Good day to you fellows!

I thought I could get this to work on my own but now I'm at a point where I don't know how to solve this or what causes this problem.

I can't deploy or retract the probe nor do a selftest via M280 P7S120.

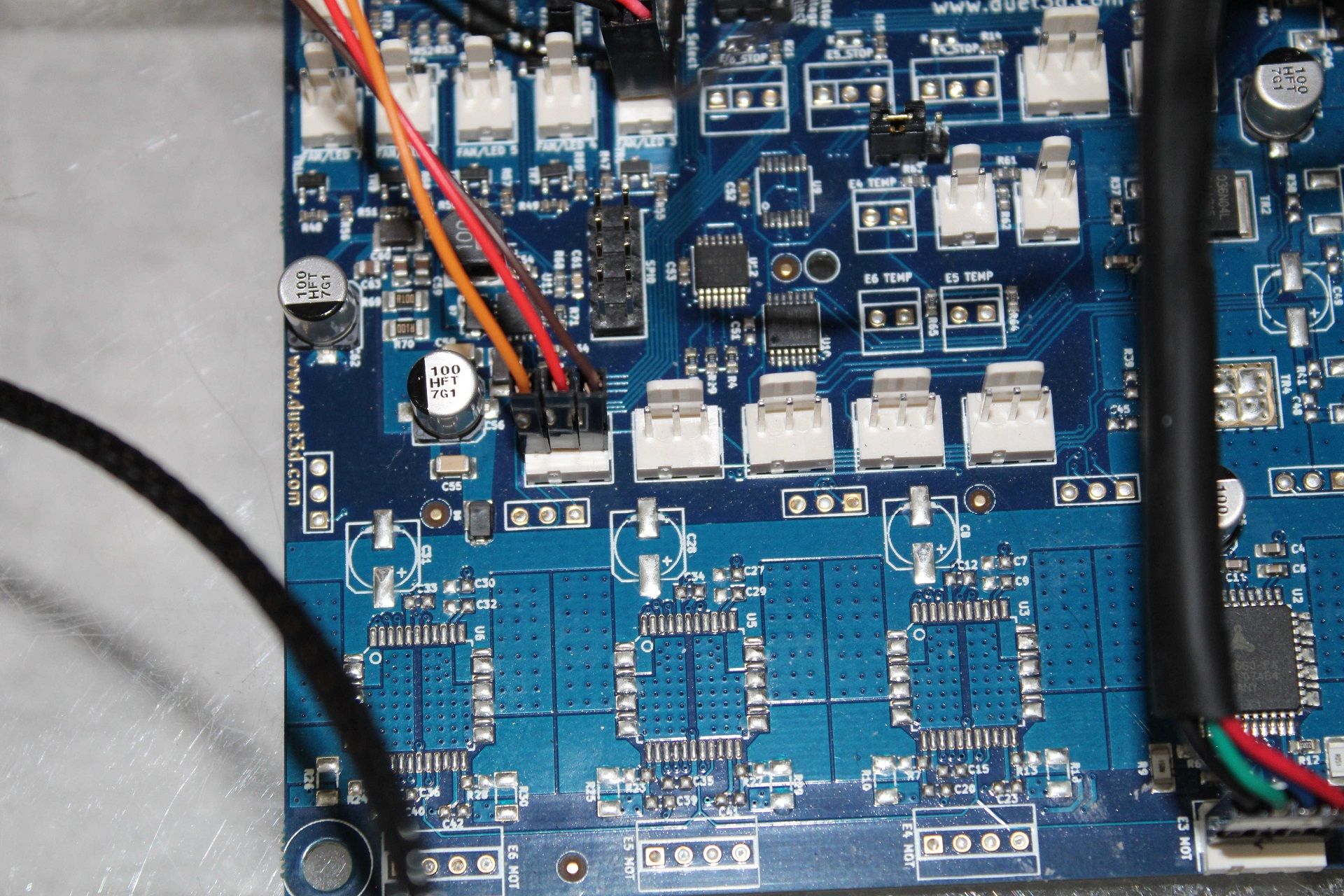

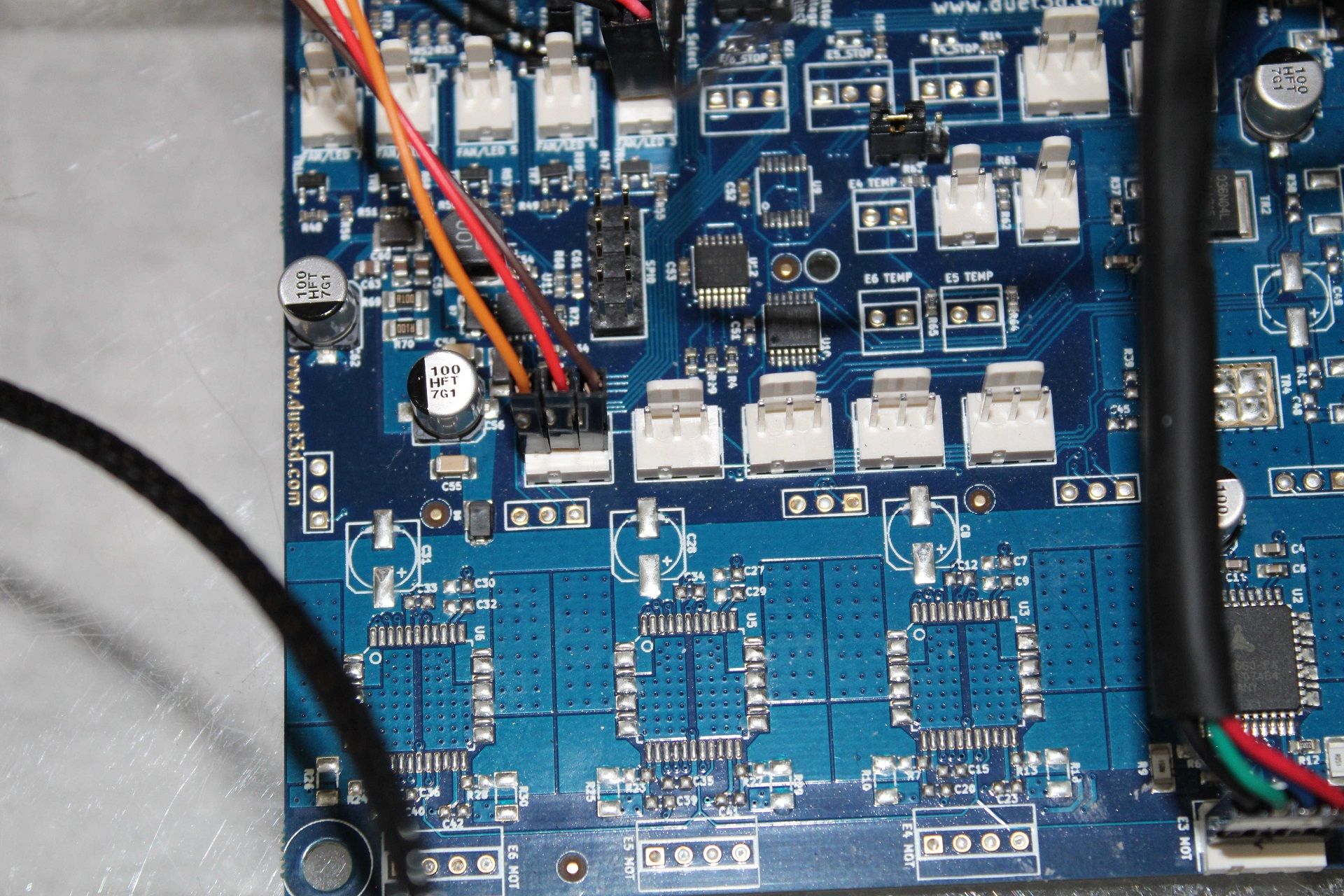

My Setup is a Duet WiFi 1.02 with a DueX2. I'm using the Firmware version 2.05.

