strange discontinuous infill

-

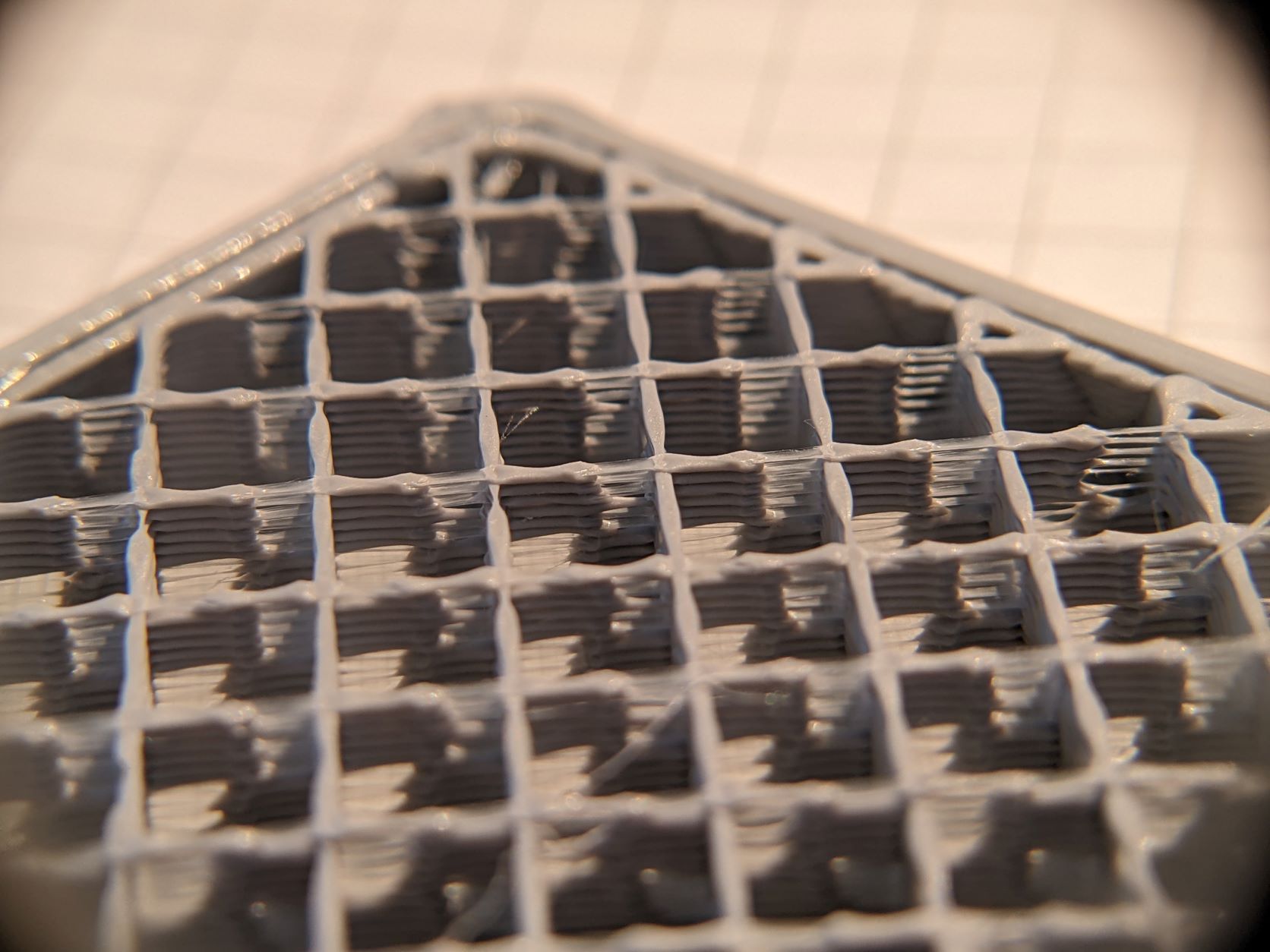

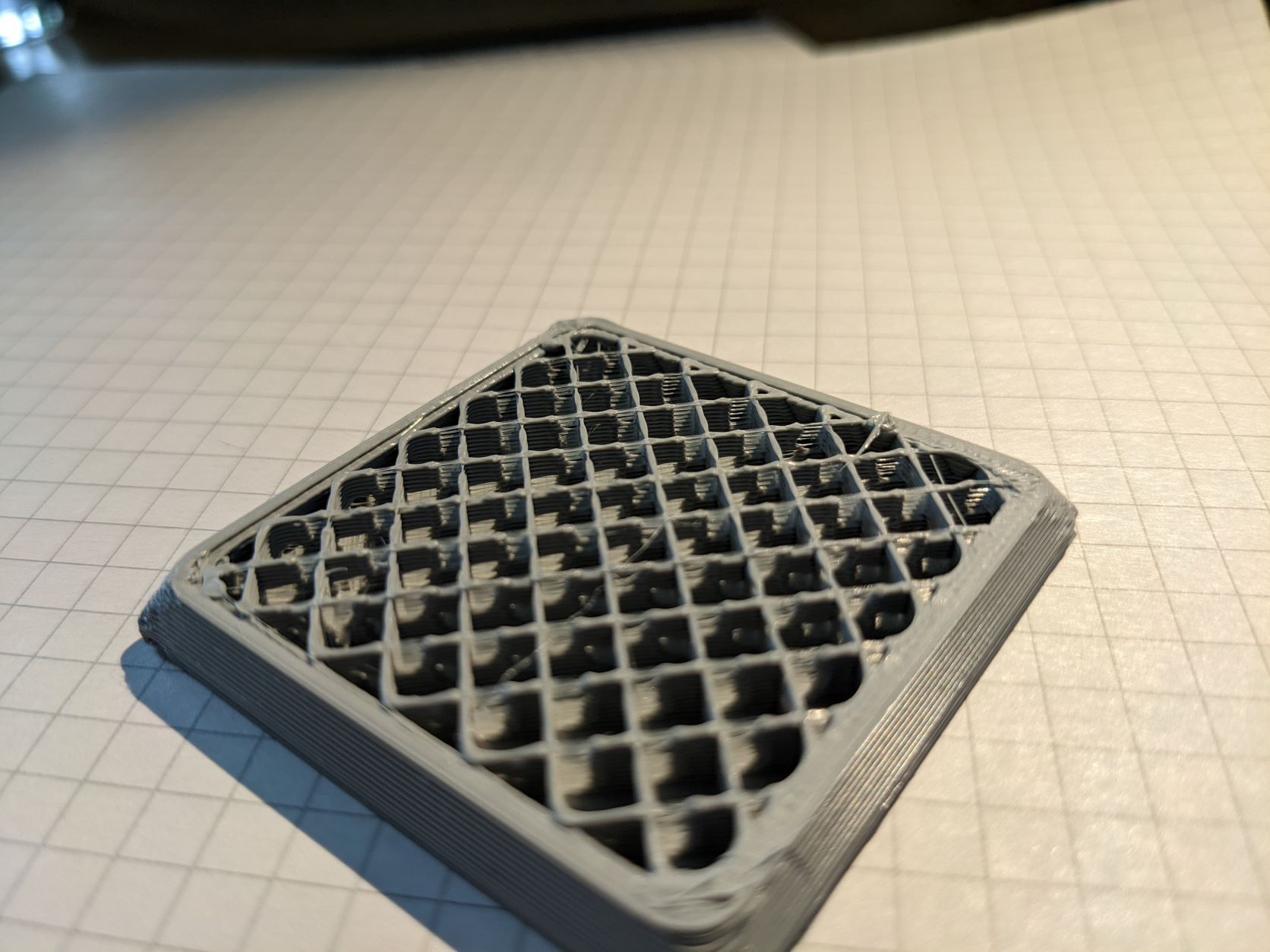

Can any of the assembled expertise shed some light on what might cause infill like this:

