@oliof done, ordered. Thanks for pushing me that direction.

Filastruder is running a 20% off sale, perfect timing.

@oliof done, ordered. Thanks for pushing me that direction.

Filastruder is running a 20% off sale, perfect timing.

@oliof said in Upgrade Duet2 Wifi - add the Duex5 or Duet3 Mini with 2+:

@SuperJETT for future proofing, the Duet3mini plus 2 stepper expansion is the way to go IMO.

EDIT: It also means you get to keep your old printer running while the new one is being built.

Good points, thanks.

I have had my Duet 2 Wifi since Feb 2017, still a workhorse and love it, but I'm building a new printer with 3x Z motors so need some extra steppers.

I also have a Chameleon (that I haven't touched in 2 years) that I control with a small pancake motor that activates a switch instead of moving the gantry to hit a switch.

X, Y, Z1, Z2, Z3, E, Chameleon means I need 7 steppers total.

Opinions? Money is a factor, but not the biggest one probably. No matter which option I go with, I'm going to have have an extra board.

I'm still running my original Duet 2 Wifi I bought in February 2017. It's still amazing for my needs (self-designed CoreXY).

I'm rarely on this forum nowadays because my printer just works, firmware upgrades (nowadays) are pretty simple and so sophisticated at the same time, and I just haven't needed support in a while.

I'm just thankful I jumped on 'semi-early' I guess? Back then, Duets were fairly rare and when I'd post a pic of the web interface in a group somewhere people would be amazed and ask what it was. Now, there is more competition but it's still there at the top IMO.

Looking in the Firmware forum, I would guess I was on v1.17 or something at the beginning, currently on 3.4.6. That's a big jump. There were a few hiccups with firmware versions along the way, but the community and company worked together to get through them, continually improving.

No real point to this post, just kind of a shout out to the product and people. @dc42 and @Phaedrux are legends in this world to me.

@fcwilt Like mentioned, it takes time for the movement to go hit the switch, so this would eliminate those moves each color change.

I have a few different ideas, but what would be the best way to have the Duet control a 3D Chameleon electronically instead of moving the gantry to hit a limit switch?

The Chameleon is triggered by a limit switch which takes time for the gantry (or whichever part you use to hit it) but since that takes time for the movement, I'd rather be able to just turn a pin on/off.

Best way?

I'm actually considering using E1 with a motor and an arm on the shaft to hit it because that will give me the ability to physically trigger the switch instead of having to use a macro, but macros would be pretty easy too so I'm exploring that option.

Thank you so much Phaedrux. You are a legend in my book. I was pretty frustrated but wanted to give another last ditch effort before ordering a Maestro (which would have been a step down since I do use sensorless homing) and your post helped motivate me.

Wow.

I had tried 2 different 'known good' cables on both my gaming desktop and work laptop and never got the port to recognize, no Windows tone, nothing, but as a last resort I grabbed another USB cable here at work and just got the port to recognize.

Baffled.

The rest should be easy...

But seriously, always keep trying. (I had been working on this since Saturday trying all the troubleshooting steps but if you can't get the port to appear, it's hard)

@Phaedrux

Here's where I am:

plugged into 5v power supply or computer, 5v lit, 3.3v lit, USB lit, and DIAG lit. The reset button is not stuck, appears to operate properly. The wifi module has a small blue LED lit. This is with or without the SD card installed.

With my Paneldue plugged in, it loads the main screen but says Connecting in top right. I can go to the Console and enter M997 S1 but get no response.

The LEDs that are lit never change no matter what I do.

I'm fairly frustrated that it has died in under 4 years. Had I been running high currents or printing 24/7 or had some wiring issues, I might understand it, but for a (relative to others) expensive board to fail this soon to me is surprising and disappointing.

I was on firmware 2.0.5 and started having a loss of connectivity through network and Paneldue would lose connection also. This wasn't that big of an issue except this weekend I needed to do a couple of multicolor prints with filament changes and on the first one it was locked up when hitting the pause.

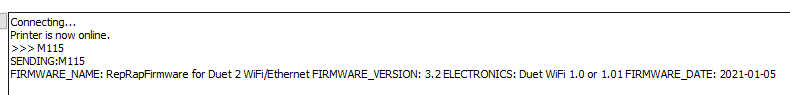

So, I figured I needed to finally go to v3 then v3.2 The update to v3.0 was fine, M115 reported the correct firmware so I uploaded v3.2 and lost all connectivity. No wiring changes were made during any of this, it was installed normally and I had just finished that failed print 30 minutes prior.

