Evening all I recently swapped out the bltouch sensor for an aus3d ir sensor I'm getting some random homing heights.

I have it wired into the z probe connector on the duet wifi 2 board with the connector viewed at the bottom from left to right yellow black green and finally red.

Is there likely to be anything residual in the settings ?

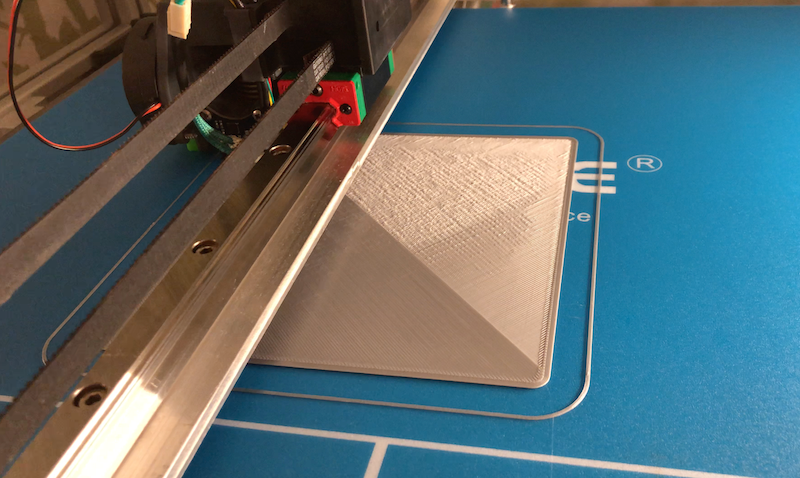

I'm using a cctree (textured blue surface) wondered if this could be causing an issue!

Just wondered if i had covered all my bases before suspecting the sensor at fault have attached my config is there anything I should enter g code wise prior to executing the G28 command within simplify to home all .

It looks as if its doubling my z height as it looks to start printing where it should be starting from lol

; Configuration file for Duet WiFi (firmware version 2.03)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.2 on Tue Nov 12 2019 21:26:56 GMT+0000 (GMT)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"COREXY" ; set printer name

M669 K1 ; select CoreXY mode

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z1600.00 E420.00 ; set steps per mm

M566 X600.00 Y600.00 Z120.00 E300.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z600.00 E1200.00 ; set maximum speeds (mm/min)

M201 X1200.00 Y1200.00 Z500.00 E1000.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z2000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X-220 Y-220 Z0 S1 ; set axis minima

M208 X220 Y220 Z660 S0 ; set axis maxima

; Endstops

M574 X1 Y1 S0 ; set active low endstops

M574 Z1 S2 ; set endstops controlled by probe

; Z-Probe

M558 P1 H3 F150 T6000 A5 S0.015 ; set Z probe type to modulated and the dive height + speeds

G31 P25 X2 Y32 Z4.55 ; set Z probe trigger value, offset and trigger height

M557 X-205:215 Y-205:195 S20 ; define mesh grid

; Heaters

M140 H-1 ; disable heated bed

M305 P1 T100000 B4725 C7.060000E-8 R4700 ; set thermistor + ADC parameters for heater 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C

; Fans

M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T30 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

; homeall.g

; called to home all axes

;

; generated by RepRapFirmware Configuration Tool v2.1.2 on Tue Nov 12 2019 21:26:56 GMT+0000 (GMT)

G91 ; relative positioning

G1 Z15 F6000 S2 ; lift Z relative to current position

G1 S1 Y-445 F1800 ; move quickly to Y axis endstop and stop there (first pass)

G1 Y5 F6000 ; go back a few mm

G1 S1 Y-445 F360 ; move slowly to Y axis endstop once more (second pass)

G1 S1 X-445 F1800 ; move quickly to X axis endstop and stop there (first pass)

G1 X5 F6000 ; go back a few mm

G1 S1 X-445 F360 ; move slowly to X axis endstop once more (second pass)

G90 ; absolute positioning

G1 X0 Y0 F6000 ; go to first bed probe point and home Z

G30 ; home Z by probing the bed

; Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 S2 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioning