@chrishamm thanks i missed that on that general page

Posts made by moth4017

-

RE: 3.6.0rc1 DWC baby stepping values incorrect value displayedposted in Beta Firmware

-

RE: 3.6.0B4 object model calibration final deviation valueposted in Beta Firmware

@dc42 Why would i use more then points than lead screws to tram the bed ?

-

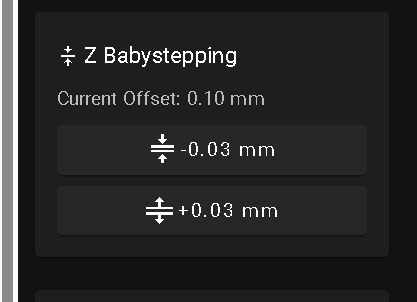

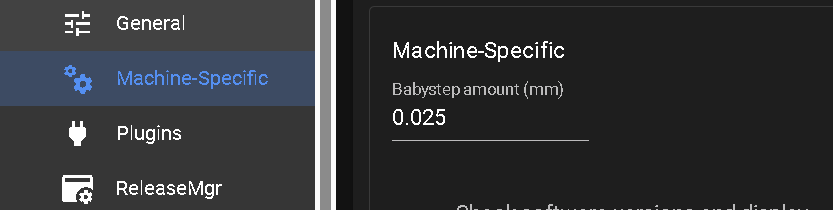

3.6.0rc1 DWC baby stepping values incorrect value displayedposted in Beta Firmware

