unusual/unnerving noises + error codes

-

@jay_s_uk So after following the link i can confirm that all motors are connected correctly now and sound alot better. Now to the end stops + Probe.

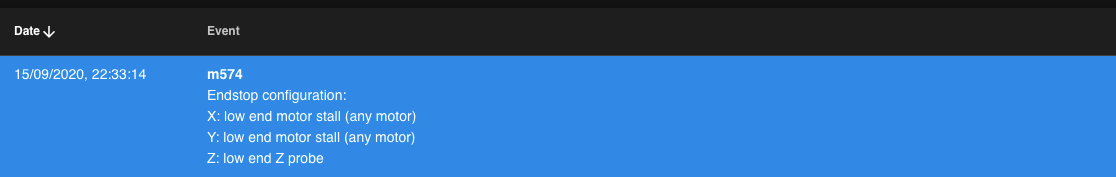

Obviously at the moment i still cant home the axis (X and Y) because the end stops seem to not be working. Ive done some reading and found that M574 give a status, which is below. However when putting the gcode in it send a message saying 'Response too long see console'

m574Endstop configuration:

X: low end motor stall (any motor)

Y: low end motor stall (any motor)

Z: low end Z probeany ideas?

-

can you post your latest config.g?

That response seems to indicate that you're trying to use stall detection rather than an actual endstop -

@PR1OR said in unusual/unnerving noises + error codes:

'Response too long see console'

And if you go to the console do you see the result?

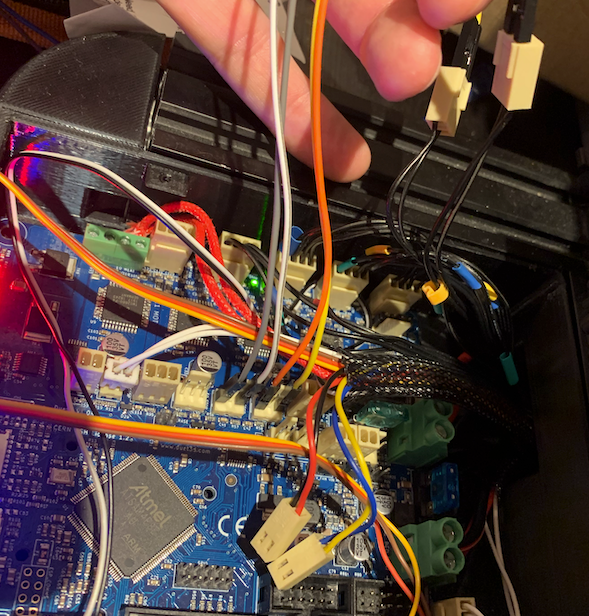

How do you have the endstops wired? The two wires from the endstops should be connected to the outer two pins of the board connector. Doesn't really matter which wire goes where.

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+1:+Wiring/37#s119

-

@Phaedrux said in unusual/unnerving noises + error codes:

w do you have the endstops wired

so that was the result :s

Below is a picture of the wiring, ive been using dupont wire until ive made sure they are wired correctly. but from what you are saying the seem to be fine. The LEDs are on (green, i read somewhere they should be red but i assume this was an old/new board) when the the endstop switch isnt pressed. When it is it turns off. So i found from wiring diagram that the LEDs didnt correspond to the plugs like it does in the diagram

-

just had a thought and checked the axis limits as the ender 3 pro has a bigger print area. i have now updated that but still having issues

-

could it be something to do with the gcodes for the end stops?

Like the changing S to H?

; Endstops

M574 X1 Y1 S3 ; set endstops controlled by motor stall detection

M574 Z1 S2 ; set endstops controlled by probe -

@PR1OR said in unusual/unnerving noises + error codes:

; Endstops

M574 X1 Y1 S3 ; set endstops controlled by motor stall detectionS3 is stall detection. Try S1.

