8mm Cast Tool Plate Design Advice

-

My experience with PEI was anything but happy. PEI is a 'wear surface' that can be easily damaged and it's a royal pain to remove that surface if it was glued on. In my case I installed the PEI on a glass plate to allow replacement. What is even more troubling (and this is based on my own experience so YMMV), getting the PEI installed flat is a BIG problem. I don't know how flat PEI is but in my experience, glass is not really that flat so no matter what you do, you will need to use height compensation. Also, a tiny air bubble getting trapped in the adhesive can cause you all kinds of grief. The PEI that i attempted to use came as a separate sheet of glue (marked with ' 3M' all over it) and the PEI so twice the possibility of air bubbles getting trapped.

The real kicker for me was the tendency for the PEI to curl at higher temperatures and the glue layer letting go. The force of the PEI curling was very strong and if I recall correctly, anything over about 100C for the build plate resulted in disaster. This was a fairly thick, maybe 1 mm (it's been a long time) sheet of PEI and I would never attempt to use a relatively thick sheet again. Both the PEI and the glue came from Amazon so it is debatable if either or both were made with chinesium in them or what. I still have the glass plate with the PEI stashed away someplace to remind me to never do this again.

I have no experience with spring steel build plates but I have no confidence in these either. In my humble opinion, unless you get the surface of the magnet being absolutely level with the surface of the build plate, you will have issues with surface distortion. I do not know if Mandala Rose surface grinds his plate after the magnets are installed but you pretty much double the price .....I have not seen complaints of people experiencing the issues that I had so who knows, maybe I was just lucky.

I have a cast aluminum tooling plate and I use a plain sheet of glass on top of it. I have a 500mm* 500mm printer with a fairly thick plate because of the overall size and I need to give the printer some time after the tooling plate is at temperature before the glass surface is at temperature. If I do not give it enough time (5 min is good), the print does not stick. I use no adhesion enhancers.

On my 300300 printer I have a thinner sheet of glass and the surface of the glass seems to be up to temperature if I wait to heat the hot end until the build surface is reported to be at temperature. The bit of delay heating the hot end seems enough to equalize the glass surface temperature.

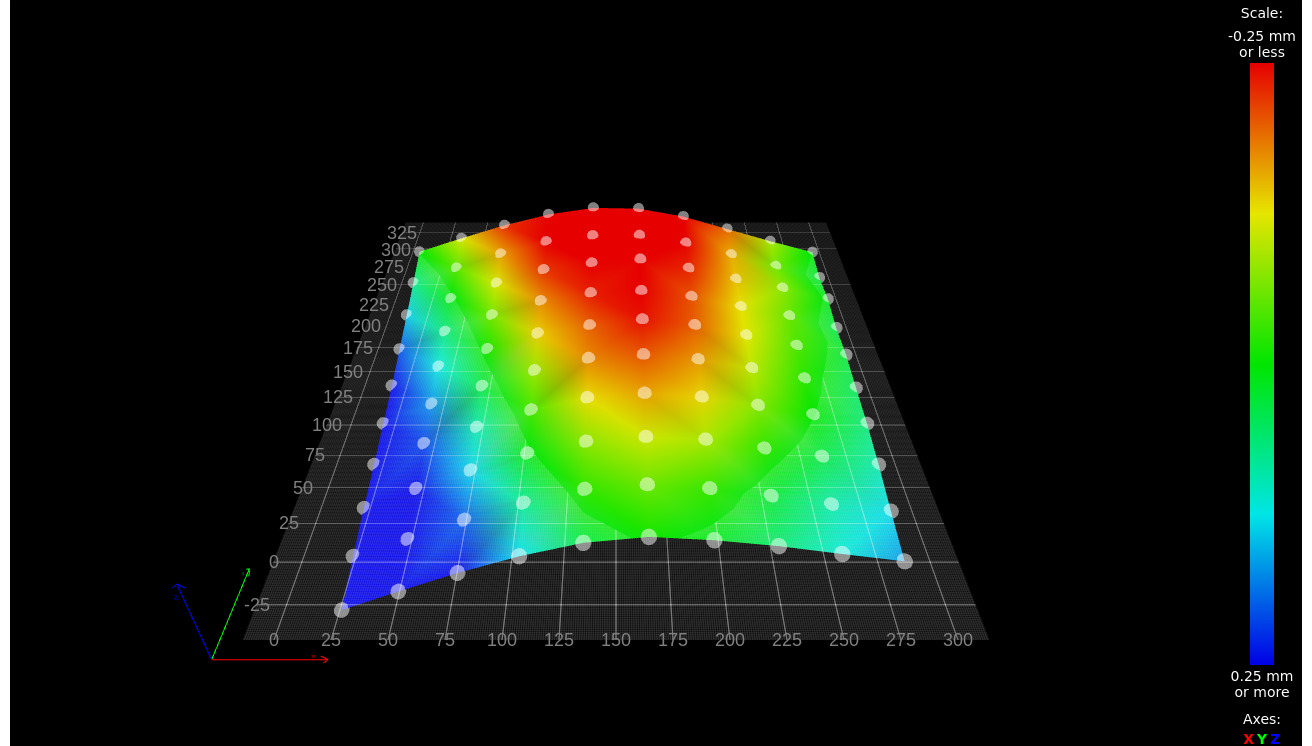

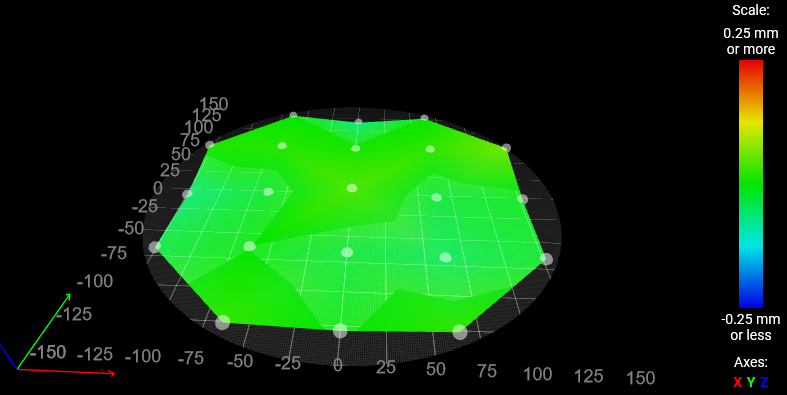

I have seen some amazingly flat print surfaces being shown here but I do not recall if those surface maps were the bare aluminum or the actual print surface on top of the aluminum. I am not that lucky. Here is my 300300 surface measured with 100 points with glass installed:

My tooling plate is supported by three points - a single point in the center of one side and two points at each corner of the other side. This allows for tilt to be adjusted. All three points are shown in green (perfect) and everything else is just crap. I am really glad that I have surface compensation!

