Battling sources of vibration and noise

-

At this moment I am debating whether to take the money dive and have the old style brackets cnc machined out of steel (weerg.com has a promotion that makes the steel options cheaper than alu at the moment

)

)A user on the reprap forums reported that improved noise vibration issue he had with his nema23's (link to the post). It could make sense from a rigidity standpoint as well as the added mass, more mass is normally less vibrations right. Yet then again all the previous things I tried made sense too, and they didn't cost €360 to 'try out'.

-

@Nxt-1 if it is definitely the belt thats causing the resonance issues, I'd focus my efforts on that. Did you try the 20T pulleys? What about making a significant change to the belt length (longer or shorter)? Granted this might be tricky given the machine design... have you also tried using 9mm or 12mm belts instead? They'll at least have different mass/stiffness properties.

-

@engikeneer said in Battling sources of vibration and noise:

@Nxt-1 if it is definitely the belt thats causing the resonance issues, I'd focus my efforts on that. Did you try the 20T pulleys? What about making a significant change to the belt length (longer or shorter)? Granted this might be tricky given the machine design... have you also tried using 9mm or 12mm belts instead? They'll at least have different mass/stiffness properties.

I should have explained it better, I don't believe belts are causing resonance issues, the belts simply allow the vibrations to travel from the motor to the other parts of the machine instead of staying isolated to just the motor vibrating. If the belts themselves were sources of vibration you'd expect the frequency of the noise to change with varying belt tensions or lengths, which is is the opposite of what I am observing.

Just as an fyi, I am using 9mm proper gates belts on 20T pulleys

-

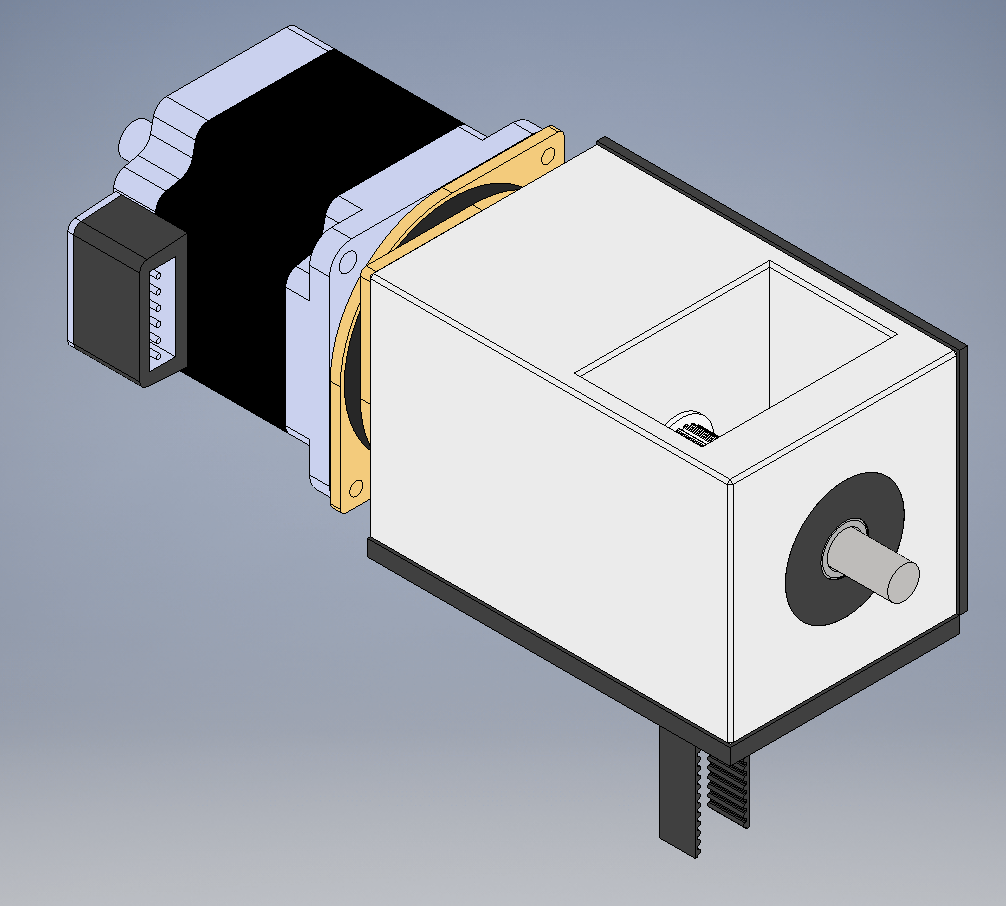

@Nxt-1 What is the loading range of the mounts you are using in the pic? IMO they seem way too rigid - they do not yield enough elasticity to absorb the vibration energy for this application. That is if the vibration energy is emitting from the motor itself.

