So it seems the heat gun is out. A number of other heat source options have been put forward in this thread. They are as follows.

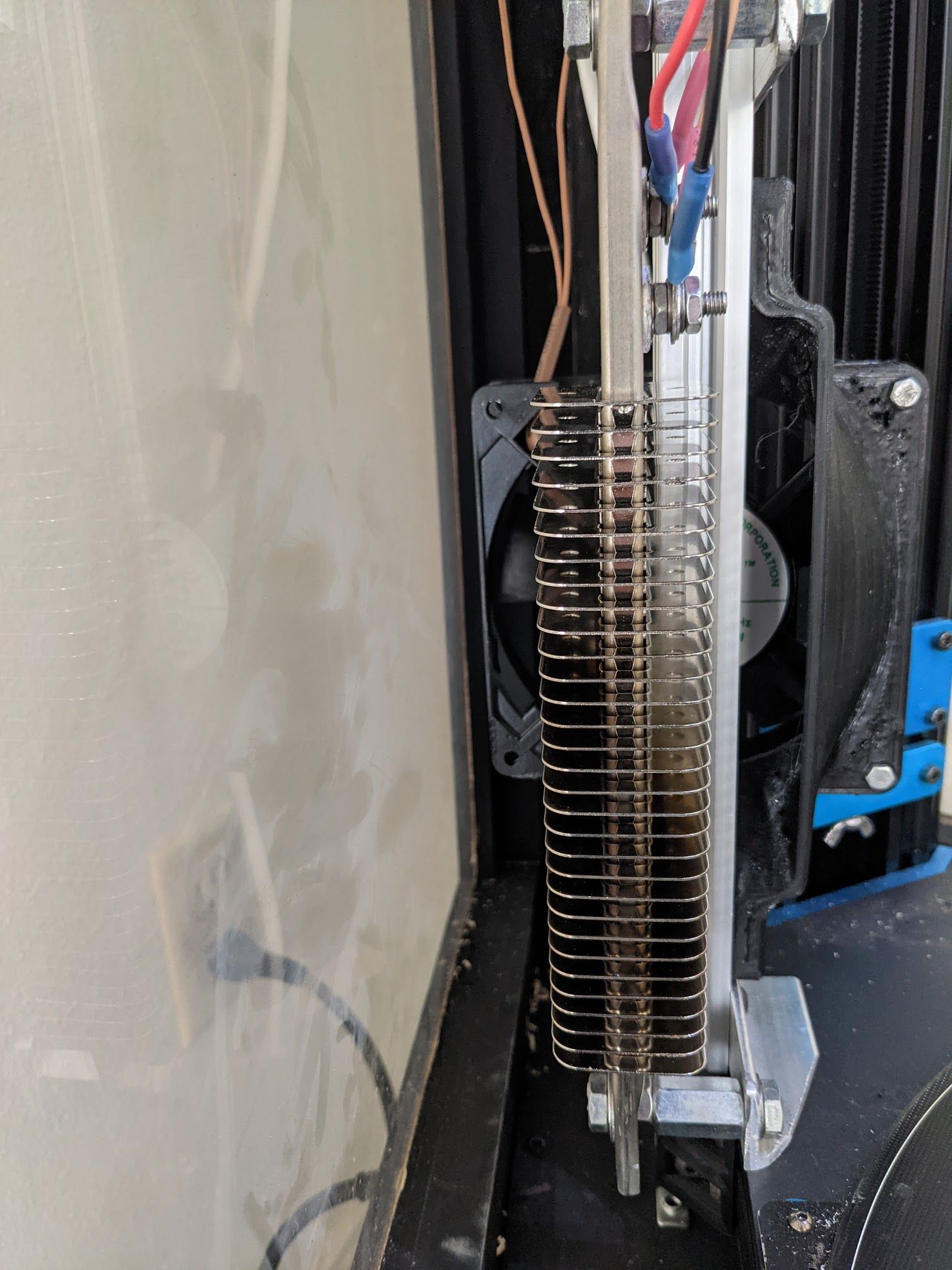

