Do you mean in the home all section? Sorry I am a little slow when programing

Posts made by Thunder

-

RE: Z calibration offsetposted in My Duet controlled machine

-

RE: Z calibration offsetposted in My Duet controlled machine

Yes like the last one, this code is in slicer start program.

-

RE: Z calibration offsetposted in My Duet controlled machine

Ok i checked and you are right. In the startup i had a M375 command. I deleted the line and replaced the command with G29 S1. And now my next question if load the g code of a part for printing the machine homes and makes the printer use the height map that i did eariler with G29 S0. But my nozzle is stil a few 0.1 mm from build plate. Do i correct this with baby steps ?

Thanks for all of your input

-

RE: Z calibration offsetposted in My Duet controlled machine

Ok, I have now managed the calibration. But when I start the program from the slicer I get the Error: M375: Heightmap file bareplate.csv not found I think this means my startup code is not ok

thank you

-

RE: Z calibration offsetposted in My Duet controlled machine

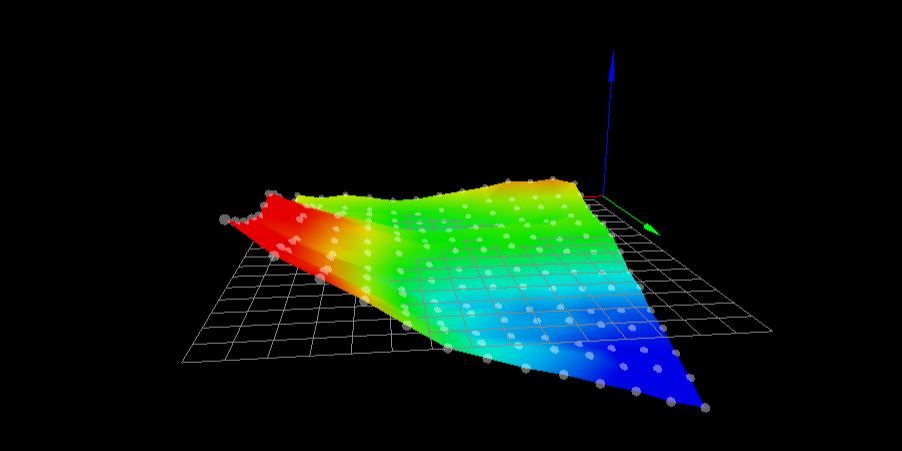

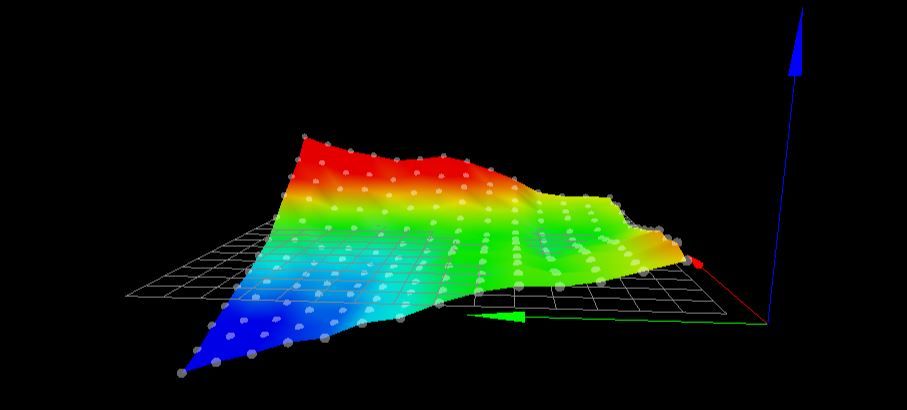

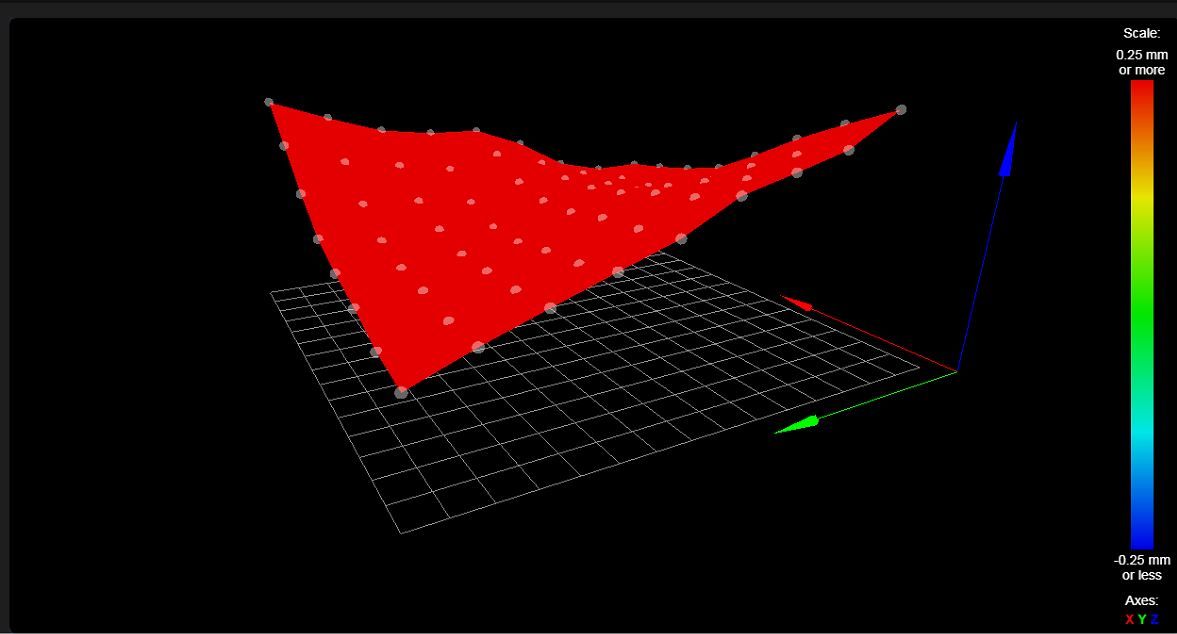

Yes, this is right. Ok, came home and started the machine and a couple of settings were wrong. Now I have managed the home all to touch the probe for z and started the G29 S0

but I still get the same result. Can anybody point out what I am doing wrong? I am new to programming and this kind of setup.System My Printer g29 s0 Status Busy Tool Position X 346.4 Y 320.2 Z 7.15 Extruder Drives Drive 0 0.0 Speeds Requested Speed 3 mm/s Top Speed 3 mm/s Sensors Vin 12.0 V MCU Temperature 28.4 C Fan RPM 0 Z-Probe 0 Tools Extra Control All Tool Heater Current Active Standby Tool 0 T0 - Load Filament Heater 1 off 16.9 C 0 0 Bed Heater 0 off 18.2 C 0 0 