@droftarts Got it. It was the delta radius issue. I didn't think that would prevent the move, but, apparently it did. Thanks.

Posts made by Legrand

-

RE: Duet conversionposted in General Discussion

-

RE: Duet conversionposted in General Discussion

Changed to X2, Y2, Z2, LED's now illuminate when away from end stops, printer homes, but still cannot move axis.

-

Duet conversionposted in General Discussion

So, I've used the duet on a few (5 or 6) printers for several years, but it's been a while since I was in the nitty gritty of setting one up. I inherited an old delta and switched all the wiring over from the MKS setup. I can access the web portal and home the printer, but I cannot move the printhead. Any ideas on what might be going on here? Endstops seem to be correct, as it homes and the LED's light up upon homing.

; Configuration file for Duet WiFi (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Mon Jul 10 2023 14:44:47 GMT-0400 (Eastern Daylight Time); General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"LargeDelta" ; set printer name

M665 R325 L247 B150 H260 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them; Network

; M551 P"tigger1968" ; set password

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z80.00 E663.00 ; set steps per mm

M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2)

M906 X350 Y350 Z350 E650 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 Z0 S1 ; set minimum Z; Endstops

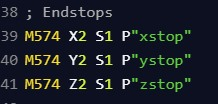

M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop

M574 Z1 S1 P"zstop" ; configure switch-type (e.g. microswitch) endstop for low end on Z via pin zstop; Z-Probe

M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

M557 R85 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

T0 ; select first tool -

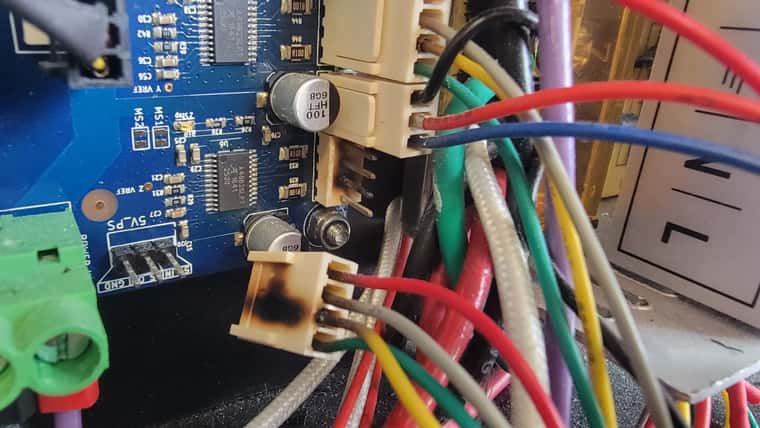

Z-axis wiring burnoutposted in General Discussion

So, I've had this printer running at work for years. Came in this morning after a successful print and tried to start another. Z axis drive was going bonkers. Opened up the back cover and found burned connector. Any ideas as to why this may have happened?

Is this board toast?

More info: The Z-Axis has two 1.5A motors running in parallel on it: https://www.jugetek.com/product-page/nema17-60mm-1-5a-high-0-65nm-high-torque-stepper-motor

-

Gnarly Bandingposted in Tuning and tweaking

Anyone have any ideas on what the issue(s) might be with my delta? I have four printers here, two deltas and two TF5's. Neither of the FT5's show this issue (after years of upgrades) and neither does the large delta that I built from scratch.

This print is off the first delta I built a few years ago (FT kit with upgrades) and I've never been able to get it to perform as good as the others. I'm wondering if it's thermal in some way since it seems to get worse in the winter, or if it's just some mechanical problem. I've never understood why it does the helical pattern either.

-

So, I blew up a WK8 P9 at TR5posted in Duet Hardware and wiring

As the subject says, I have a Duet WiFi, V1.02, and a wire was ripped from the hot end assembly (fan wire, if I recall correctly) which shorted the board. The board boots up but it's not working correctly anymore. It appears as though a component labeled "WK8 P9" (transistor, I assume) with three leads on it located at TR5 blew up.

Can someone tell me what this is so I can attempt to get a replacement and fix the board?

Thanks.

-

RE: Motor Driver Madnessposted in General Discussion

Update:

I had been trying to save the print, but eventually just gave up and rebooted the printer this morning. Guess what.. It's working fine.

