Need help! G29 mesh bed compensation over compensation

-

I'm New the the duet world and I'm building a corexy machine with a 500x500 bed.

I can't get a good first layer. I run G28 and home with the z probe in the center of the bed. Then I run the G29 command and it starts printing.

The parts of the bed that are low it really grinds the filament into almost touching the nozzle to the build platform. Then the parts that are high it doesn't stick at all and lifts z way too high.

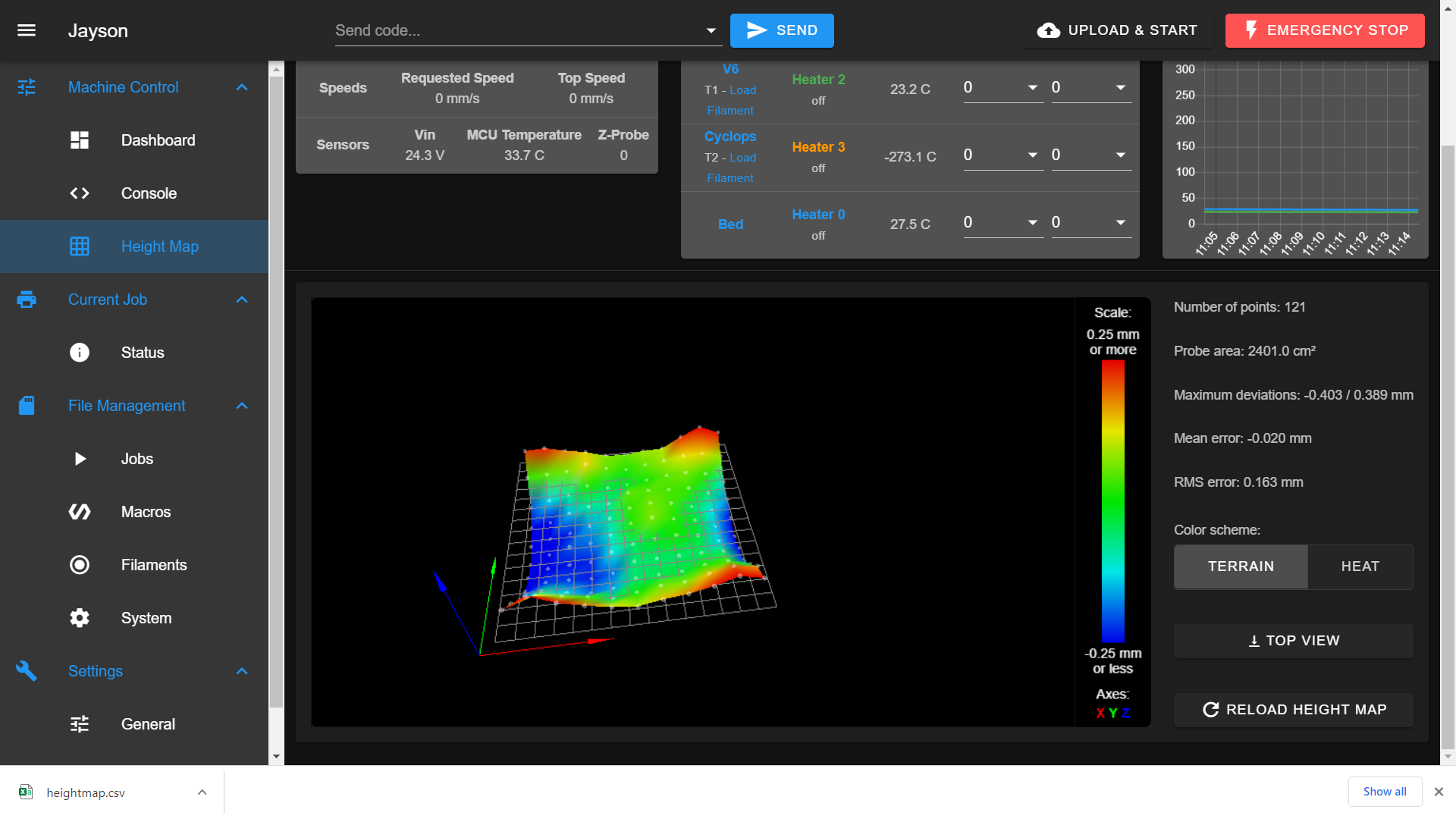

I have probed the bed multiple times in a row with 121 points and the mesh on the web interface is vary consistent and the first layer has the same issues in the same areas every time

I'm running the latest firmware.

-

Please Post your config.g and a Sample gcode aswell as the heighmap.csv

-

-

my bed is warped and I have plans to fix it but g29 shouldnt have any trouble compensating that.

here is the start of the gcode i was using. it came from the teaching tech websight.

