronxy X5S. Bought it for the 400mm cubic print area, the core XY, and the unique steel rod rails on aluminum extrusion axes. I never set it up with the stock extruder and electronics. Chucked them in the bin and installed a Duet 2 board, Paneldue, and E3D Hemera Revo. Added a BL Touch style Z probe and off I went. The Duet automated bed tramming made all the difference. Can't wait to set up the new Z axis probe on my Toolchanger.

-

RE: Scanning Z Probe giving erratic Z valuesposted in Duet Hardware and wiring

While we're talking about the SZP documentation.

I see we get both the 12mm and 15mm probes in the box with my Revo Roto Toolboard.

In the documentation it points out the two probes, but doesn't give any guidance as to the differences/preferences between them. Could anyone clarify? I assume that the 12mm probe is for lower probe distances, but it would be nice to get more exact recommendations. -

Recommended Canbus E3D Toolchanger Cable Managementposted in Duet Hardware and wiring

Hi all,

Just purchased a Duet 3 Mini 5+ with the Canbus Duet 3 ToolBoard for Roto Extruder and the Duet 3 Tool Distribution Board to update my E3D Toolchanger. The demo stuff shown at the RMRRF2024 E3D/Duet3D booths had really nice black cloth looking covers on the Canbus cable lead to the printhead. The kit did not include cable management components, so I plan to use 28" (711mm) X 5mm cable ties as the flex control for the cable. So the cable bundle to the toolhead will consist of the 4 Canbus wires and the PTFE guide tube for the filament.Two questions:

1: What cable wrap should I get? I like the cloth stuff, but am open to suggestions.

2: Should I run the cable tie inside or outside the cable wrap, like with small cable ties every 100mm or so?I'm used to the E3D 4mm metal band flex controls with woven plastic cable wrap. Never liked it, and would like to do better with this upgrade.

Any suggestions will be appreciated.