What do you use as a slicer?

-

@Veti Did you hand had physical contact with a big chunk of polished steel and a chunk of printed plastic? And did you feel a difference?

It is like "cylinder capacity" at a car engine.. you can replace it only with more capacity to make it better.

-

I use simplify3d... When I got it, it was 6x faster than slicer. Maybe the latter has improved over time, but I like the s3d interface & features so I haven't shopped around. (It ain't broke...)

-

-

@3mm

sure why not. The slicer doesn't really care what the kinematics are (other than the build volume and shape). The firmware takes the gcode commands and does the kinematics processing to move the motors based on the moves the slicer commands. -

@3mm I'm using superslicer with a delta. Feel free to reach out if you get stuck.

-

PrusaSlicer_config_bundle.ini.txt

here is a config_bundle for a Q5 Delta Printer i found some time ago. (You have to delete the .txt ending)

This one can be used in the superslicer and prusa slicer

-

@PCR and you have to change the Firmware Flavour to RepRap!

-

@PCR I wonder what reprap flavour tastes like...

-

@jay_s_uk

chicken? -

Home made soup like mom used to make.

-

@sylvaindc said in What do you use as a slicer?:

@3mm I'm using superslicer with a delta. Feel free to reach out if you get stuck.

Thanks. Actually, I have bumped into a 'sticker'. I am running the SuperSlicer calibration functions. One of the issues I've been working for some time is likely a temperature problem so when I saw the temperature tower 'calibrator', I said to myself, "Yipee!" Only there is a problem, it doesn't work!

I am receiving the following SuperSlicer v2.2.54 error message, upon 'generate':

"Empty layers detected, the output would not be printable.

Object name: smart_compact_temp_calibration

Print z: 9.015000

This is usually caused by negligibly small extrusions or by a faulty model. Try to repair the model or change its orientation on the bed."In the tower dialog, I've set the steps to 5, and 2 up, 2 down. I don't what's wrong, I searched on the 'Net and also read the SuperSlicer wiki and haven't found anything related to the problem. The program does not generate the gcode.

Any suggestions are appreciated.

3mm

-

@3mm disclaimer, I never had that error...

Could you do the bed-level and filament flow calibrations?

-

I have used in the past

- replicatorG (

)

) - cura

- kisslicer1.x

I am using:

- Simplify (what we have at work)

I want to try

- kisslicer2.x

- 3d-optimizer

- replicatorG (

-

I used kisslicer originally, and compared slicers often ( I had more free time). then during the dark times before its V2 update I swapped to S3D originally thinking they'd be diligent in feature updates ( they didn't and then teased a big update for another purchase... ha). I stopped using it and swapped to cura after testing slicers again a couple months ago when the faint moire / salmon skin that has plagued than i wantme for many upgrades straight up disappeared.

I have a complicated relationship with cura though. We have differences of opinion on what some terms mean, and for all the shiny features and options it has the lack of fine grain control it offers hurts my soul. It just "calculates" more things than I want it to. Example: I tell you cura what the line width I get at a layer height and you determine the infill spacing from that, I don't need it to be a redundant flow rate multiplier that you already have as an option. I don't like having to either just crank up flow rate or try to predict if you'll apply overlap just to clear up infill gaps.

-

Yes, I did all the calibrations in order as suggested by the SuperSlicer program. I can't figure out what it means?

I found a switch that I missed going through the slicer dialogs, named: "Print Settings --> Slicing --> Allow Empty Layers"

which enables the generation of the gcode and no error code, but there is missing temperature 'layer'. I'm still working that. Whereas without that switch, the error emits without generating any gcode.I must be missing something obvious, as others have successfully used that calibrator.

Oh...and I discovered the where-abouts of the error message, as after I enabled "allow empty layer" setting, I looked in the gcode, and I counted the number of M104 temperature changes and discovered that instead of five, that there were only four, and so I reasoned that these are very similar blocks of code so I mathematically determined the count boundaries where the temp changes periodically occur and I realized that the

"Print z: 9.015000" is a Z axis reference, and its in that code chunk that is missing the layer! Looking in the gcode is informative. I have a lot to learn about slicers. They are much more intricate than initially appears.Regarding these towers, how are the 'bridges' printed? Are rafts used? Supports? I can't figure that out, how is that accomplished without supports?

