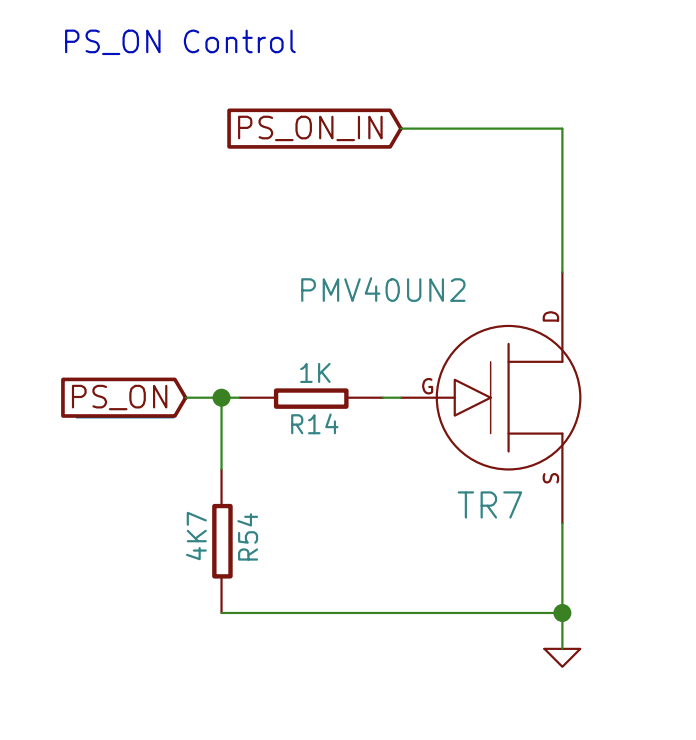

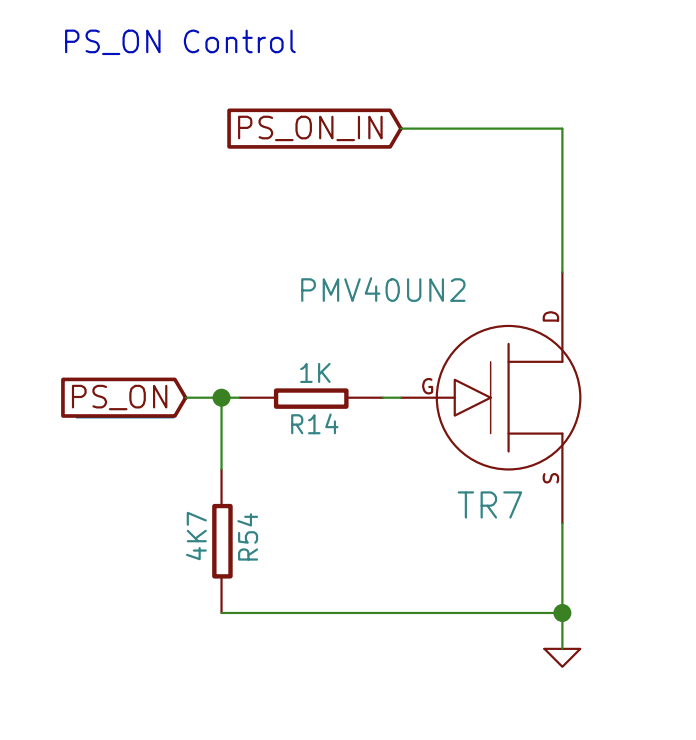

@Danal looks to me as if PS_ON switches PS_ON_IN via mosfet to ground. I think using 12V should not be a problem.

@Danal looks to me as if PS_ON switches PS_ON_IN via mosfet to ground. I think using 12V should not be a problem.

@fcwilt Thanks for the quick help. Changing to relative E distance worked.

I've a custom tool changer build based on Duet 2 Wifi + Duex5, giving me a total of 10 Stepper drivers and all of those drivers are in use.

Now I want to include a stepper driven wiping station for all tools, and would require another driver. Could this be solved with the Dual Stepper Driver Expansion Module from Duet?

@fcwilt Thanks for the quick help. Changing to relative E distance worked.

is there any other work-around? I always thought you are supposed to use absolute extrusion values for higher precision?

Using PrusaSlicer, "use relative E distances" is unchecked. So I guess absolute?

Hi,

I have a tool changer running a prime.g script after picking up a tool.

Prime.g is supposed to brush over the nozzle, purge the nozzle with filament, brush again and start printing.

