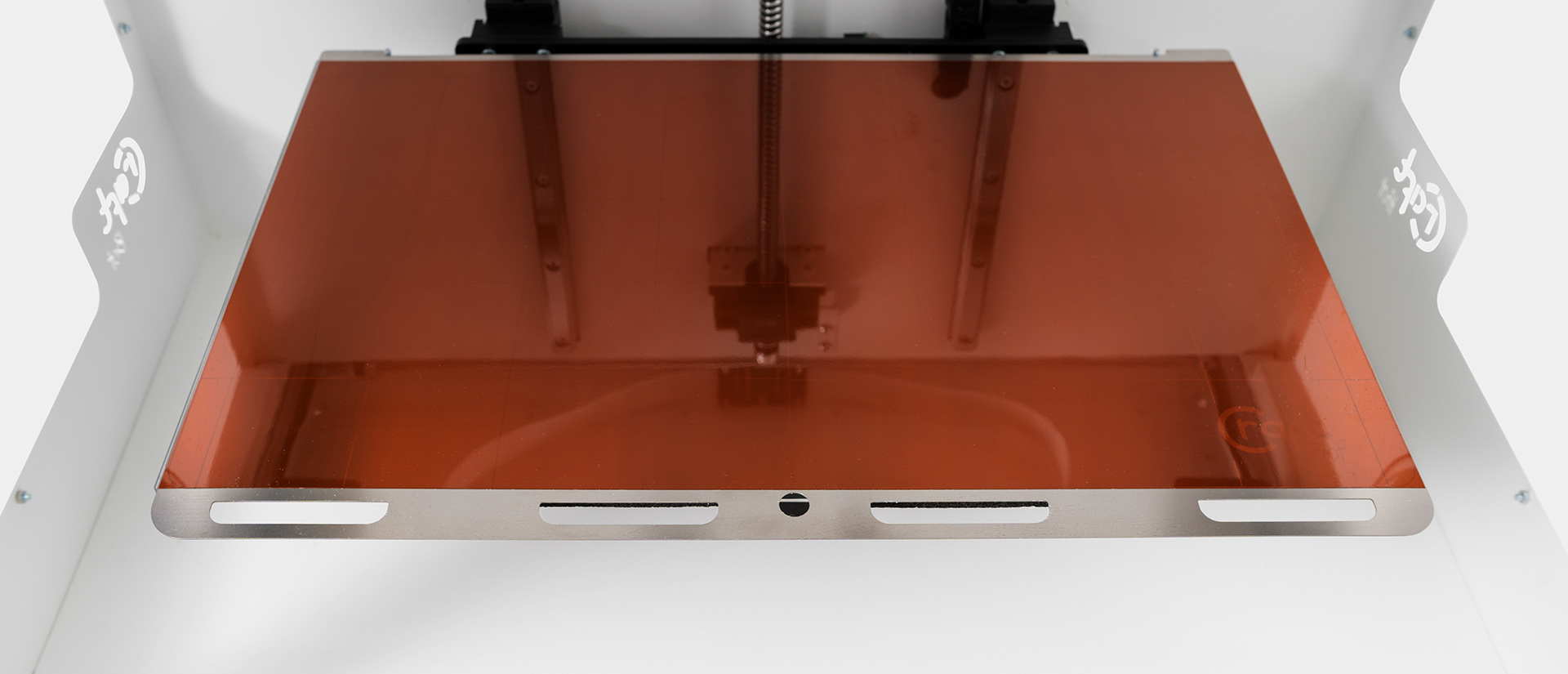

@dc42 The whole point of what I am asking is that the tool offsets are found automatically without the need for the user to print a veneer or any other shenanigans. The cavity is only available on the first layer.

