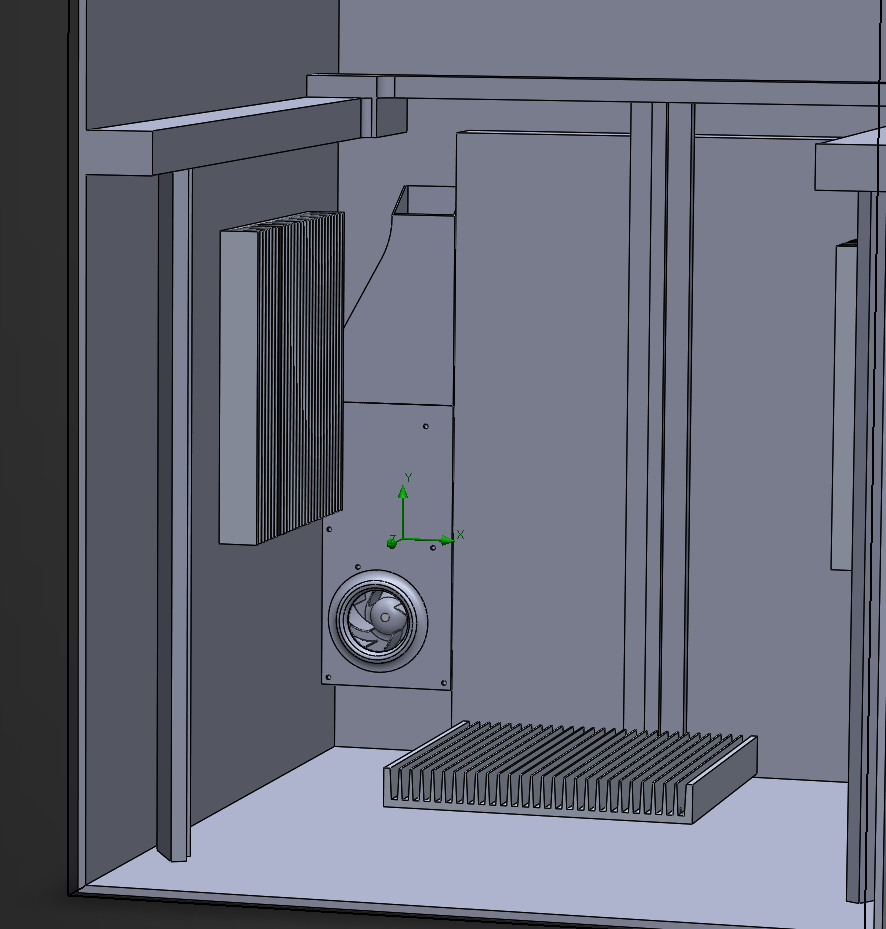

Heated chamber air circulation fan

-

@tlas I found a few fans with a max operating temperature of 90°C but that’s still too low for me. Problem with the kitchen stuff fans is the size, price or noise if you even are able to get them. My current solution is a radial fan out of a temperature resisted filament.

Currently calculating the optimal geometry and simulating the flow inside the fan and the chamber but I have no idea what motor I should use. My electrical knowledge is not the biggest so I have no idea what the best solution would be for this application. -

This place has a range rated at 150'C continuous, going down to quite small ones:

https://www.justfans.co.uk/commercial-fans-smoke-extract-high-temperature-fans-c-27_96.html?sort=2a

ps. For evening out the temperature, you should try a duct set up with a fan that pulls or pushes air down from the top to the bottom of the enclosure.

That moves hot to cold, countering some of the convection transfer and maintaining overall circulation.

-

@rjenkinsgb I totally agree with you but sadly there is no space left on top of the chamber for a fan and I plan to use the camber fan with swappable outlets so I can use the fan for part cooling as well. The link you posted is looks promising, thanks for that.

-

I'd mount a motor outside the chamber with a shaft going through the wall of the chamber, and use a metal fan blade inside the chamber. You might need a shaft coupler that won't transfer much heat from the shaft to the motor, but it shouldn't be too hard to find a suitable material.

