Z-Wobble vs temperature instability - Video

-

I seen this exact effect with an old mk42 clone. Even on PID it would do it a little. It just seemed to have very slow response either from the heater or the thermistor, I'm not sure. I did several tests with it, and when I printed with the bed heat off, the z wobble effect disappeared entirely. Swapped the bed after that and never had the problem again.

-

We've been advising users to use PID for the bed for years because of exactly this issue.

-

My bed is 400x400mm 850W Bang bang controlled DC Aluminum 8mm bed. It does expand initially but settles after target is reached and doesn't rise/lower when heater is turned off/on. Temperature fluctuates +/-0.2 Degrees. The heater is turned always on when temperature goes below target temperature, which I don't think is a good way to control temperature via SSR as it connects so rapidly. Is there a way to add hysteresis to bang bang controlled bed (for RRF3.2 / Duet 3)?

My bed heat expansion:

https://youtu.be/tOQ3MXlgEK0 -

@visionary, I must admit that I am floored by the amount of change in your bed height .... I was expecting (gut feeling) 0.1 mm or so but a full 0.4 mm is amazing.

I am usually quite casual about heating up the bed before doing measurements except when doing a full bed probe. Your video clip has instilled in me new respect for heat related dimensional change. Thanks for posting !

-

@visionary said in Z-Wobble vs temperature instability - Video:

Temperature fluctuates +/-0.2 Degrees.

That's at the thermistor. Can it have larger fluctuations at other points of the bed?

-

Hard to say. The thermistor is embedded in silicon heater that is glued to 8mm aluminum plate. In order to measure temperature on other points I would need several thermistors placed in many different points or perhaps a really good thermal imager. Note that I never have had to re-level the bed because of it, but only set new endstop trigger height.

-

That´s a very interesting Topic

2 Weeks ago, i changed my 450x450x4mm stock-print bed to a face milled 10mm Cast Aluminum Plate with a 1200W AC Keenovo Heaterwith the new 3.3beta and PID, the temperature barely fluctuates slow around 0.1°C when heated to 65°C.