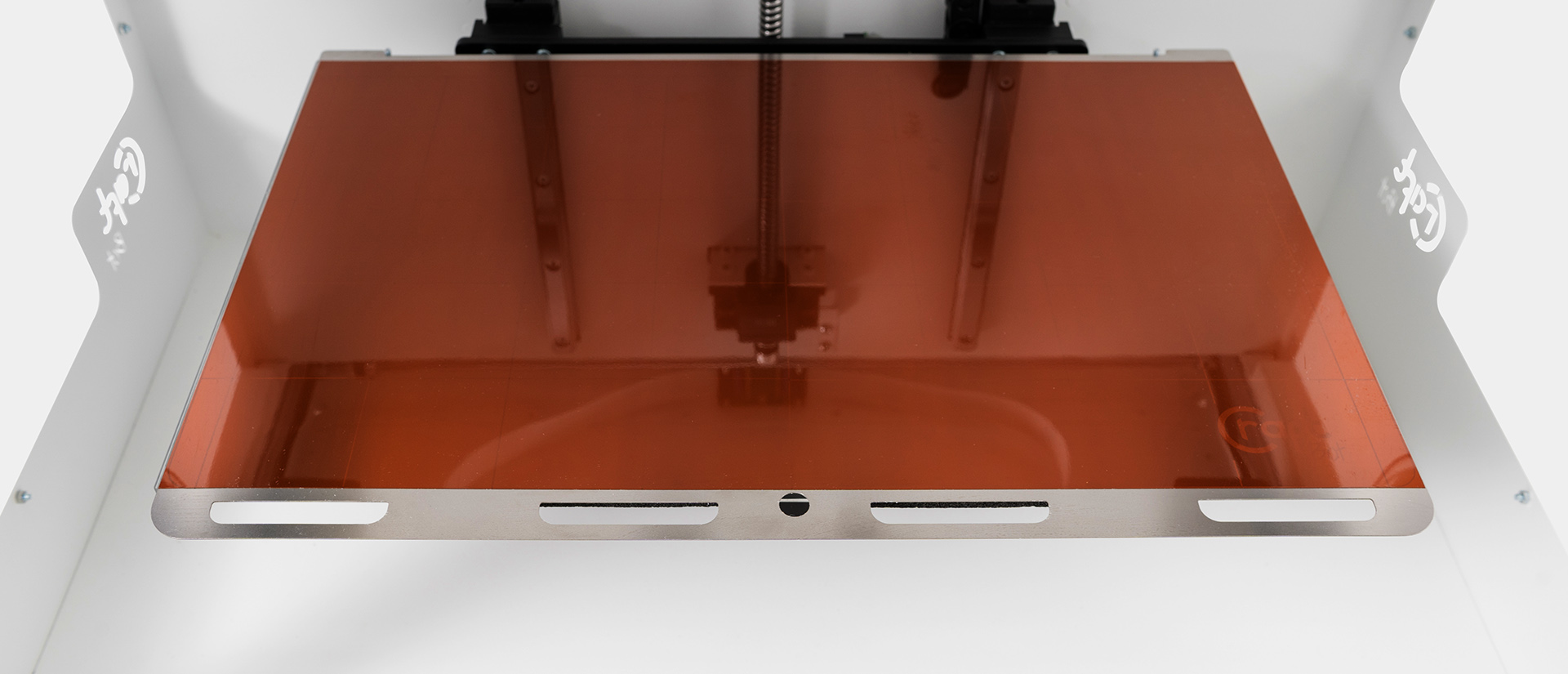

This is a machine that has an identical feature. They allow the user to run probing on that cavity when the machine falls out of calibration instead of having to waste tons of time finding offsets. The machine then stores these values.

My idea behind running this homing at the start of each print is simply so that the user never has to worry about the machine falling out of calibration, making the alignment completely hands-free, completely automatically. The user simply has effortless dual material printing experience.

The next step is enabling servo lifting on the two nozzles so that they automatically maintain themselves in that axis.

In my case I have 10 idex machines. I have not ever considered using dual material mode as maintaining an accurate calibration on 10 machines is completely unsustainable without it being automatic or wasting tons and tons of time. Adding a cavity to probe? Now that is a cakewalk.