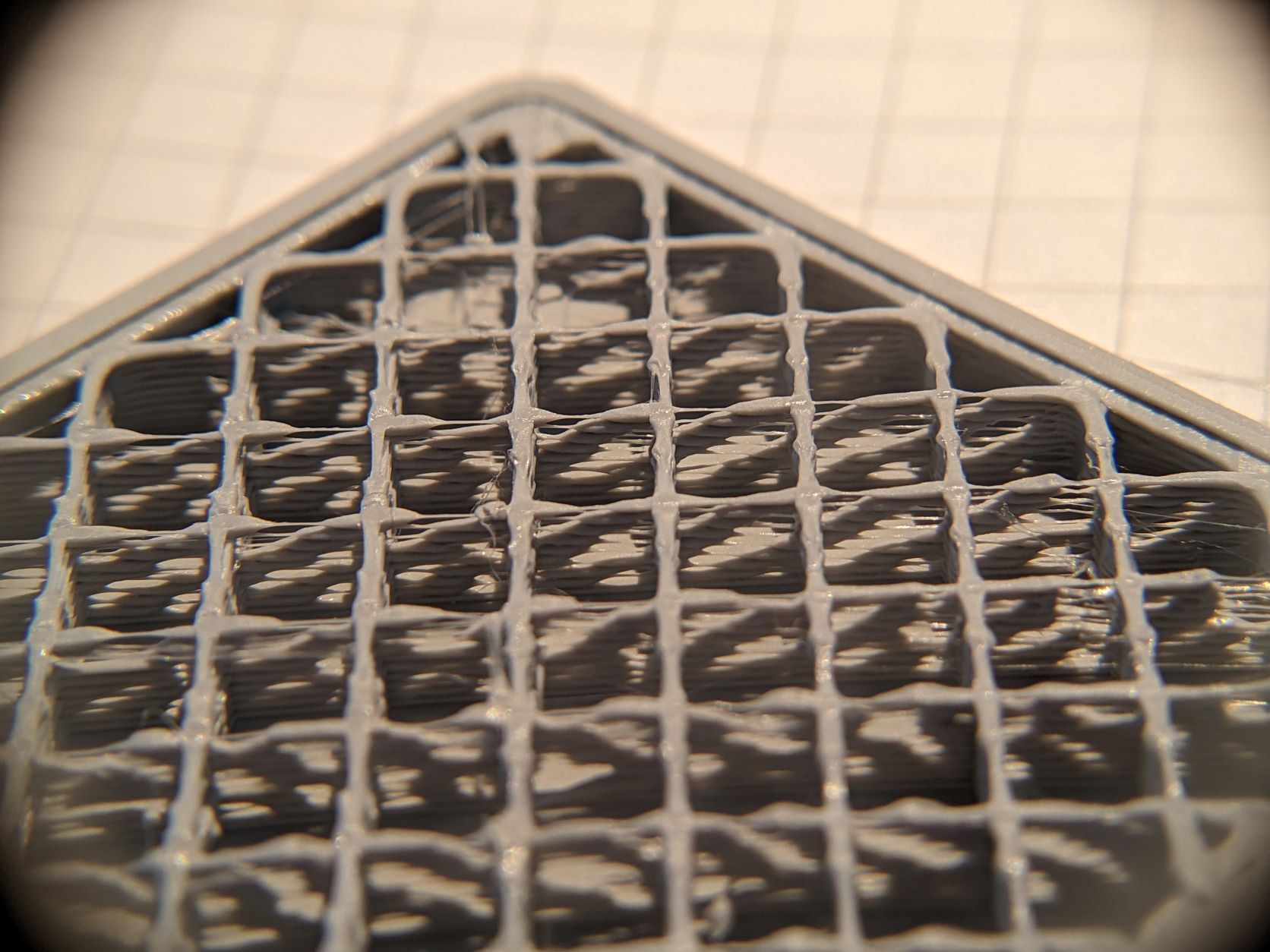

By adjusting speed I can get even more curious effects, but I haven't found a speed that eliminates the gaps / starved portions. In the above, the infill is printing at 90 mm/s and in this one the infill is at 120 mm/s:

The perimeters (inners at 90mm/s in the above and 75mm/s in the top, external 50mm/s in both) are printing fine. If I lower infill to 50mm/s (ie slower than inner perimeters) the gaps / starved regions are slightly shorter, but still present:

It's almost as if as the nozzle crosses the previous bead of extrusion, and the flow is blocked, it takes a period of time to start flowing out teh nozzle again. If I measure the gap, it equates to about 0.025 seconds (for all speeds, though it's a bit difficult to decide the size of the gap in the diagonal case). I can't really expain the diagonal banded one, though.