Is it possible that the driver overheated?

-

Motor Driver Madnessposted in General Discussion

So I've been running couple of printers with Duets for a while now (years) and I just had my converted FT5 (an XY variant) wig out on me. I was 97% of the way through a 5 day print when one of the stepper motors started acting like it was wired incorrectly, making grinding type noises and moving strangely.

I thought maybe one of the wires to the motor was frayed or something so I ran a new set in through the harness. Same problem.

I then ran a separate set of wires outside the machine from the board to the motor. Same problem.

I had another new stepper motor lying around, so I ran the new wires to it and ... same problem.Did one of the stepper drivers die on this thing? I can't think of anything else it could be at this point.

-

RE: Restart a print after fault pause and timeout?posted in General Discussion

It's right there.... in my last post... the third picture. I'll post it here again, but this time not as a picture?

5:57:08 AM M115

FIRMWARE_NAME: RepRapFirmware for Duet FIRMWARE_VERSION: 1.21 ELECTRONICS: Duet 0.85 FIRMWARE_DATE: 2018-03-21 -

RE: Restart a print after fault pause and timeout?posted in General Discussion

Here's the relevant info:

-

RE: Restart a print after fault pause and timeout?posted in General Discussion

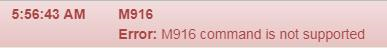

M916 isn't supported. It's saying "M916 command is not supported".

-

RE: Restart a print after fault pause and timeout?posted in General Discussion

I did that.

The documentation says "... you can use command M916 to resume the print from where it stopped."As I stated above, I set up the file sys/resurrect-prologue.g, but when I sent the M916 command, I got an "unsupported command" error.

I was guessing that this was because I didn't catch it in the first three hours?

Is there some other way to restart the print? -

RE: Restart a print after fault pause and timeout?posted in General Discussion

I added the resurrect-prologue.g file to the sys folder when I was trying to get it restarted this morning, but it didn't make any difference.

-

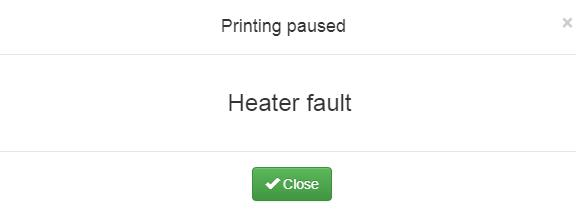

Restart a print after fault pause and timeout?posted in General Discussion

I was printing a rather large print at work over he weekend, and after about 40 hours of printing, the printer had a heater fault. Three hours later (10800 seconds), the console reported that the print was cancelled due to the un-cleared heater fault.

I've read that you can resume a print using resurrect.g, but when I try to use M916 to reactivate, I receive an "unsupported command" error. Is there any way for me to salvage this print, or am I dead in the water?

-

RE: Aluminium for Print Bed - 1050, 5083 & 6082posted in General Discussion

Speaking as a machninist/journeyman tool & die maker/mechianical and manufacturing engineer (yes, I'm old), what you want is commonly known as aluminum "jig plate". It's more formally known as MIC6. https://www.mcmaster.com/#=1c9j1n4

Jig plate is normally very flat on the top/bottom so it will make a decent heat bed. 5000 series aluminum is generally used in fabrication (punching/forming) applications, and as such, can be flat, but is usually sheared which can leave the sheet twisted. I used .25" (~6mm) 5000 series for my 12" X 12" (300mm square) printer and it's fairly decent when it comes to flatness. I should have used jig plate, but it was a bit more expensive and we had the 5052 here in stock.

-

RE: New Duet ethernet initialization, firmware upgrade - disaster…posted in Firmware installation

OMG, I'm an idiot.

In my defense, I had this board laying around for a few months before I installed it (at work), and I thought it was the "ethernet" version…. I just searched the board for the version info this morning.

I'm sorry to waste your time everyone (especially Dave).

-

RE: New Duet ethernet initialization, firmware upgrade - disaster…posted in Firmware installation

I've tried 1.18, 1.19 and 1.21, all called "DuetEthernetFirmware.bin" as I don't see anything specific for the V0.8.5.