DIY wire sheathing/insulation

-

@gnydick I wrap mine in expanding nylon braid. e.g this sort of stuff https://www.amazon.co.uk/Expandable-Braided-Sleeving-Protector-Automotive/dp/B09MKB2P1G/ref=sr_1_3?crid=M6O5B7SBKNC8&keywords=expanding+nylon+braid&qid=1660060362&sprefix=expanding+nylon+braid%2Caps%2C138&sr=8-3

-

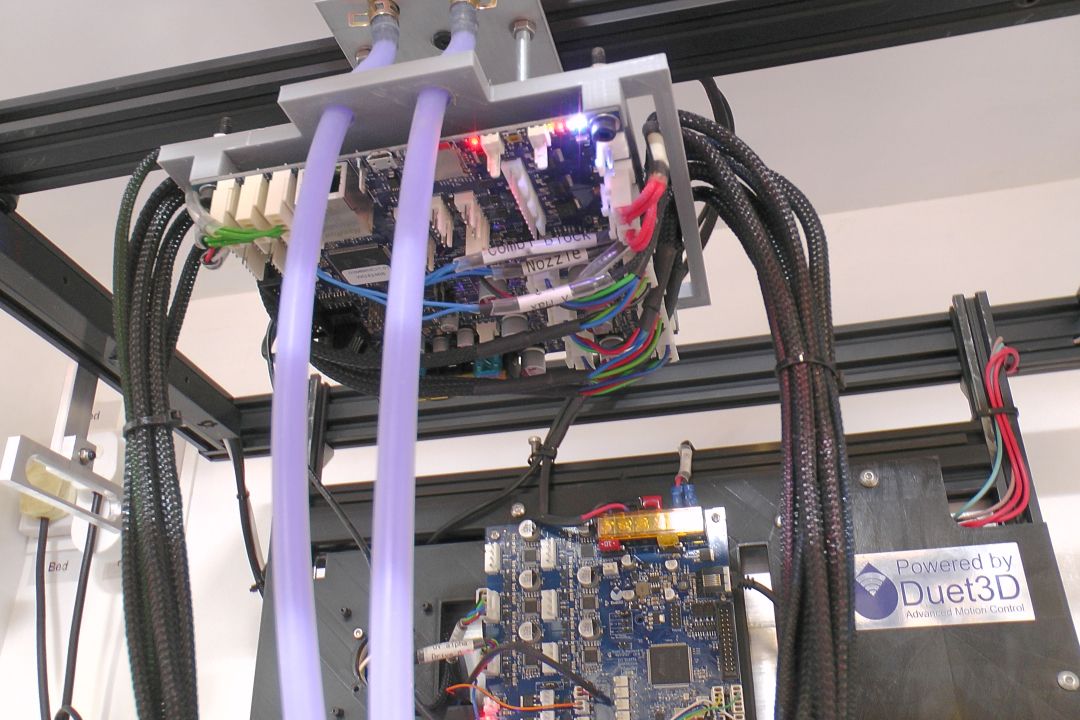

To give you an idea, here is a pic of the braided cables which carry 6 sets of extruder motor wires, two hot end heaters and their associated thermistors, and various assorted fans and end stop wires to the 6HC that I'm using as an expansion board and which is mounted above the hot end gantry.

-

@gnydick another alternative is automotive style Tesa cloth harness tape like this:

https://www.amazon.co.uk/Tesa-15mm-Adhesive-Wiring-Harness/dp/B00EVSD52M/ref=asc_df_B00EVSD52M/?tag=googshopuk-21&linkCode=df0&hvadid=272030589264&hvpos=&hvnetw=g&hvrand=12980541646026056246&hvpone=&hvptwo=&hvqmt=&hvdev=m&hvdvcmdl=&hvlocint=&hvlocphy=1007201&hvtargid=pla-761119842153&psc=1

It's possibly easier to apply (particularly if you want to branch wires!), but is a bit of a pain if you need to replace anything... -

@deckingman, thanks, I have those, they're OK. Was just curious if there's something that looks more tidy.

-

There is another option that I have been meaning to try:

I currently have the expandable nylon braid but if you expect that you might need to get at the cables for some reason, this product might be better. Expandable braid is nice but difficult to deal with if you need to revise things.

-

This is an option I've used before, maybe not 'soft', but it looks clean and easy to break out different wires at different points: https://www.amazon.com/dp/B07JQ1QHVF/

Other thing I've used is paracord sleeving, something like this: https://www.tweaktown.com/guides/5175/case-smithing-getting-started-with-diy-cable-sleeving/index.html

Paracord is a little softer than the expanding nylon sleeving and looks better IMO, also has a large color selection.

-

@gnydick said in DIY wire sheathing/insulation:

@deckingman, thanks, I have those, they're OK. Was just curious if there's something that looks more tidy.