-

@mrehorstdmd that was my current plan but i couldn't find a suitable motor. like i sad i dont know too much about electronics so i have no idea which motor is suitable for this application because i would like to control it with the slicer fan configuration

-

Since you're just trying to even the air temp you don't need anything more than turbulence so a real fan blade design isn't even needed. All you need are paddles on a spinning shaft. That would simplify the design considerably.

-

@chris94 said in Heated chamber air circulation fan:

I totally agree with you but sadly there is no space left on top of the chamber

The corner duct type of setup in your drawing would be fine, just with the fan at the bottom pulling air downwards rather than blowing upwards?

ps. Have you used high temperature cable all the way through for the motors etc?

Normal PVC insulation is not rated for 120'C - the industrial "Tri-rated" cable we use in machine tools etc. is only rated to 105'C. -

@phaedrux The Mechanical design is not my problem. But the selection of the electronic component is. I Don’t have a problem putting an oven fan in the chamber but controlling it would kill my knowledge because I don’t even have a clew how to control such a motor or if it’s even possible to do so. My favourite solution would be a simple fan motor outside the chamber but I don’t know witch motor I should use and how I should control it. I just want the fan to be quiet (1k rpm) and easy to use so I can control it via the slicer. Is it necessary to design a radial fan from the ground up with a part cooling in mind? No decently not but I like to learn as much as possible while building this printer and that’s why there is so much “overcomplicated” stuff like the hydraulic tool changer inside. I just need someone to guide me a bit in the right direction.

@rjenkinsgb Yes everything inside this Printer was selected with the Temperature of 120°C in mind (HT- cables, Stepper and Hotend are watercooled etc.). The position of the inlet isn't ideal but it should works good enough and if I put the whole thing upside down I wouldn't have a chance to use the fan in the future as a "part cooler" as well -

@chris94 said in Heated chamber air circulation fan:

My favourite solution would be a simple fan motor outside the chamber

If the fan is outside the chamber where is it drawing air from? If it's drawing air from inside of the chamber that is at 110c then you'll be hard pressed to find a plastic construction fan and motor that would survive that. Best I've seen rated at 70c.

-

@phaedrux the fan itself sits in the chamber and is connected to the motor by a shaft through the chamber. same principle as an oven fan

-

@chris94 said in Heated chamber air circulation fan:

My current solution is a radial fan out of a temperature resisted filament.

What filament?

-

@phaedrux 3dktop

-

@chris94 said in Heated chamber air circulation fan:

3dktop

Wow, I've never heard of that before.

https://3dk.berlin/en/3dktop-heat-resistent/200-3dktop-white.html

-

@phaedrux it's quite nice and not too expensive for its properties

-

Well since you have the fan blade portion possibly solved, the external motor and it's control is where you're stuck?

How heavy is the shaft/blade? Do you have a normal fan you could cannibalize to attach to the shaft?

-

@phaedrux the rotor itself is currently 16,54 Grams and the inertia is at 86,87 gcm². the shaft will be as small as possible and so not really heavy. cannibalize of some random fan would be possible but I don’t have one on hand and i would rather by a separate motor (less getto style)

-

Buying a new motor for the task is going to be unnecessarily expensive when so many fans are available for pennies. I'd pick up an old desk fan at a garage sale, especially if it has a metal blade, and add a shaft coupler. You're not trying to control the speed, just stir the air, so all the controller has to do is switch it on and off. One of the controller's standard fan outputs can drive a small SSR to operate the fan. If you don't want it running very fast add a small speed controller and just set it to run slow.

Whenever you're running the chamber heater you probably want to run the fan, too, so you could just power the two from the same source.

-

What about using a convection blower of an oven?

Used ones are really cheap and metal blades are included.... -

@diy-o-sphere all the cheap ones are loud but the bigger problem is that there is no space for one. under the chamber is a filament drawer so its not possible to mount something down there. i cant put something in the top part because of the motion system. so the only place left is at the back between the side panel and the cabel cover (95mm)

-

This post is deleted! -

undefined chris94 has marked this topic as solved

undefined chris94 has marked this topic as solved