duet2 and duex5 expansion, v3.3, 4 z steppers, i have run g32, however the heaters shutoff right at the first probe point....

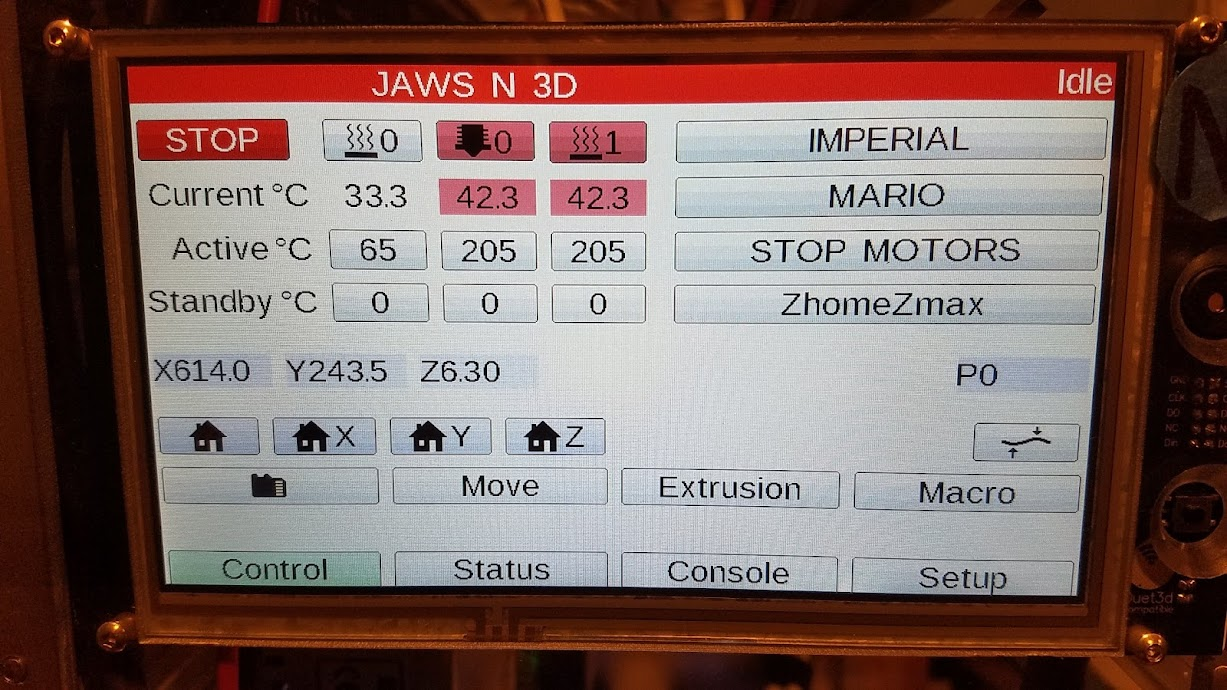

I also somehow managed to display a second bed heater on the paneldue...but its temp sensor and operation follows the hotend readings/control. i believe this is related somehow. removing my try at a chamber temp probe resulted in no change.

I think I've sorted out as much as we can on our own. as i have an issue trying to do a test print.

simple cube test print, even tried older files that worked with 2.03 on this same machine before we ripped it all apart for high quality steppers and belts.

I've been setting up start/stop.g to keep everything on the machines side and outta Cura.

using m117 I have narrowed down when this occurs to right after the g28 but well before the end of start.g as the m117 at its end doesn't show up till after the print finished notification.

i do not call for any compensation to minimize possible headaches.

simulation on the paneldue shows a 27minute cube. and im not even sure it actually sees the gcode file as i believe the start.g macro should be fully complete before it chews on the g code file

so i know i chooched something up fairly well.

forgive all the commented out code and extra's dating back to 2.03....ive been trying to keep moving forward and havent edited anything out to streamline things as i probably should.

for all i know the extra baggage is related to my issues but ya'll deserve to see how messy my brain is.

i appreciate the help, we have 3 of these duet2/duex5 board setups for our three printers (one 4 z, one 3z, and one 2 z machine)

im going to spend some time saving the current mess into a backup folder and trimming the fat.

thanks for your time.

