Macro's - Repository?

-

@deckingman thanks, I will take a look

-

If I knew how to use github i would add these directly...

I did not write the first one, someone on the old forum did.

Sorry stranger for not writing down your name.

[EDIT: @dc42 and @burtoogle are responsible for this macro]The second one is a simple probe repeatability test with moves between.

These aren't rocket science but have helped me.

0_1530932915653_non linear test.txt

0_1530932923605_probe test.txt -

@alex-cr The non-linear extrusion test is interesting, but how do you use the results? Non-linear extrusion is on my list to explore next.

-

@alex-cr Thanks. I have added them to the repository.

-

@phaedrux said in Macro's - Repository?:

@alex-cr The non-linear extrusion test is interesting, but how do you use the results? Non-linear extrusion is on my list to explore next.

The intent is to measure the length of the extruded sections to ensure they all come out the same length, regardless of extrusion speed.

I need to add to the macro to supply rectraction because of my 1.2m bowden tubes on my main printer now so in reality I have not used the macro very much.

I really wish I could find the forum post to reference... -

But how do you fit the measured values, to get A and B params?

-

I found the link! Turns out it was @dc42 and @burtoogle that wrote the macro. Thanks guys!

https://forum.duet3d.com/topic/3625/new-beta-firmware-1-20-1rc2-and-duetwifiserver-1-20-1/14@fma Set A=0.015 and B=0.0012 and start there. At least that's what I did. Extrusion was more consistent at higher speeds. These numbers worked on my direct drive system at the time.

I was not very scientific with it, it just helped so I left it there. That's what @dc42 had come up with on his setup.

I need to look into this again but since upgrading to a bondtech extruder the problem hasn't resurfaced.

-

I'll try these values, but I would like to know how to compute them from a set of measures...

-

@fma This involves solving for a nonlinear equation. A recent posting shows sort of how to do it.

https://forum.duet3d.com/topic/5588/non-linear-extrusion

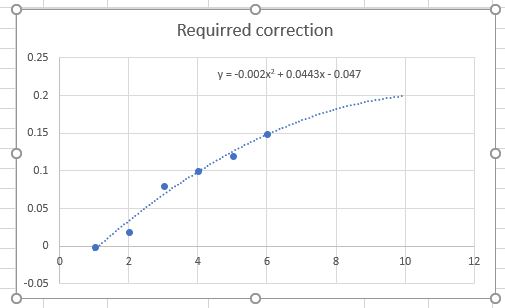

I have build an excel form to create a best fit equation, this may help you.

The values in the form are bogus, do not use those... enter your own. -

@alex-cr that's great. I will definitely be checking that out.

-

@Phaedrux I hope it's not too rough. My old engineering professors and current coworkers would kill me for not labeling all the axis...

-

Thanks! I used gnuplot, which is able to fit any curve, and successfully computes A and B. Here is how I did:

-

extrude 50mm (for example) at different speeds and read the real extrusion length;

-

build a table with 2 cols: first col = speed, second col = error from theorical extrusion / theorical extrusion. You need to revert the sign so the table contains the correction to retreive the correct extrusion;

-

save this table in a file called 'extrusion.dat';

-

in gnuplot, do:

A = 1

B = 1

f(x) = A * X + B * x * x

fit f(x) 'extrusion.dat' via A, B <<<<< will print A and B and errors

plot 'extrusion.data'

replot f(x)Hope this helps.

-