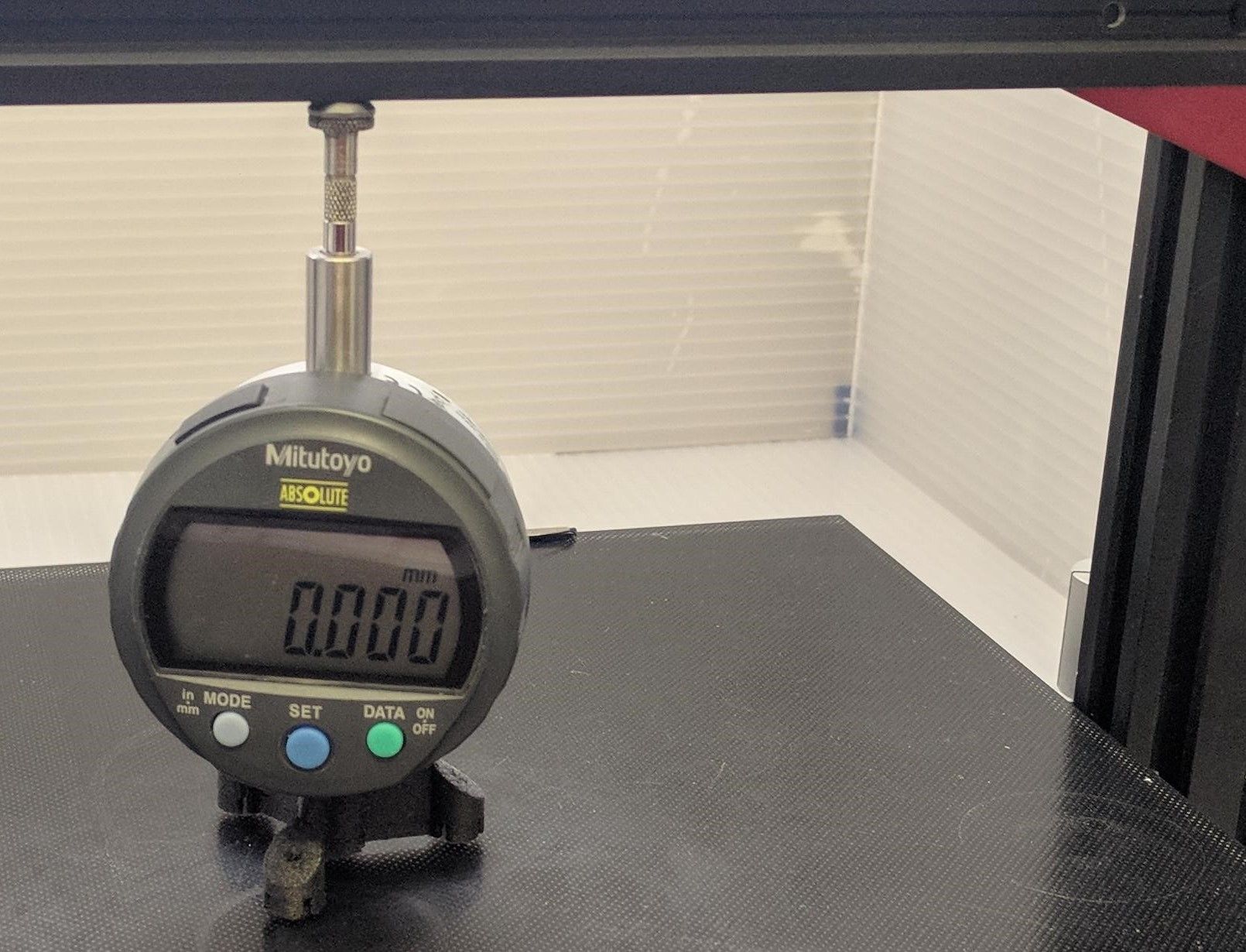

I also have a few 0.01 indicators (digital/analog) and will test that also with the plate alone and again with an additional 4mm borosilicate glass plate on top or a FR4 that i have laying around.

@Visionary

That thermal expansion is amazing !

How long was that in real time ? -

I think this effect is most common on thing PCB heaters. Silicone AC heater pads bonded to thick aluminum plates are a bit different.

From what I've gathered it's not so much the aluminum expanding and contracting as it is the traces of the heater itself rapidly heating and cooling that is causing it to change shape. The thermistor may only report a 1c oscillation, but the heater traces themselves will be changing much more than that since it's going from full power to no power.

-

@phaedrux said in Z-Wobble vs temperature instability - Video:

Anyone have a dial indicator they can throw on the bed?

Another interesting experiment that doesn't require equipment is to try to induce z-banding via bed temp changes. E.g. with PID enabled, and using the slicer's layer change script set alternate bed temperature every few layers (e.g. 60C, 50C, 60C, ...).

-

@phaedrux This is definitely where I've seen it happen. With the large PCB heater bed I initially had on my coreXY, it was profound. I could see it plainly by eye, no indicator necessary.

-

I took some time to test this pseudo z wobble thing out on one of my printers with the same configuration as the one in the video, aka Prusa style bed slinger. The biggest difference with mine is that it has a fair bit more glass between the edge of the heater and where the bed is supported on the ends. about 80mm. The 4mm boro bed measures 380x250 with a 200x200 keenovo 500w a/c heater in the center configured as PID but I also manually turned the bed on and off to maintain +-1°.

The heat input is not causing thermal growth in the way I was thinking its making the bed buckle downward in the center (expanding the heater side surface, dah). Using 3, Interapid tenths indicators (i'm converting from imperial) positioned at center and ends the center drops .2mm between 30 and 100° and the center indicator starts moving as soon a the bed gets power. When it noses over at 100c and cuts the power the bed comes back up .1mm then it wallows around until the temp starts to stabilize. When it does stabilize the temp fluctuates .4° and the indicator moves over a range of .01mm. Not bad. Moving all 3 indicators over the heater I did notice the bed is not bowing in a consistent arc. The hinge appears to be right at the edge of the silicone so the bed seems to be staying flat in the heater area just moving up and down.

Repeating the test with the different indicator positions and manually cycling the bed to get the +-1° it is creating the effect CNC kitchen described. The bed is moving over a range of .05mm which obviously is a lot. Even with a sloppy PID range of 1° is still moving .04mm so having PID doesn't guarantee you wont have a problem, the temp needs to be dialed in to hold at most .4 or .5° range in my case.

I would also theorize that if the heater wasnt producing consistent heat throughout then the part could be tilting as the heater cycled. The taller the print, the more pronounced this will become. Geez, this is getting messy

Another useful thing I got out of this was measuring the actual bed surface temperature. I have always checked it in the past with an IR gun and its been within a few degrees of the thermistor. While testing with the indicators I used thermocouples specifically designed to measure surface temp. Using 3 different setups to validate it is at best 20 deg lower than the thermistor is reading. Perhaps this is because the IR thermometer is measuring the source of IR not the surface temp of the glass. Not sure -

Next time any of you guys with bed slingers run a print would you mind looking to see if your bed temp is stable? When I auto tune the bed it's dead on and doesn't budge. Maybe .1deg here and there then when I start printing it starts to fluctuate with an occasional swing of almost 2 degrees. Now that I know the bed moves alot over this range I'm thinking this may be why I've been chasing quality issues for so long on this machine

-

@3dpmicro, I have two bed slingers. One is running in bang-bang mode and fluctuates about 2 degrees C. It is a 300X300 CR10. I see no obvious issues.