I've tried a full erase/reset, commented out M552 in config.g, but am stuck with the 5v, 3.3v, DIAG, and USB leds lit and no connection via wifi or USB. I've tried multiple USB cables and ports but am fairly certain it's just dead.

I bought it in Feb 2017 which is almost 4 years of excellent printing running fairly low current steppers and not printing that often, maybe a few hours/week average except for doing faceshields last year for hospitals and a few other times.

Any other suggestions to try to recover it?

Also, was it just at its EOL? I expected it to last a lot longer than 4 years.

What's next, a Maestro or go to a SKR Mini E3 maybe? I'm not sure I want/need to shell out the money for another Duet. I do have a Paneldue, but it's the second of those as my first died after about a year.

I do a ton of color changes in my prints and have for years. Recently after updating to 2.05 I'm seeing a layer shift after color changes that I've never had before. My pause.g is the same, no changes to config.g before/after the firmware update. Same Titan Aero, same process I always do, etc.

Is anyone else seeing this? I'm running another print right now and will watch it carefully.

I've given up on dual extrusion for now, even went into config.g and commented out all of the lines related to the second extruder.

I tried a different 2-1 adapter (linked above by @Scachi ) but same results - likely from my all metal hot end but who knows. I have done exactly 1 dual color print successfully, about a year ago, and I think that was luck because there are just so many variables to deal with when trying a 2-1 setup.

A dual nozzle hot end won't work for a lot of the stuff I sell (I do some stuff on Etsy, custom personalized designs) because they tend to have flat tops and the second nozzle would mess up the finish too much for me.

I'll revisit IDEX one day when I feel like completely redesigning my printer. Thankfully I have a printer in my office if I need to make parts while mine is down.

Thanks everyone for the help/suggestions.

@scachi Thank you for the links and your code.

I yank 3mm, ram it back in just under 3, wait 2 seconds, then yank 20 and ram 20 then yank 110mm total.

During testing it works great, the filament ends looks great, everything is very smooth, but during printing it eventually has a bad stringing change at some point, normally once it gets out of the bottom solid layers so the layers print much quicker which may be part of the problem.

@danal Yeah, Palette is super nice but a bit beyond what I'm wanting to spend right now - I'm revamping my lens collection as I'm getting more serious about photography.

@scachi said in Best dual extrusion setup in your opinion?:

I had a magnetic dual tool parking tool based on one from thingiverse https://www.thingiverse.com/thing:1446731

modified to work on my old anycubic prusa i3 clone without losing print area.

It was working very good once the tool offset was adjusted correctly.

Here are a few pictures of it (bowden): https://imgur.com/a/ZCPiut0

I used it with direct extruder too: https://www.thingiverse.com/make:462322I have changed to a core xy with a bigger print area and using a y-adapter for now as I would have to change a lot on the carriage system to get a magnetic tool change working again similar to the one I had on my anycubic.

Haven't used the dual y-adapter a lot but seems to be working ok.

The magnetic one was a lot more fun and less settings (less retraction on tool change, no puge/prime) to care about.

@Scachi Can you share your tfree/pre/post files so I can compare against them?

Thank you both for the input. IDEX is one option I forgot to include but something I'm not opposed to.

I'm ready to make a change, again. I built my corexy a while back, Duet powered from the beginning, originally with a Titan Aero then switched to Bowden with E3D V6, then added a second extruder and have messed with a 2-1 splitter A LOT but like most people can't get it consistent.

So, what should I do?

get my 2-1 working properly

E3D Chimera

E3D Cyclops

Give up on dual extrusion

I do lots of multicolor prints and design my parts to faciliate changing color at a specific layer but would rather have some of my stuff true 2 color which is why I keep revisiting this.

My current setup: 2x SeeMeCNC EZR-struders (love them), 1.9mm PTFE tubing to an SLA printed 2-1 splitter I designed that works great really, genuine E3D V6.

I can do tool changes one after the other with extrusions between, but when I do an actual print the tip of the filament ends up a different shape and eventually jams in the splitter.

Cool stuff. I know from being a PLC programmer years ago that there had to be a something that would limit an axis but wasn't sure what.

Thanks for indulging the question.

What math limit would prevent going any larger on a printer from the Duet's perspective? How big would it be?

I just got my tfree/pre/post working over the weekend, so this might help:

EDIT: David corrected my info in the following post

I'm not currently home so I can't post my code.