IDEX CoreXY, With Only 2 Motors.

-

@RichardDuke

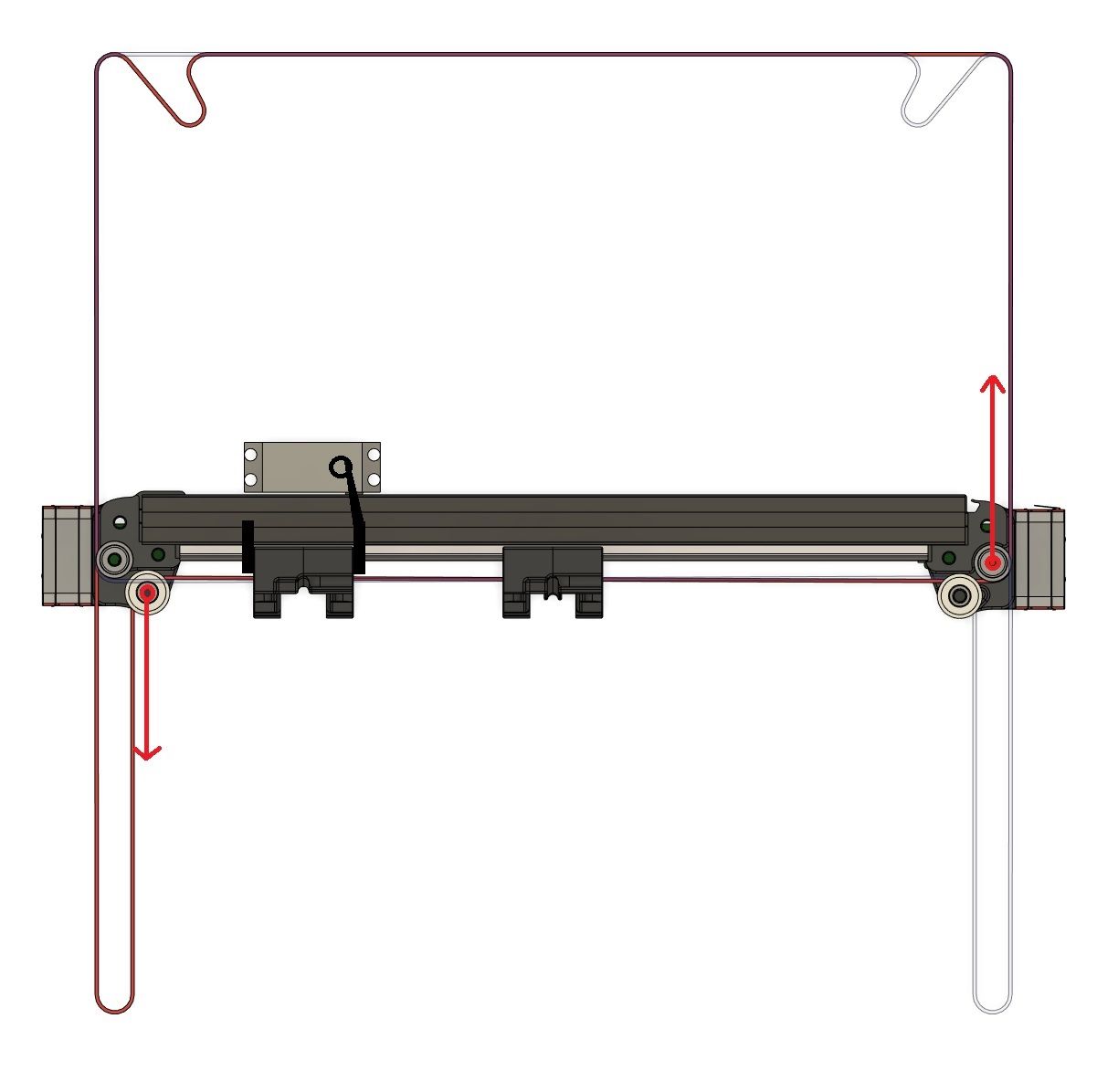

I think, racking won't be an issue the way you guide the belts.

I've played around with a "dual roller constraint" which works the same way.

A short video how it works.

It's common practice in big CNC machines by the way.I've built a simple XY-penplotter with only one rail for the Y-axis and used this method to avoid racking.

You can see the green string here and a hint of the rollers (which are the belt idle rollers in your case)

IMHO the result speaks for itself.

-

Why don't you build a toolchanger while you are at it? Your idea already basically is one, only the tool stays on the X carriage when parked ....

-

@RichardDuke said in IDEX CoreXY, With Only 2 Motors.:

The kinematics of this directly correspond to that of Markforged, except at every toolchange, both X and Y motor logic is swapped and reversed.