One of these days I will run the surface mapping without the glass to see how flat the tooling plate is.Edit:

OK, so now I am starting to doubt myself - I can't recall if the plate I used was a cast tooling plate. It might have been a plain old 6061 piece of aluminum. I brought in two plates, one tooling plate and one plain plate and I might have used the plain plate to do the first milling run as a test but I never did a second run. I will run a surface scan in the next few days to see what the bare aluminum plate looks like. -

Just to throw my 2P worth in.... I run glass on ali and had trouble with the glass taking on the plates shape and having inconsistent flatness. Both solved by dabbing heat transfer compound onto the ali plate in a grid then placing the glass on top. Better heat transfer is a bonus (no waiting for the glass to heat) but the real kicker is the HTC is viscous enough to let the glass sit on it without running away, so the glass can retain it's own (very good) flatness without following the plate. It also stops the glass easily sliding laterally, should the nozzle contact a blob or suchlike. I still run bed comp but I'm well under 0.1mm and so consistent it's almost pointless to remap. I use it to tell me if one of the two Z screws has dropped really, though I should stop being lazy and set them up independent and get the machine to sort.

Removal is easy enough, just pull a single strand of wire through like a cheese wire to break the HTC. Clean and reapply. If you get a hump in the middle, just heat up and put some weight on. Leave it half hour and the glass naturally want to go back to flat, squishing the HTC where it needs to.

I'm not using anything expensive: stock Ender 5 Plus plate and glass bed. Also pulled the same trick on my much Frankensteined Anet A8, the bed of which is truly atrocious but perfectly serviceable with HTC and borosilicate glass slapped on top. It doesn't even have a probe or bed compensation! At the end of the day, ali is terrible at dimensional stability when heated. It's also full of stresses whether billet or cast. If it's not really well annealed to normalise it, those stresses will appear every time heat is applied. Tooling plates should be better than any old cheap slab, of course.

Hope someone finds it helpful, thought I'd throw into the discussion. -

Just my twopence worth on the topic of using glass as a build surface. Others may disagree of course but this is my personal experience having tried almost every other surface.

For me it is the perfect solution. I use 6mm thick float glass which is surprisingly difficult to break. When I first built my printer I had the glass toughened. This proved to be a mistake as the toughening process distorts the glass. So plain, unadulterated float glass works best for me. Glass is cheap, and readily available so I have 3 sheets. This means that once a print has finished, I can quickly and easily swap out one sheet, and start another print. This is important to me because my thick, insulated bed takes and awfully long time to cool.

I do use 3D Lac. This is primarily because it allows me to lay down the first layer at normal print speed (usually 80mm/sec). That saves a lot of time especially when printing large parts. When experimenting with high volumetric flow rates, I have printed at up to 300 mm/sec - including the first layer. I don't know of any other print surface or treatment product that will allow me to do that, but please correct me if you know otherwise.

I don't use any form of flatness or levelling compensation. The only time I even check for level is if I've taken the printer apart and transported it somewhere. No mesh compensation, no levelling, nothing - I just turn on the printer, home, heat then print (and I can print edge to edge). Not trying to brag or anything - just saying how it is for me.

-

My printer's bed is 8mm tooling plate with a 0.7 mm layer of PEI. The plate is 300x300 mm but has ears for the kinematic mounting points. The heater is 300x300 mm so the entire printable surface of the plate is heated. I would recommend against using a heater that is smaller than the print area because the temperature will fall off as you approach the edges of the plate and you may have trouble getting prints to stick reliably near the edges. It may also be cause for the plate to bow when heated, but that can be corrected if you use a bed sensor and sufficiently complex Z axis construction.

I print TPU, ABS, PETG, and very rarely, PLA, and find that everything sticks to PEI. Yes, it wears as you pry prints from the surface, but it can be easily buffed up with a melamine sponge. A few drops of IPA at the base of the print help release it from the PEI after the print is finished. The adhesive that holds the PEI on the plate tends to let go after a couple years so you periodically have to replace it. I suspect that sealing the edges with silicone will prevent the adhesive from drying out and letting go of the PEI.

When you order the bed heater, get one without any adhesive and glue it down using high temperature silicone.

-

@deckingman said in 8mm Cast Tool Plate Design Advice:

Not trying to brag or anything - just saying how it is for me.

You might not be trying but you are succeeding

Does the 3Dlac let go when the build plate cools down? Do you apply it before every print or does it last a long time once applied ? -

@jens55 said in 8mm Cast Tool Plate Design Advice:

Does the 3Dlac let go when the build plate cools down?

Yes absolutely. Parts just fall off or at worse need a light tap. One caveat - don't use 3D Lac with Woodfill filaments - you need a hammer and chisel to remove the part which will destroy it. There may be other filaments that react this way but I haven't found any - "normal" PET-G, ABS, ASA, PLA etc all work fine for me.

Do you apply it before every print or does it last a long time once applied ?

I apply ever print. I'm fairly sure, but not certain that any residue sticks to the part rather than the glass. I occasionally have to scrape excess residue off glass which has been applied outside the print area - once every 30 or 40 prints or so. But it's easy to do and I find a sharp 2 inch wood chisel works well as a scraper or a dedicated gasket scraper.

-

For completeness sake ....

