slant lines

-

@dc42 yeah I'm pretty much convinced it's how the worm gear works and you can get lucky and have everything aligned perfectly and you wouldn't notice the artifacts... but I think that if you look close enough you'd see them anyway. I'll try with a standard extruder to discard any possible issue with the machine mechanics and report back.

@arhi thanks for digging out your old prints. My slant lines are definitely less bad then yours were, also I can really notice them only in 1-wall prints. On normal prints the problem translates into a fuzzy texture. I have a feeling that if you print a 1 wall cube at a decent speed and look close enough you'd notice some sort of slant lines even with the new shaft.

-

@matt3o actually did a bunch of single wall prints to calibrate extruder and no slant lines with the new shaft and new hotend. I don't think I changed anything else.

-

@arhi we would need to check the same model at the same speed I guess, because if it's not the extruder I wouldn't know what else

-

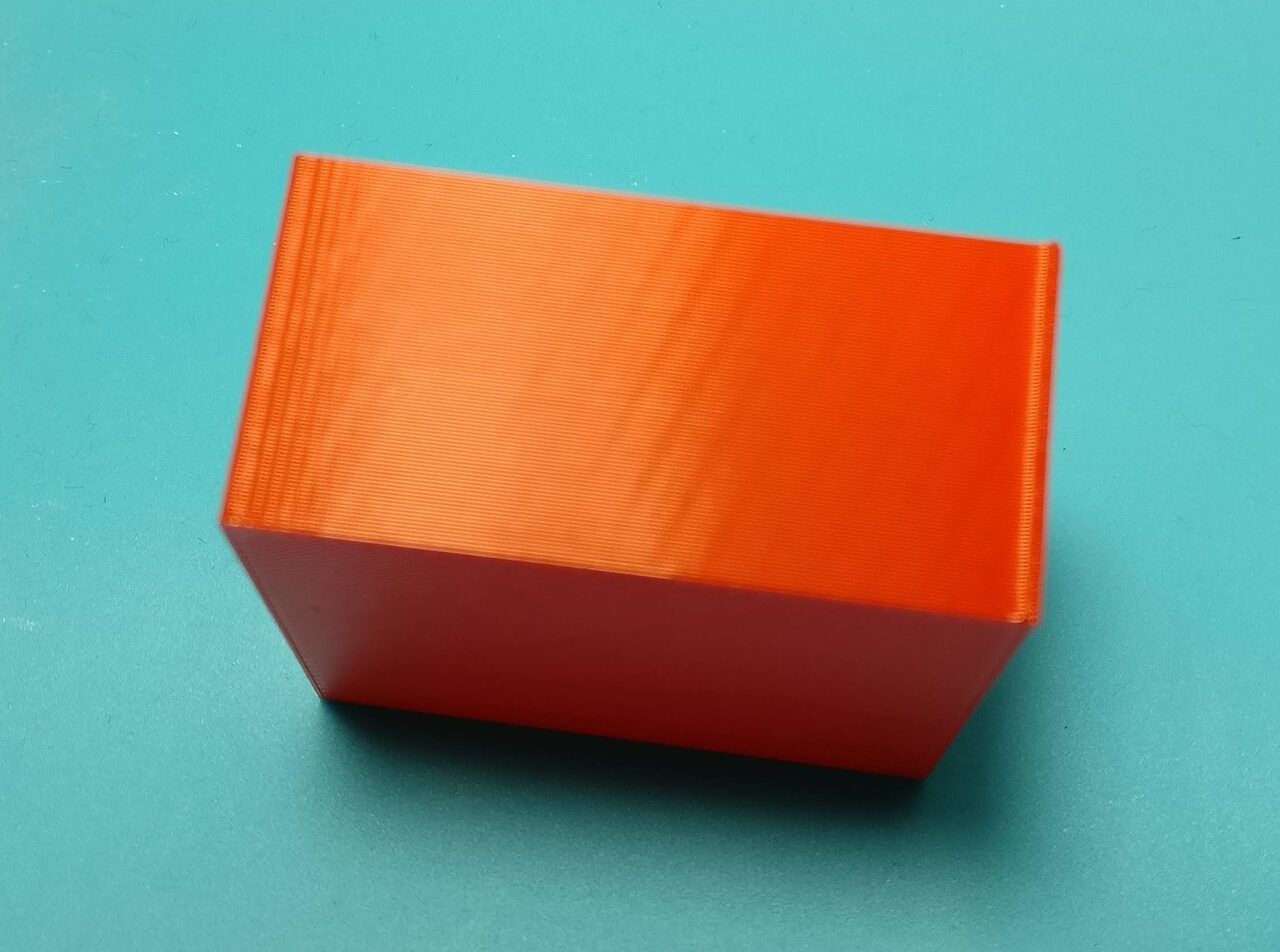

That print is

- ABS (gray, one of the most unforgiving colors)

- 0.2mm layer

- 0.5mm nozzle

- 0.6mm extrusion width

- 4/4/4 (top/bottom/perimeters)

- 90% * 60mm/s outline speed

the lines are not as visible live as on the images I uploaded, that's with light coming under a very shallow angle so that effect is more prominent.