; G-Code originally generated by Simplify3D(R) Version 4.1.2, based on proposed code by vector76

;M80 ; power supply on

G90

M82

M106 S0

M140 S60 ; custom bed temp

M190 S60 ; custom bed temp

M104 S200 T1 ; custom hot end temp

M109 S200 T1 ; custom hot end temp

G28 ; home all axes

G29 ; probe ABL

;M420 S1 ; restore ABL mesh

; custom start gcode

; process Color1

; layer 1, Z = 0.200

;T1

G92 E0.0000

G1 E-1 F2400 ; custom retraction -

What Kind of probe are you using?

The negative value in the G31 looks strange.

Have you done the offset calibration?

The Offset is different than for marlin.

-

@PCR I did an offset calibration.

My printer is tool changing so I mounted a simple micro switch to my carriage.

When I pick a tool the nozzle hangs down about 4mm below the trigger hight.

So it's a negative value of around 4mm -

Ah ok then this make Sense!

-

M350 X256 Y256 Z128 I0 ; configure microstepping without interpolation

this will overload the cpu. unless there is a specific reason, you should go with x16 and interpolation.

G31 P500 X0 Y50 Z-4.09 ; set Z probe trigger value, offset and trigger height

as jason said, negative values this big would bean the nozzle goes 4mm into the bed before the probe activates

also make sure what the offset is correct. is you probe really 50mm behind the nozzle?

M558 P5 C"^zprobe.in" H2 F900 T24000 ; set Z probe type to switch and the dive height + speeds

P8 is preferred to P5 unless you really need the filtering

-

@Veti you lost me at interpolation....

I would really appreciate it if you could type out the replacement command for M350 X256 Y256 Z128 I0. Then I can just copy, paste and call you a genius

I can handle switching P5 and P8.

And yes my probe it really 50mm behind and 4.09mm above my nozzle. I just have to make sure that no tool is mounted when I probe.

-

@Jayson said in Need help! G29 mesh bed compensation over compensation:

And yes my probe it really 50mm behind and 4.09mm above my nozzle. I just have to make sure that no tool is mounted when I probe.

can you post a picture of the assembly?

change the steps like this

M350 X16 Y16 Z16 I1 ; configure microstepping without interpolation

M92 X80 Y80 Z900 E420.00:1888.21:420.00:420.00 ; set steps per mmHowever. when converting the numbers back i realized the Z900 is very strange.

What kind of z setup do you have?

Common values are 400 (most printers tr8x8)

800 (sfu1204)

1600 (tr8x2) -

@Veti I implemented your changes and it solved a few problems. Something was holding back my top speeds and I guess it was an over loaded cpu.

Trying a test print now.

The few extra z steps are from a slight gear reduction by a belt from my z stepper to my lead screws

Thanks a lot for the help. I will post again when the test print is completed

-

here is a picture of what I'm going to refer to as my chuck, without a tool and ready for probing.

the second picture is with a custom machined water cooled cold end with a v6 and zesty nimble. (still vary much a work in progress)

-

still having the problem....

this picture is from my most recent test.

as you can see two are too close and three are too far.

-

Are those the actual locations where the cubes were printed or did you move them?

-

post a picture of your heightmap

-

I kept the same orientation, just moved them in close for the picture

-

I have tried the print with the heat bed off at room temperature to eliminate thermal expansion but still the same result.

I have also shimmed the low side of the bet up 3 mm to drastically alter the bed mesh and the prints come out looking the exact same.

-

it is a 500x500 bed with a silicone heater and buildtak flex plate.

it has a 1/4" T6 6061 aluminum plate that I sheared from a piece of scrap at work. It defiantly has some warp that I am working to physically straighten now. -

@Jayson said in Need help! G29 mesh bed compensation over compensation:

it has a 1/4" T6 6061 aluminum plate that I sheared from a piece of scrap at work.

that is not thick enough for a 500x500 build plate. as you can see from the sagging heightmap.

see this recent discussion

https://forum.duet3d.com/topic/19398/height-map-500mmx500mmx4mm-aluminium-build-plateyour testprint is not even good in the center. so you have not dialed in the z trigger height well enouch.

adjust with babystepping while printing until you get a good first layer, then adjust the offset with the babystep value.also measure the z probe trigger heigh in each of the corners.

i would assume for your build they are different.

this can be due different factors.

one possibility for your printer with such a large print area is sagging axis due to its own weight, which introduces rotation of the carriage. this causes varying probing offset.one way to compensate for that is use a probe that uses the nozzle like a precision piezo

-

I would suggest moving your z probe to be X0, Y0 and Z0.

From there, you can set the tool offsets using G10.

It makes working everything out so much easier.

You can than use TAMV to calculate the X and Y offsets of each tool in relation to the z probe.

That's how I have my toolchanger set up.