#- (hash) printer with super simple gantry

-

@mikeabuilder @fcwilt

you both describe a Kelvin mount. I opted against it, because I wanted to have three identical ball-guides.A filed 45° corner would have to be perfectly machined. The Acorn nuts will drive you crazy, because they are only casted with high tolerances. (They are produced for the looks, not for accuracy)

The 120° approach would be easy to implement on a circular bed on a Delta frame, but a square bed frame ends in 90+2x150° angles. Not too bad, 'cause we don't need equal expansion.The whole build is experimental, I expect more trouble with the XY gantry. (and slicer/firmware issues)

-

I made a short demo video as appetizer for things to come.

It shows how two tools can draw different shapes at the same time. The other two tools can draw other shapes, but not at the same time.

Four tools could draw/print the same pattern simultaneously, eg. the four feet of The Eiffel tower. That would even be easier to slice and postprocess...

I'm using feltpens for now, but with extruders it would be ready to 3D print. (adjustment of individual Z-height per tool is important then) -

@o_lampe said in #- (hash) printer with super simple gantry:

@fcwilt

you both describe a *[Kelvin mount]After reading about the different kinds of mounts I decided to follow your lead.

I modified my printer to use a mount similar to yours.

My bed is supported by a frame made from 20x20 extrusions and the mounting points are on the frame well away from the heat of the bed.

I now have three one piece printed parts with a V for the ball to ride in.

They seem to be working fine.

Here is one of them:

Thanks for leading me to a better design.

Frederick

-

@o_lampe looks very good! impressive that it can manage 2 different designs at once.

Looking forward to seeing this thing print! -

@jay_s_uk said in #- (hash) printer with super simple gantry:

impressive that it can manage 2 different designs at once.

Well, I cheated a bit since both objects have the same path-count.

circle vs square would be much harder to merge into one file.

Then I'd have to keep an eye on layer times. Probably have to slow down one tool to see them finish at roughly the same time.

I'd have to split long straights into short segments and sync them with the arc-moves (G2/G3 is another story)

And let's not forget the missing independant Z-adjustment, I'm still trying to figure out.sigh we will see feltpen-demos forever

-

@o_lampe I can see where that would be difficult. you'd also have to do something about ooze/moving a tool out the way as well

-

@jay_s_uk Oozing can be nasty on multitool printers. I have a parking-slot on my IDEX printer, which has a nylon part where the nozzle rests on.

The good thing about the hashPrinter is, they (could) have way less tool changes than the classic toolchangers. (in the future) -

@fcwilt said in #- (hash) printer with super simple gantry:

Thanks for leading me to a better design.

To be honest, in the end I wasn't sure if it's better. The arguments about misaligned guides made me think. But from a 3D perspective, the Maxwell design is easier to build. (How would I drill a really round hole with my cheap drillpress? They tend to be triangular)

-

@o_lampe said in #- (hash) printer with super simple gantry:

(How would I drill a really round hole with my cheap drillpress? They tend to be triangular)

try to use a reamer?!

-

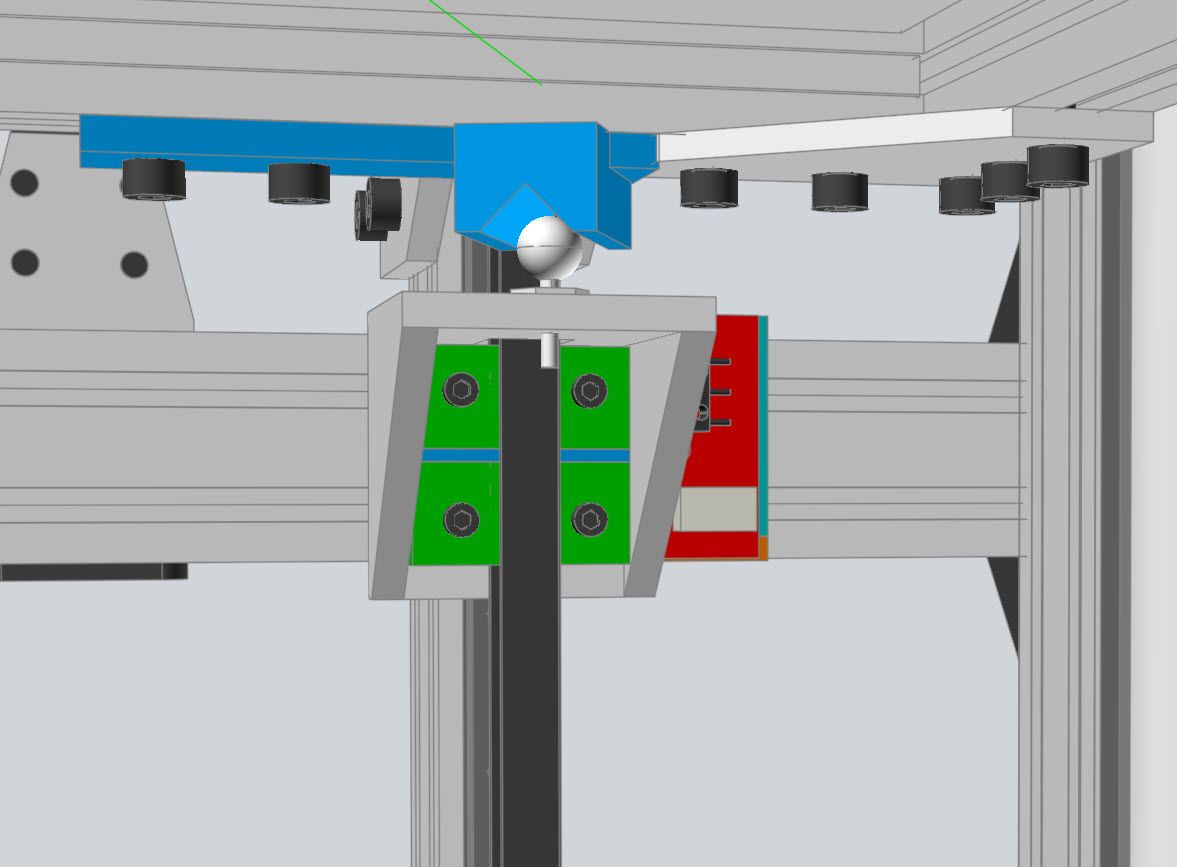

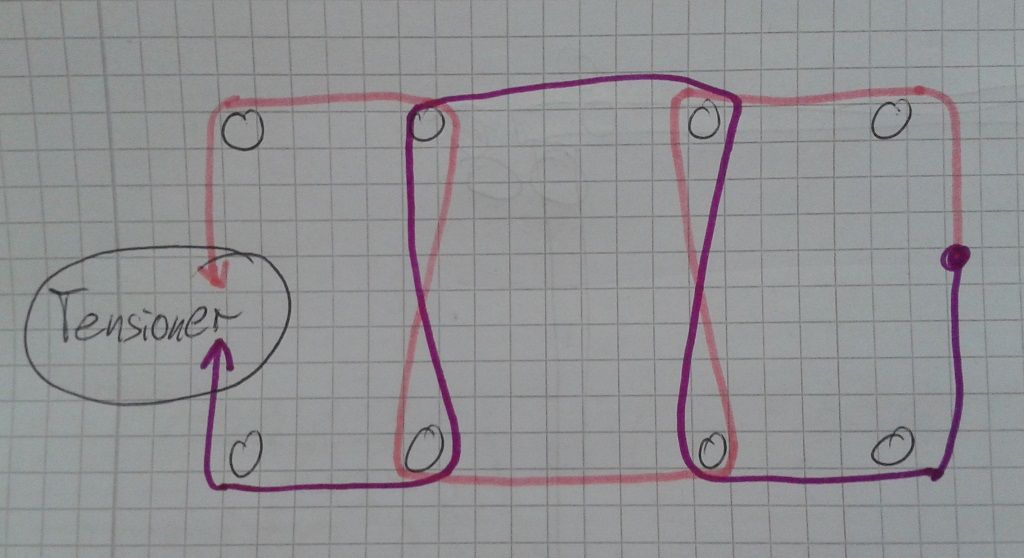

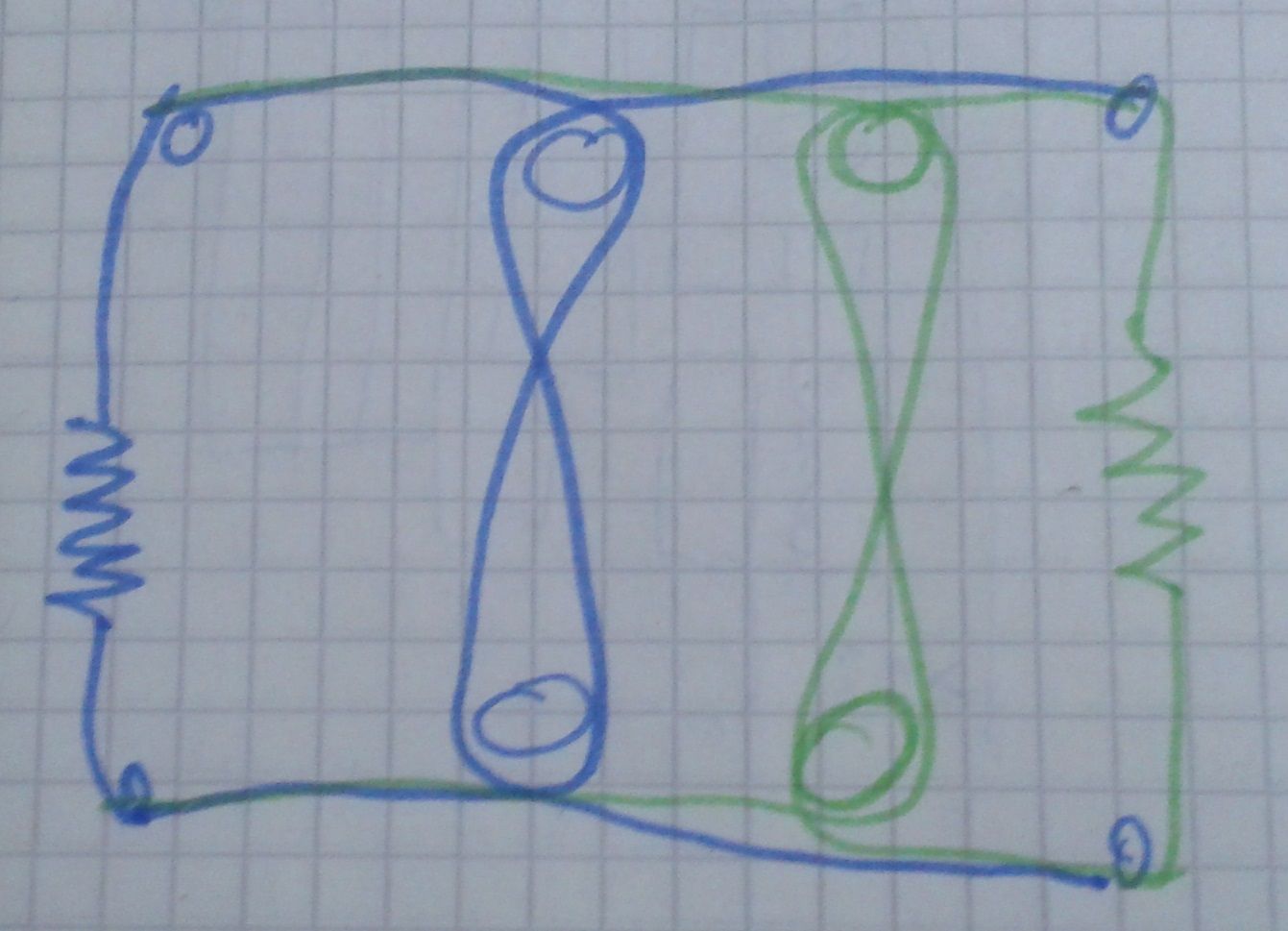

More and more test hours for the gantry and it is beginning to show an issue. The dual-dual roller constraint fails sometimes.

I think, I have to split the Aramid-line into two parts and fix the ends. Which means, I have to disassemble the whole gantry

Before/after:

-

Just for the record, I have configured bed leveling (G32) and mesh leveling with the mini-IR probe.

It's blazing fast, the first G30 to set Z=0 always scares me

-

@o_lampe Almost forgot to mention that it runs with the split dual roller constraint now and it never failed yet.

It's time to add some extruders and print some benchies.

-

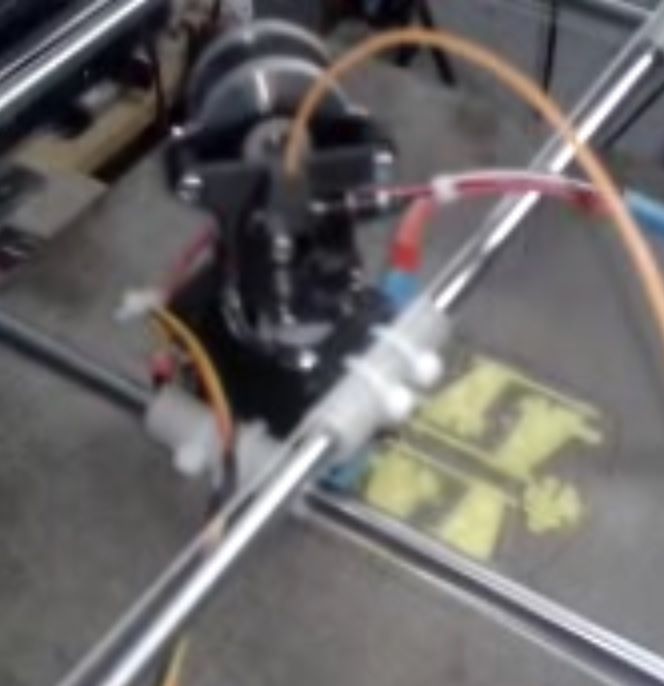

It's ALIVE...

Actually no big things to report here, it just finished the first print. With only a single nozzle and without a fancy mini-Z axis. I just want to see if the two smooth rods are stable enough to carry a direct drive sherpa mini and to gather some experience with the new_to_me pertinax build plate. (feel free to share your findings with yours and PLA, PETG)The result reminds me a bit of my first prints on a Prusa i3...there's room for improvement

Sorry for the blurry pic, it's a screenshot from a short video

-

@o_lampe

I have to add more tie-raps (*), just doubling up the drylin bearings doesn't help much.*) can you believe it, German hardware stores are running out off supplies?

-

I use 0.5mm FR2 (pertinax) on flex steel sheet, needs a good sanding and then works pretty well and is very resistant to abuse (-;

-

@oliof I skipped the steelplate and placed it directly on selfadhesive ferro-film 1mm.

What about bed-temps? I'm at 65C for first layer, but through the thick magnetic sheet the temp drops 5-8 degree (and takes extra pre-heat time of ca. 5min.)

-

No discernible difference compared to PEI sheet at 0.5mm. I know it can take a long time to heat up at higher thickness.

-

@mrehorstdmd calling

Everytime I see your sand table videos, I want to build one.

Now I think to build a square or round hashTable with 4 steel balls zipping around. They could draw the same mirrored pattern or 4 individual patterns ( two at a time)

The main argument to do this, is the lack of slicer and RRF options to run a printer with hash gantry. -

@o_lampe Why do you think RRF couldn't run a hash printer? It looks like a pretty linear relation ship between axis so should be definable with M669 matrix option. While tool changing might be a challenge, 4x copy/2x2mirror mode should be relatively straightforward to setup.

-

@oliof

I've already prooven that the XYUV kinematics work, but a printer needs a perfect first layer and that's the culprit for now.

RRF3.5 will have means for individual Z-axis adjustment of heightmap-corrections, but until then I have to find usecases with less critical Z-height. Sand table or laser engraver or feltpen plotter comes to mind.Quad ball sand table is by far the coolest option IMHO.