@bot The reason I say it is terrible is complicated. While functional and useful, I am unsure of the marketability of the product. Other similar designs offer different advantages that may be preferable to most other people.

Honestly it is quite alarming how little I know about getting this to work at a firmware level. Any tips on where I could get better guidance?

If you are interested I wrote a little about it in response to a strictly theoretical build. While I have not received all the pieces to my machine from the machine shops, I regard my design as functional given that myself and two senior level engineers, one with a doctorates in mechanical engineering, have reviewed the design. Furthermore I have done extensive FEA on the assembly with a safety factor of 5 for a total deflection of 0.2mm on the Z, and 0.02mm on the X/Y axis. The critiques on my final design were in fine alignment and assembly, not mechanical functionality. It has been completely re-engineered 5 times.

"I have engineered an H-bot motion system. The reason my design works and this design will not is due to FEA. If you ran FEA on this design it would not be stiff at all.

Not to mention you would never actually be able to assemble this due to all of the excess rails. Getting them all aligned would be a nightmare. Not to mention you have all your pulleys and motors cantilevered outside the frame. You have all of the extrusions running the thin way where all of the twisting moment is applied to the y carriages.

Look at how the makerbot replicator H bot is designed. These are engineers from stratasys if I am not mistaken.

My H-Bot design is infinitely more stiff and requires no more space than a coreXY because of the type of pre-loaded linear rails I used and in what orientation I used them. Christ, I have them bolted to a half inch of blanchard ground steel almost a foot wide stretching the length of the machine reinforced by two 50x100mm aluminum extrusions and the rest of the machine is built with 40x120mm. Bear in mind, this is a large machine.

Having an IDEX H-bot is a mistake from a complexity standpoint, this did not stop me from trying. I mounted the pullies with roller bearings on 12mm steel rod with polymer bushings in between. Yes you can get it to work, but to what end? Two printers for the price of 1 but at 4x the cost of a simpler design? There would need to be strong motivation, like high precision and speed milling operations to warrant such a design.

CoreXY is not as accurate as H-bot simply because when you have the rigidity required for high accuracy, H-bot is simpler to design. Unfortunately, for using H-bot in 3d printing specifically, 3D printers are not required to be high accuracy. It is a very messy process, there is no benefit from having high precision.

As for speed, H-bot wins again. When you have enough stiffness, you can use huge motors. To re-iterate, H-bot is easier to engineer when you have enough stiffness. You need to take advantage of that stiffness if you do not want to lose speed.

Speaking of cost the original makerbot cartesean system is far superior to all the other 3d printing specific designs. You can make 10 adequate sheet metal cartesean machines for the price of one high-precision H-bot machine not including the labor intensive process of FEA engineering the H-bot. It took me a full year to design a great H-bot when I could have designed an adequate sheet metal machine of the same size in a few months. Granted it would need to have the Z axis bolted to a cement wall, or have multiple lead-screws ( eww ).

The motivation for my exercise in futility, encase you had not guessed, was space and time. I have space and electricity for one painfully large 500kg, 35A of 220V machine, not two. Furthermore, I want highly dimensionally accurate parts fast in PEEK, PEI, and PC. I cannot waste time and money playing with taking a part off the printer onto a $30,000 CNC I dont have. Ontop of that, I want to be able to have the option of having two half sized machines when I do not need the full build envelope. Hell, maybe other people feel the same way. Maybe they will pay top dollar for my work."

