What screen is that on? I will create a CSS override for the dark theme to fix that up!

Posts made by MSquared

-

RE: Attn Web Master - Dark Theme Problemposted in General Discussion

-

RE: 0.36º stepper motorsposted in General Discussion

@badscript The Duet would generate the step pulses using the drivers attached to the Duex. The Duet doesn't really care about 1.8 vs.9 or even .36 degrees per step because you tell the firmware how many steps there are per millimeter of movement desired for each axis/motor. So if you tell the Duet that it needs to move 200 steps per mm it will generate 200 steps for each mm of movement that it sees in the GCode that comes from the slicer. In this case the steps per mm would just be much higher than a typical 1.8 degrees per step (200 steps/rev) or .9 degrees per step (400 steps/rev) motor. The actual steps you need per mm also vary depending on your setup, movement system, belts, cogs, gears, pulleys, etc...

-

RE: New firmware 2.0RC5 availableposted in Firmware installation

@zerspaner_gerd I also cannot seem to load filaments anymore.

-

RE: Berd-Air pump configuration notes for Duet usersposted in Tuning and tweaking

@klcjr89 said in Berd-Air pump configuration notes for Duet users:

Brushless?

This was actually the brushed version. I will put up something with the brushless in a day or so.

-

RE: Berd-Air pump configuration notes for Duet usersposted in Tuning and tweaking

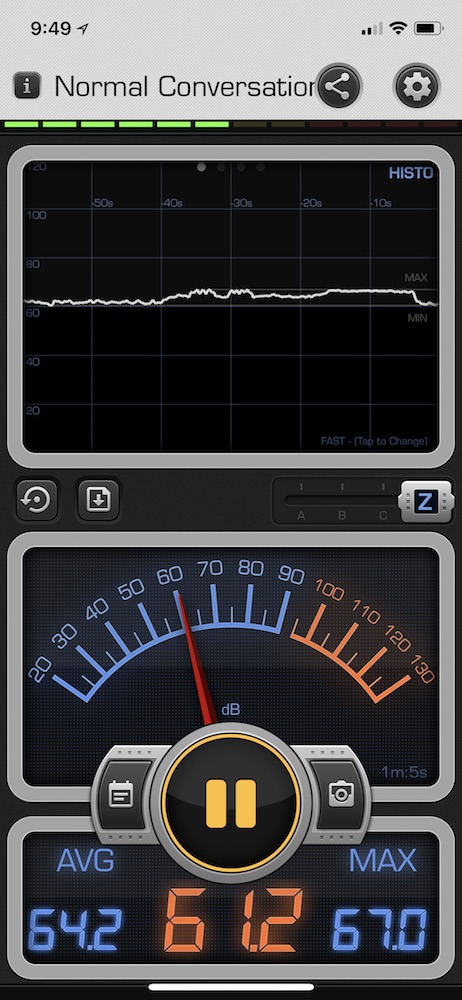

For reference here is a DB monitor of the pump running at very near full speed during a print. This is with the phone about 1" from the pump.

-

RE: Berd-Air pump configuration notes for Duet usersposted in Tuning and tweaking

@davea said in Berd-Air pump configuration notes for Duet users:

I'm a bit confused about PWM. I have a Berd-Air pump on fan 0 through an e-switch mosfet.

If I add an F25500 parameter to the M106 I have very little control over fan speed.

If I leave off the F parameter I can vary pump speed from 0 to full speed. It seems that the higher the PWM frequency the less control over fan speed.When you run with a high PWM frequency are you still going through an e-switch?

I was not. I still have my e-switch lying around and I may get a chance to test that later tonight or tomorrow and let you know my results. It is very possible that the e-switch may not respond to high PWM values as well as the pump does directly. If that is the case I have a DC-DC SSR lying around and I may give that a shot to see if it makes a difference.

-

RE: Using a mirror as toolplateposted in General Discussion

@fma While I use a MIC-6 aluminum tooling plate as my heat spreader / heated bed I do use mirrors that I purchased from Home Depot as my "glass" and affix PEI/Printbite/gluestick to them as required. They seem to be reasonably flat and have been working out great for me. One negative thing I will say is that the mirror backing causes significant heat drop when compared to standard glass.

I would be concerned about using a mirror without a heat spreader primarily due to potential warping / breakage if the glass didn't heat evenly.

