@Phaedrux said in Chiron+Duet3+BlTouch:

It's a bit hard to tell from your copy and paste which files are which. It looks like the homing files got pasted into the config.g portion? And that all might be in the middle of bed.g?

M98 P"homeall.g" ; run home all command

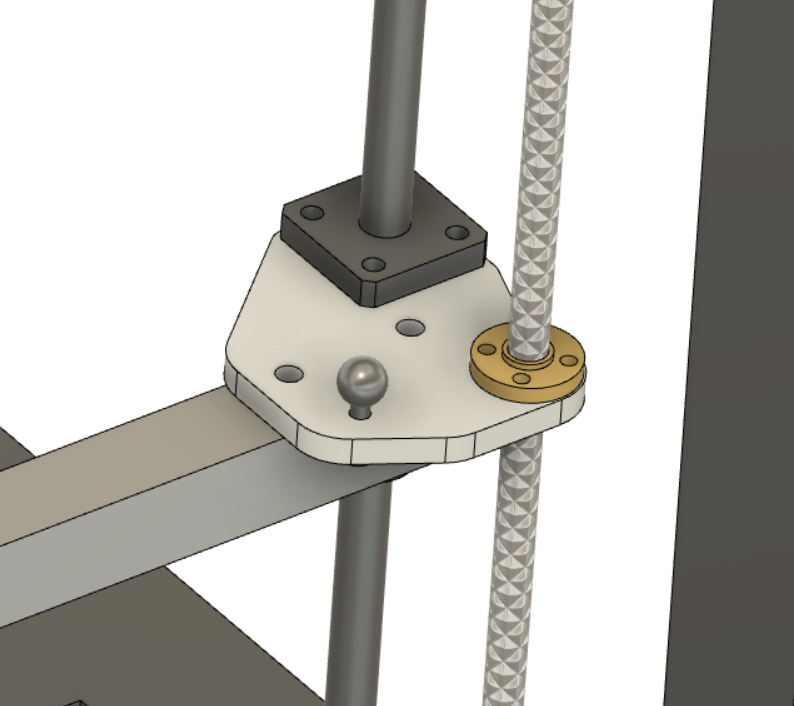

G30 P0 X42 Y0 Z-99999 ; probe near a leadscrew , the left one

G30 P1 X400 Y0 Z-99999 S2 ; probe near oposite leadscrew and calibrate 2 motors

Where is that from?

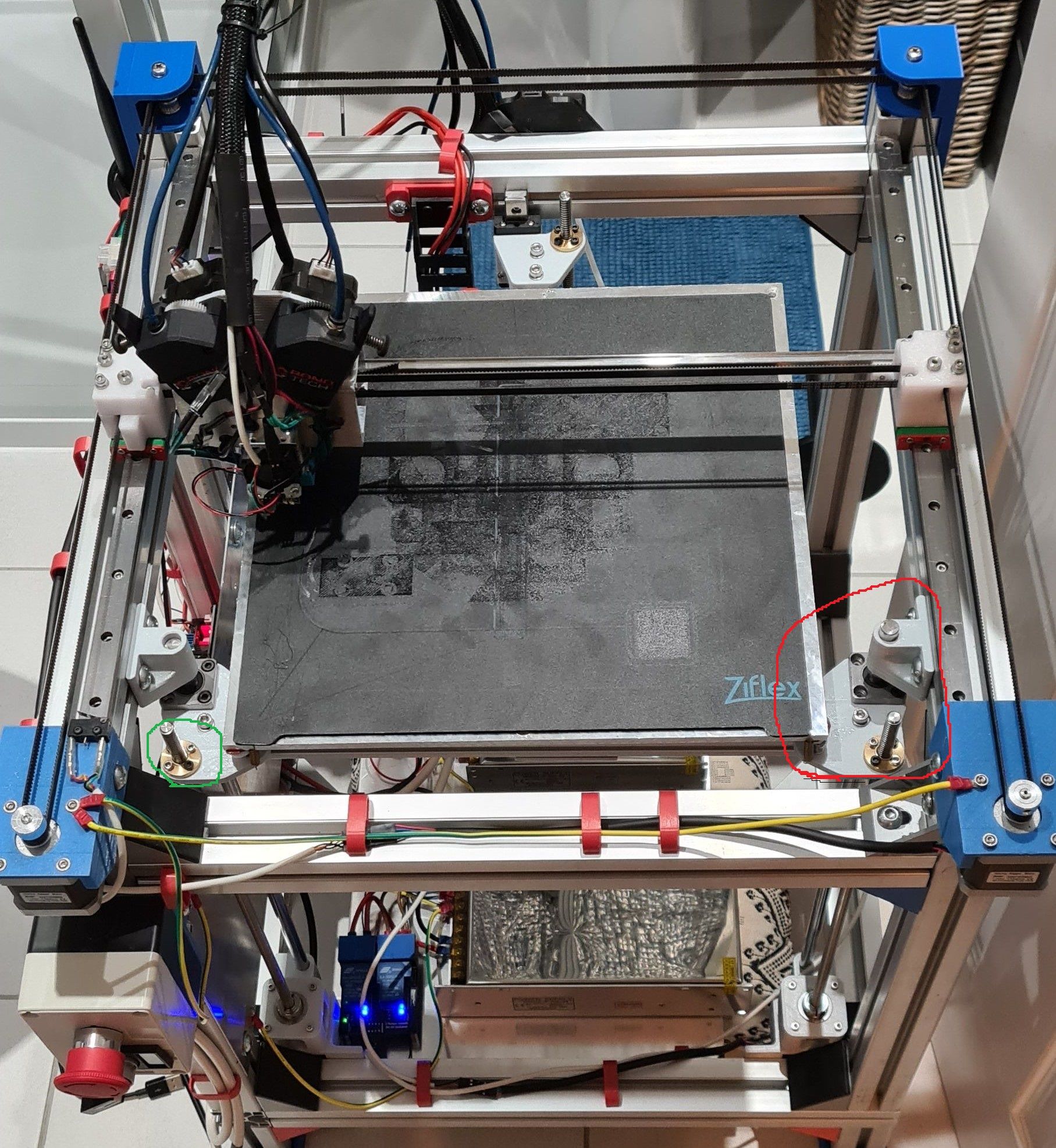

This is just a macro I am using to home all and level the gantry. My plan is/was to use this and after that to run G32 or just a single probe and load height map. I level the bed with the stock endstops because I know they are in the same spot always and to make sure the things are as square as possible. After I am doing this I disable the stock end stops and use only the BLT......because the stock endstops are about 7-9mm above bed surface...still trying to figure out how can I use them always and use the BLT only for mesh compensation

In homeall.g don't use M280 P0 S90 to retract the pin. Use M402 instead. That way the firmware is made aware of the pin retraction.

Ok I will change this.....

Also in homeall and homez, G30 H1 Z-455 F360 is not a valid way to use G30. It's just G30 by itself. The speed is set by the M558 command in your config.g. The H1 etc etc will be ignored probably.

Yes everything is ignored after G30....just copied the normal end stops and changed G1 to G30

bed.g

config.g

config-override.g

deployprobe.g

homeall.g

homex.g

homey.g

homez.g

level_gantry.g

pause.g

resume.g

retractprobe.g

sleep.g stop.g