Is it possible to do the swap during a tool change? What does the firmware do in that case? There are some restrictions to the stepper parameters, IMHO some require a reboot? @Phaedrux ??

-

I guess the main idea behind this was to try implement indipendent dual extrusion to an existing platform without heavily modifying the original design. If it works, it would potentially be possible to a second carriage to just about any CoreXY printer.

@fcwilt yes the Voron is a CoreXY, designed for minimal racking, but with this modification the racking could become an issue as the gantry would now be pulled in the Y direction from opposite ends of the rail. It could potentiality be overcome with alternative belt routing, but that will require a design overhaul, in which case id probably look to just add an extra motor and belt anyway

@oliof a toolchanger could be an option, the coupling of the tools sound like it could be challenging though. Id probably look to retrofit the e3d carriage and park the tools off the gantry though.

@o_lampe I have had a conversation with Tony from Duet who doesn't think there will be an issue, but we will cross that path later.

-

I wish you hadn't put the idea in my head of converting my MarkForged style printer into a IDEX unit.

Like I don't already have enough projects!

Fredereick

-

@fcwilt you and me both! I haven't even finished tuning my recent Cartesian IDEX build and I'm already looking for something else!

-

@RichardDuke said in IDEX CoreXY, With Only 2 Motors.:

with this modification the racking could become an issue as the gantry would now be pulled in the Y direction from opposite ends of the rail

I disagree.

The B-belt is passive during Y-moves, but it is still there and it's tension makes all the difference.

Both ends of the crossbar are wrapped in belts, that's important for the constraint.My CoreXY is easy to modify with your idea. I'll print a second carrier-dummy and try it out today.

I could need some help with the kinematic-matrix. -

@ all

what would be a good testprint to show (the absence off) racking? -

Just to chime in on the alleged h-bot racking -- that all seems to go back to an old Hackaday posting where the author later admitted to using low quality belts and self-made cantilevered pulleys. I am poised to assume the claims about h-bot being terrible are a bit overblown in practice.

-

@oliof of course it is .

many industrial motion systems use h bot . startasys used hbot in their printers . it all depends how rigid your design is . -

In this special case it's the equal belt tension that keeps the crossbar in line. Also the tension shouldn't be too low.

-

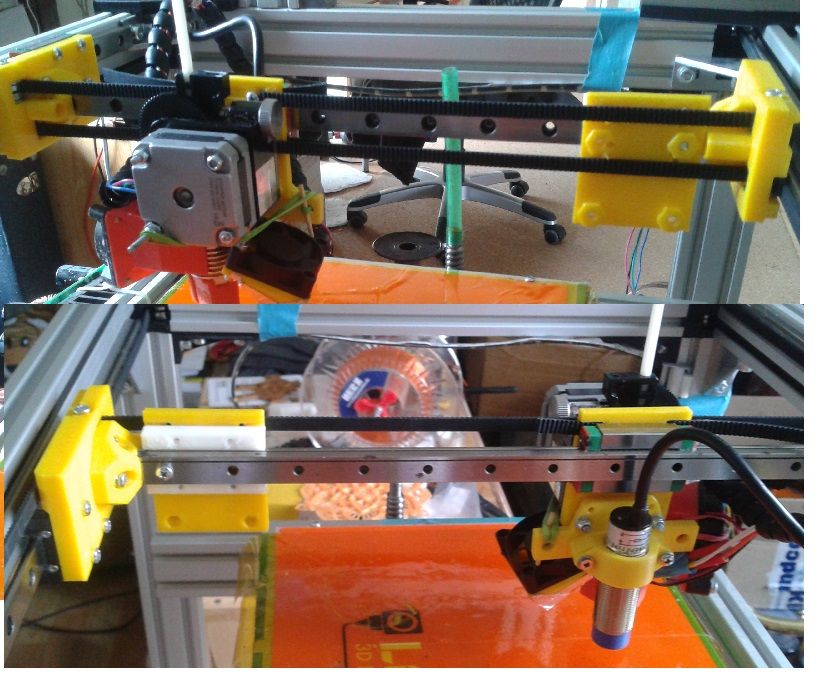

Here's a little teaser of the dummy U-carrier waiting to be connected and mapped.

It's an IDEY CoreXY BTW...just in case someone has a clue how to run this.

-

I found this in the wiki, but there is also a K11=MarkForge type of kinematics, but no further explanation. I guess it's trial&error time , as usual...

CoreXY with extra Markforge U axis (see https://forum.duet3d.com/post/136554 ) M669 K1 X1:1:0:0 Y1:-1:0:-1 Z0:0:1:0 U0:0:0:1 -

@RichardDuke

It's alive

The kinematic is the same as MarkForge (M669 K11) but I had to modify it, because my crossbeam is the Y-axis.