Regards, James and Al

config.g

; Configuration file for Duet WiFi (firmware version 2.03)

; original FT6 stuff generated by RepRapFirmware Configuration Tool v2.1.5 on Sun Jan 12 2020 13:37:35 GMT-0600 (Central Standard Time)

; NEW JAWS6 build Configuration file for Duet WiFi/Ethernet (firmware version 3.1.1)

; executed by the firmware on start-up

; generated by RepRapFirmware Configuration Tool v3.1.9 on Sat Nov 28 2020 17:26:32 GMT-0600 (Central Standard Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

G21 ; Work in millimetres

M575 P1 B57600 S1 ;set paneldue i7 baud to 57,600

M550 P"JAWS N 3D" ; set printer name

;M98 P/macros/MARIO

; Network

M552 S1 P192.168.4.2 ; enable network

M553 255.255.255.0 ;set mask

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S0 ; physical drive 0 X-axis goes backwards

M569 P1 S1 ; physical drive 1 Y-axis goes forwards

M569 P2 S1 ; physical drive 2 Z-axis goes forwards Z1

M569 P3 S0 ; physical drive 3 HERMES/HEMERA goes reverse

M569 P4 S1 ; physical drive 4 goes forwards

M569 P5 S1 ; physical drive 5 goes forwards

M569 P6 R-1 ; physical drive 6 disabled

M569 P7 S1 ; physical drive 7 goes forwards Z2

M569 P8 S1 ; physical drive 8 goes forwards Z3

M569 P9 S1 ; physical drive 9 goes forwards Z4

M584 X0:5 Y1 Z2:7:8:9 E3:4 ; set drive mapping

M350 X16 Y16 Z1 E16:16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z1000.00 E409.00:420.00 ; set steps per mm

M566 X4000.00 Y1000.00 Z3.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X30000.00 Y8000.00 Z30.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y800.00 Z0.1 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X1400 Y800 Z800 E800:800 I10 ; set motor currents (mA) and motor idle factor in per cent

M84 S0.01 ; Set idle timeout

; TESTING MULTI Z STEPPERS

M671 X-117.0:-117.0:829.15:829.15 Y7.7:337.9:7.7:337.9 S0.5 ; leadscrews at RIGHT REAR Z1, RIGHT FRONT Z2, LEFT REAR Z3, LEFT FRONT Z4

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X700 Y320 Z685 S0 ; set axis maxima test volume

;M208 X790 Y340 Z685 S0 ; 7 2021 WARNING ROUGH measured print volume USE WITH CAUTION ESPESIALLY WITH PART FAN INSTALLED

; Endstops v2.03

;M574 X1 Y1 Z0 S0 ; OLD v2.03, Define active low (S0), X/Y : low end (1), Z : unused(0

; ENdstops v3.1.1 code

M574 X1 S1 P"!^xstop" ; configure active-low endstop for low end on X via pin xstop

M574 Y1 S1 P"!^ystop" ; configure active-low endstop for low end on Y via pin ystop

M574 Z1 S2 ; The BLtouch Z probe acts as a Z axis end-stop & is located at Z axis's minimum

M950 J1 C"e1stop" ;Configure EMERGENCY STOP E1 endstop

M581 P1 T0 R0 ;EXT TRIGGER PIN1, TRIGGER ANYTIME

; Z-Probe v2.03

; OLD CODE ** BLTouch in config.g

;M307 H3 A-1 C-1 D-1 ; BLTouch - servo pulse on heater 3 pin - disable heater

;M558 P9 X0 Y0 Z1 H5 F200 T5000 ; P9 for BLTouch on later 2.xx firmware (Normally closed switch on Z-probe inputs) H is dive ;height+speed