in the DWC status window , displayes 0.03mm

but in the machine specific its set up as

-

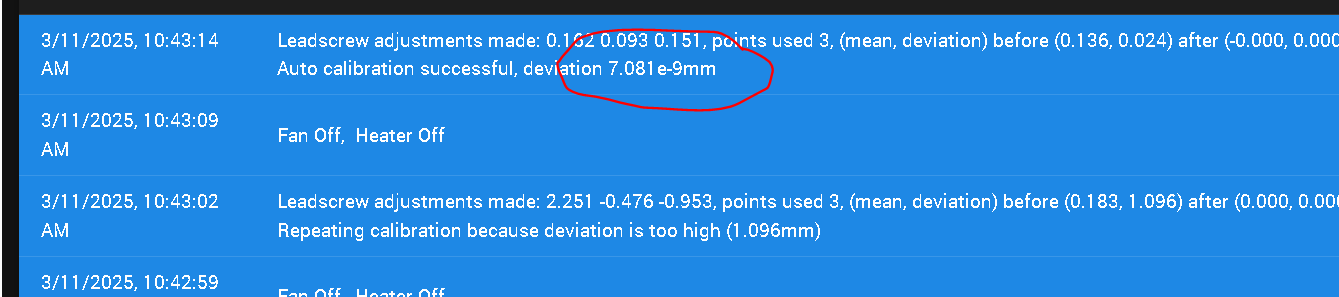

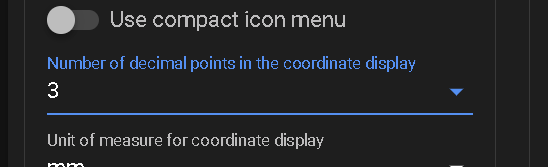

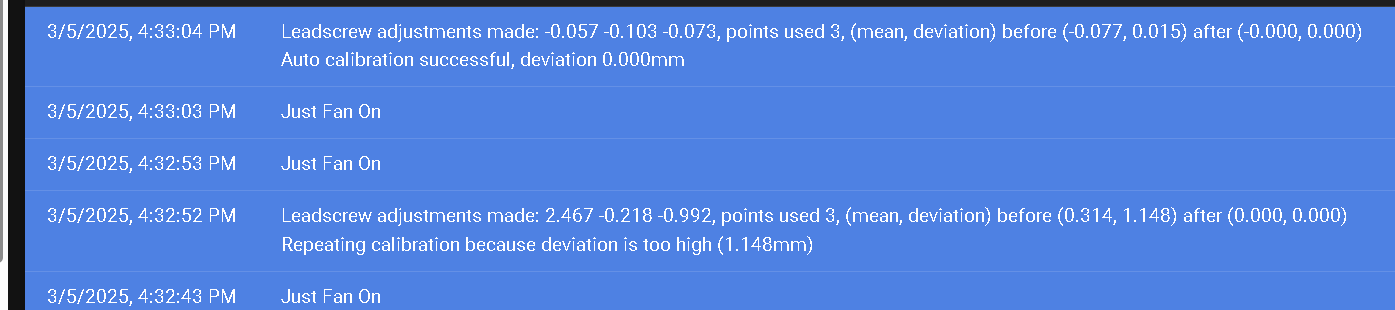

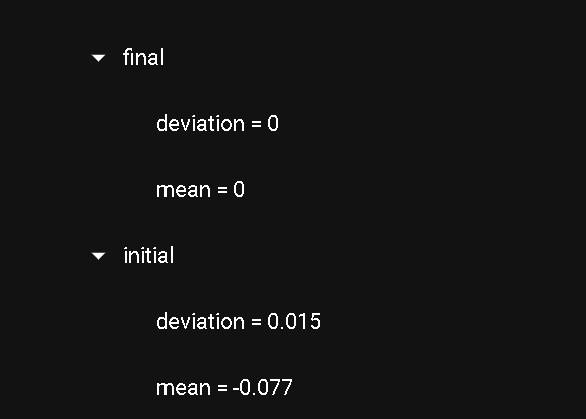

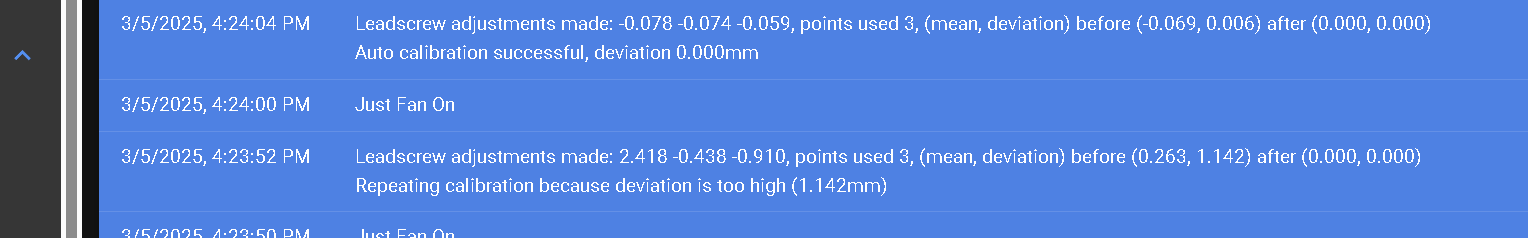

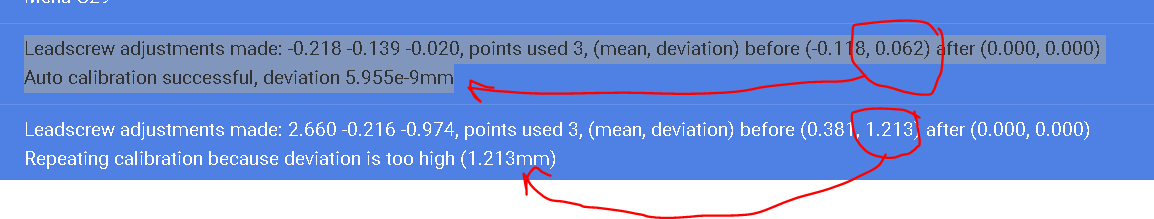

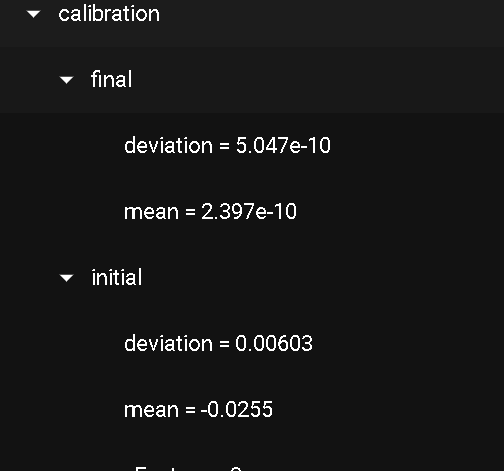

3.6.0B4 object model calibration final deviation valueposted in Beta Firmware

in the new beta versions v6.3.0 the value displaying the final deviation value has changed from mm rounded to 3 decimal places to a scientific notation format , will it be like this in the future or is this a mistake?

v3.5.3

v3.60b2

v3.6.0b4

it would be nice to select the number of decimal places , but as it was was ok

-

RE: M950 to add servo controlposted in Firmware wishlist

@T3P3Tony i still need to control a vent/solenoid / servo as my chamber is sealed , i just thought it would be away to kill 2 birds one stone

-

RE: M950 to add servo controlposted in Firmware wishlist

@jay_s_uk @T3P3Tony I have 2 applications for this cooling and venting, I sometimes need to vent the printer chamber through a carbon filter because of the fumes ,but can only do this when the chamber is cool enough for the activated carbon, I'm sure there will be other uses, as always I