Thanks, 3m

-

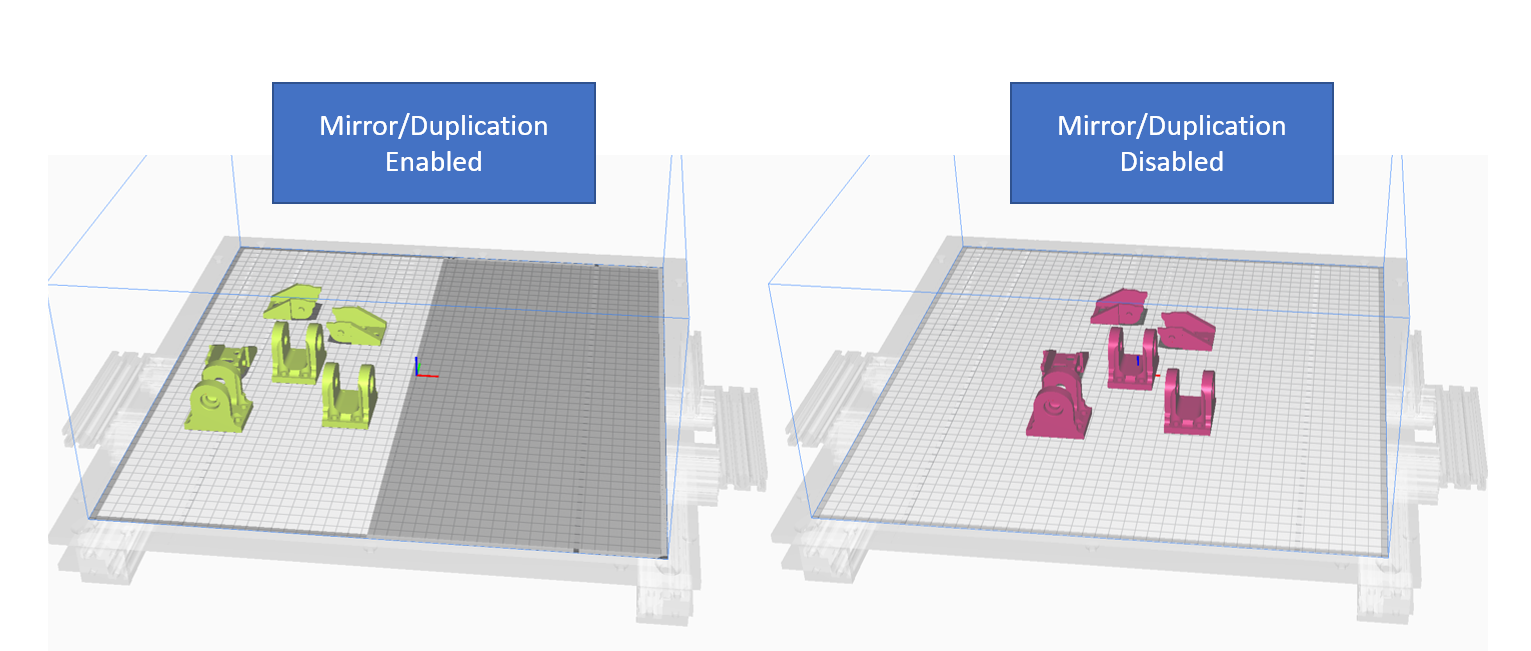

I use Cura (specifically the SmartAvionics build) for my IDEX setup. I created a machine profile that, depending on the number of tools selected, automatically (magically?) limits the available buildplate to 1/2 its typical width for use in mirror or duplication modes - much like you would see in the BCN3D version of Cura.

The SmartAvionics build has additional settings I like to use, as well as additional bugfixes. I believe that Cura is quite powerful for multi-extrusion/tool setups.