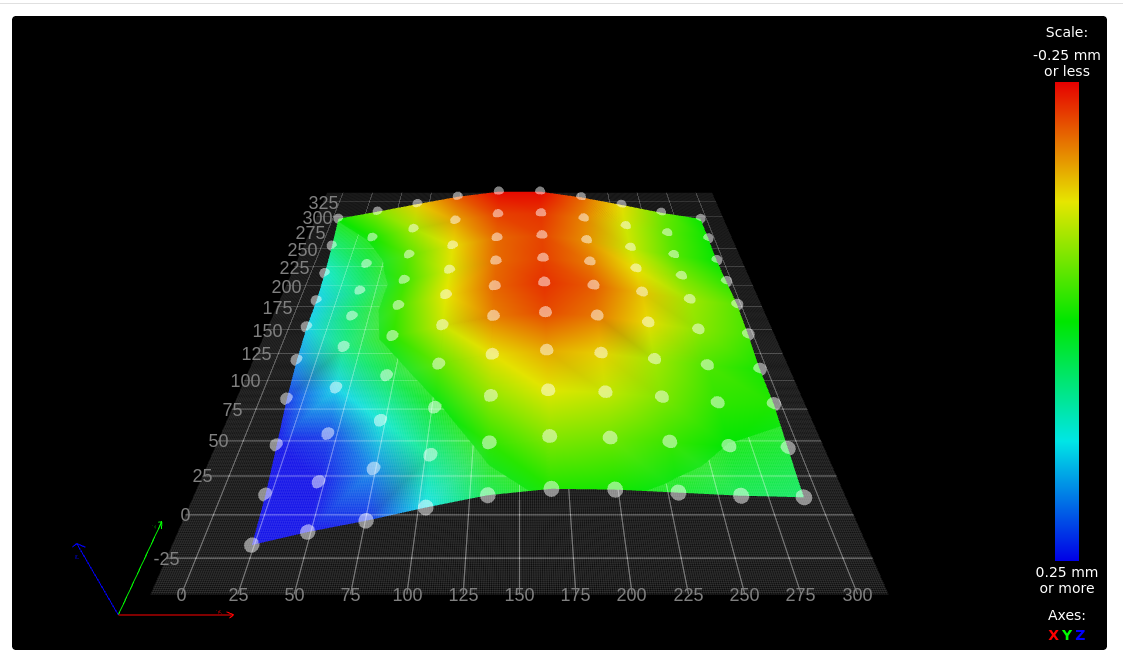

My plate is 7 mm and it is normal aluminum and not cast tool plate. Below is the height map without the glass plate installed (ie measured on bare aluminum). It is eerily similar to the height map with the glass plate installed. It would seem to indicate that the glass plate either conforms to the build plate or that this particular glass plate has, over time, conformed to the build plate. Glass is after all a liquid .....

So I was curious. I re-installed the glass plate but rotated 180 degrees. The result confirms that the glass plate takes on the shape of the bed. This is a fairly thin glass plate ....!

-

@jens55 said in 8mm Cast Tool Plate Design Advice:

............ Glass is after all a liquid .....

Ahh - that's where you might be going wrong - suggest you reduce the bed temperature to below 1700 Deg C where the glass will become solid.

This is a fairly thin glass plate ....!

On a more serious note, suggest you use thicker glass and ignore the naysayers who will tell you that glass is an insulator - if it was we wouldn't need to double or triple glaze our homes to keep them warm.

-

@deckingman, I sit corrected. A quick internet search seems to suggest that the glass being liquid is an urban myth. I was always told that really old windows were thicker at the bottom than the top which proved that theory. Unfortunately it turns out that manufacturing methods at the time were such that glass varied in thickness and the thicker section was always oriented towards the bottom of the window.

Just to be on the safe side, I will do as you suggest and reduce my build plate temperature by roughly 1635 degrees.The word 'insulator' is a relative term. Compared to aluminum or copper, glass is a poor conductor of heat. Compared to something like asbestos (or for that matter a gas filled space between two glass panes), it probably conducts heat a lot better. It definitively takes more time to heat a glass plate sitting on top of an aluminum bed than it would take to heat an aluminum plate sitting on top of that same aluminum bed (assuming intimate contact between plates).

I use mirror glass tiles as a 300*300 bed - extremely cheap but I have no choice on thickness.

If I was really curious, I would take my cast tooling plate, lay it on top of the existing bed and do a surface analysis. Alas, I am not THAT curious.

-

@Dizzwold

Why not use magnetic sheet instead of multiple magnets? You can buy a high-temp mag-sheet and use your springsteel PEI surface.

That's what I did on my last build, but the PEI easily crackes from part removing (might not like the flexible steel?)

So I replaced the springsteel with 1mm Pertinax held in place by a ferro-sheet. Don't go for two mag sheets, the one I picked has a north/south alternating magnetic pattern, which is very strong.

Pertinax is so far the best surface, but same as glass it takes a while to heat up. -

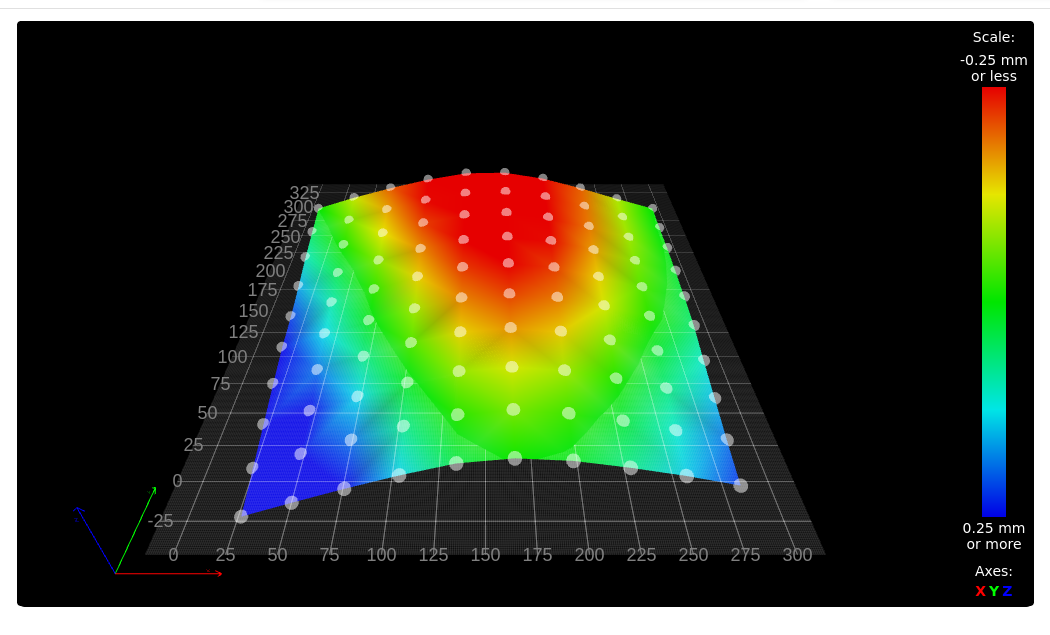

So, an interesting development ....