I've called it simple-IDEX or s-idex and linked the video to this thread.

Here's a short video with a fixed dummy U-axis.

Next I'll fix the Y-axis and work on the reversed kinematic. -

@o_lampe said in IDEX CoreXY, With Only 2 Motors.:

@RichardDuke said in IDEX CoreXY, With Only 2 Motors.:

The kinematics of this directly correspond to that of Markforged, except at every toolchange, both X and Y motor logic is swapped and reversed.

Is it possible to do the swap during a tool change? What does the firmware do in that case? There are some restrictions to the stepper parameters, IMHO some require a reboot? @Phaedrux ??

Nothing requires a reboot to configure. Everything can be done on the fly. The only reason DWC suggests a reboot after changing config.g is so that your changes can be applied. Could also be accomplished by sending M98 P"config.g" to execute the file as a macro.

Some changes may have a quality impact if executed during a print, but if done stationary no problems should arise.

-

@o_lampe said in IDEX CoreXY, With Only 2 Motors.:

@RichardDuke

It's alive

The kinematic is the same as MarkForge (M669 K11) but I had to modify it, because my crossbeam is the Y-axis.

I've called it simple-IDEX or s-idex and linked the video to this thread.

Here's a short video with a fixed dummy U-axis.

Next I'll fix the Y-axis and work on the reversed kinematic.Soooooo..... that is awesome! You're a superstar for testing this out! What an wicked post to wake up too.

I guess I am going to have to start ordering some parts and join in on the SIDEX action!

-

@RichardDuke

Goooooood MORNING!

I thought about the name of the new born baby, maybe locked IDEX describes it better?

I also have found a way to include the lock and a small servo to my X-carriers. Will photoshop the idea for all of us to discuss.I printed two things yesterday, expecting to see more overshooting at the corners, where the single belt has to catch all the moving mass, but a test cube was practically identical to a formerly printed one.

The second doesn't show any signs of difference, but I'll inspect it again in bright sunlight today. Still unsure how racking would show? Lost steps and screeching carriers?The only downside is, I was so proud about the small frame with regards to the print area, but now the second carrier eats up a lot of space. Maybe I have to order a few longer 2040 extrusions and reassemble the whole frame.

-

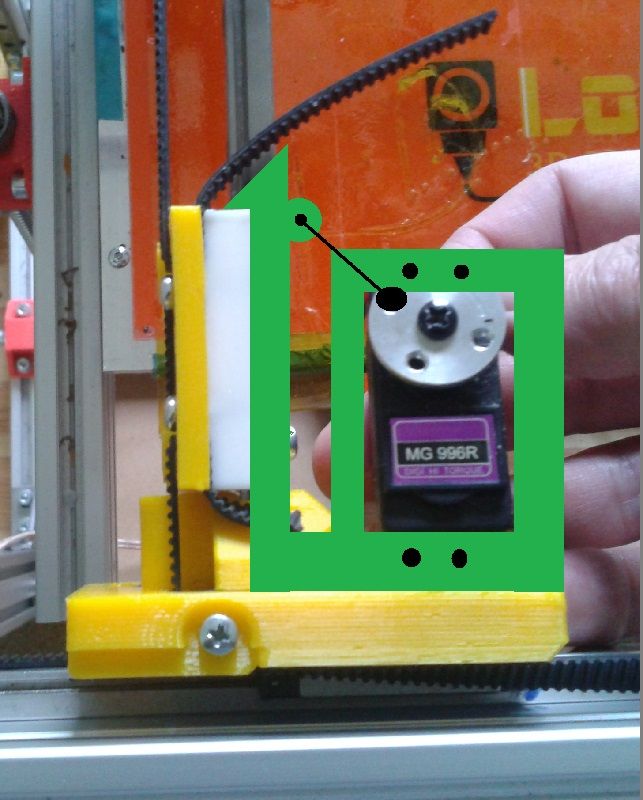

Here's the basic idea of a servo-locked carrier. The servo arm should be at top_dead_center when the carrier is locked. This way we can switch it off when not needed.

I'm not sure if the small 9gram servo can pull the PETG-hook away from the carrier, but the other servos I have are 60gram standard servos ready to rip the hook off if necessary

PS: @Phaedrux why are my pictures always rotated 90° CCW, when I upload them the first time?

The 60gram Servo looks more like it.

-

@o_lampe said in IDEX CoreXY, With Only 2 Motors.:

why are my pictures always rotated 90° CCW, when I upload them the first time?

possibly because they are saved rotated, but your phone "unrotates" them for display?