-M

-

RE: Firmware 2.0RC1 and 1.21.1RC1 releasedposted in Firmware installation

@dc42 I upgraded and used it over the weekend with no issues. Hardly a torture test but it seemed to be performing well...

-

RE: Maximum Frequency of PWM Fansposted in Duet Hardware and wiring

It is my understanding that the ground is actually pulsated, while achieving the same effect (pulsating the input voltage) it is an important note all the same.

-

RE: Berd-Air pump configuration notes for Duet usersposted in Tuning and tweaking

Seriously...check the PWM frequency on the fan port you are using to drive it. Once I bumped the PWM freq up to 20k the temp on the motor dropped like a rock.

-

Berd-Air pump configuration notes for Duet usersposted in Tuning and tweaking

I have seen a lot of questions about setting up a Berd-Air pump on the Duet and since I have done just that recently I figured I would post some of my experiences.

-

If you are running a newer Duet you can wire the pump directly to the board so long as you are using an appropriate flyback diode, and follow @dc42's recommendations in this thread to make sure you are protecting the fan MOSFET adequately. I believe on older Duets you will in fact need to use the e-switch or an equivalent external relay / mosfet / opto-isolating circuit. I have an e-switch which I used initially and it requires some soldering skills to build, but worked really well. I also used the YJ-Pad which simplified the wiring somewhat.

-

Running the pump at an adequate PWM frequency will DRAMATICALLY reduce the noise and vibration from the pump. I run mine at 25500khz with no issues. I find that the pump/tube combination is noticeably quieter than my old axial fan /shroud setup and I really barely notice the pump noise over the sound of my extruder most of the time.

-

Running the pump at an adequate PWM frequency will DRAMATICALLY reduce the amount of heat that the motor generates. When running at a low PWM frequency my motor was often too hot to touch after running for only a few minutes. Once I bumped that up the motor gets only slightly warm after running for a few hours.

-

If you are planning on mounting it to the frame of your printer vibration dampening is essential. I found that my piezo probe was quite helpful in this regard as I was able to test several different strategies and monitor the results by looking at the piezo sensor level. I ended up using the 3mm larger standard mount with some pieces of 1/4" ID rubber vacuum tube from an automotive shop as "insulation" between the mount and the motor, and the mount and the frame. To accomplish this I cut some lengths of tubing and then cut that tubing in half across it's diameter, this gave me a nice "arch" of tubing that I then wedged into the mount to act as a dampener as shown in this picture:

I used three pieces of tubing in the mount, and one between the mount and the frame. Ideally I would have also isolated the screws going into the frame as they are still quite capable of conducting vibrations but I have not yet designed that mount.

I run the Berd-Air from about 20% - 75% in my slicer for PLA and it works great, I plan on dialing that in a little bit more but thats a good starting range.

Hope this helps someone!

-M

-

-

RE: Fans vs Berd-Airposted in Smart effector for delta printers

Hey All,

I received the pump from @klcjr89 and have played with it a little bit. I plan on doing more extensive testing and a full write up I wanted to give you all some of my initial impressions.

Technical Stuff

- The build quality of the pump seems very good, it feels solid with a good fit and finish

- It absolutely provides enough flow / pressure for the Berd-Air tube(s)

- Connected directly to the PWM fan output of the Duet with no issues

- Due to it being a brushless motor PWM output is a bit more fussy (see notes below)

- Might get hotter than the standard pump (see notes below)

Aesthetic Stuff

- It is much more attractive than the default Berd-Air pump

- It should mount much easier than a Berd-Air pump (see notes below)

- It is more compact than a Berd-Air pump

- Without the mufflers (I do not have a set, but may purchase some) it seems like it might be louder than the standard pump (see notes below)

Other Notes

@klcjr89 mentioned some strange harmonic/auditory issues when running at less than 100% (255 PWM) I found that this only occurs when you are running a PWM frequency that is substantially in the range of human hearing (20hz ~ 20khz). I found that running it above ~17khz resulted in no uncomfortable sounds, which makes sense since I am old enough I probably can't hear above that range anyways .

.That being said 2-wire BLDC motors don't always like being PWM'd. You have to get your PWM frequency set to your liking (I settled on someplace in the 20k range for my initial testing). Depending on the PWM frequency used you will lose a little bit of responsiveness in either the low (<10%) or high (> 90%) range where changing the PWM output will not adjust the pump speed. I don't think this is an issue since with a Berd-Air I rarely need these ranges anyways.