If you have a test case I'll be willing to try it out, I now have E3DV6 with .3mm mozzle on that G5 now, currently PLA loaded but I can easily switch to ABS/PETG/PC/PA

-

@arhi The pulsing could be caused by the flex cable not turning consistently/smoothly, but as @matt3o has tried it with a NEMA 8 motor (replacing the flex cable) and still has artifacts, it does seem the worm gear is most likely responsible. As I said waaaaay back at the beginning of this thread!

Ian

-

@droftarts yup, only I replaced the hotend and the shaft and the gears are still the same but lines are gone

-

It might be your shaft that caused the issues too. If could have been was pulling and yanking the little worm around. The period of the errors are the same for the worm and the cable.

I like your bracing mechnism holding the shaft in place. -

@bondus possible, that's probably why shaft broke and that's why I added that bracing mechanism so that it does not break again. The worm sits in the two bearings, one on each end, it's not really yenkable

that easy. Dunno, important that it's gone and was never there before too. Jason sent me new shank that I'm expecting every day now. He said that the new one is much thicker then the original one I had and that it shows improvements over original one too. We'll see, I was pretty happy with performance so far

that easy. Dunno, important that it's gone and was never there before too. Jason sent me new shank that I'm expecting every day now. He said that the new one is much thicker then the original one I had and that it shows improvements over original one too. We'll see, I was pretty happy with performance so far

-

@arhi said in slant lines:

The worm sits in the two bearings, one on each end

The worm sits on just 1 bearing, the other on top doesn't hold the worm but it is just leaning on it. That is in my opinion the first design issue with that extruder.

-

holy s*$#t!

So I put a bondtech extruder in direct drive on a mosquito. I had to redo the whole head, but I had to try.

The overall quality is good but.... I still get the slant lines! They are completely different but they are still there. I am going nuts! I don't know what else to try...

-

Have you tried a different driver for the extruder yet?

-

@matt3o, if you print a box with a thin single perimeter wall, do you see the lines on both sides of the wall? If so, are they symmetric or opposite?

(trying to distinguish between X/Y irregularity and extrusion width irregularity.)

-

@Phaedrux said in slant lines:

Have you tried a different driver for the extruder yet?

I tried on a new driver on the duex5, no difference. Do you think it is woth trying on the main duetwifi?

@zapta said in slant lines:

@matt3o, if you print a box with a thin single perimeter wall, do you see the lines on both sides of the wall? If so, are they symmetric or opposite?

(trying to distinguish between X/Y irregularity and extrusion width irregularity.)

The pattern is the same on all sides, from bottom left to top right (this time). Looking at the same side the pattern is the same in the inside and the outside.

-

@matt3o said in slant lines:

Do you think it is woth trying on the main duetwifi?

When you're grasping at straws... why not?

-

@Phaedrux said in slant lines:

When you're grasping at straws... why not?

Yes, that's correct. Possibly having larger pulleys on the secondary belt will allow to reduce tension there without increasing backlash (and having non equal pulleys may allow increasing the steps/mm).

-

@matt3o said in slant lines:

The pattern is the same on all sides, from bottom left to top right (this time). Looking at the same side the pattern is the same in the inside and the outside.

Do you mean that where it bulges on one side of the wall it also bulges on the other side of the wall? If so I would think it's uneven extrusion.

(I presume it's not related to Z issues such as automatic bed mesh compensation which can also affect the extrusion width).

-

I tried 2 drivers on the duex and 1 on the duetwifi. No difference whatsoever. @Phaedrux thanks for the suggestion, I really hoped that would work.

I changed cables. Niet.

I tried a new motor. Nada.

What the f...

@zapta the texture is so faint that I can't really tell what XY direction it is going. I'd probably need a microscope, I'll try to take some macro shots but I don't know if that would be enough.

-

@matt3o said in slant lines:

@arhi said in slant lines:

The worm sits in the two bearings, one on each end

The worm sits on just 1 bearing, the other on top doesn't hold the worm but it is just leaning on it. That is in my opinion the first design issue with that extruder.

You sure? I know the original design I had was holding both bearings strongly... will check the G5

there are bearings on both side ... ah you are right I just checked the worm does not go in to the bearing on top only the flex goes trough the bearing

-

@zapta said in slant lines:

Do you mean that where it bulges on one side of the wall it also bulges on the other side of the wall? If so I would think it's uneven extrusion.

That's what I had (have on this print I dug from the trash). The Z is even, the XY is even the amount of plastic varies sinusoidally.

(I presume it's not related to Z issues such as automatic bed mesh compensation which can also affect the extrusion width).

nope, not Z related I'd say

-

@matt3o said in slant lines:

So I put a bondtech extruder in direct drive on a mosquito. I had to redo the whole head, but I had to try.

are they the same frequency as the one you had with flex3drive. Bondtech also comes with a gear

what else to try

I'd up the current on the extruder motor to try out that too