Need help! G29 mesh bed compensation over compensation

-

@Veti I implemented your changes and it solved a few problems. Something was holding back my top speeds and I guess it was an over loaded cpu.

Trying a test print now.

The few extra z steps are from a slight gear reduction by a belt from my z stepper to my lead screws

Thanks a lot for the help. I will post again when the test print is completed

-

here is a picture of what I'm going to refer to as my chuck, without a tool and ready for probing.

the second picture is with a custom machined water cooled cold end with a v6 and zesty nimble. (still vary much a work in progress)

-

still having the problem....

this picture is from my most recent test.

as you can see two are too close and three are too far.

-

Are those the actual locations where the cubes were printed or did you move them?

-

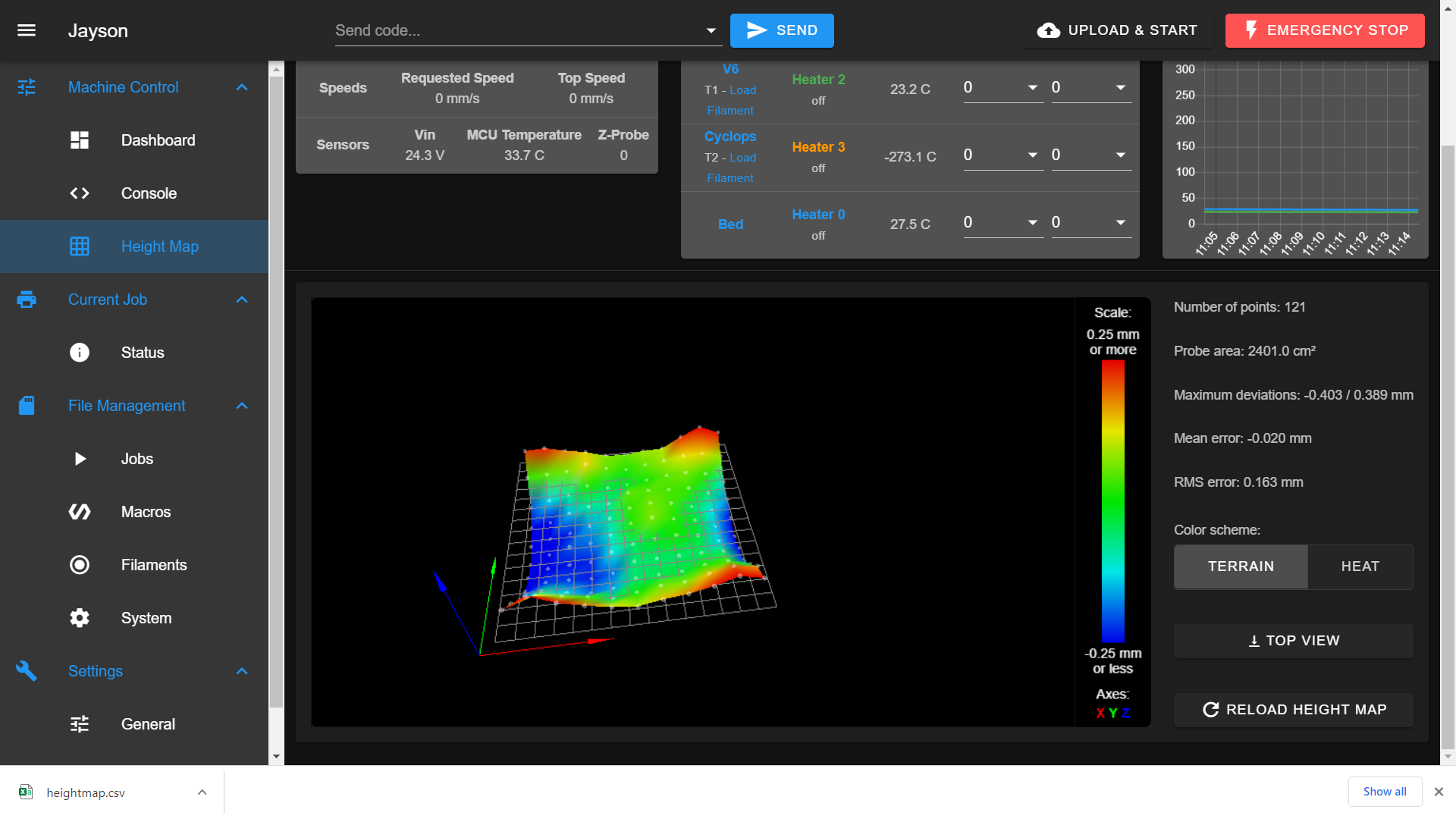

post a picture of your heightmap

-

I kept the same orientation, just moved them in close for the picture

-

I have tried the print with the heat bed off at room temperature to eliminate thermal expansion but still the same result.

