I thought it was z wobble...

-

So I got this texture on a corexy I've built. It's 3x leadscrews+rails.

The pattern looked very regular, so I thought z wobble.

Changed z motor mounts, leadscrews, couplers aaaand... same result. Nothing changed at ALL.

Pulled the trigger and bought a digital microscope.

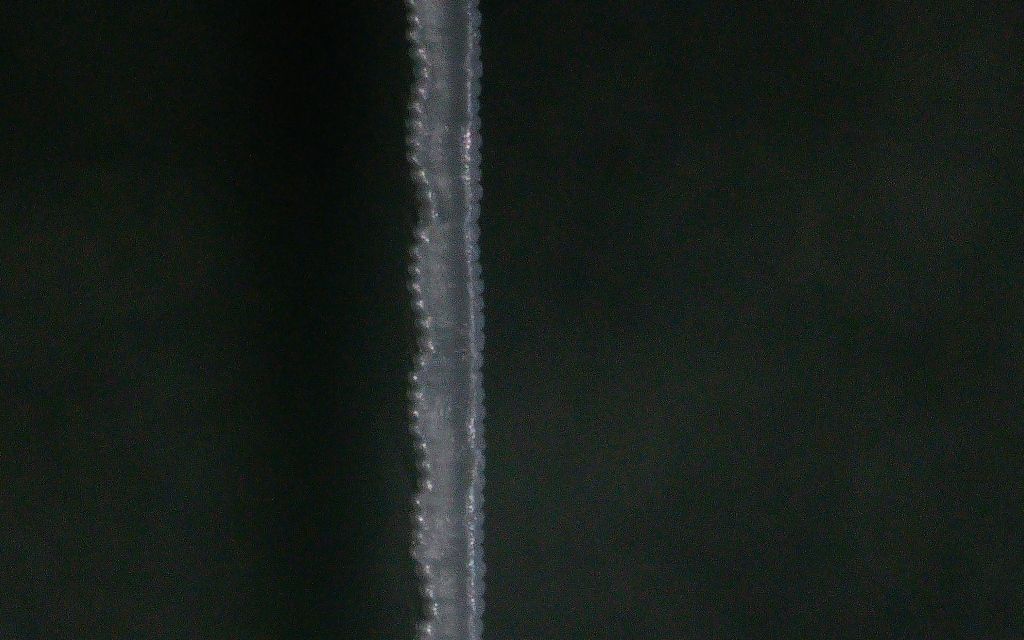

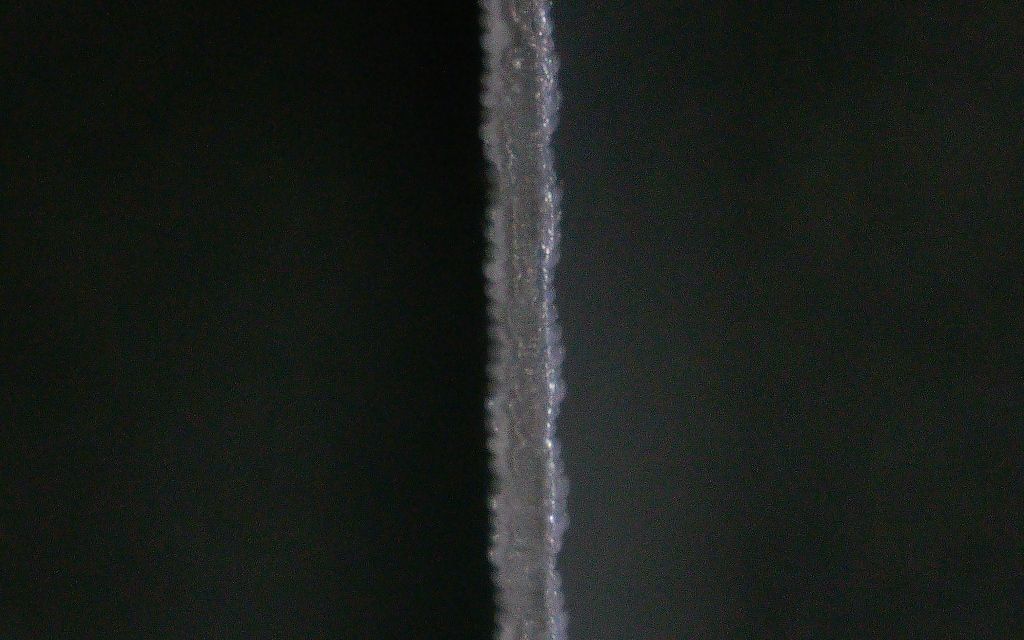

I printed a 1-wall cube. This is the result of two opposite sides (sections).

