@hagrid @chimaeragh Completely forgot to post the macros.

Here you go:

Z probe:

M291 P"Make sure the probe is connected and is in position." R"Warning" S3

G91

M563 P49 S"XYZ-Probe"

T49

; M585 Z10 E4 L0 F250 S1

M585 Z10 P1 F250 S1

M400

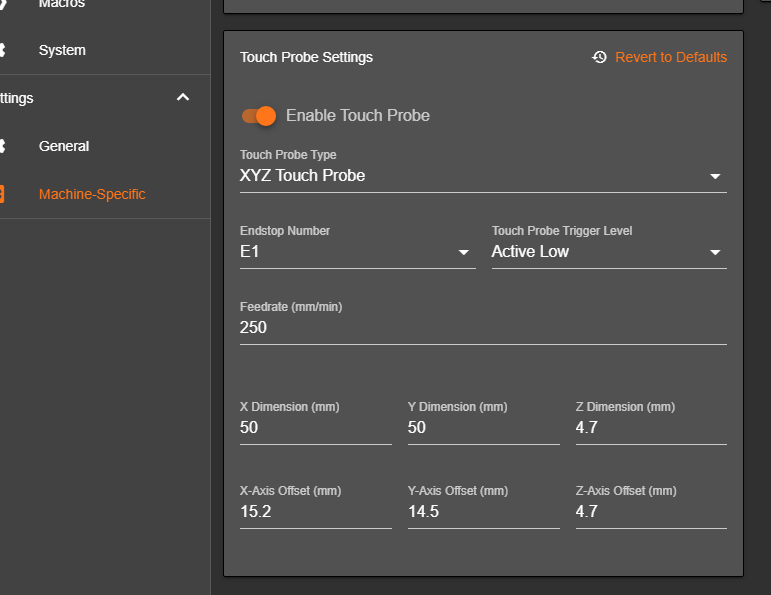

G10 L20 Z4.72 ; Adjust this to match the thickness of your touch plate

G1 Z5 F250

G90

M291 P"Probe complete. Please remove probe." R"Success" S1

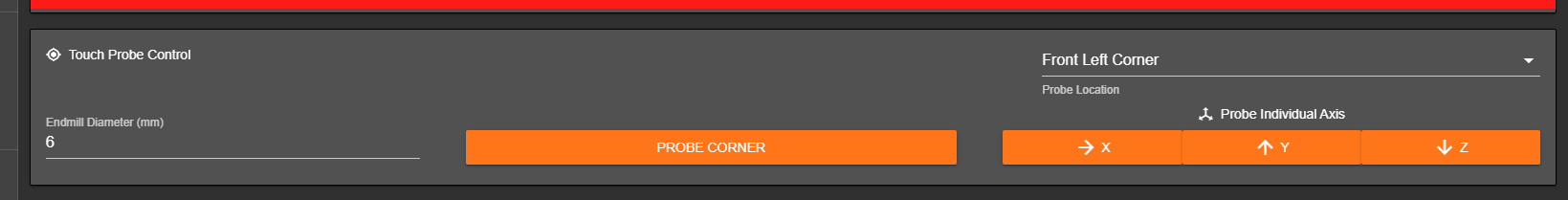

XYZ probe with 8mm bit

M291 P"Make sure the probe is connected and is in position." R"Warning" S3

G91

; M563 P49 S"XYZ-Probe"

;T49

T1

G1 X20 Y20 F500

; M585 Z10 P1 F250 S1

M585 Z50 P1 F250 S1

G10 P1 X0 Y0 Z0

G10 P2 L20 Z4.72 ;Please adjust the Z value here to match the thickness of your touchplate.

G1 Z3 F500

G1 X-50 F500

G1 Z-5.5 F500

M585 X50 P1 F250 S0

G10 P1 X0 Y0 Z0

G10 P2 L20 X-19.3 ;Please adjust the X value to match the X thickness of your touch plate + the radius of the your endmill. Make it negative.

G1 X-3 F500

G1 Z5.5 F500

G1 X50 F500

G1 Y-50 F500

G1 Z-5.5 F500

M585 Y50 P1 F250 S0

G10 P1 X0 Y0 Z0

G10 P2 L20 Y-19 ;Please adjust the Y value to match the Y thickness of your touch plate + the radius of the your endmill. Make it negative.

G1 Y-3 F500

M500

T0

G90

G55

G1 Z8 F500

G1 X0 Y0 F500

M291 P"Probe complete. Please remove probe." R"Success" S1