To some extent I'd say there is a trade off between neatness and practicality. Taking my own printer as an example, it would undoubtedly look tidier if all the wires were bundled into two bunches - one each side of the expansion board. But my 6 input hot end is in a more or less constant state of change and I've learned over the years that it's generally best to limit the braiding to a single component. It just makes it easier and less disruptive to change something. But if you have a printer that does everything you want and you are unlikely to make changes, then some other solution might work better. If you do use braid, then one tip that I would give is to use glue lined heat shrink on the ends. I've found that the braid can get pulled out of "normal" heat shrink leaving a fraying mess. I also print labels for the cables and attach these by putting them under clear heat shrink.

-

@deckingman said in DIY wire sheathing/insulation:

If you do use braid, then one tip that I would give is to use glue lined heat shrink on the ends. I've found that the braid can get pulled out of "normal" heat shrink leaving a fraying mess. I also print labels for the cables and attach these by putting them under clear heat shrink.

Great points !

-

If you're not planning on making a lot of modifications, you can simply braid the wires together. Twist the pairs that need to be twisted, then braid the twisted pairs. As long as it isn't rubbing against something in the machine, braiding alone is OK, and keeps the wires together. It can be a PITA if you need to remove wires later, but so is most cable sheathing. Adding wires is easy- just poke them through the braids every few cm and they'll stay put.

-

@gnydick

This is how I would do it to secure the braid at the end.

(YouTube Video)

Be careful not to pull the braid too tight when securing the second end. -

@norder, that is pretty slick .... both the method for locking the braid and the way he gets all the lengths just right (one of my big frustrations). Very neat and tidy ..... but is he using a braid for each individual wire?

I wonder if you can use the braid melting method if you have a whole bunch of wires inside the braid - I suspect that this doesn't work and the heat shrink method is the way to do it. -

@jens55

If you are putting multiple wires into a braid, do it exactly as in the video except allow some of the braid to protrude from under the heat shrink, then heat the heat shrink so it contracts, and then fuse the end of the braid to a ring.

In this way you prevent the braid from fraying and looking unclean and damaging the cable sleeves.A clean piece of shrink tubing can then always be made over the end for a better look.

You may want to do some hot glue over the end of the braid before you heat shrink, like @deckingman mentioned.Google Translate

--- Original Text ---Wenn Du mehrere Kabel in ein Geflecht steckst, dann mache es genau so wie im Video, mit der Ausnahme dass Du etwas vom Geflecht unter dem Schrumpfschlauch überstehen lässt und dann den Schrumpfschlauch erwärmst so das er sich zusammen zieht, und dann verschmelze das Ende vom Geflecht zu einem Ring.

So verhinderst Du dass das Geflecht ausfranst und unsauber aussieht und die Hüllen der Kabel Schaden nehmen können.Für einen besseren Look kann dann immer noch ein sauberes Stück Schrumpfschlauch über das Ende gemacht werden.

Eventuell vorher noch etwas Heißkleber über das Ende des Geflecht machen bevor der Schrumpfschlauch darüber kommt, so wie @deckingman es bereits erwähnt hat. -

I also plan to reroute my cables.

It's such a mess at the moment and so many cables that the air from the fan can hardly get through.

I intend to do it the way it is done with today's computer cases... I put in a second floor under which all the cables disappear and that you only see the duet where the cables come out of the floor just next to the board and to the lead connections.It's always a pain when you want to change something on the board... you always have to cut the cable ties first to get there.

It doesn't look annoying or pretty either.

And... the cooling would definitely work better.Google Translate

--- Original Text ---Ich habe auch vor, meine Kabel neu zu verlegen.

Das ist momentan so ein Durcheinander und so eine Menge an Kabeln, dass die Luft vom Ventilator kaum noch durchkommt.

Ich habe es so vor wie es bei den heutigen Computergehäusen gemacht wird... ich lege einen zweiten Boden ein unter dem all die Kabel verschwinden und das man nur noch das Duet sieht wo die Kabel kurz neben dem Board aus dem Boden kommen und zu den Anschlüssen führen.Es ist immer eine Qual wenn man am Board etwas ändern möchte... erst muss man immer die Kabelbinder zerschneiden um ans Ziel zu kommen.

Nervig und schön sieht es auch nicht aus.

Und... die Kühlung würde bestimmt besser funktionieren. -

@jens55 I'm not sure I'd want to wrap my pets in it though

-

@nightowl said in DIY wire sheathing/insulation:

@jens55 I'm not sure I'd want to wrap my pets in it though

Say what ??? I am so confused .....

-

@norder said in DIY wire sheathing/insulation:

You may want to do some hot glue over the end of the braid before you heat shrink, like @deckingman mentioned.

Just to clarify, I suggested using glue lined heat shrink rather than glueing the braid separately. This type of heat shrink has a hot melt glue coating on the inside of the tubing. So when heated, it both shrinks and melts the glue.

-

-

@deckingman

That sounds good, I didn't even know that.

-

@deckingman said in DIY wire sheathing/insulation:

glue lined heat shrink

I didn't even know that was a thing.

What a great idea!

-

Thanks, everyone, great tips!