;G31 X0 Y-25.0 Z1.4 P5 ; Z=trigger height, P=trigger value, not needed for contact probe, X/Y distance from nozzle

;M558 H5 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved

; Z-Probe v3.1.1 NEW cofig

M950 S0 C"duex.pwm5" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H3 F30 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X1.0 Y-28.5 Z3.3 ; set Z probe trigger value, offset and trigger height

M557 X15:700 Y15:300 S100 ; define mesh grid

; OLD Heaters v 2.03

;M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0 - BED HEATER

;M143 H0 S100 ; set temperature limit for heater 0 to 100C

;M140 P0 S65 R0 ; set bed temp active to 65c standby to 0c

;M144 P0

;M305 P1 T14 B1504 R4700 ; set thermistor + ADC parameters for heater 1 - VOLCANO

;M143 H1 S320 ; set temperature limit for heater 1 to 280C

;M305 P2 T100000 ;set thermister for heater 2 for chamber temp

;M143 H2 S300 :set temperature limit for Heater 2 to 300c

; Heaters v3.1.1 NEW CODE

;BED HEATERS 2x 400X400 110V MAINS PADS, CONTROLLED IN PARALLEL BY 2x SSR, 110V MAINS KILL VIA "PS_ON" CONTROL OF 110V CONTACTOR-SOON

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 A"BED TEMP" ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 Q5 ; create bed heater output on bedheat and map it to sensor 0 aka bedtemp Q is pwm 5hz

M307 H0 B1 S1.0 ; disable bang-bang mode for the bed heater and set PWM limit

M140 P0 H0 S62 R0 ; map heated bed to heater 0, active to 62c standby to 0c

M143 P0 H0 S280 ; set temperature limit for heater 0 to 120C

M144 P0 S0

;TOOL 0 HEATER

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 A"E0 TEMP" ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.0 ; disable bang-bang mode for heater and set PWM limit

M140 P1 H1 S200 R0 ; map extruder 0 to heater 1, active to 222c standby to 0c

M143 H1 S280 ; set temperature limit for heater 1 to 280C

;M308 S2 P"e1temp" Y"thermister" T100000 B4138 A"SENTINEL TEMP"

; Fans original generated by reprap

; i0=default, i-1=disabled, fxxx=frequency, Lnnn=minimum speed, Bnnn=Blip time, Hnn:nn:nn=heaters selected thermostatic mode, Tnnn or Tnn:nn trigger temp or range

;

; Hotend cooling fan

;M106 P1 I0 F500 H1 T50 L1.0 ; Thermostatic control start at 50°C, directly to 100%

; Electronics cooling fan

;M106 P2 H100:101 T40:55 L0.3 ; @30% when above 45°C gradually increasing to 100% at 55°C, virtual heaters =CPU and TMC's

;FANS from duet forum v2.03 OLD CODE- WORKED

;M106 P0 S0 I0 F500 H T45 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned on

;M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

; Fans

;Parts cooler fan0

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S1 H-1 ; set fan 0 value. Thermostatic control is turned off

;Hemera Fan1

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

; Tools OLD

; Define tool 0 = Extruder 0, Heater 1

;M563 P0 D0 H1 F1

;G10 P0 X0 Y0 Z0 R0 S215 ; Set tool 0 axis offsets, tool 0 active 215c and standby temperatures to 0C

; Tools v2.05 OLD FT6

;M563 P0 D0 H1 S"Volcano" ; Define tool 0 Uses E0 and Heater 1

;G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

;G10 P0 S215 R0 ; Set initial tool 0 active S and standby R temperatures

;M302 P0 S180 R180 ; set min extrude /retract T's

;M563 P1 H2 S"Chamber" ; creates tool w/no drive, but displays chamber T. No heater

; Tools v3.1.1 NEW CONFIG

;TOOL 0

M563 P0 S"Volcano E0" D0 H1 F0 ; define tool 0 with heater 1

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M302 P0 S180 R180 ; set min extrude /retract T's

;TOOL 1 NOT YET

;M563 P0 S"Volcano E1" D1 H2 F0 ; define tool 0

;G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

;G10 P0 R0 S215

; Extruder v2.05 OLD FT6 CODE-maybe use?