-

@Phaedrux updated to S1 and i got this

G28

Error: Failed to enable endstops -

however i played with it a little and S2 works but it only moves each axis by a couple of mm before stoping

but it does say its homed which i think is getting somewhere

-

; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystopTry that instead

It looks like you had stall detection for homing selected in the configurator so it didn't have any endstop switches defined.

-

From what i seen in the video im wondering are you sure the z stepper is wired correctly

It sounds like one of the steppers is not paired properly y moves then x .... does it start the noise before it hits the x stop?? If so you wont know the z is correct untill it hits the x stop if the shaking starts then ...when you hit the xstop i would say the z stepper is causing the problem with the strpper fighting itself... i noticed that the x gantry didnt start down. It might be the video. Or just me ill watch it again

ill watch it again -

What i do is start homming then manualy trip the limit to see if it in fact work.. just cause the led goes out doent mean the g code responded

-

@Phaedrux said in unusual/unnerving noises + error codes:

; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystopPerfect thank you!! this has worked!! i can now home my X and Y axis

is there anything for the Z probe though?

i get this as a return when homing all

Error: in file macro line 9: G30: Z probe 0 not found

Error: Homing failed -

So it was as Phaedrux had said above the code wasnt correct. Once id checked/sorted the wiring out it was only happening when both X and Y got to the end stop

-

If you're still having problems with the probe please post your config.g.

-

@Phaedrux

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Tue Sep 15 2020 08:55:40 GMT+0100 (British Summer Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 2 Wifi" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S1 ; physical drive 1 goes backwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E93.00 ; set steps per mm

M566 X1200.00 Y1200.00 Z24.00 E300.00 ; set maximum instantaneous speed changes (mm/min)

M203 X30000.00 Y30000.00 Z300.00 E1500.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z100.00 E5000.00 ; set accelerations (mm/s^2)

M906 X400 Y400 Z400 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S300 ; Set idle timeout; Axis Limits

M208 X-5.5 Y-10 Z0 S1 ; set axis minima

M208 X220 Y220 Z250 S0 ; set axis maxima; Endstops

;M574 X1 Y1 S3 ; set endstops controlled by motor stall detection

;M574 Z1 S2 ; set endstops controlled by probe; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop; Z-Probe

M307 H64 A-1 C-1 D-1 ; disable heater on PWM channel for BLTouch

M558 P9 H2.5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P25 X-31 Y0 Z0.6 ; set Z probe trigger value, offset and trigger height

M557 X20:215 Y20:215 S20 ; define mesh grid; Heaters

M305 P0 T98801 B4185 R4700 ; set thermistor + ADC parameters for heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M305 P1 T98801 B4185 R4700 ; set thermistor + ADC parameters for heater 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S1 I0 F500 H0:1 T45 ; set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

;G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

;G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

ok we'll have to convert more of your config.g over to use RRF3 syntax.

If you send M98 P"config.g" what errors do you get?

-

@Phaedrux said in unusual/unnerving noises + error codes:

M98 P"config.g"

M98 P"config.g"

HTTP is enabled on port 80

FTP is disabled

TELNET is disabled

Error: in file macro line 44: M307: parameter 'H' too high

Error: Missing Z probe pin name(s)

Error: Invalid Z probe index

Error: M305 has been replaced by M308 and M950 in RepRapFirmware 3

Error: Heater 0 does not exist

Error: M305 has been replaced by M308 and M950 in RepRapFirmware 3

Error: Heater 1 does not exist

Error: Fan number 0 not found

Error: Fan number 1 not found

Error: Fan number 2 not found -

The fans aren’t connected so that will be why they can’t be found

-

I've made a config for you to try using the web configurator tool.

First make a backup of your /sys folder in DWC by putting check boxes next to all the files and then right clicking and selecting download as zip. Then save it to you computer. That will be a backup of your current config files.

Here download this and change the extension from .txt to .zip. And then upload the whole zip file as is (don't extract it) to the /sys folder in DWC.

Reboot and it should be a bit closer to working I think.