I measured the noise level using a dB meter on my phone and the brushless pump is louder than the standard Berd-Air pump when properly configured; however I don't feel that comparison to the standard pump is not entirely fair at this point. My standard pump is mounted in a way that dramatically reduces the vibration of the pump. For testing this pump it was not mounted at all, I just had it sitting on rag on my desk. I have designed a similar vibration-dampening mount for this pump but I have not yet printed it or tested it; I plan on doing that for the full write-up, as well as posting the mount if people are interested. I also do not yet have the mufflers installed, which would destroy some of the aesthetic benefits of the pump, but would probably reduce the noise level even more.

I didn't run the pump for a full print, so I cannot fully comment on how hot the motor gets at this point, in my initial testing it seemed like it got hotter than my properly configured standard pump.

Thats all for now, I will post a full write up later this week if I have the time to get all the testing I want to do completed!

-M

-

RE: How include photos in new forumposted in General Discussion

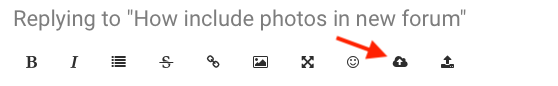

You can upload photos from the editor by clicking on the "upload image" button as shown below:

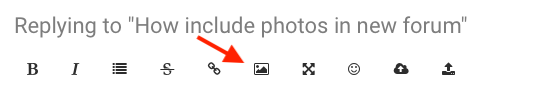

or if you have the images hosted someplace else, you can use the "picture" button as shown below:

-

RE: Duet WiFi - User Interfaceposted in My Duet controlled machine

@dc42 Just curious is there a reason that the settings are not persisted to the SD card?

-

RE: Fans vs Berd-Airposted in Smart effector for delta printers

Indeed I do.

I am currently running a standard Berd-Air pump and have spent some time dialing it in so I plan on posting a comparison between the two in terms of performance, ease of install / mounting, and noise level once I get my hands on it!

Stand by!

-M2

-

RE: Advice on Stepper Motor Specsposted in Duet Hardware and wiring

@phaedrux said in Advice on Stepper Motor Specs:

I use the same steppers in my CoreXY build and they work well. I run them at a current of 1.4-1.6 on a 24v system and they handle it very well.

Ditto on my CoreXY

-

RE: Fans vs Berd-Airposted in Smart effector for delta printers

@klcjr89 said in Fans vs Berd-Air:

If you're in the USA, I have an extra 24V brushless pump I could sell, but I do not have an extra set of mufflers.

I would be very interested in this. What would you be asking? Feel free to email me directly about it.

-

RE: Material Order of Preference for Machine Components?posted in General Discussion

@doctrucker I have been using Atomic Filament: Carbon Fiber Extreme for most of my gantry parts and am loving it. It is basically as easy to print as PLA, but slightly more compliant (less than straight PETG), with MUCH better structural integrity. The compliance can be an issue in parts that are too thin, or poorly designed. but in my C-Bot this only proved to be an issue in a new part that I designed poorly.

The Tg of PLA can be an issue anyplace, not only near the hot-end. Even though I started with PLA for all my parts I never actually had a problem with parts near the hot end, somewhat ironically, it was actually my motor mounts that had issues first as prior to switch to a Duet the motors would run quite warm and eventually allowed the PLA to bend under the tension from the belts. Less surprisingly my bed mounts also suffered once I started heating my bed up to 100c+ to try and print replacement motor mounts in ABS. Eventually I was able to print replacement bed mounts in ABS and switched to the CF Extreme for pretty much everything else.

I have used Nylon in the past for a few parts, it was awesome, but the challenging to get tuned well enough to print larger parts consistently.

My current preference is:

- Carbon Fiber PETG

- ABS (anything exposed to ambient temp > 60c)

- PLA (in a pinch / prototyping)

-M

-

RE: Aluminum Buildplate Cast tooling plateposted in General Discussion

For those people in the US that are interested in getting tooling plate I have used these guys in the past and am VERY happy with them. They ship quickly and the plate they sent me was perfect.

@DjDemonD I would be interested as well. I was looking at trying to do something like this myself, but the machining of the plate poses a challenge for me currently. I will reach out to you by email to discuss further!

-M