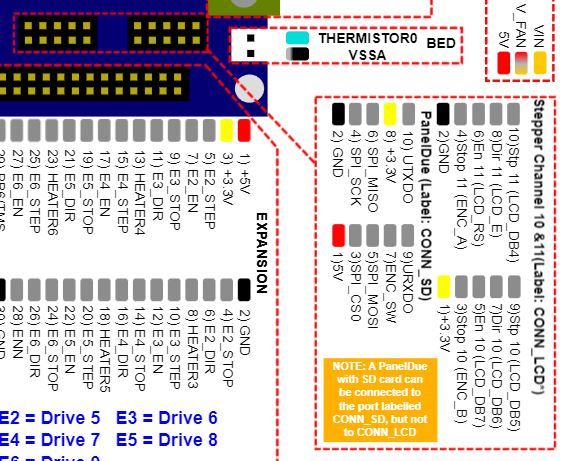

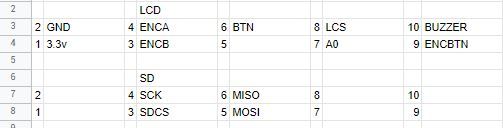

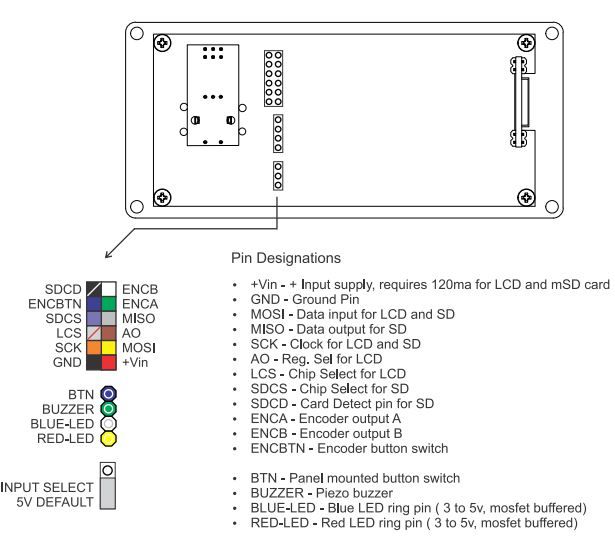

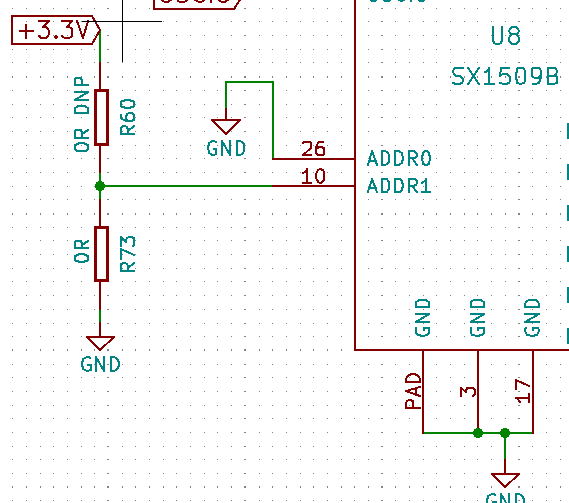

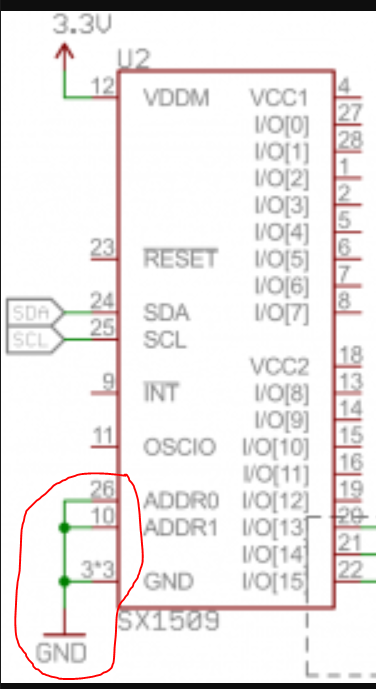

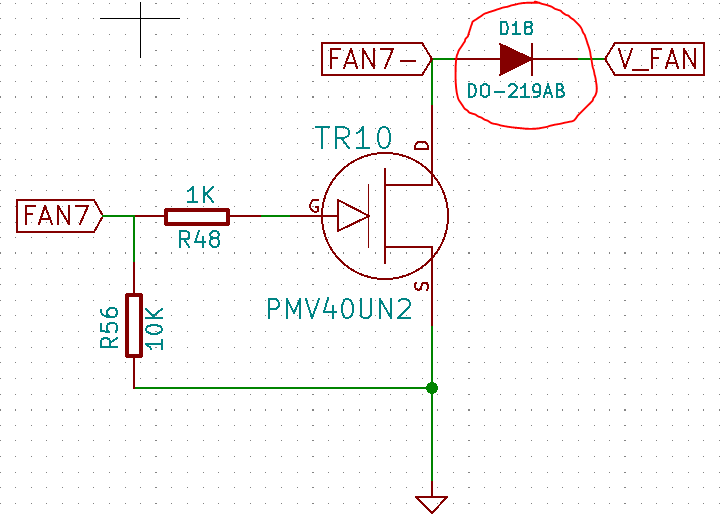

just need to wire it properly, call it in config.g and create the menus.

just need to wire it properly, call it in config.g and create the menus.