What the hell is going on? The wobble in just on one side of the wall?! Help me Duet3d Forum, you are my only hope!

Extruder is bondtech. Extruder motor I tried with a 1.8 moons and a 0.9 LDO. Nozzle is brand new high quality. If I change layer height the "wobble" seems to be the same (that's why I thought it was caused by the z axis).

-

What is the layer height on top and bottom image?

If you underextrude (set flow rate to 80% for e.g.) how does it compare?

What speed is this? If you drop the speed to 50% how does it compare?

-

@arhi layer height in the two magnified pictures is 0.1. I believe the first picture is 0.2. I made various tests at various speeds (30 to 80mm/s) with very little difference in the end result. I tried to change temperature but I don't think I have tried to lower the flow rate to 80% (I'll try and let you know but I tested the extrusion length and it's very accurate)

-

I can't see from the images, is the issue parallel to the XY plane or is it under angle (like for e.g. https://forum.duet3d.com/topic/14607/slant-lines?_=1596031813446 )

-

So the line width is varying but only to one side...

Is the hot-end perpendicular to the bed?

How tightly screwed down is the drive gear adjustment screw on the extruder?

Are the drive gears clean?

How consistent is the diameter of the filament you're using?

Are you using any pressure advance or nonlinear extrusion? -

@arhi said in I thought it was z wobble...:

I can't see from the images, is the issue parallel to the XY plane or is it under angle)

they look pretty much parallel.

@mrehorstdmd said in I thought it was z wobble...:

So the line width is varying but only to one side...

Is the hot-end perpendicular to the bed?yes but the width variation is not always on the same side. if the head wasn't leveled shouldn't the wavy lines be always on the same side?

but I'll double check that. Thanks!

How tightly screwed down is the drive gear adjustment screw on the extruder?

I tried to make it very loose and very tight but I can't say I noticed much difference.

Are the drive gears clean?

Brand new.

How consistent is the diameter of the filament you're using?

I'll double check that but it is supposed to be good quality.

Are you using any pressure advance or nonlinear extrusion?

No, I disabled everything while testing.

PS: just wanted to thank you @mrehorstdmd for your great blog, I've built my printer mostly thank to your posts

-

@matt3o Thanks!

Is there any play in the extruder carriage bearing block or in the mounting of the X axis rail?

Are pulley and motor mounts solid? -

@mrehorstdmd said in I thought it was z wobble...:

@matt3o Thanks!

Is there any play in the extruder carriage bearing block or in the mounting of the X axis rail?

Are pulley and motor mounts solid?the extruder is mounted on hiwin rail+carriage and I'd say it's pretty solid. The pulleys are mounted on shoulder bolts secured on top and bottom.

The only thing I'm not sure about is the belt tension. It feels very tight on the short side (on the X connecting to the head) and slightly floppy on the long side (on the Y). It's a 400x400 printer. But I don't see any vertical banding... so I guess it's okay

-

did you try swapping your nozzel?

-

I tried to change filament and to set the extruder screw very tight. I didn't notice a huge improvement.

I'll try with a new nozzle in case the one I got was defective from factory.

-

Is your bed PID tuned? Bang-bang on the bed can lead to some weird rhythmic warping.

-

Try printing a 40mm cube in vase mode with no top or bottom layers and post a picture. Have a feeling there’s an issue with inconsistent extrusion.

-

I set it PID and recalibrated, but same result @Phaedrux . I actually also tried without bed heating.

I also tried to change the nozzle with no improvement.

