I've a 0.4mm nozzle and a 0.25mm spare that only used once. I've been printing since 2013 and never found an excuse to install the smaller one.

I think that the 0.4mm nozzle has the perfect speed-resolution ratio.

EDIT: typo

I've a 0.4mm nozzle and a 0.25mm spare that only used once. I've been printing since 2013 and never found an excuse to install the smaller one.

I think that the 0.4mm nozzle has the perfect speed-resolution ratio.

EDIT: typo

Because of step unit error. With a 15 tooth pulley, 16 microstepping and 1.8º motor your steps per mm would be of 106.666¨ instead of just 100 with a 16 tooth pulley.

Check out this article, it's well explained and interesting reading:

https://nutz95.wordpress.com/2014/12/02/reprap-how-to-choose-your-pulleys-for-your-3d-printer/

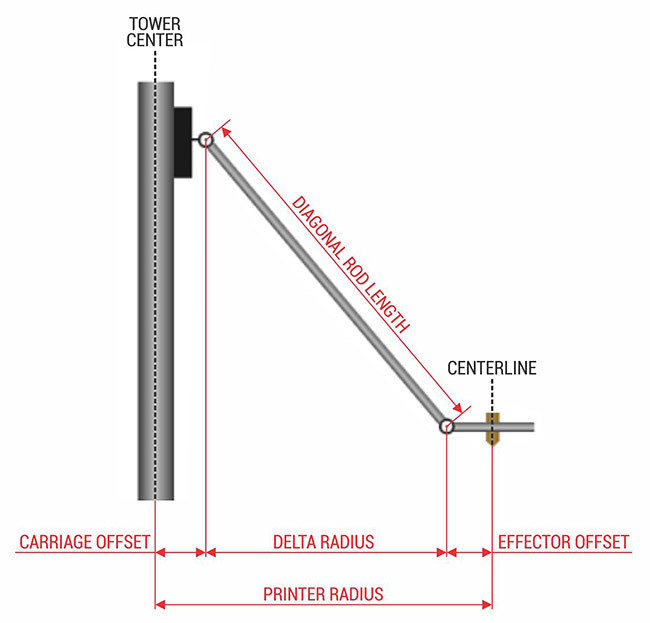

Hi, as for what you should measure, this pic might help you:

I don't think you actually need to measure it, those values should be inside Marlin's config or whaterver firmware the Anycubic has.

And how about the bowden path? If you feed it by hand, do you find any resistance?

I once had a filament that was just a bit thicker and it got stuck inside the bowden tube.

Maybe you are trying to move them too fast?

David provided a spreadsheet to work out the speed at which torque starts to drop off:

https://www.dropbox.com/s/5z66rgjc8gptn5o/StepperMotor.ods?dl=1

EDIT: It was found here: https://duet3d.com/wiki/Choosing_stepper_motors

You are right. I got confused, sorry.

I'm going to bed now

Hello, M350 needs to be set before M92.

not really, if you use M92 before M350, the firmware assumes 16x microstepping for M92.

Uhhm, yes, but he is using x32 miscrostepping.

Hello peirof.

What's your bed surface? Did you paint it black?

I tried using M579 on my Delta to fix a dimensional error on just one axis, but the prints came squeezed near the center (was using a negative Y value). Maybe this g-code is only meant for cartesian style printers. Do as Simon says and adjust the rod length for calibrating X-Y. Or try it, who knows, maybe it works for you.

If the wiring is too long, the thermistor can catch noise.

Have you tried twisting the wires and/or using shielded cable?

I had a similar issue and twisting them solved it for me.

Hello Arthur, same M305 values here. I had a similar problem, but in my case, redoing the wiring and twisting them solved the issue.

If you want to compare both readings, the best location I've found to place the external thermocouple was inside the hole were the M3 screw tights down the thermistor cartridge.

They claim that the high speeds are for loading filament.

As a Titan Aero user too, I only use 5 and 1 mm/s. The 5mm/s speed sometimes skips if the temperature is a bit cold.

Either way, I like your request.

+1 for a customizable or at least less agressive extude speeds.

At the center is Z=10, but if you move to the edges of the bed the nozzle rises right?

What happens if you send the nozzle back to the center? Does it go back to Z=10 or it keeps going up?

If it goes back to Z=10 my guess is that your delta radius is way off.

Happy new year for the ones that are close to midnight!!!

16:12 here in Argentina, we just finished making all the arrangements for today.

Wish you all enjoy today's celebration.

Happy new year!!!!!