;M305 P1 T100000 B3950 R4700 ; Set thermistor + ADC parameters for heater 1

;M143 H1 S300 ; Set temperature limit for heater 1 to 300C

;M307 H1 A395.4 C174 D4.1 V24 B0 ; PID

;M200 D1.75

; Custom settings are not defined

;M911 S16.0:20.0:22.0 ; OLD v2.03 CODE auto-pause at 20V, then either stop at 16V or auto-resume at 22V

;G29 S1 ; disable and put in start.g load stored bed height map

M376 H10 ; Bed compensation tapered up to 10mm

M501 ;load config.g on startup

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M911 S18 R20 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

G4 S10

M400

G4 S5

M400

M98 P/macros/MARIO

;G4 S1

;M98 P/macros/IMPERIAL

bed.g

; bed.g

; called to perform automatic bed compensation via G32

;

; v2.03 OLD CODE FOR BLTOUCH

;generated by RepRapFirmware Configuration Tool v2.1.5 on Sun Jan 12 2020 13:37:35 GMT-0600 (Central Standard Time)

;M561 ; clear any bed transform

;OLD ** BLTouch

;

;G21

;G28 ; home all - sys/homeall.g

;G91 ; relative mode

;G1 Z5 F2000 ; move bed down a bit for clearance

;G90 ; absolute mode

;M401 ; call sys/deployprobe.g

;M557 X10:690 Y10:310 S25 ; probe every 25mm from 10 to 690 in X and 10 to 310 in Y

;G29 ; run auto bed mesh level

;M402 ; call sys/retractprobe.g

;G1 X10 Y10 Z10 F5000 ; back to safe position out of the way

; bed.g v3.1.1

; called to perform automatic bed compensation via G32

;

; generated by RepRapFirmware Configuration Tool v3.1.9 on Sat Nov 28 2020 17:26:32 GMT-0600 (Central Standard Time)

M564 S1 H1 ;H1 = forbid movement of axes that have not been homed, H0 = allow movement of axes that have not been homed S1 = limit movement within axis boundaries, S0 = allow movement outside boundaries

M561 ; clear any bed transform

M671 X-117.0:-117.0:829.15:829.15 Y7.7:337.9:7.7:337.9 S0.5 ;Z leadscrews at RIGHT REAR Z1, RIGHT FRONT Z2, LEFT REAR Z3, LEFT FRONT Z4

; Z SCREW LOCATION FROM ORIGIN CAN BE NEGATIVE NUMBERS OUTSIDE PRINT AREA

; MULTIPLE Z STEPPER TESTING

;G28 ; home

;M401 ; deploy Z probe (omit if using bltouch)

G30 P0 X0 Y0 Z-99999 ; probe near a leadscrew

G30 P1 X0 Y330 Z-99999 ; probe near a leadscrew

G30 P2 X712.15 Y0 Z-99999 ; probe near a leadscrew

G30 P3 X712.15 Y330 Z-99999 S-1 ; probe near a leadscrew and calibrate NOW 4 motors

G1 X300 Y175 F3000

G30 ; probe the bed and enable compensation

;M402 ; retract probe (omit if using bltouch)

start.g

G4 S5

M117 "start.g begin"

G21 ;METRIC

M83 ; Absolute extrusion mode

T0 ; Tool 0

M117 "TOOL0 SELECTED"

G4 S3

M140 S69 ; Set bed temperature

M117 "SET BED TEMP TO 69"

G4 S3

G10 P0 S224 ; Set tool 0 active temperature

M117 "SET TOOL0 VOLCANO TO 224"

G4 S5

M117 "HOMIE AL"

G4 S5

M400

G28 ; Home

;ARGH PRINT FINISHED PROBLEM AREA

M400

M117 "G28 COMPLETE"

G4 S5