I put a cast tool plate over top of my bed and did a surface analysis - turns out that it appears to be pretty much identical as per the previously posted surface maps. This leads me to believe that there is something weird going on with my motion system. I am running a Jubilee printer with two linear y rails and one cross-rail which is X. Z also uses linear rails and height is done via three individual motors.

It doesn't make sense that the cast tool plate would show the same surface map unless something is out of whack with the gantry. At this point, I am guessing that my cross rail (x) has a slight bow in it -

@jens55 it's common for the X gantry to sag slightly under the weight of the print carriage. This leads to a height map that appears to show the bed being higher at mid X values.

-

@dc42, the Jubilee has it's z sensor on the carriage and the bed map is done without a tool head mounted. I doubt that it the weight is much more than 50 gr. Now once a tool head is mounted, I can see a bit of deflection even though the gantry on the Jubilee seems very sturdy.

As it turned out, loosening all the screws on the crossbar and tightening them ever so carefully from the center out got me a much improved picture. At the back things are out +- 0.02 mm and at the front it varies between +0.072 and - 0.073 mm. Very much improved. I am gobsmacked that the mounting screws of the x rail could cause so much distortion ... I guess when you are dealing with tiny dimensions, normal ways of thinking do not apply.Next I will go back to my original build plate which is not a cast tooling plate and see how that looks. I will run it both hot and cold, just for the heck of it.

-

@jens55 said in 8mm Cast Tool Plate Design Advice:

I am gobsmacked that the mounting screws of the x rail could cause so much distortion ...

Maybe there was a different room temp when you tightened them the 1st time?

If possible, I leave one end of the crossbar floating to be able to compensate fluctuations. -

Thanks all for the advice, this is very timely... I'm about to rebuild my TronXY as a VzBoT, but with a Jubilee-style kinematic bed.

Ian

-

Okay, thank you.

Pertinax, just looked this up. It's apparently a Trade Name for FR-2, or in other-words a PCB without the copper layer.

I do remember seeing a video from Makers Muse a while back and he recommend FR-2 or something similar.Regarding using these stick-on magnetic sheets. I was under the impression that these could cause undulations, and this was the reasoning behind milling pockets on the underside of the tool plate for neodymium magnets.

I don't know weather to go with neodymium magnets now or not. You've got to get the correct strength in force, at the correct depth, and have enough of them strategically placed.

@droftarts said in 8mm Cast Tool Plate Design Advice:

I'm about to rebuild my TronXY as a VzBoT, but with a Jubilee-style kinematic bed

Do you have any idea on what magnets are used on the jubilee bed and at what depth?

@mrehorstdmd said in 8mm Cast Tool Plate Design Advice:

everything sticks to PEI

Do you not bother with any adhesives, and would adhesives not help to save the PEI sheet?

I know I'm going to do as @deckingman has previously advised and drill a 3mm hole from one edge, as deep as I can towards the centre for the thermistor and also screw a TCO to the edge as well.

-

@Dizzwold I don't use any adhesives on the PEI at all. Everything I print with sticks. I sometimes have trouble getting larger TPU prints to let go. That's where a few drops of IPA help the print to release. I use a very sharp Olfa scraper to pry prints up. The PEI surface gets scratched up a bit, so I occasionally smooth it with a melamine sponge and frequently clean it at room temperature with IPA. The PEI that's on the bed now was installed when I built the machine, so 4 or 5 years ago. It lasts. The adhesive that holds it down is good for about 2 years, then it let's go of the PEI. So you just clean off the bed plate and the PEI and reassemble with a fresh sheet of adhesive. Then just a tram check/set and z=0 set and you're done. I suspect that sealing the edges of the PEI/adhesive with silicone would prevent the adhesive from letting go of the PEI. I'll be replacing the adhesive on my printer in the next week or two and will try it and see.

If you have the heater secured to the bed plate in a reliable mechanical way, you can mount the TCO on the plate. But if you use adhesive to mount it on the underside of the bed plate, the TCO should be fastened to the heater, not the bed plate. If the adhesive fails and the heater drops away from the bed plate, the plate mounted TCO won't do its job. I mounted the TCO on the heater in my printer using high temperature silicone, the same stuff I used to mount the heater on the bed plate.

-

@Dizzwold said in 8mm Cast Tool Plate Design Advice:

I don't know weather to go with neodymium magnets now or not. You've got to get the correct strength in force, at the correct depth, and have enough of them strategically placed.