The BLTouch is working and does a self test on startup.

This is my second printer with a BLTouch and I've tested the Sensor with the wires hooked up to my second printer. It works!

If I detache the DueX2 and wire it directly to the H7 pin like in the description on betrue3d.dk and also Invert the signal it works perfect!

If I connect the DueX2 again, wire all up like I should and don't invert the signal it doesn't work.

deployprobe.g and retractprobe.g is in the sys folder.

Here is my config.g:

; General preferences

M111 S0 ; Debugging off

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M555 P1 ; Set firmware compatibility to look like RepRapFirmware

; Machine Informations

M669 K1 ; Select CoreXY mode

M208 X0 Y0 Z0 S1 ; Set axis minima

M208 X400 Y225 Z250 S0 ; Set axis maxima

; Endstops

M574 Z0 S2

M574 E0 S0 ; Set active low endstops

M574 X1 Y1 S1 ; Set active high endstops

M558 P9 X0 Y0 Z1 H5 F600 R0.05 A2 B0 T14000 ; Set Z Probe to type Switch or Digital output where Z probe connector is used. Used for z only.

;Offset for E3D Nozzle

G31 P500 X0 Y100 Z0.0 ; Set Z probe trigger value, offset and trigger height

; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S0 ; Drive 3 goes forwards

M569 P5 S1 ; Drive 5 goes forwards

M569 P6 S1 ; Drive 6 goes forwards

;3-Z config

M584 Z2:5:6 ; Driver 2,5,6 for the three z-axis

M671 X-55:455:200 Y5:5:288 S10.0 ; defines leveling screw locations

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80 Y80 Z1600 ; Set steps per mm

;M92 E2700 ; Nimble

;M92 E418.35 ; Belted Extruder

;M92 E418.5 ; E3D Titan Aero

M92 E418 ; Bondtech BMG

M566 X500 Y500 Z200 E1200 ; Set maximum instantaneous speed changes (mm/min)

M203 X40000 Y40000 Z600 E12000 ; Set maximum speeds (mm/min)

M201 X3000 Y3000 Z200 E1500 ; Set accelerations (mm/s^2)

M906 X750 Y750 Z700 E700 I20 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Heaters

M301 H0 S1.00 P10 I0.1 D200 T0.4 W180 B30 ; Use PID on bed heater (may require further tuning)

M305 P0 T100000 B3988 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4725 C7.06e-8 ; Set thermistor + ADC parameters for heater 1

M143 H1 S310 ; Set temperature limit for heater 1 to 310C

; Tools

M563 P0 D0 H1 F3 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

; Disable heaters for free PWM channels

M307 H7 A-1 C-1 D-1 ; Disable heater 7 for BLTouch PWM pin

; Network

M550 Pbig_one ; Set machine name

M552 S1 ; Enable network

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet

; Fans

M106 P0 S255 I0 F400 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

;M106 P3 S0 I0 F400 ; Set fan 4 value, PWM signal inversion and frequency. Thermostatic control is turned on

; Custom settings are not configured

M501

Also my config-override.g file:

