slant lines

-

@dc42 said in slant lines:

What happens to the pattern when you change the layer height?

the pattern changes. Increasing the layer height I get a lower frequency pattern, but steeper.

-

@matt3o said in slant lines:

@dc42 said in slant lines:

What happens to the pattern when you change the layer height?

the pattern changes. Increasing the layer height I get a lower frequency pattern, but steeper.

That's what I was expecting. It sounds like non-uniform extrusion to me. But it's odd that you get it with different extruders. Does the horizontal repeat bear any relation to movement of the hobbed shaft, for example once per rev or once per tooth? Does your new extruder use any parts from the original Flex3drive?

-

@dc42 said in slant lines:

Does the horizontal repeat bear any relation to movement of the hobbed shaft, for example once per rev or once per tooth? Does your new extruder use any parts from the original Flex3drive?

my extruder doesn't share any component with the flex3drive. flex3drive is a 40:1 0.5 pitch gearset. Mine is 30:1 0.6 pitch. My hob is basically the double geared bondtech (7.3mm), the flex3drive uses a 10mm hob.

It's rather complicated to find a relationship between gears and pattern. I can probably find the angle and approx distance. I find it puzzling that I see it with both extruders even though they are both worm-gear-based.

-

@matt3o Did you use the same Nema 8 motor on both extruders? Just wondering if that's the issue. Perhaps it doesn't play nicely with micro stepping and jumps to the nearest full step?? Dunno if that's possible - just bouncing some ideas around. What happens to the pattern if you change micro stepping?

-

@deckingman said in slant lines:

Did you use the same Nema 8 motor on both extruders?

thanks for your feedback!

with the flex3drive I used a nema17 with the flexible shaft and a nema8 in direct drive, and they both present the same issue... I also tried to disable and altering microstepping, but that doesn't seem to change anything.

My extruder uses the same nema8 I tried on the flex3drive, I should have another model around I could try but doesn't seem to be the issue.

-

I had such a problem with my delta. It depends on the belts and pullys I used.

-

@CaiJonas I'm on a corexy and I'm using original gates belts/pulleys on shoulder bolts held on both ends. I use precision shims to separate the pulleys where needed. I think the only improvement I could do would be to replace the 3d printed parts or maybe use tougher filaments.

Is there anything specific you'd improve?

-

@matt3o First, define if the problem is an extruder or X/Y axis issue. Break one of the parts across a layer and have a look at the extrusion. If it's an extruder problem, the filament path should be getting fatter and thinner. If it was in X/Y, and the hot end was wandering relative to the layer below, the extrusion width would stay the same, but wiggle. I'd assume an extruder problem, because I'd think wandering in X/Y would stack on top of each other.

In the case of an extruder problem, I'd look at the period of movement. At a guess, it's one rotation of the worm gear. Looking for play and/or lift on each rotation in the worm gear would be my first check.

To rule out the Duet, you could move the extruder to a different stepper driver. For example, if your drives section is something like:

M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mappingChange to:

; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M569 P4 S1 ; physical drive 4 goes forwards M584 X0 Y1 Z2 E4 ; set drive mappingand move extruder from E0 to E1 driver.

Ian

-

@droftarts said in slant lines:

If it's an extruder problem, the filament path should be getting fatter and thinner. If it was in X/Y, and the hot end was wandering relative to the layer below, the extrusion width would stay the same, but wiggle.

the pattern is really faint and visible only on an angle, I tried to understand if it changes in width or position but it's impossible to say at least with a 0.4 nozzle. I may try with 0.8... that should help

thanks for your input, I'll triple check the gears but I went through a dozen prototypes by now and the position of the gears seems to be spot on.

I've already tried to change the extruder driver, it's on the duex5 and I moved it from E5 to E6 (I have

M584 X0 Y1 Z2:3:4 E5now). I haven't tried to place it on the duetwifi directly though -

@matt3o Have you got Pressure Advance enabled, or using volumetric extrusion? Try turning it off if you do.

Ian

-

This must be frustrating for you. I'm as puzzled as you. It seems you have taken great care in designing all aspects of your machine, and used good components.

Crazy stab in the dark question: are you using the same filament for all these prints that show this behaviour?

I guess, I don't know if it has been mentioned, you could look at temperature consistency, too.

-

@droftarts said in slant lines:

Have you got Pressure Advance enabled, or using volumetric extrusion?

for all the tests I disabled PA and DA (not using volumetric extrusion)

@bot said in slant lines:

This must be frustrating for you.

you can say it twice. Apart from that the printer is amazing and the dimensional accuracy is incredible, but this thing is driving me crazy. I'm going to reprint some parts with a tougher filament, see if that changes anything but I still believe the problem is in the extruder. I think I'm also gonna test a standard bondtech extruder.

@bot said in slant lines:

are you using the same filament for all these prints that show this behaviour?

nah, I tried 3 different PLA filaments, ABS and PETg. Doesn't seem to change much

-

Is your filament tensioner preloaded with a spring? I recently changed from spring tension to a fixed distance rigid mount for my hobbed gears (also bondtech) and the performance is dramatically better (more consistent).