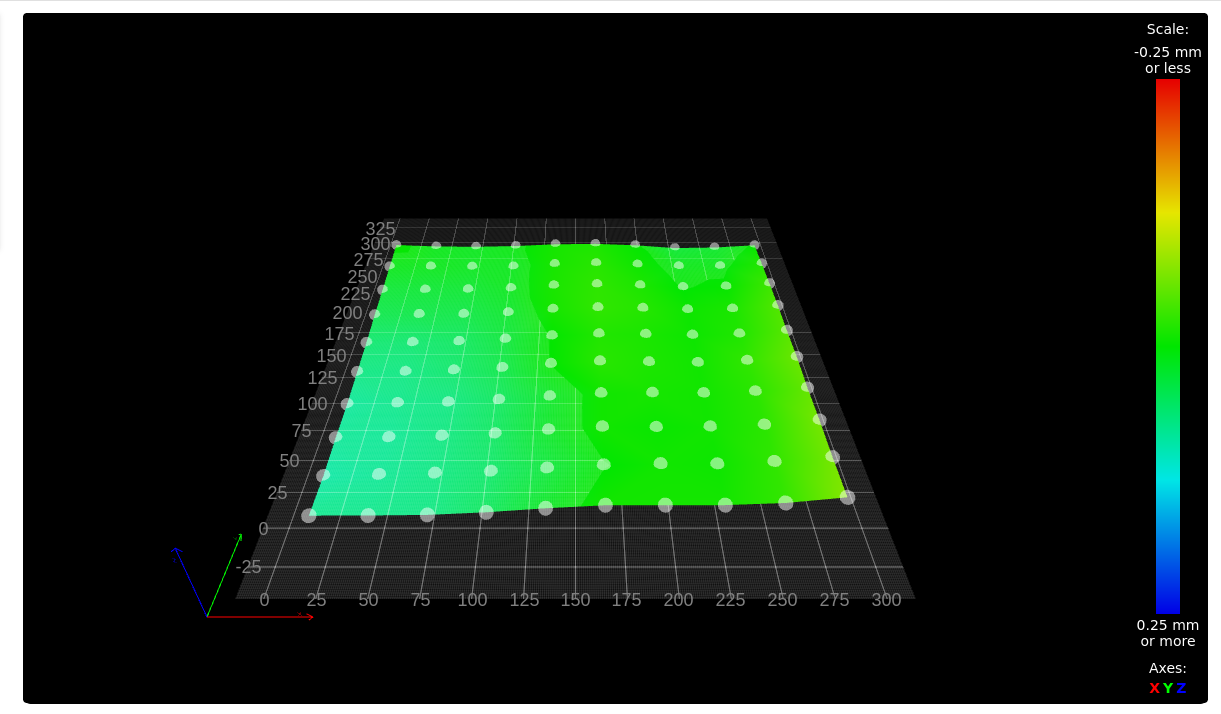

I used 6mm plain ordinary aluminium sheet (I didn't specify grade to my supplier, they supplied 5083 grade, apparently). It's not machined or cast or flatted, with a magnetic-held spring steel plate. It's flat enough for me:

The print bed plate is 'floating' on cork insulation. That is, there's an aluminium plate bolted down on the printer frame (actually, it has a thin PETG isolator to limit thermal conduction), then a stack of cork tiles with the print bed plate on top. The whole stack is lightly (ie, snug but not torqued down hard) clamped together with 3mm bolts at three points, but they are relatively flexible so I don't expect them to restrict plate expansion. I've never detected any bowing or warping as it heats.