@mwolter I usually print 1-walled 50mm cube (no infill, no top), but not in vase mode. This way the result should be more reliable as you stop and restart at each layer. Does it make a difference?

-

A vase mode print is often a good test since it focuses more on printer hardware because it doesn’t utilize retractions and eliminates retraction tuning as a possible issue. It also makes it very easy to see repeating patterns that would indicate an extruder issue.

-

thanks for the heads up @mwolter

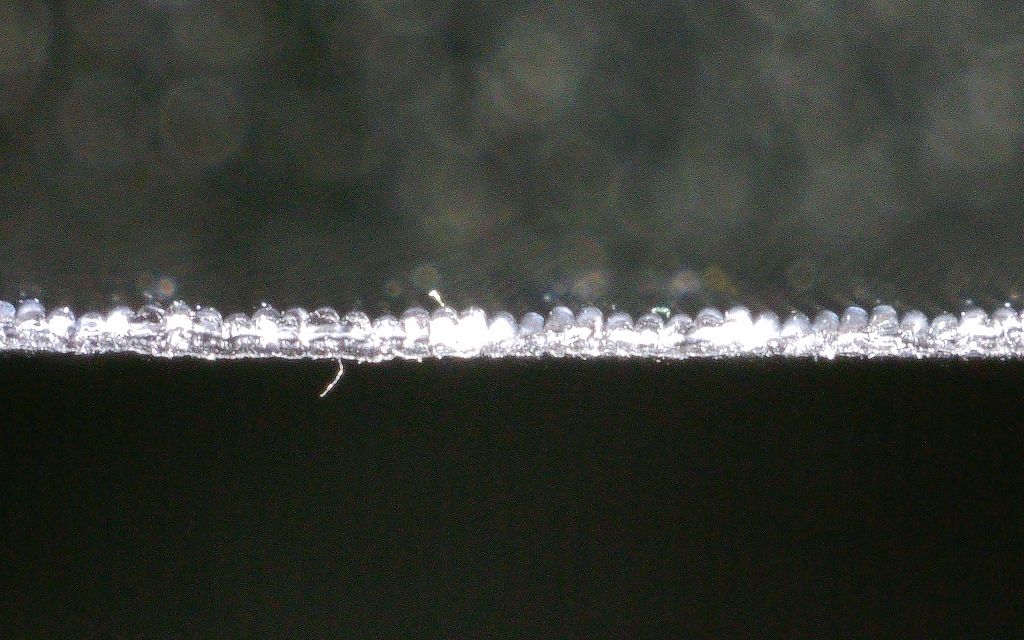

this is the cube in vase mode

this is the section

basically the same. super smooth on one side, wobbly on the other.

-

Try increasing your extruder motor current or even try printing at a higher temperature.

You can get a similar repeating pattern if the nozzle builds up pressure that the extruder drive can't overcome. If your system is a bowden system, that could also have issues if the nozzle builds up pressure that the system can't overcome.

The nozzle pressure issue can look like a z-axis wobble problem when its not.

-

Are all of printed in the center of the bed? Have you tried printing one at one of the corners/edges of the bed?

I've been struggling to figure out how you can possibly get such an asymmetry in the inside and outside walls when you have a clean nozzle that's parallel to the bed. The only thing I've been able to come up with is the possibility that there's a slight 'wobble' in the bed as it travels up Z, causing the vector orthogonal to the print plane to rotate around actual Z such that the nozzle is always 'tilted' slightly towards the outside of the box.

If that were the case, I would expect a box printed at one of the edges of the bed to show the pattern on the outside of the face closer to the edge of the bed and the inside of the face closer to the center.

-

@PDBeal I'm direct drive but I'll try to pimp the motor current. I tried to print at various temperatures already but couldn't see much difference.

@whopping-pochard that's actually an interesting idea. Let me try that as well and I'll report back!

thank you all guys for your continued help!

-

unfortunately I don't see any difference in printing in the corners... also giving more amps to the extruder doesn't seem to work...

(╯°□°)╯︵ ┻━┻

-

┬─┬ノ(ಠ_ಠノ)

Can you show us some photos of the printer?