@dc42 :

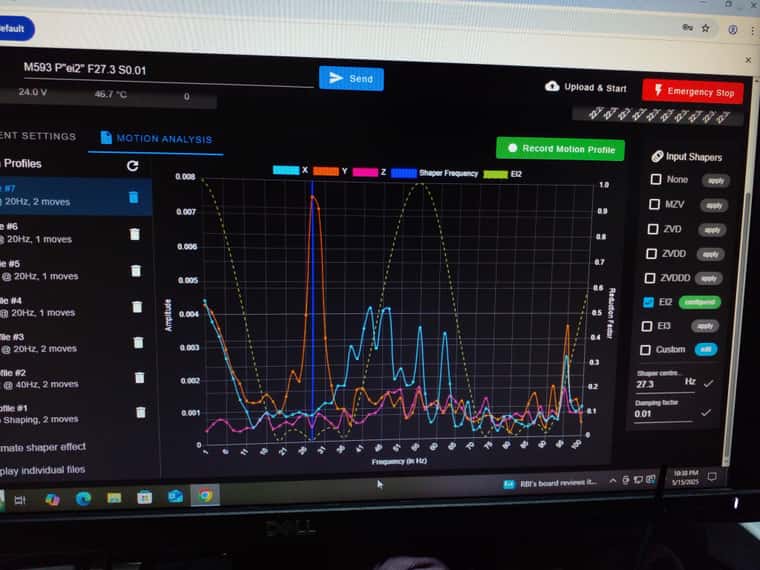

Hi David, I still see enough ringing despite using ZVDD& ZVDDD modes, but none reduce the ringing much. What am I missing here? The best frequency that works 20Hz with EI2 mode. But i still see lines on the plane Y facet.

Can you suggest what can be optimized in Settings or the design to eliminate this ringing in Y direction?

With cartesian i was able to solve ringing but could never attain acceleration > 800mm/s2 & speed >100. Same is the case with coreXY as well. I am not able to move to higher acceleration or speed.

P.S.:

- I tried 0.9 degree double stack as well

- ZVD ZVDDD modes with 20Hz frequency.