I also have a 500x500 CR10-5S with PWM heat control and it is rock steady.I do have issues here and there but bed heat is not anywhere near the top of my 'need to fix' list. If your printer is perfect in any other way (which by definition excludes a bed slinger IMHO), then you can worry about bed heat.

-

Thanks @jens55 Since I've recently verified that a 2 deg swing raises the bed up and down a total of 25% of my preferred layer height (.2mm) Im thinkin' that's a big'en

-

@jens55 said in Z-Wobble vs temperature instability - Video:

If your printer is perfect in any other way (which by definition excludes a bed slinger IMHO),

The canonical desktop 3D printer (Prusa MK3) is a bed slinger.

(And it runs on a 8 bits processor and has no wifi)

-

To get an idea of the bed vertical issue I made some Z measurements on a CR10S pro with a heated glass bed. A dial gauge sat in the center of the bed with the plunger pushing up on the bottom of the 2020 X axis extrusion. This setup is mechanically rigid and repeatable but the digital gauge can’t take the heat so quick measurements are needed when the bed is over 45C.

First test: Heating the 400W bed at the full power starting at 20C and stopping at 40C. This creates a large temperature difference between the top and bottom of the bed causing the bed center to lower 100um. Then with the heater turned off the bed temperature equalizes down to 30C with the final bed center 10um lower than at 20C.

Second test: Bed set to 35C with the bed temperature cycling 0.3C over a 6 second on/off heating cycle. When the heater is on the bed quickly bounces down about 10um then slowly returns.

Third test: Setting the bed temperature to 110C and waiting about 10 minutes. Just before the 110C temperature is reached and the heater is still fully on, the bed is 133um lower. Allowing several hours for thermal equilibrium to be reached inside an insulating corrugated plastic enclosure before the next measurements are made. The warm enclosure air is 45C while the bed heater cycles on for 2 seconds and off for 2 seconds maintaining the bed at 110C and varying 0.1C. The bed height is now 100um lower that at 20C and it still bounces down a further 6um when the heater is on. (I used a current meter on the mains voltage to know when the heater was on and off).

The stock printer has a circuit board style heater bonded to an aluminum plate with an insulating blanket below. Not stock are the glass plate build surface clipped on top of the aluminum and two thin and wide brass sheets located between the aluminum and glass. This is to reduce a trench and improve the overall glass plate surface flatness.

-Peter -

@peter120, thanks for taking the measurements.

What I get out of this is that it is important to map one's bed surface after everything is warmed up as we can see a difference of 0.1mm between a cold bed and a hot bed but that a temperature swing of a degree or two will see a difference of maybe 0.01 mm which in my books is insignificant and well within the mechanical error of the whole system. Heck, assuming the printer is sitting in a wood structure (ie normal North American house built), I suspect a person walking past the printer would induce an error well in excess of this value due to slight deflections of the feet of the printer that vary based on the position of the person.

As a side note, when my 22 kg dog walks past my heavily padded easy chair, I can feel the floor moving/deflecting. It's slight but it's there. -

I've since gone to adjustable voltage control for bed temp (manually set). Before with PID I could get it dialed in to a .2deg fluctuation but as soon as I started a print the temperature became unstable sometimes swinging 1 degree or more. Turns out that varying airflow from bed movement affected the insulated thermistor (that came installed on the Keenovo 500w heater). Discovered this by lightly blowing on it a foot away. Ive been chasing quality issues with this machine for years. Seems to be finally fixed but only time will tell for sure

-

@3dpmicro, this seems quite odd, The Keenovo (and many others) bury the sensor right in the pad and it is covered to the outside with a layer of silicone. You should not see fluctuations (and really there shouldn't be air flow) like that. A fluctuation of 0.2 sounds normal.

Lightly blowing from a foot away should not result in a noticeable temperature drop. It seems to me that there is something else going on or that your 'lightly blowing' is actually a minor hurricane .....

A proper setup from the bottom to the top should consist out of an insulation pad, the Keenovo heater, the aluminum bed plate and then your print surface. If you have that insulation under the heat pad there is no way that 'light blowing' will affect things this much.