-

RE: M950 to add servo controlposted in Firmware wishlist

@jay_s_uk

so M950 set min & max angel

and

M106 still be 0 to 100% -

RE: M950 to add servo controlposted in Firmware wishlist

@T3P3Tony

cpap/fan , controlled via A fan output,

servo Controlled via A fan output

Flap homing via digital inputrequired 2 fan outputs and 1 input in total

-

RE: M950 to add servo controlposted in Firmware wishlist

@T3P3Tony fan speed stays the same the flap varies the output 0 to 100%

-

M950 to add servo controlposted in Firmware wishlist

M950 add the option so a sevo motor can be control for options like this

https://github.com/vitals78/Flap-controlled-CPAP -

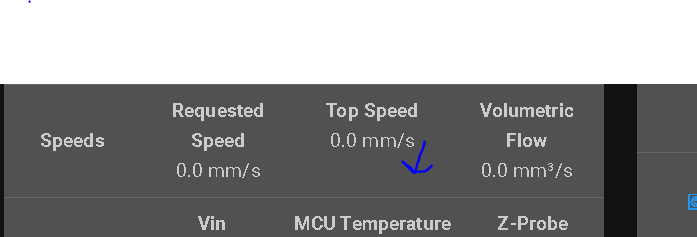

speeds not in line , messing with my headposted in Duet Web Control

it may be just me but the speeds not being in line is messing with my head

-

RE: better error reportingposted in Firmware wishlist

@magnets99 hi

that what i did to find the error was to comment out each macro, it would be nice if the file could be listed as well as the line number and the column -

RE: better error reportingposted in Firmware wishlist

@Phaedrux the error isnt in the config it was in another macro called by the config file, but you dont know which macro that causes

the error message -

better error reportingposted in Firmware wishlist

i have this error in the console

Error in start-up file macro line 36: in file macro line 36 column 26: meta command: expected an expressionbut its not in the config file as line 36 is:-

its in another macro somewhere ?

-

backing up with zip filesposted in Duet Web Control

Backing up the system/macros files and folders , if you select all the files and folders in either system or macros it wont let you save to a zip file until you unselect the folders , can this be changed so everything can be zipped?

-

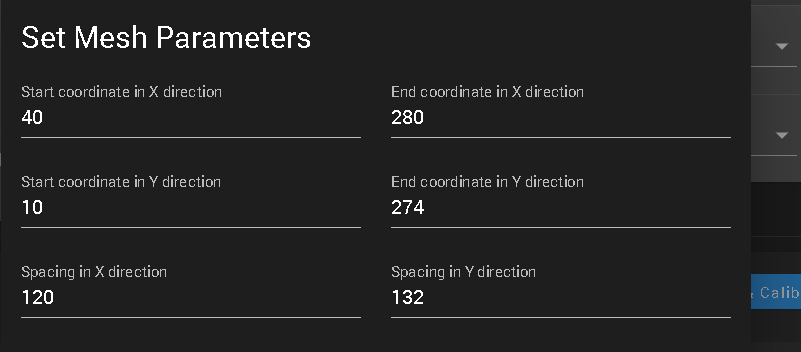

m557 define area of bed mesh compensationposted in Duet Web Control wishlist

in the above dialogue box can there be an option to add number of measurements in x and y , instead of distance.

eg, X=5 y =8 -

RE: Bed PID Tuning: How long should it take?posted in Tuning and tweaking

from the settings above i ran an auto tune to see how long it would take , ambient air 18C

M303 H0 P1 S100

the PID tune took 37 minutes and i got back this responseWarning: heater behaviour was not consistent during tuning

Auto tuning heater 0 completed after 4 idle and 25 tuning cycles in 1620 seconds. This heater needs the following M307 command:

M307 H0 R0.812 K0.268:0.000 D3.35 E1.35 S1.00 B0

Edit the M307 H0 command in config.g to match this. Omit the V parameter if the heater is not powered from VIN.My first auto tune took much longer

so my bed has been working fine with those settings above and the results were not much different .

previous settings working ok "M307 H0 R0.838 K0.331:0.000 D3.08 E1.35 S0.90 B0"

settings after the PID tune "M307 H0 R0.812 K0.268:0.000 D3.35 E1.35 S1.00 B0" -

RE: Bed PID Tuning: How long should it take?posted in Tuning and tweaking

@DonStauffer the bed PID tune does take a long time i have a 340mm x 340mm x 8mm thick Keenovo 700W /220Vac , if you have a heated or insulated chamber even longer .

here is my PID tune if it helpsMy sensor is in a hole drilled in the edge of the aluminum bed . not using the one on the silicone heater

M307 H0 R0.838 K0.331:0.000 D3.08 E1.35 S0.90 B0

if you send M307 H0 in the console you will get a report

Heater 0: heating rate 0.838, cooling rate 0.331, dead time 3.08, max PWM 0.90, mode PID

Predicted max temperature rise 198°C

PID parameters: heating P69.2 I2.156 D149.1, steady P69.2 I6.103 D149.1