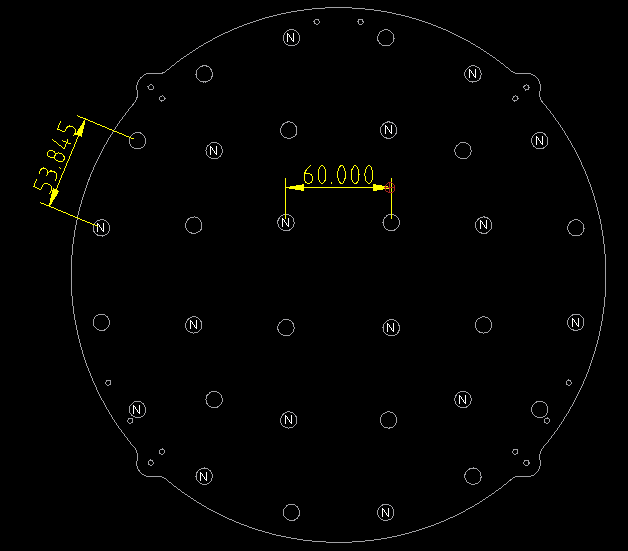

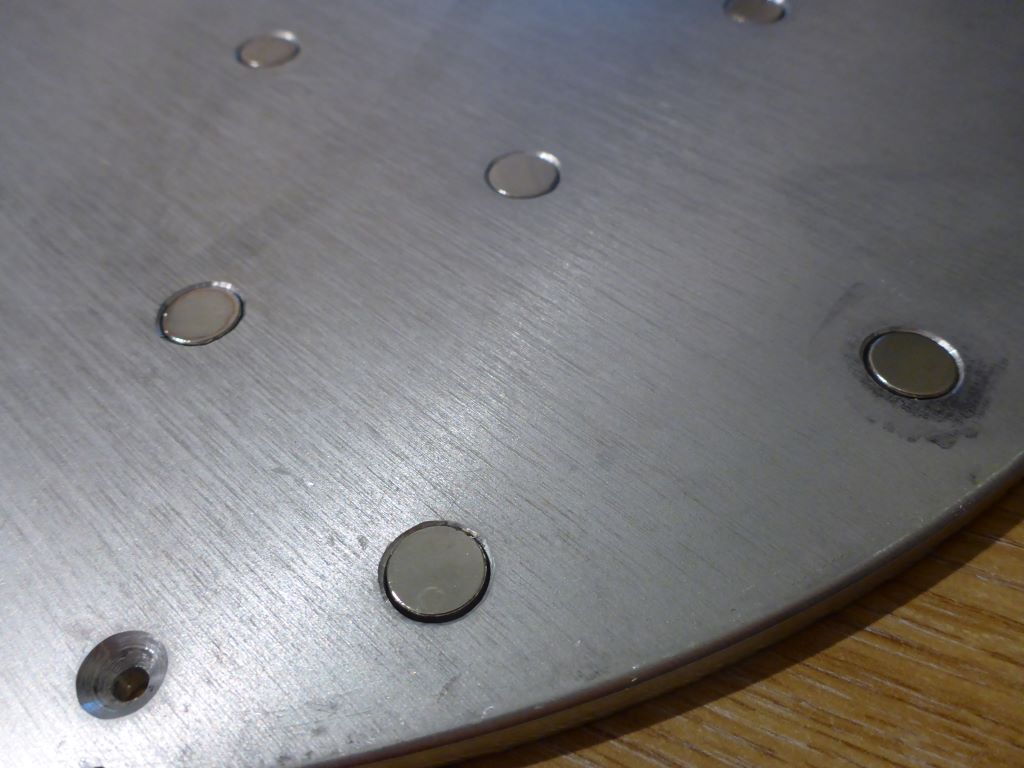

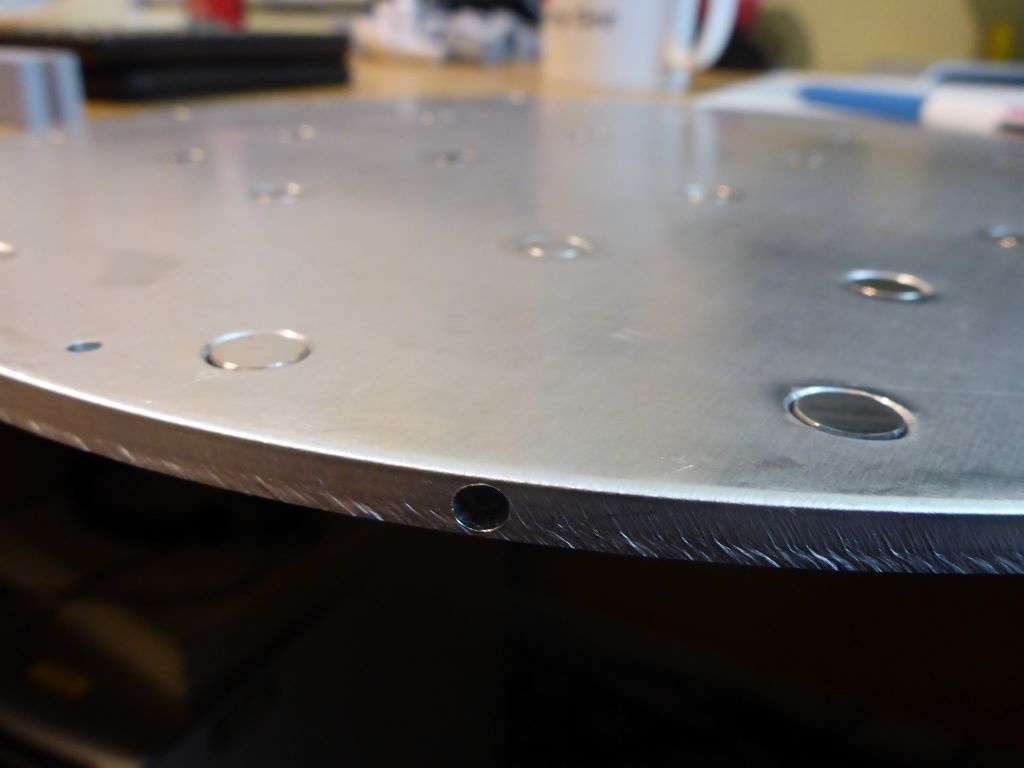

I only decided to do magnets after getting the plate cut, so the magnet holes are drilled by me with a hand-held electric drill, straight through (i.e. giving a hole all the way through the plate). That means the magnets are in (pretty much) direct contact with the steel plate. Top surface:

Magnets are 9mm dia, 3mm thick Samarium Cobalt, nominally 1kg pull (when in contact with a large steel plate 3mm thick). There are 32 magnets on a 300mm diameter bed. The central ones are spaced at 60mm. The layout and number was decided by eye and some playing around with different layouts held by sticky tape before drilling the plate. They alternate in pole orientation:

They are glued in place with a high temperature epoxy. Specifically MG Chemicals 8329TFS which is claimed good for 150C service indefinitely, lowish viscosity (similar to 'ordinary' araldite - flows, but slowly) so it fills up the holes, long pot life (4 hours) so I wasn't rushed.

tds-8329tfs-2parts.pdfIt needs a heated cure. I just clamped the plate face-down on a glass sheet, dropped magnets in holes (they are a very loose fit - holes are probably 0.5 to 1mm larger diameter than the magnets), filled up the hole behind the magnet with epoxy, put the whole assembly in my (ordinary kitchen domestic) oven to cure. I gave it 90 minutes at 80C and then switched oven off and left it to cool in situ. This has a high shrinkage (even for an epoxy). I over-filled the holes and sanded down the back afterwards so the heater mat could be stuck on.

Bottom:

(Side note on oven - I ran some test cycles with thermocouples in it - my oven does massive overshoot on the first cycle, then much smaller variations subsequently, so I preheated the oven to avoid the massive overshoot.)

In service, one magnet has come loose (almost immediately - within a couple of weeks), leaving the epoxy in place. I refixed it with a drip or two of loctite 648 and it has stayed in place since.

I use a 0.5mm spring steel plate with PEI.

If I did it again I'd want a little more grip - I've never had a problem, but the plate doesn't grip as well as on my Prusa i3. I'd ideally go for about 50% more grip, so either close magnets up to 40mm or more powerful magnets. Obviously, if your magnets are actually set away from the surface, you'd need more powerfual and/or closer magnets too.

Note that this bed does grip a Prusa spring steel sheet as strongly as the Prusa printer - the Prusa plates are thicker, and possibly a more magnetic grade of steel.

Do you not bother with any adhesives, and would adhesives not help to save the PEI sheet?

I never put any adhesives on the PEI. For PETG I clean it first with 'Windowlene' (UK clear bluish spray not the pink cream), for PLA I wipe over with isopropanol. For flexibles I would use masking tape on the bed because otherwise it sticks too well and I can't get the print off without tearing it (but that's actually experience from a different printer - this one is a long bowden and I haven't tried soft flexibles) . The only problem I've had was with some other filament type I've forgotten, which bonded too tightly and pulled a lump of PEI out of the middle of the surface (so I replaced the sheet).

I know I'm going to do as @deckingman has previously advised and drill a 3mm hole from one edge, as deep as I can towards the centre for the thermistor and also screw a TCO to the edge as well.