Temperature Chart System Directory 0:/sys/config.g ; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Sun May 24 2020 20:05:38 GMT+0200 (Central European Summer Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"My Printer" ; set printer name ; Network M551 P"GoBevk" ; set password M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S0 ; physical drive 1 goes backwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X160.00 Y80.00 Z800.00 E837 ; set steps per mm M566 X900.00 Y900.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X1400 Y1700 Z1400 E800 I50 ; set motor currents (mA) and motor idle factor in per cent M84 S50 ; Set idle timeout ;Bl-touch heaters M307 H3 A-1 C-1 D-1 ; disable heater on PWM channel for BLTouch ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X500 Y500 Z500 S0 ; set axis maxima ; Endstops M574 X1 Y1 S1; ; set active high endstops M574 Z1 S2; ; Z-Probe M558 P9 H5 F500 T4000 X0 Y0 Z1 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X-66.4 Y-10.2 Z2.15 ; set Z probe trigger value, offset and trigger height M557 X70:433.6 Y70:498.8 S30 ; define mesh grid ; Heaters M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M305 P1 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v2.0.4 on Sun Sep 15 2019 21:01:39 GMT+0200 (Central European Summer Time) G91 ; relative positioning G1 Z5 F6000 S2 ; lift Z relative to current position G1 S1 X-500 Y-500 F1800 ; move quickly to X and Y axis endstops and stop there (first pass) G1 X5 Y5 F6000 ; go back a few mm G1 S1 X-235 Y-215 F360 ; move slowly to X and Y axis endstops once more (second pass) G90 ; absolute positioning G1 X250 Y250 F6000 ; go to first bed probe point and home Z G30 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing G91 ; relative positioning G1 S2 Z20 F100 ; lift Z relative to current position G90 ; absolute positioningThanks in advance

