So I think I have been making some progress on my print quality issues and it seems to be related to print speed.

@Phaedrux how do i enable this in DWC I am running 1.21.2-b2. Its mentioned in this post. Apologies if I am missing something obvious.

So I think I have been making some progress on my print quality issues and it seems to be related to print speed.

@Phaedrux how do i enable this in DWC I am running 1.21.2-b2. Its mentioned in this post. Apologies if I am missing something obvious.

@Phaedrux Thanks for the the info ill give those values a try.

@dc42 Yes the the Gcode specifies the area should be flat. Ill try the formula and let you both know what happens.

I have been trying to solve the issue of the vertical grove.

From reading posts on this forum and others, I initaly thought it was something to do with pressure advance.

Adjusting the pressure advance has made a postive differance to my prints but not solved the issue with the corner.

So I think it has something to do with my instantaneous speed changes, maximum speeds and maximum accelerations here is my config file. Or maybe its something else?

What i would like to do is create a couple of macros to see and compare the changes intantaniously but being new to 3d printing and duet this has raised even more questions.

So as I understand it I can enter the M556 (and M203, M201) but does it have to be Xnn Ynn Znn Enn or can it be just Xnn or one parameter at a time?

If M556 is entered via DWC or Paneldue how quickly is this applied to the print and where is that figure stored?

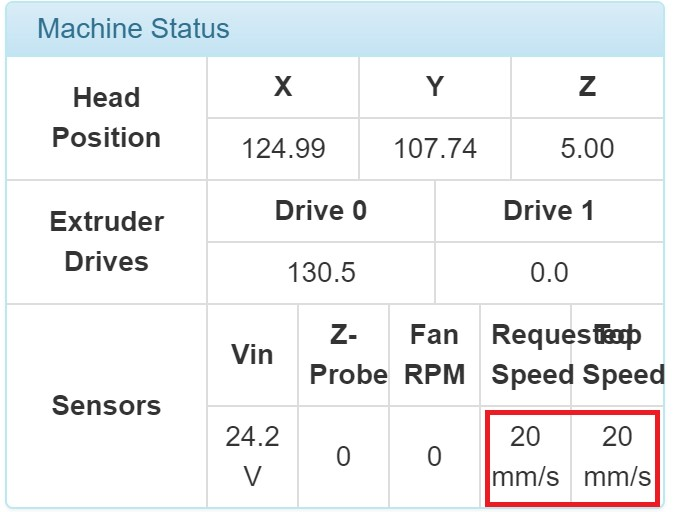

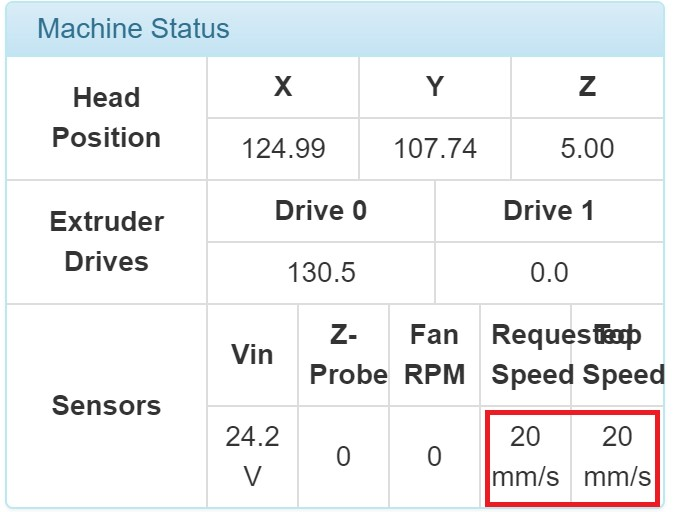

Is there a way of reporting the current speeds, as towards the top of the print in the picture something is right in the settings and that would be good to know\discover?

I am running a P3steel printer with a bowden tube of approxamatley 470mm

Duet 2 Wifi

RepRapFirmware 2.0

webserver 1.21

DWC 1.21.1

Hope that all makes sense

Not a problem, ill get my order placed.

Thanks.

Just noticed that the DuetWIFI is out of stock!

Any Idea how long it will be before they are available again?

Thanks

Reverting back to 1.21 solves all the issues and anecdotally my WiFi connection has improved.

Yes. I upgraded to 2.0 and as far as I can tell there are no problems with it.

My issues are with the DuetWebControl-1.21.1.zip and the problems that has had in my origional post. I am now doubting if I should have used this at all?

So I have had some issues with DWC 1.21.1 and sorted them, so i feel this is more of a "bug report"

The first is that it would only stay connected for very short periods of time and on re-connection "machine status" and "Heater temps" would only update sporadically.

Also I could not save/update any filament configuration files or macros.

All of this was solved by rolling back to 1.21 although this could not be done via DWC as it just reported errors when uploading the zip file.

Since going back to 1.21 it seems that the wifi connection is more stable.

@fragglerok said in Duet wifi p3steel mounting:

Thanks ill give them a look, the p3 steel can be a bit of a nightmare as there seems to be a lot of variations with different hole placement, tried loads of power supply mounts before I found one that fitted mine

Which one have you got? Mine is the orballo printing one.

I'm in the middle of doing the same as you. I have designed a spacer/mount for this Box www.thingiverse.com/thing:2481027.

The mount is here www.thingiverse.com/thing:2847223 it's still a work in progress but it might help.

Living in the UK I ordered a silicone heat bed from aliexpress (400x400 750w) and was pleasantly surprised by the speed of delivery, 8 days and no additional charges.

It was sent via epacket as that was the free shipping option.

Hope that helps.

I have had an issue with the Vin connector beginning to burn/melt, completely my fault as I had not attached the ferrules. This is because my initial crimping method was not successful and having ordered some more not got round to reattaching them.

So my question is what is the best way to crimp these ferrules on a) using the method shown here https://duet3d.dozuki.com/Guide/2.%29+Wiring+your+Duet/9 or b) using a quad crimp tool or does it not matter?

Thanks for the reply's.

Is the Z in your M92 correct now? If you use DWC and command the Z movement 100mm, how far does it move?

Yes I am pretty sure it is but I will double check that it moves 100mm when commanded.

That can happen if your steps / mm aren't easily divisible by your layer height.

For example, we had a 16T pulley on our Z stepper, belt driven to a 30T pulley. Since the math came out funny, every third layer or so was smooshed. We switched to a 16T / 32T pulley, our steps/mm are now 1 step = 0.01mm, and everything's happy.

I don't think this is an issue as the the leadscrews are T8's and should give me increments of 0.04mm (if my maths is correct).

Would print speed make a big difference on a small test print?

So I have spent the weekend setting up my new Duetwifi board, mostly straight forward but I have one issue I cannot solve.

When printing the second and third layer are smooshed by the hotend. I have checked all the axis movements are correct and have had to change what the configurator suggested (M92 X100 Y100 Z400 E420 ; Set steps per mm) to get the correct distance travelled.

Is this where my problem originates or should i be looking elsewhere. I have also tried various settings in Slic3r but nothing seems to make a difference?

Any Ideas?

Link to Image of smooshed print.