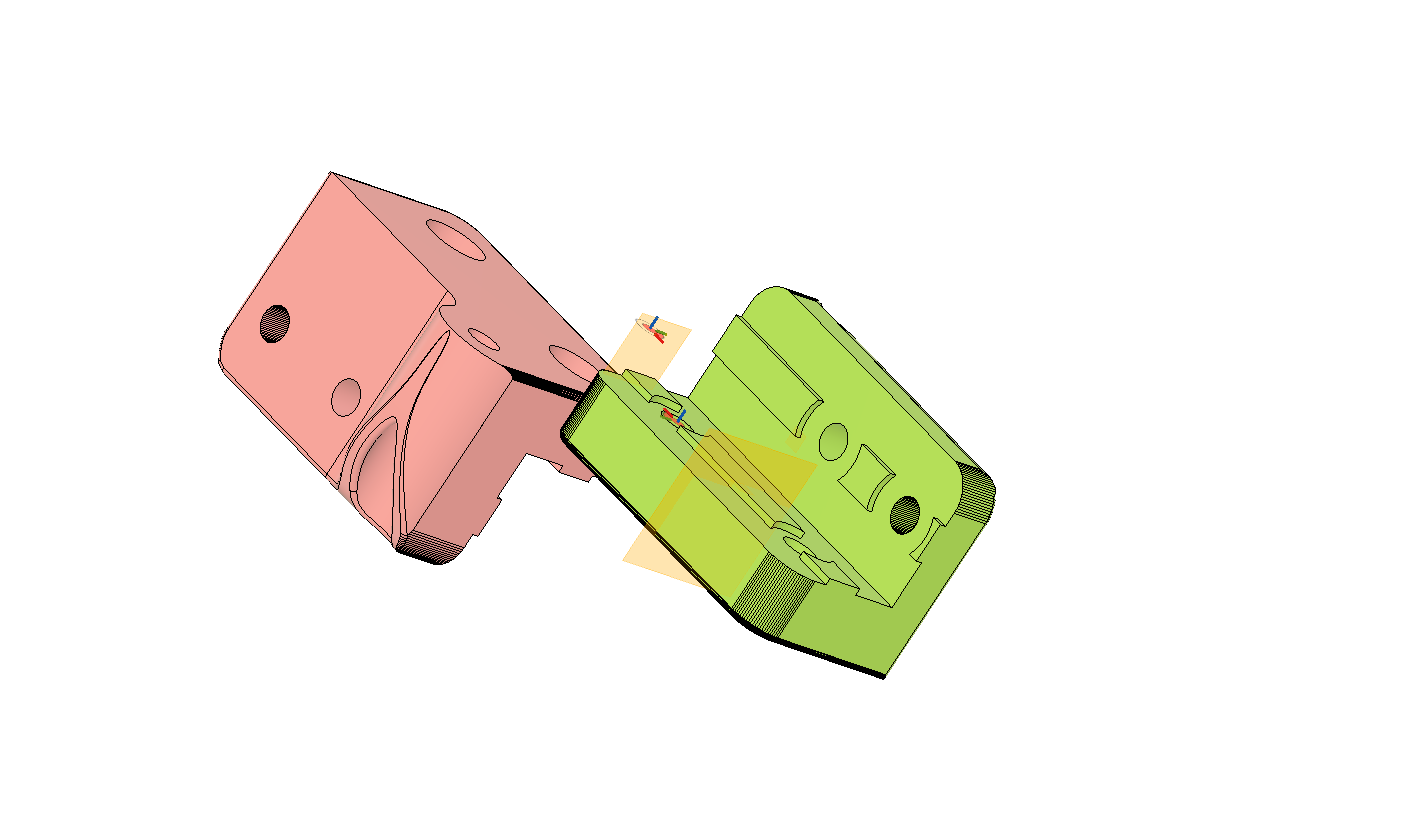

Works well for me, though mine's a 4mm hole in a 6mm plate. Hole is about 40mm deep, again just drilled by hand-held electric drill, but slowly and with a printed guide / jig:

-

@mrehorstdmd said in 8mm Cast Tool Plate Design Advice:

the TCO should be fastened to the heater, not the bed plate. If the adhesive fails and the heater drops away from the bed plate, the plate mounted TCO won't do its job.

Wow, that I missed. That could've be a very serious mistake in a worse case scenario. Thank you for correcting me with this.

@achrn

What can I say other than Thank You. Very informative and gives me a greater idea of where I'm possibly going with this.

A great blueprint to work from -

@achrn @mrehorstdmd @droftarts @o_lampe @jens55 @dc42 @deckingman @Lo-Fi @jay_s_uk

Hi Guys,

Right then after all this time the tool plate is in the machine shop.

For the moment I've decided not use magnets and go with the full 1 x 400 x 400mm PEI sheet.

The bed will be fastened to the bed frame using 4 x 25mm M4 PEEK screws from High Performance Polymers, that will screw 4mm into the tool plate.