-

@bot said in slant lines:

Is your filament tensioner preloaded with a spring? I recently changed from spring tension to a fixed distance rigid mount for my hobbed gears (also bondtech) and the performance is dramatically better (more consistent).

my extruder has a spring, yes, but the flex3drive I started with is fixed and doesn't seem to change much. Thanks for your feedback anyway, it's something that I will certainly explore. I don't think it would solve this specific issue, but it's an easy enough mod to try

-

With flex3drive G5 + mellow -> got exactly the same lines. I changed 3 different extruder motors lines persist. Removed mellow and put e3dv6 and slant lines are gone. No clue why they were there, I never seen them before and I hope never to see them again.

-

It looks very much like the issue I had with my Nimble, periodic uneven extrusion. Something about the worm gear not engaging at the right angle.

If you print a cone or pyramid you should see some funny patterns instead of diagonal lines.

In my case it was probably related to that my mount was very slightly twisting the body of the extruder.

Have a look at https://drmrehorst.blogspot.com/2018/04/designing-low-cost-printable-worm-gear.html, or google "worm gear, periodic error, telescope" for more info on the topic.

-

@arhi said in slant lines:

With flex3drive G5 + mellow -> got exactly the same lines. I changed 3 different extruder motors lines persist. Removed mellow and put e3dv6 and slant lines are gone. No clue why they were there, I never seen them before and I hope never to see them again.

I can certainly try with an e3d, but I'm on mosquito now... I hope it's not that with all that I spent for it

Thanks @bondus I'll check that too

-

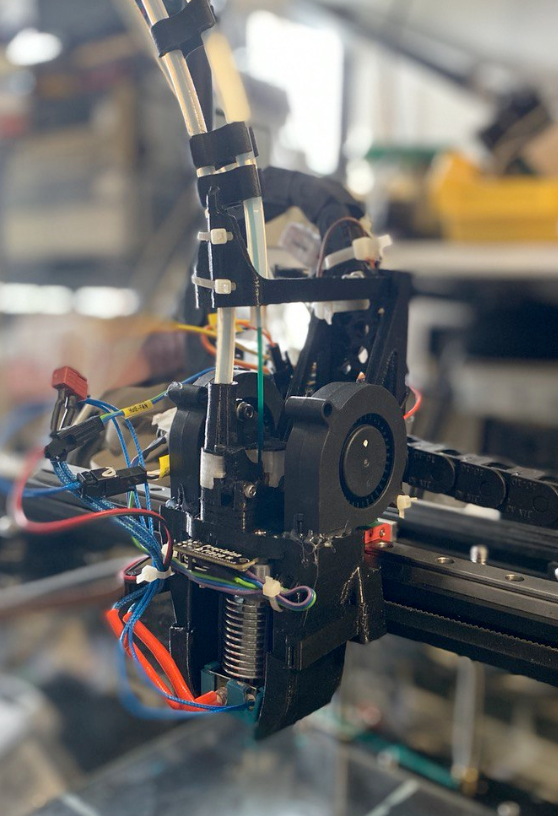

@bondus it is gone now, that mellow is totally useless for PLA and that particular printer (ender5) I purchased to use mostly (only) for PLA. Thermal images I took show that it will never print PLA properly so I moved it to a drawer, will use it on some other printer for ABS/PC/Nylon, it did print those pretty nicely. So, I can't test the cone. Good idea none the less. I did have a failure right after I removed the mellow nf crazy hotend, the flex shaft broke, it is possible I had issues with flex shaft and that fix was that I replaced the flex shaft (luckily I have dual flex3shaft that I split into 2 single G5) and not that I replaced the hotend, but I'm not returning mellow back in to test that theory. I was using the 1st ever shaft flex3drive was testing, waiting for the replacement one to arrive that is supposed to be custom made, thicker and in many ways better than this old pre-release one I have, we'll see. It would be very hard for worm on G5 to not fully engage the drive gear, the part is very sturdy (I printed from PETG) and has bearings everywhere, but since shaft failed few cm from the gear I assume there was issue where shaft was bending so I designed a "tower" on my carriage to grab the flex shaft again few cm after the G5 .. lemme illustrate

(ignore the mess of wires, that's still work in progress)

(ignore the mess of wires, that's still work in progress)

-

@matt3o said in slant lines:

I can certainly try with an e3d, but I'm on mosquito now... I hope it's not that with all that I spent for it

Do not mistake mellow nf crazy hotend (that I used in this test) with mosquito, the only similarity between them is visual! Friend is using original with way worse setup than mine without a single issue with PLA and even without cooling

My mellow experience got him scared so he added cooling

My mellow experience got him scared so he added cooling

but it worked even before forced cooling (you just can't go too crazy with retraction as with any all metal) so if you are rocking original mosquito don't worry. Also check out the vent from @smece (my neigbor who introduced me to duet2eth btw) about his mellow https://forum.duet3d.com/topic/14161/mellow-nf-crazy-hotend?_=1582807022109 again, none of those issues are visible on the original mosquito.

but it worked even before forced cooling (you just can't go too crazy with retraction as with any all metal) so if you are rocking original mosquito don't worry. Also check out the vent from @smece (my neigbor who introduced me to duet2eth btw) about his mellow https://forum.duet3d.com/topic/14161/mellow-nf-crazy-hotend?_=1582807022109 again, none of those issues are visible on the original mosquito. -

I recall similar issues with the zesty nimble being solved by changing the lubricant, I only looked into it since I recall some reports of flexible shaft having bad short lifespan on delta machines.