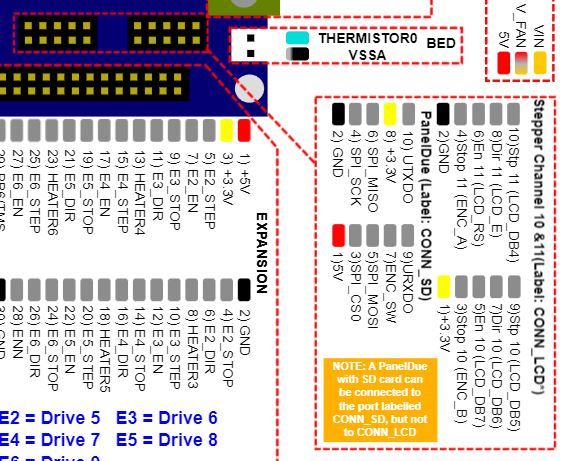

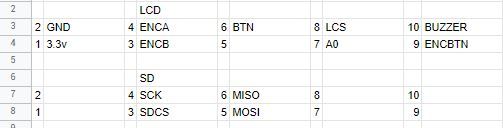

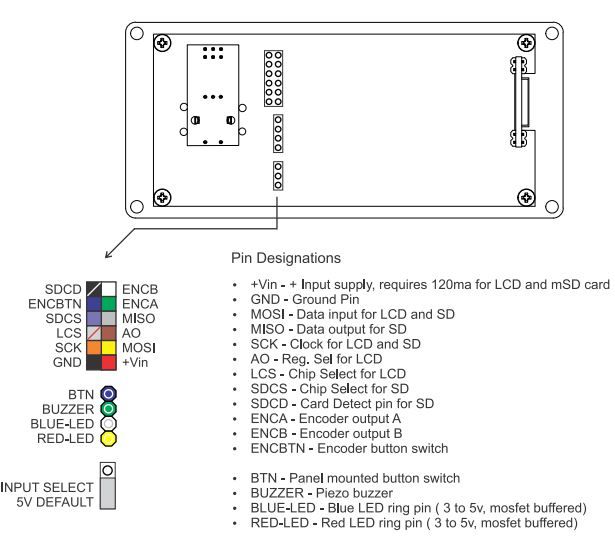

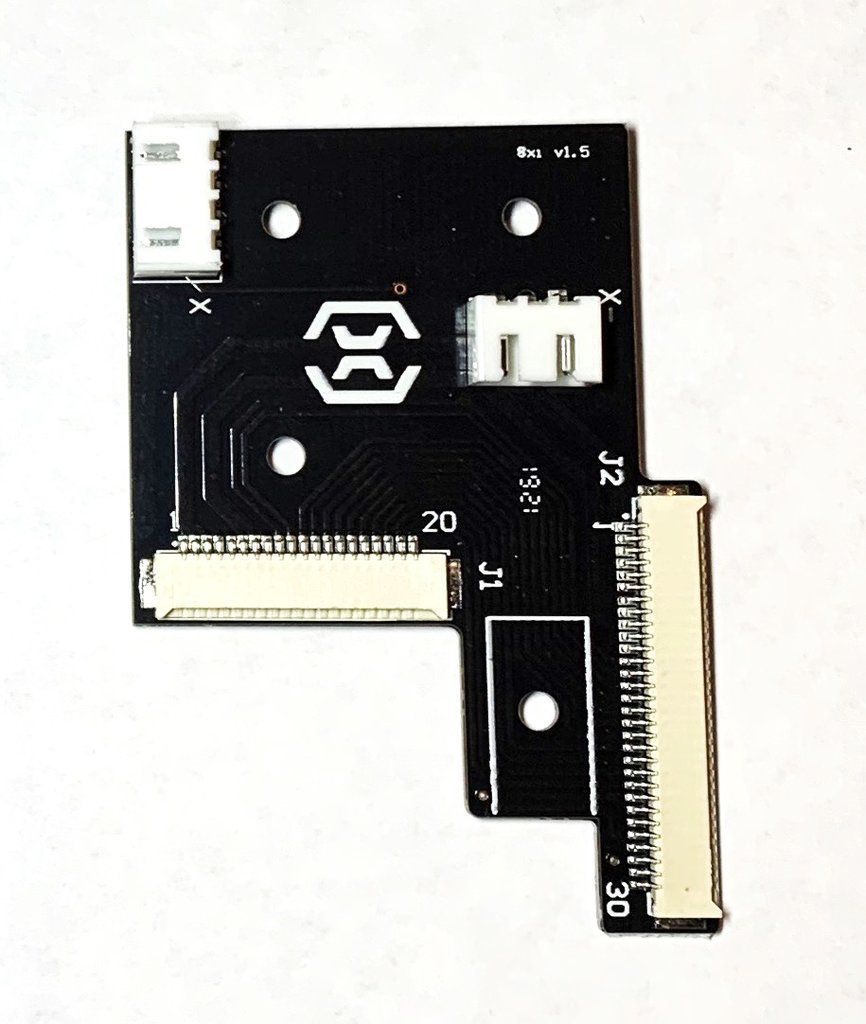

just need to wire it properly, call it in config.g and create the menus.

just need to wire it properly, call it in config.g and create the menus.