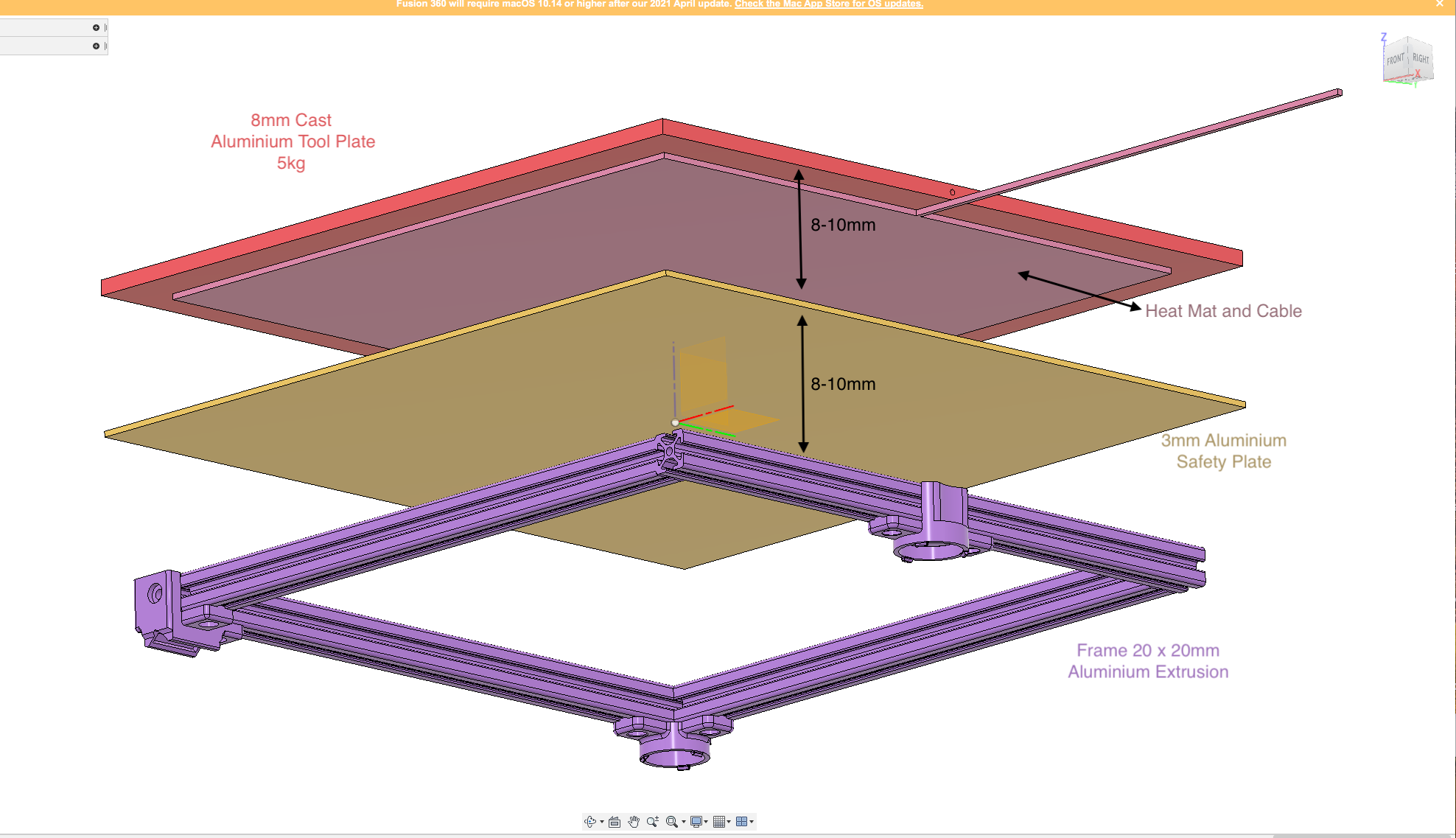

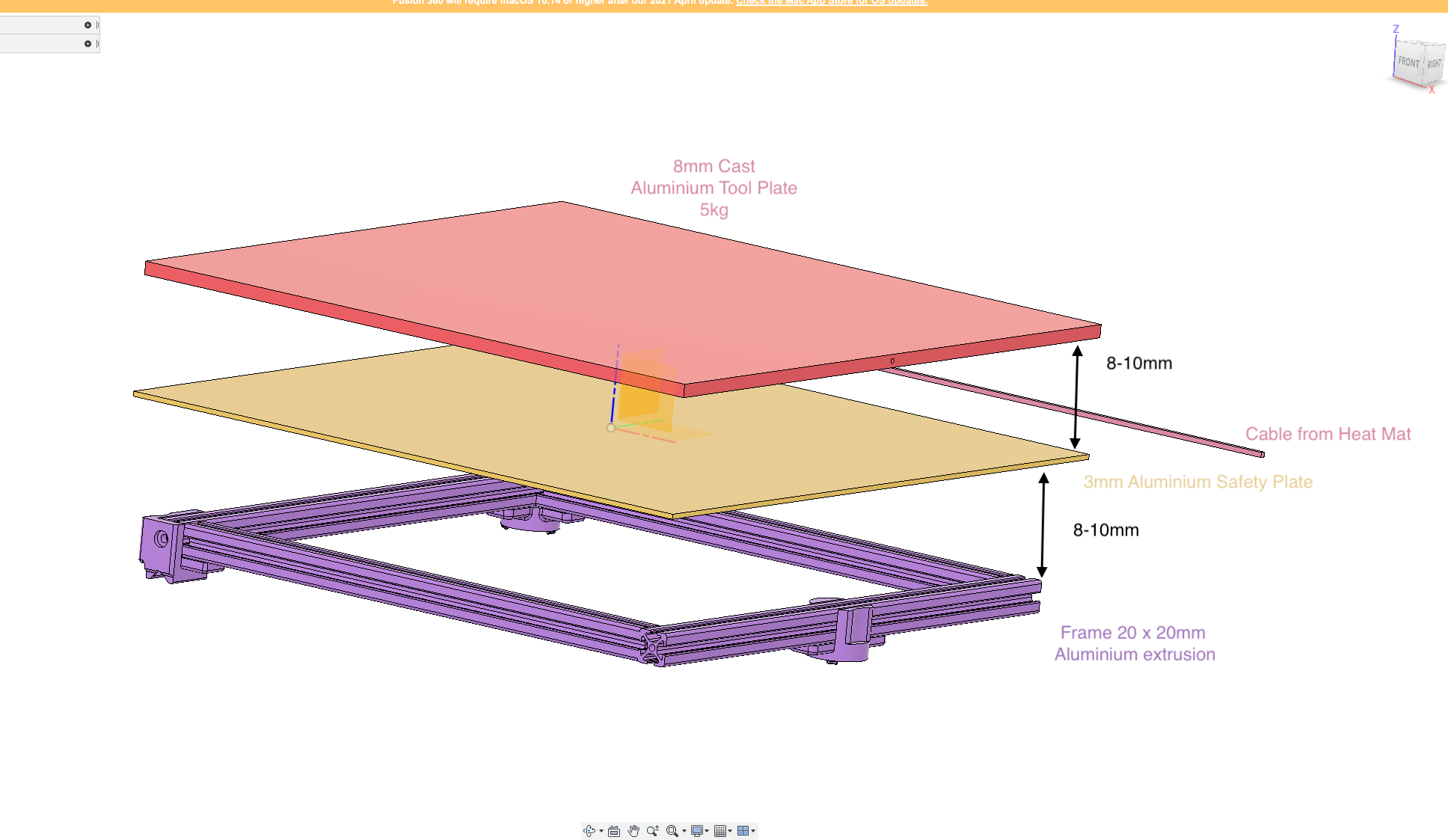

There will be a 3mm aluminium sheet held in place on the underside 'sandwiched' between the tool plate/heat mat and the bed frame, approximately 6mm under the silicone heat mat, to act as a safety feature should the high temp silicone adhesive fail. This silicone will also be used to hold a TCO in place on top of the heat mat.Please ignore the 8mm distance used in the following images. These where drawn more for illustration purposes.

These are the brackets to hold the bed to the frame;

For the bed's temp sensor there will be 3mm wide channel milled out from one edge to the centre 3mm deep, to allow for replacements when needed.

Now to my question;

I'm looking for recommendations for an adhesive to bond the PEI sheet to the tool plate. I would prefer to avoid epoxies if possible due to if at any point the adhesive does fail, I'll still be able to salvage the tool plate. I also appreciate this may not be possible.

@achrn mentioned the MG Chemicals 8329TFS for the magnets but is an epoxy, and @mrehorstdmd mentioned the 3M 468MP giving up after a few years, although he did suggest placing mastic around the edges may increase it's longevity?

I do have a sheet of 3M 468MP, maybe this this the way to go as it can be replaced, with some work?I'd be grateful for your thoughts, although if any are regarding the tool plate this may already be machined. Hey-ho.

Dizzwold