-

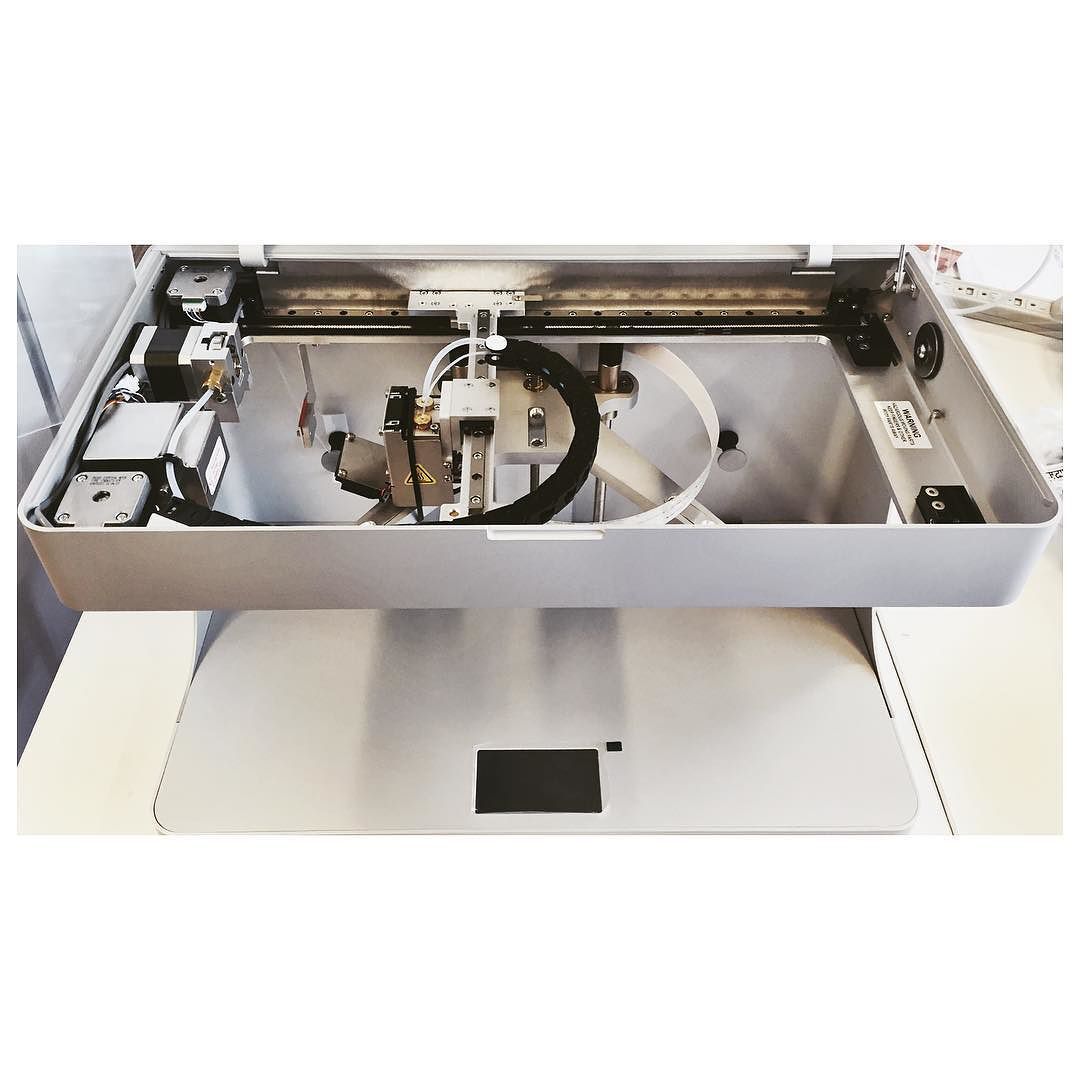

I also have a (dual) Markforged printer and to weigh in a little on the racking issue. I agree with @fcwilt, two Y-axis belts is a good idea or you have to have a very ridged bearing setup like on the Mark one.

Notice the solid one piece gantry with two bearing on each end spaced apart to keep it from skewing. This allows them to get away with just one Y-axis drive. Personally I think its better to add another belt to keep it square considering it does not add any moving weight like additional bearings and a heavy gantry. If you want a IDEX though, it makes more sense to double up on the markforged, which will also equal out the racking forces.

I think its a good thought, but I'm not sure I understand the purpose of locking the carriages to save a stepper. You would just be adding more moving weight, as the second motor on a dual markforged is parked on the frame.

You are welcome to check out my project, it might give you some ideas at the very least. https://github.com/3dprintingworld/MULDEX