-

RE: Z calibration offsetposted in My Duet controlled machine

; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Sun May 24 2020 20:05:38 GMT+0200 (Central European Summer Time) G91 ; relative positioning G1 H2 Z10 F24000 ; lift Z relative to current position G1 H1 X-505 Y-505 F12000 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X5 Y5 F24000 ; go back a few mm G1 H1 X-505 Y-505 F240 ; move slowly to X and Y axis endstops once more (second pass) G1 H1 Z-505 F240 ; move Z down stopping at the endstop G90 ; absolute positioning G1 X100 Y100 F2000 ; put head over the centre of the bed, or wherever you want to probe G30 ; lower head, stop when probe triggered and set Z to trigger height ; Uncomment the following lines to lift Z after probing G91 ; relative positioning G1 Z10 F400 ; lift Z relative to current position G90 ; absolute positioningHere is my file, also i dont understand "Where is the your code to create the height map?" ? I was folowing this guide :link text

-

RE: Z calibration offsetposted in My Duet controlled machine

Ok, how about now ?[0_1612359597243_homeall (1).g](Uploading 100%)

-

Z calibration offsetposted in My Duet controlled machine

Greetings,

I need help with my calibration file or with other words with my machine.

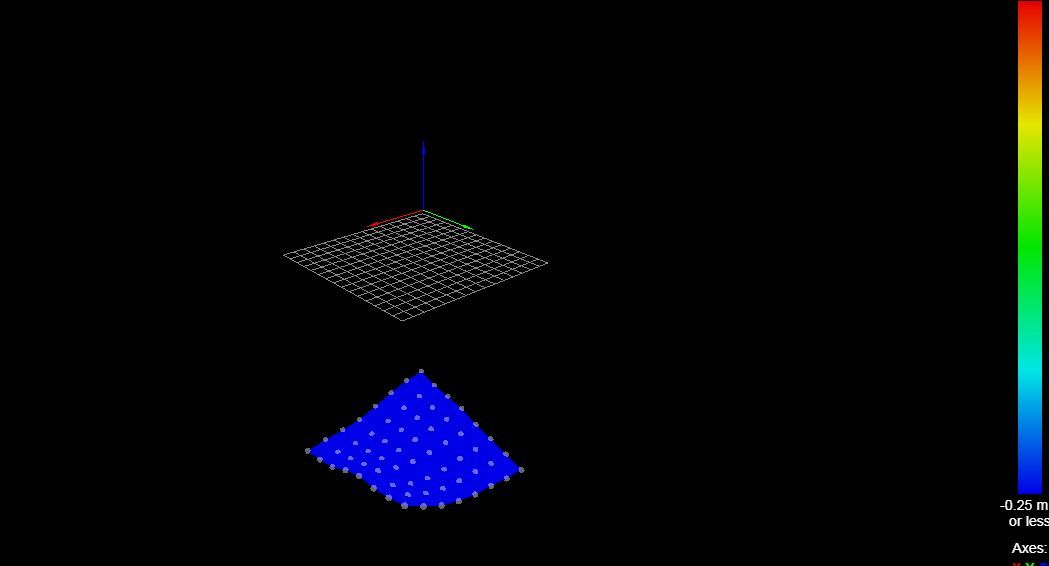

I don't know what the hell is going on. I printed two parts 300mm diameter with no problem, and then i didn't change anything and this happens. The bed calibration was off. Can somebody tell me what to change that the machine will work. I know the bed is curved, but i will solve this first ( Bl-touch,CR105S)

Here is my config file:

homeall.g config.g bed.gThank you.

-

RE: CR 10 5sposted in My Duet controlled machine

@ziggymanpopo Thanks. I also upgraded the z-axis and the x-axis to linear rails. Still have to upgrade the x-axis. Why did you decide to change the ball screws? Thanks for the compliment :).