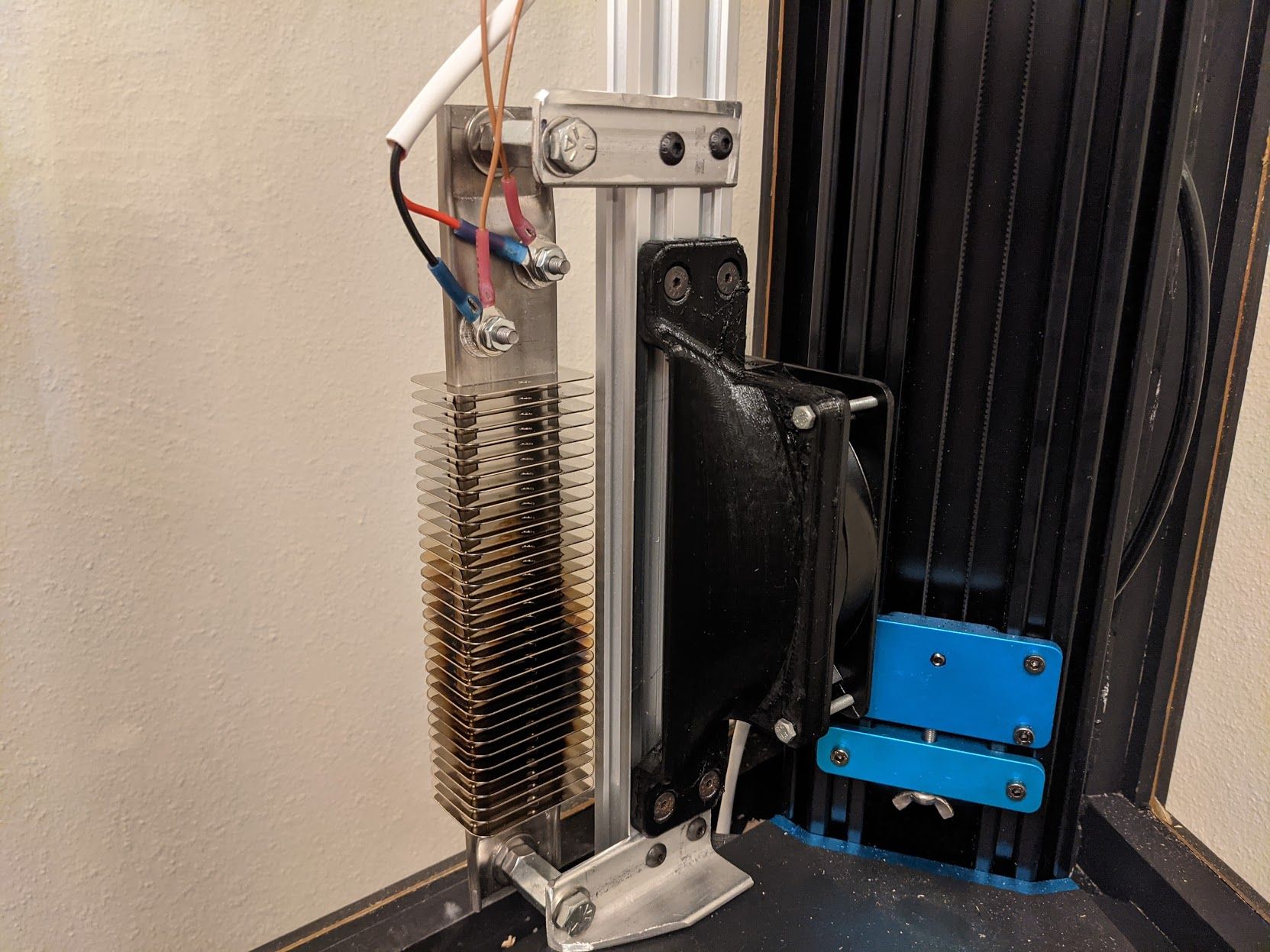

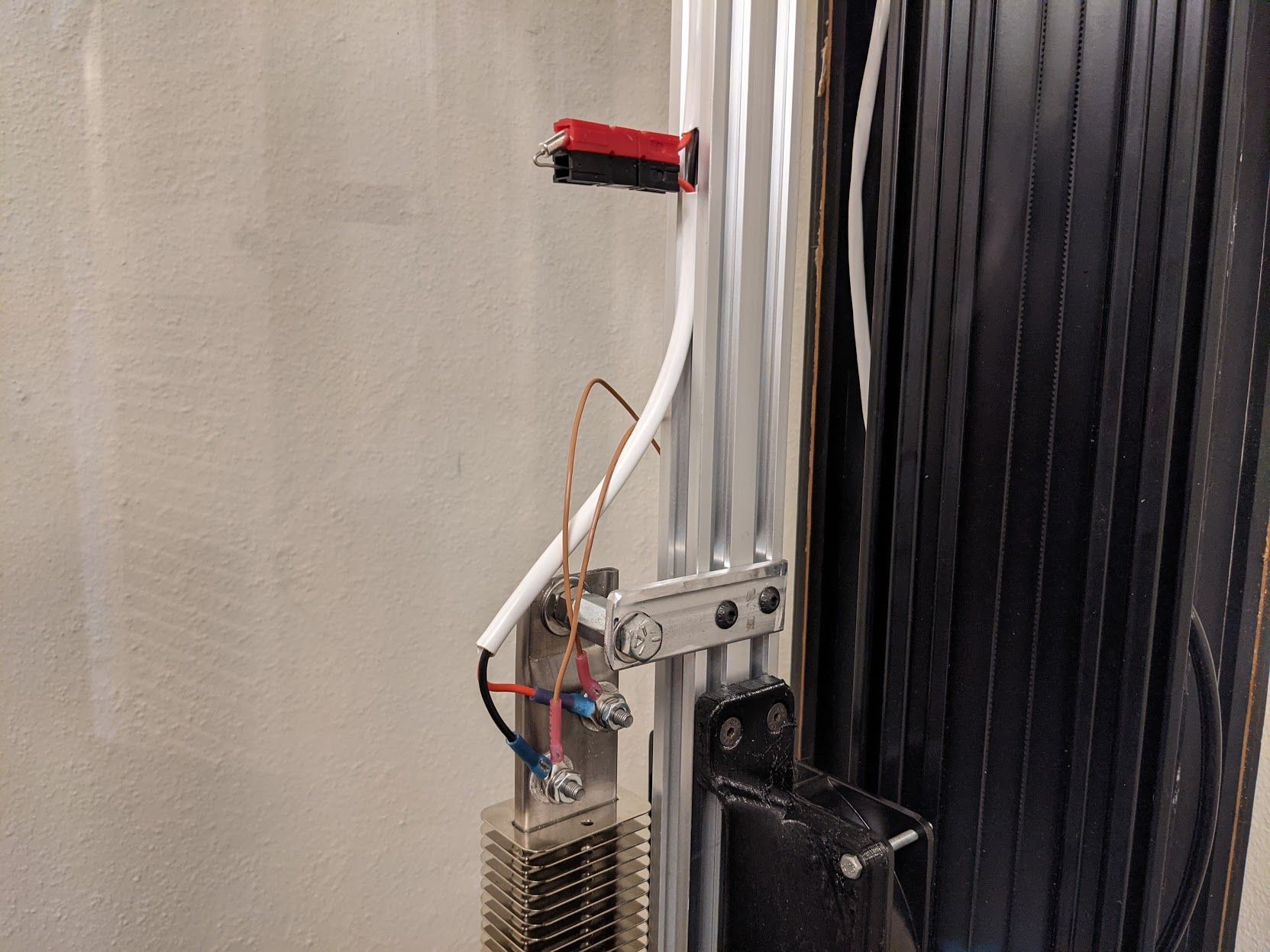

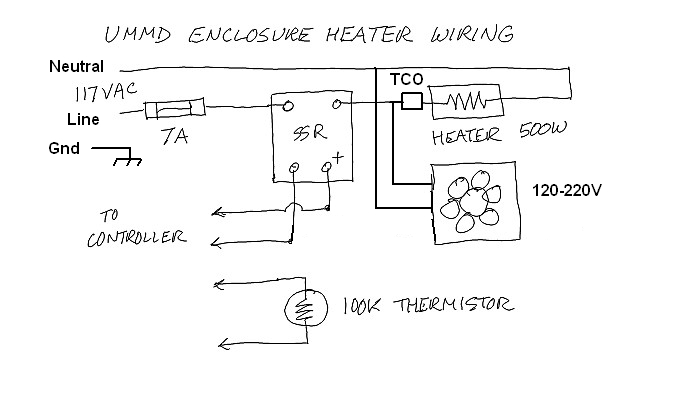

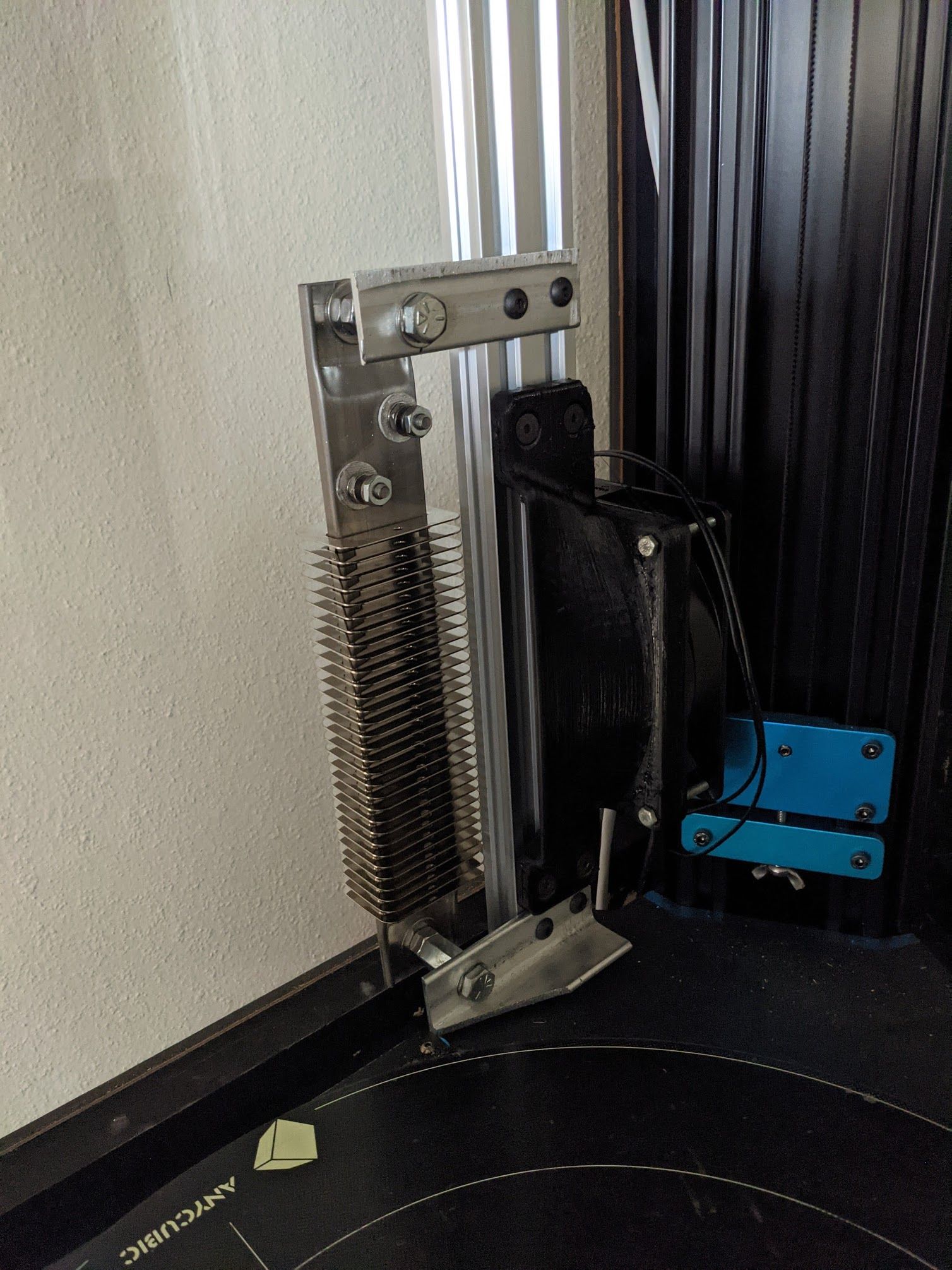

$65 500W Bolt-Mount Heater from mcmaster who also sells a

$30 500W ceramic lamp heater which are also at amazon as

$16 200W ceramic lamp heaters(suggested to use 2) and I also found

$20 500W PTC heating element, available in many wattages, i just list the 500W for comparison sake

all of these will require a fan to circulate the heat generated, so I'm not factoring that into the comparison.