-

@Kolbi said in Battling sources of vibration and noise:

@Nxt-1 What is the loading range of the mounts you are using in the pic? IMO they seem way too rigid - they do not yield enough elasticity to absorb the vibration energy for this application. That is if the vibration energy is emitting from the motor itself.

Sadly hard to say, I picked them up from a local hardware store and they were specified as 'damper, type B', no more no less. I agree, due to the compact size the isn't really that much room for flexing rubber, so they are stiffer than I'd have wanted. On the other hand, from my test without the belt, I can conclude they do their job. Otherwise the vibrations would still travel trough the rubber into the frame, which wasn't the case.

-

Finally some good news!

Yesterday evening I decided to try the inertial damper route. Someone linked it before in this thread and it's basically a high rotational inertia disk that you bolt on the stepper shaft. The added inertia functions similar to a smoothing capacitor in electronics and smooths down the riple, in this case of the vibrations caused by the motor.

Because I didn't have the time (nor the budget to just try) to get the real stuff from Oriental, I designed a very simple DIY intermediate. With lead disks and a printer cover to keep them in place. While it certainly is DIY

it provides a night and day difference. I will most likely order the proper ones this week.

it provides a night and day difference. I will most likely order the proper ones this week.

-

@Nxt-1 aren't those supposed to slip?

-

@arhi said in Battling sources of vibration and noise:

@Nxt-1 aren't those supposed to slip?

Examining what little documents I can find on the proper dampers that could very well be the case. And I see it making sense to smooth movement while continuously turning, yet not hindering acceleration/jerk.

I don't think that level of performance is going to happen with what I just build here though, it's either all slip or no slip

I just placed an order for 3 of the proper ones from Oriental so we'll find out more soon enough I guess

-

-

@Nxt-1 said in Battling sources of vibration and noise:

find out more soon enough

Hope it goes well, I was wondering how those would be in regards to acceleration and jerk.

-

@Nxt-1

I'm curious to see the numbers once you have three installed. I would expect that you can still get the motors to vibrate, but the dampers are probably shifting that frequency to a place you'll never get to...I'm also curious if they make a difference to print quality.

-

@Nxt-1, I just had an idea on determining your motor vibration emission, not sure on how effective though.

If you cut the current down by ~75% it should decrease the intensity of motor generated vibrations while the movement (drive train) generated vibrations would stay the same. This could let you know what to expect with the installation of the rotational dampers / help separate the two possible offending sources. -

@Kolbi said in Battling sources of vibration and noise:

@Nxt-1, I just had an idea on determining your motor vibration emission, not sure on how effective though.

If you cut the current down by ~75% it should decrease the intensity of motor generated vibrations while the movement (drive train) generated vibrations would stay the same. This could let you know what to expect with the installation of the rotational dampers / help separate the two possible offending sources.This is what I am doing at the moment to keep the noise levels down whenever I want to. It's a far from ideal solution but quite effective. Further reinforcing my point that the motors are the major source if not the only real source.

-

@Nxt-1 Did you make any progress with the Oriental clean dampers?

-

@Kolbi Define progress, I am 2/3's of the way through waiting for them to be shipped

Oriental is disappointingly slow this time around, the expected shipping date is the 24th

Oriental is disappointingly slow this time around, the expected shipping date is the 24th -

@Nxt-1 Ug, that sucks.

-

Finally some decent news, the dampers arrived as predicted on the 25th. Installation was quick and easy, two setscrews and done. On thing that I noticed right away is that they are light, the datasheets specs them at 61g. Compared to the ~300-400g of lead I had on there before, that's absolutely nothing. This made my quite hesitant as to there performance.

Yet after some first moves I can say that the dampers do not disappoint. Not a magical noise reducer by any means but they definitely take the edge off and bring the noise down to something acceptable. I need to do some more testing but at this point I'd say they are worth ~€120 for a set.

At this point I still plan to have the motor brackets machined out of steel, but for a number of reasons (including cost) that will have to wait for a while. What I do want to try out soon-ish is removing the stepper face dampers again. Just to see what would happen.

-

Nice.

(filler text).

-

@Nxt-1, now that you've had the mechanical clean dampers on for a bit, have you observed any print quality effects?

-

@Kolbi said in Battling sources of vibration and noise:

@Nxt-1, now that you've had the mechanical clean dampers on for a bit, have you observed any print quality effects?

I am sorry for the late reply, I have been and will continue to be limited on time for 3D printing stuff sadly. My opinion has not really changed since my last post. I have done some small prints now and then with the Duet running all out at 2.4A and the noise is acceptable. I still have to test without the face dampers and printing at the outer edges (so the carriages have to move faster) but I do not have a plan for when I am going to do that.

In terms of actual print quality I see no difference. There were no real print quality issues to improve on anyway. If anything I'd expect increased ringing at corners due to the increased rotational inertia. Yet again the viscous clutch style internals of the dampers should combat that as much as possible.