What I find is happening, that after the purge I'd like to have 3mm retraction, but I get approx. 10mm (10second long, not sure how much). Does anyone see where it comes from?

purge.g:

;brush in

G1 X-23 Y171 F25000

G1 X-23 Y207 F25000

G1 X-23 Y171 F25000

G1 X-23 Y207 F25000

;Park for prime/purge

G1 X-23 Y223 F50000

;Prime

G92 E0

G1 E50 F200 ;extrude 50mm

; HERE: approx. 10s of slow retraction. Why?

G1 E-3 F200 ;retract 3mm

G92 E0

;Run Out

G1 X-23 Y207 F50000

;Brush Out

G1 X-23 Y205 F25000

G1 X-21 Y200 F25000

G1 X-23 Y195 F25000

G1 X-21 Y190 F25000

G1 X-23 Y185 F25000

G1 X-21 Y180 F25000

G1 X-23 Y175 F25000

G1 X-21 Y170 F25000

G1 X-23 Y170 F25000

G1 X-23 Y205 F25000

;brush in

G1 X-23 Y171 F25000

G1 X-23 Y207 F25000

G1 X-23 Y171 F25000

G1 X-23 Y207 F25000

@deckingman Thanks. This solved the heatbed not showing issue.

The heatsink cooler turning on depending on hotend temperature does still not work. Incorporated your changes and tried with S0 and S1. Both did not work for me.

; Configure Heaters and Sensors

M307 H0 ; A65.3 C100.4 D1.1 V23.6 B0 ; disable bang-bang mode for the bed heater and set PWM limit

M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; Configure bed temperature sensor -

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M140 H0 ; Informs the firmware that bed heater 0 (implied, because no P parameter is provided) uses heater 0.

M307 H1 A580.0 C256.6 D6.4 V23.8 B0

M308 S1 P"e0_temp" Y"thermistor" A"Main Nozzle Temp8" T100000 B4725 CC0.0000000706 ; Configure extruder_0 temperature sensor. Attach sensor to e0_temp refer to wiki. Trianglelabs thermistor.

M143 H1 S280 ; set temperature limit for heater 1 to 280C

; Fans

M106 P0 S0 H-1 C"Parts Cooler" ; set fan 0. Parts Cooler on Printhead

M106 P1 S1 H1 T45 C"Noctua" ; Set fan 1 to thermistically. H=sensor number

;

; ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

;

; Define Sensors and Fans - Once you configure the heaters and sensors above, you need to now define their use.

M950 H0 C"bedheat" T0 ; Define heater 0 (bed heater) - bind the bed_heat pin and Temp Sensor 0 together

; as defined above as "P0"

M950 H1 C"e1heat" T1 ; Define heater 1 (hot-end E0) - bind the "e1_heat" pin (default first extruder) and Temp Sensor 1

; together, as defined above as "P1"

M950 F0 C"duex.fan4" Q500 ; duex.fan4=dual blower print cooler

M950 F1 C"duex.fan3" Q500 ; noctua, heatsink duex.fan3 = noctua,

; ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

;

; Set up the Tools, which combine heaters, fans, and sensors to work as one Tool.

; This brings together all the definitions and configurations done above.

M563 P0 S"Main Nozzle" D0 H1 F0 ; define tool 0. Fan 0 operates with an active hot-end

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

;

; ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

;

; Miscellaneous

T0 ; select first tool

M911 S23 R24 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

M501 ; Store parameters

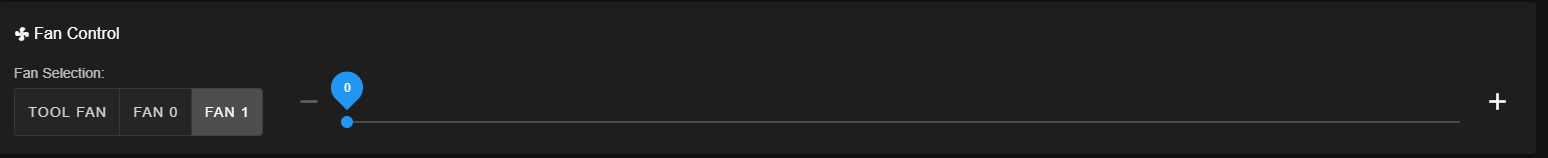

TOOL FAN and FAN0 both control the print cooling fan. Fan1 controls the heatsink fan. No idea why TOOL FAN is there.

@dc42 Release 3.0. Will check on 3.1.1.

Hi all,

I'm having an issue where my heatbed is not visible in Duet Web Control using RRF3. On rrf2.x it was visible.

Any chances I messed something up in config.g? I'm using Duet 2 Wifi + Duex5. Heatbed connected to the dedicated heatbed connectors.

config.g:

; General Global Preferences and critical Drive Configuration Section - These must come before all else.