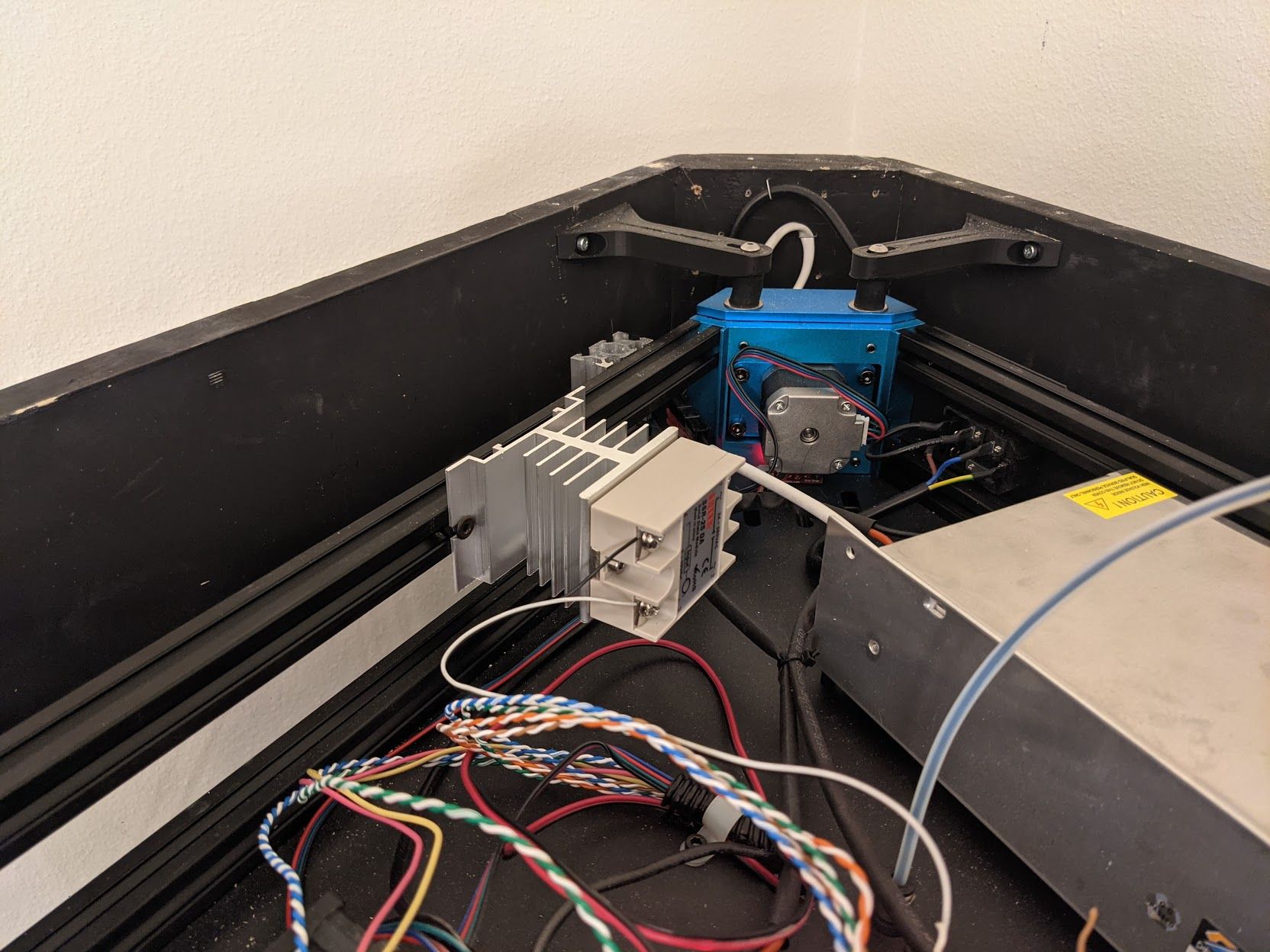

I'd rather use the maestro to control the heater so it turns on and off with the print than a standalone controller i'd have to manually turn on and off for printing.