I have also shimmed the low side of the bet up 3 mm to drastically alter the bed mesh and the prints come out looking the exact same.

-

it is a 500x500 bed with a silicone heater and buildtak flex plate.

it has a 1/4" T6 6061 aluminum plate that I sheared from a piece of scrap at work. It defiantly has some warp that I am working to physically straighten now. -

@Jayson said in Need help! G29 mesh bed compensation over compensation:

it has a 1/4" T6 6061 aluminum plate that I sheared from a piece of scrap at work.

that is not thick enough for a 500x500 build plate. as you can see from the sagging heightmap.

see this recent discussion

https://forum.duet3d.com/topic/19398/height-map-500mmx500mmx4mm-aluminium-build-plateyour testprint is not even good in the center. so you have not dialed in the z trigger height well enouch.

adjust with babystepping while printing until you get a good first layer, then adjust the offset with the babystep value.also measure the z probe trigger heigh in each of the corners.

i would assume for your build they are different.

this can be due different factors.

one possibility for your printer with such a large print area is sagging axis due to its own weight, which introduces rotation of the carriage. this causes varying probing offset.one way to compensate for that is use a probe that uses the nozzle like a precision piezo

-

I would suggest moving your z probe to be X0, Y0 and Z0.

From there, you can set the tool offsets using G10.

It makes working everything out so much easier.

You can than use TAMV to calculate the X and Y offsets of each tool in relation to the z probe.

That's how I have my toolchanger set up. -

@Jayson said in Need help! G29 mesh bed compensation over compensation:

belt

Off the topic of your mesh issue, you should really get rid of those steel core belts on your printer. From the pictures you posted earlier your idlers/pulleys are too small for a steel core belt and will cause you serious grief in the future. I don't know the exact diameter minimum but I would guess you need at a minimum a 20-25mm diameter pulley/idler to use steel core belts.

-

@Veti I suppose the rest of the world isn't messed up like Saskatchewan Canada were we use metric and imperial measurements so I will just try to keep to metric from now on. the base of my printer is an 840x840x6.5mm aluminum plate with 20x20 extrusions around the perimeter. my bed is 535x535x6.5 hard mounted in the middle of the bed. I am adding jacking bolts between the two plates hoping to dial in the flatness of my bed. I can true the bed to the frame then adjust a lead screw on all four corners of my gantry to be parallel to the bed and let auto mesh handle the rest

.

.

-

@jay_s_uk i will have to keep this in mind when i get to that stage of the build

-

@JamesM said in Need help! G29 mesh bed compensation over compensation:

@Jayson said in Need help! G29 mesh bed compensation over compensation:

belt

you should really get rid of those steel core belts on your printer.

I went to them to try minimizing stretch over the really long belts and wanted something strong enough to handle high speeds with nema23 steppers. still managed to snap a belt setting up sensor less homing. (gave up on that, not reliable enough for tool changing)

now I have homing switches.anyway. should have gone with gt2 10mm wide belts instead to get away from steel. might redesign.

-

@Jayson said in Need help! G29 mesh bed compensation over compensation:

anyway. should have gone with gt2 10mm wide belts instead to get away from steel. might redesign.

the best belts are gates.

-

@Jayson said in Need help! G29 mesh bed compensation over compensation:

anyway. should have gone with gt2 10mm wide belts instead to get away from steel. might redesign.

Have you considered stepping up to 15mm 3GT belts?

Frederick

-

@fcwilt didn't know they went that wide. my old printer came with 6mm belts so that's just what i got for this.

-

some suggestions

gate gt2 12mm

https://e3d-online.com/products/gates-powergrip -2gt-belt-12mm-x-100mm?_pos=5&_sid=9dad4abd8&_ss=r

-2gt-belt-12mm-x-100mm?_pos=5&_sid=9dad4abd8&_ss=rgt3 up to 15mm (they also sell the pulleys and idlers)

https://www.aliexpress.com/item/32246715230.html -

@Veti i can't find a 20T GT2 pully that fits a 12mm belt and a 6.35mm motor shaft. might have to order them for 5mm shafts and take them too the local machine shop.

-

@JamesM wow were you ever right about those steel belts. just a few test prints and the are broken.