M80 ; ATX ON

G4 P2000 ; Hold your Horses. Add a little time to allow things to settle and complete.

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

G21 ; Set units to Millimeters

M550 P"Printer2" ; set printer name - change this to whatever you'd like

M584 X1 Y0 Z7:8:9 E3:4:5:6 ; set drive mapping to each axis ---

M669 K1 ; Select CoreXY mode - New format

;

; ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

;

; Network Configuration Section

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

;

; ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

;

; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S0 ; physical drive 3 goes backwards

M569 P4 S1 ; placeholder for unused drive. Erratic behavior can occur if unused drivers are not bound to a driver.

M569 P5 S0 ; placeholder for unused drive.

M569 P6 S0 ; placeholder for unused drive.

M569 P7 S0 ; *EDP* - 1 Drive 7 goes backwards - z-axis: mid left

M569 P8 S0 ; *EDP* - 1 Drive 8 goes backwards - z-axis: front right

M569 P9 S0 ; *EDP* - 1 Drive 9 goes backwards - z-axis: back right

M671 X-33.743:373.743:373.743 Y170:30.5:309.5 S5 ; Set up three Z-axis location

M92 X200.00 Y200.00 Z800.00 E405.18 ; set steps per mm, based on using 0.9 degree steppers for X/Y and 1.8 degree steppers for the Z axis.

M350 X16 Y16 Z16 E16 I1 ; configure micro-stepping with interpolation

M566 X600.00 Y600.00 Z24.00 E300.00 ; set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z600.00 E2000.00 ; set maximum speeds (mm/min) *EDP*

M201 X1000.00 Y1000.00 Z100.00 E5000.00 ; set accelerations (mm/s^2)

M906 X900 Y900 Z900 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

;

; ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

;

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X330 Y330 Z450 S0 ; set axis maxima

;

; ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

;

; Endstops

M574 X1 S1 P"ystop" ; X min active high endstop switch

M574 Y2 S1 P"xstop" ; Y max active high endstop switch

;

; ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

;

M574 Z1 S2 ; set endstops controlled by probe

M558 P1 C"zprobe.in+zprobe.mod" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds

G31 P500 X-2 Y-16.4 Z0.1 ; set Z probe trigger value, offset and trigger height

G30 S-2 ; Set the Home Z by probing Z

;

; ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

;

; Configure Heaters and Sensors -

M307 H0 ; A65.3 C100.4 D1.1 V23.6 B0 ; disable bang-bang mode for the bed heater and set PWM limit

; silicone bed kenoovo with SSR.

M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; Configure bed temperature sensor -

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M307 H1 A580.0 C256.6 D6.4 V23.8 B0

M308 S1 P"e0_temp" Y"thermistor" A"Main Nozzle Temp" T100000 B4725 CC0.0000000706 ; Configure extruder

M143 H1 S280 ; set temperature limit for heater 1 to 280C

; Fans

M106 P0 S0 H1 C"Parts Cooler" ; set fan 0. Parts Cooler on Printhead

M106 P1 S0 T45 H0 C"Noctua" ; Set fan 1 to thermistically.

;

; ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

;

; Define Sensors and Fans -

M950 H0 C"bedheat" T0 ; Define heater 0 (bed heater) - bind the bed_heat pin and Temp Sensor 0 together

; as defined above as "P0"

M950 H1 C"e1heat" T1 ; Define heater 1 (hot-end E0) - bind the "e1_heat" pin (default first extruder) and Temp Sensor 1

; together, as defined above as "P1"

M950 F0 C"duex.fan3" ;Q500 ; Define Fan_0 for use - Parts Cooler on Printhead - 4010 fan

M950 F1 C"duex.fan4" ;Q500 ; noctua, heatsink

; ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

;

; Set up the Tools

M563 P0 S"Main Nozzle" D0 H1 F1 ; define tool 0. Fan 0 operates with an active hot-end

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

;

; ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

;

; Miscellaneous

T0 ; select first tool

M911 S23 R24 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

M501 ; Store parameters

Additionally, my thermostatically regulated fan on the e3dv6 heatsink is not working (12V fan plugged into duex.fan4. Not using Duet 2 Wifi ports due to system on 24V, fans on 12V). In case someone is able to spot the mistake there. Thank you for your help.

I've also been unable to get the dyze thermistor working on rrf3. If anyone found a solution, I'd be happy to hear it.

For anyone interested: the second drawing/image works. However, the Ground Pin on Duet 2 Wifi next to PS_ON had to be connected to power supply ground. I am, however, unsure why that's the case.