And of course all this work is to print ABS(without warping) which I've largely migrated away from in favor of PETG. But I've got a pretty big stockpile of ABS and it would be nice to not have it go to waste. also i like acetone smoothed ABS. its so shiny.

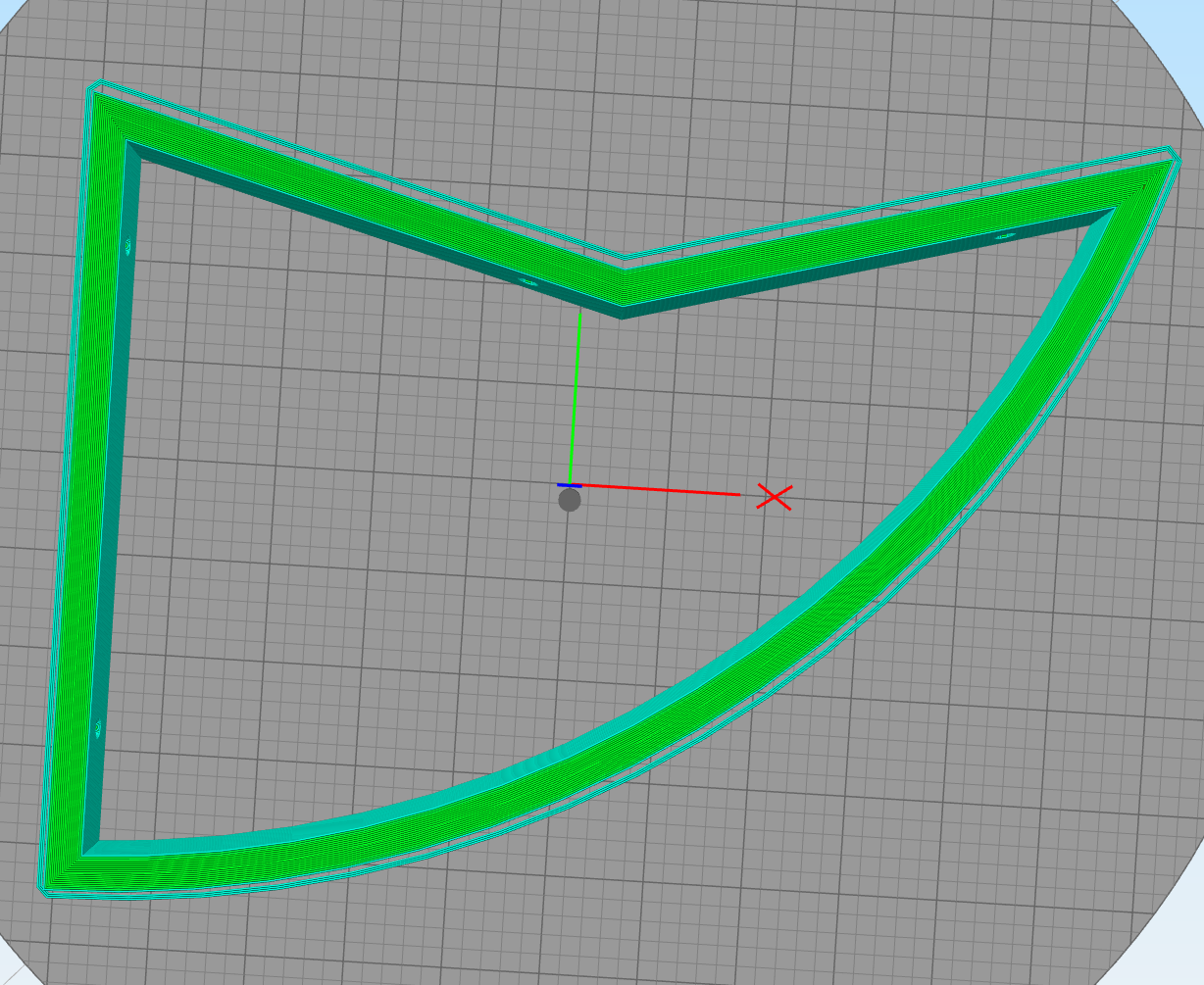

oh and a side note, I just did some quickmafs on my enclosure. It is about 350 liters in volume.