; This is a system-generated file - do not edit

; Heater model parameters

M307 H0 A90.0 C700.0 D10.0 S1.00 V0.0 B1

M301 H0 P10.0 I0.100 D200.0

M307 H1 A438.1 C214.5 D6.0 S1.00 V24.1 B0

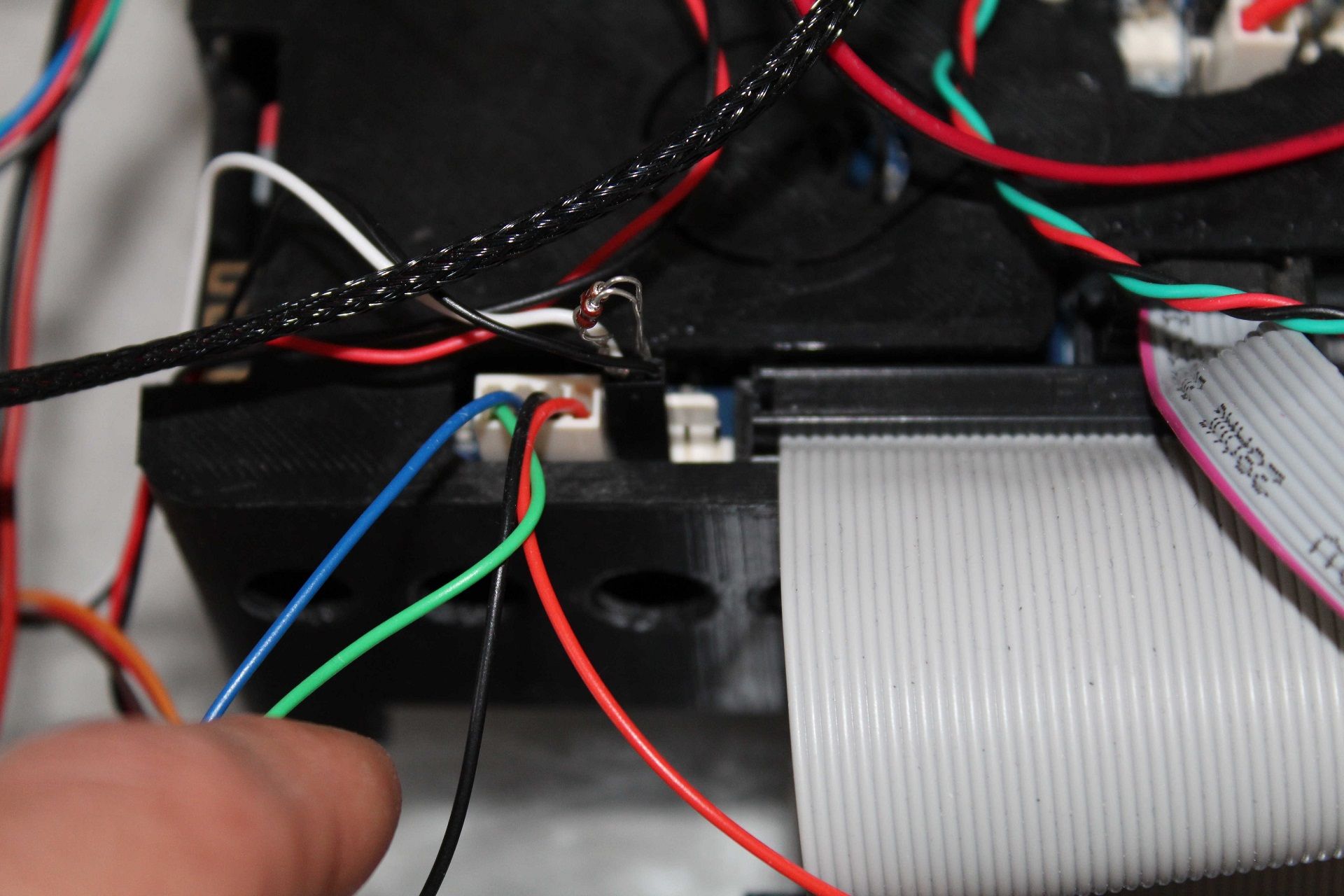

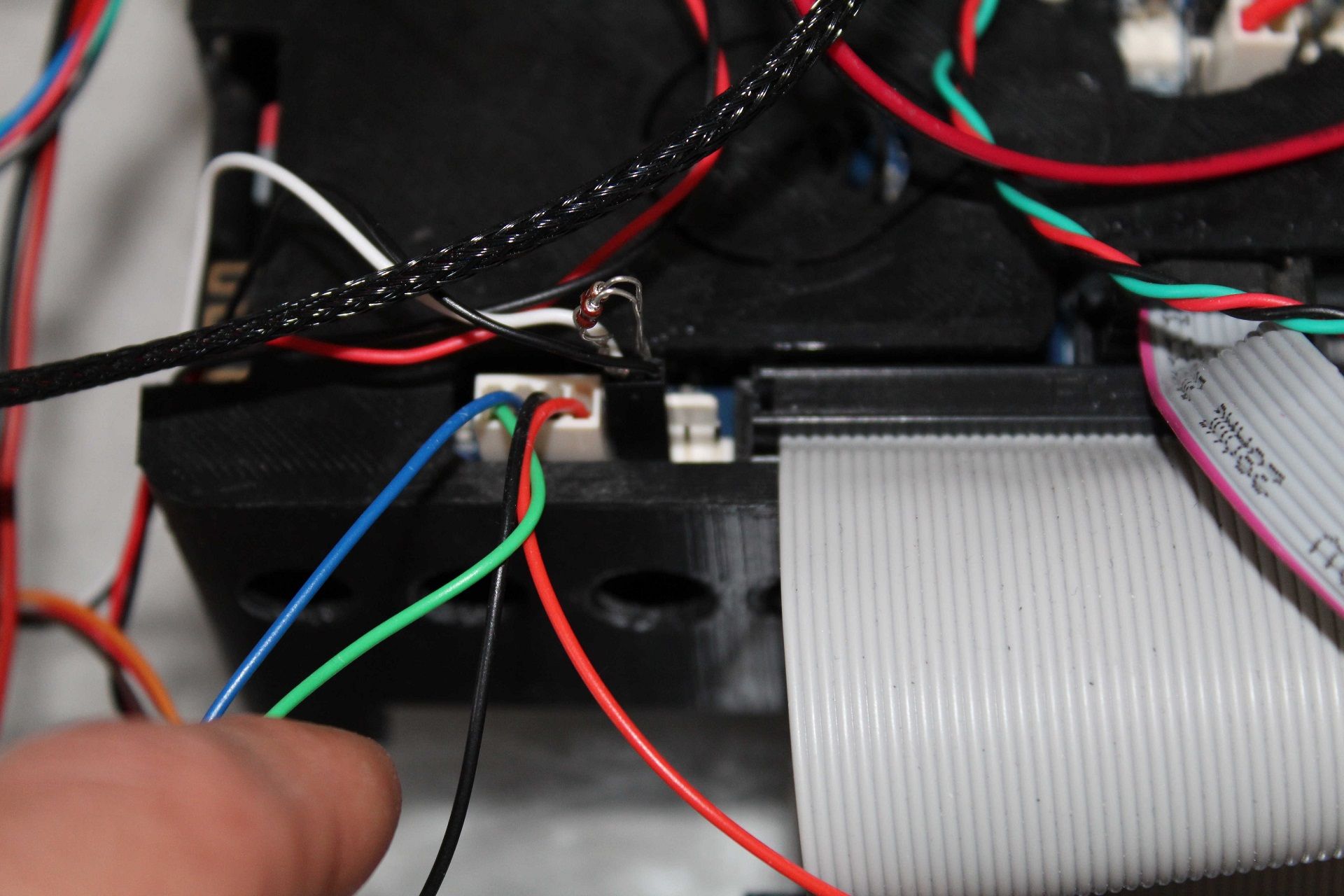

Here you can see pictures of my wiring:

I Don't get it. What am I doing wrong?

I've read through all the post and reviewed my setup more then five times also I've done some test with a different board and without the DueX2.

It would be very nice if someone could help me and point out what I'm doing wrong or not correct.

Kind regards

Andreas