What do i call it ? -

RE: CR 10 5sposted in My Duet controlled machine

Ok and now the pictures :

https://ibb.co/8MpQxcJ

https://ibb.co/NN1n4zJ

https://ibb.co/q9rRb3G

https://ibb.co/vHDkSY9

https://ibb.co/SnsXfHZ

https://ibb.co/GRvZFQ1

https://ibb.co/1z8SLzXThe nozzle is 0.8mm

-

RE: CR 10 5sposted in My Duet controlled machine

Ok. Long time no write. I have made the printer move. And now I have another problem. I have a titan aero extruder with a Vulcano hotend. And now I struggle with the top layer and the edges. I get a bit deformed left corner.

Hope anybody will see this thread. Z is the top layer

Z is the top layerHere is my config file.

; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Sun May 24 2020 20:05:38 GMT+0200 (Central European Summer Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"My Printer" ; set printer name ; Network M551 P"GoBevk" ; set password M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S0 ; physical drive 1 goes backwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X160.00 Y80.00 Z800.00 E809.00 ; set steps per mm M566 X900.00 Y900.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X1400 Y1700 Z1400 E800 I50 ; set motor currents (mA) and motor idle factor in per cent M84 S50 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X500 Y500 Z500 S0 ; set axis maxima ; Endstops M574 X1 Y1 Z1 S1 ; set active high endstops ; Z-Probe M307 H3 A-1 C-1 D-1 ; disable heater on PWM channel for BLTouch M558 P9 H5 F120 T24000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X-66.4 Y-10.2 Z2.15 ; set Z probe trigger value, offset and trigger height M557 X15:495 Y15:495 S20 ; define mesh grid ; Heaters M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M305 P1 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

Any suggestions ??:)

-

RE: CR 10 5sposted in My Duet controlled machine

sorry here is it :

; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Fri May 01 2020 16:13:33 GMT+0200 (Srednjeevropski poletni čas) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"CR10 5S" ; set printer name M918 P1 E4 F2000000 ; configure direct-connect display ; Network ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S0 ; physical drive 1 goes backwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S0 ; physical drive 3 goes backwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X32 Y32 Z32 I0 ; configure microstepping without interpolation M350 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z4000.00 E420.00 ; set steps per mm M566 X900.00 Y900.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X1680 Y1680 Z1680 E800 I50 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X500 Y500 Z500 S0 ; set axis maxima ; Endstops M574 Z1 S0 ; set active low and disabled endstops M574 X1 Y1 S1 ; set active high endstops ; Z-Probe M558 P0 H5 F120 T24000 ; disable Z probe but set dive height, probe speed and travel speed M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters M305 P0 T100000 B4092 R4700 ; set thermistor + ADC parameters for heater 0 M143 H0 S150 ; set temperature limit for heater 0 to 150C M305 P1 T100000 B4092 R4700 ; set thermistor + ADC parameters for heater 1 M143 H1 S275 ; set temperature limit for heater 1 to 275C ; Fans M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on M106 P2 S1 I0 F500 H1:0 T45 ; set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not definedThanks

-

CR 10 5sposted in My Duet controlled machine

Greetings all together.

I have a CR 10 5s and i have upgraded it with linear rails on all 3 axis and a Titan extruder with volcano hot end.

It's all wired up and moving. But here is the catch. I also bought new motors from e3d

On the Y axis i have :

NEMA 17.

1.8° Step Angle.

200 Steps Per Revolution.

4V Rated Voltage.

2A Phase.

8.2kg/cm (114oz/in) Holding Torque.

60mm Body.

5mm Output Shaft.

On x :

NEMA 17.

0.9° Step Angle.

400 Steps Per Revolution.

2.8V Rated Voltage.

1.68A Phase.

4.4kg/cm (61oz/in) Holding Torque.

48mm Body.

5mm Output Shaft.

On z 2x :

NEMA 17.

0.9° Step Angle.

400 Steps Per Revolution.

2.8V Rated Voltage.

1.68A Phase.

3.5kg/cm (48.6oz/in) Holding Torque.

40mm Body.

25mm Output Shaft (5mm diameter)

Ok, the machine is moving but not as much as i want to. I tried to reconfigure with the reprap configuration but there is something that im doing wrong. Because i click on the 50 mm button and it moves less.

Can somebody check my parameters and tell me what I am doing wrong? Attached you will find my config file

Thanks

[0_1588331232137_config2.zip](Uploading 100%)