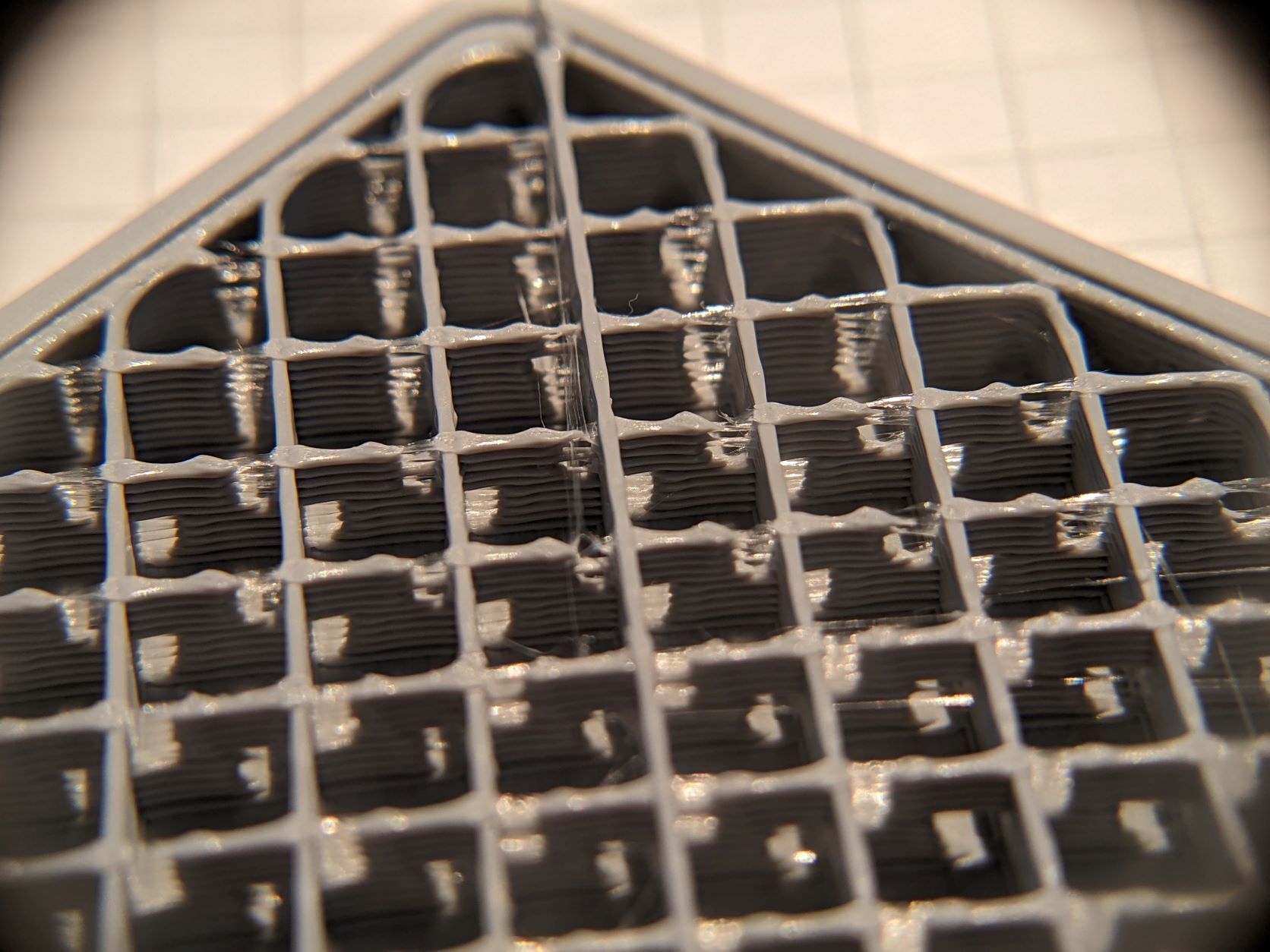

I noticed all the above while trying out my new 0.8mm nozzle (so it's all E3D's fault for selling me a Revo with multiple nozzles). I never noticed it before with a 0.4mm nozzle, but I find the effect does exist, though much less severely - this is 0.4mm nozzle with infill printing at 120 mm/s:

In this one the gap is about 0.001 to 0.002 seconds-worth.It's a MB6HC _Pi4 running 3.4rc2, printing Das Filament PLA at 120C.

-

@achrn same issue here, possibly since 3.4 RC1/2.

Thought it was the filament, but I can print perimeters just fine at 300mms@10k as well as my normal speeds (200mms@5k).

But infill (especially rectilinear) fails even at 100mms@5k. I need to go way down (like 60mms) to get rectilinear i fill to print continuously.

Will try to downgrade to 3.3 later to see if the issue still persists if nobody is quicker than me.

What slicer are you using? I currently only have SyperSlicer installed, but maybe I give Cura a shot later.

-

@bberger thanks for teh comments.

I'm not sure how it would be a firmware version problem - it doesn't seem like that sort of thing to me. I was thinking maybe the larger nozzle is more sensitive to <insert some effect or other> that means you need to tune <insert some setting> more carefully.

FWIW, I found that I had pressure advance set to zero for some reason (I don't recall when or why I did that) and putting that back on makes it much better, but doesn't eliminate it.

I'm using PrusaSlicer 2.4.0 (my other printer is a prusa).

-

@achrn Are either of you using input shaping? Some folks have reported some sort of interaction with pressure advance.

-

@gloomyandy No, I'm not using input shaping.

-

To follow up:

It's not the slicer, same strange behaviour on Cura and IdeaMaker. I've been using the 0.6 nozzle since a few months and it only recently started.I don't think it's strictly related to Input Shaper either, didn't have the problem in the 3.4 betas. It's either a problem introduced by a setting change of me or one of the 2 3.4 RCs I guess. I still have 2 hours to go on my print, will try disabling IS and PA after before trying to downgrade.

-

It's bridging infill, so you may need to increase the flow rate or extrusion width for the infill. Try grid or triangle pattern and see how it differs.

What type of filament are you using?

-

@phaedrux Mine isn't bridging (It's ordinary infill over a solid bottom layer which is on the print bed), it is grid pattern (rectilinear also breaks up, but not into a regular pattern), it's Das Filament PLA.

It's about as plain / simple a fill case as you can imagine. The total piece is 50mm square, I've stopped the print when it's about 6mm high, the bottom is three solid layers. All layers are 0.4mm.

-

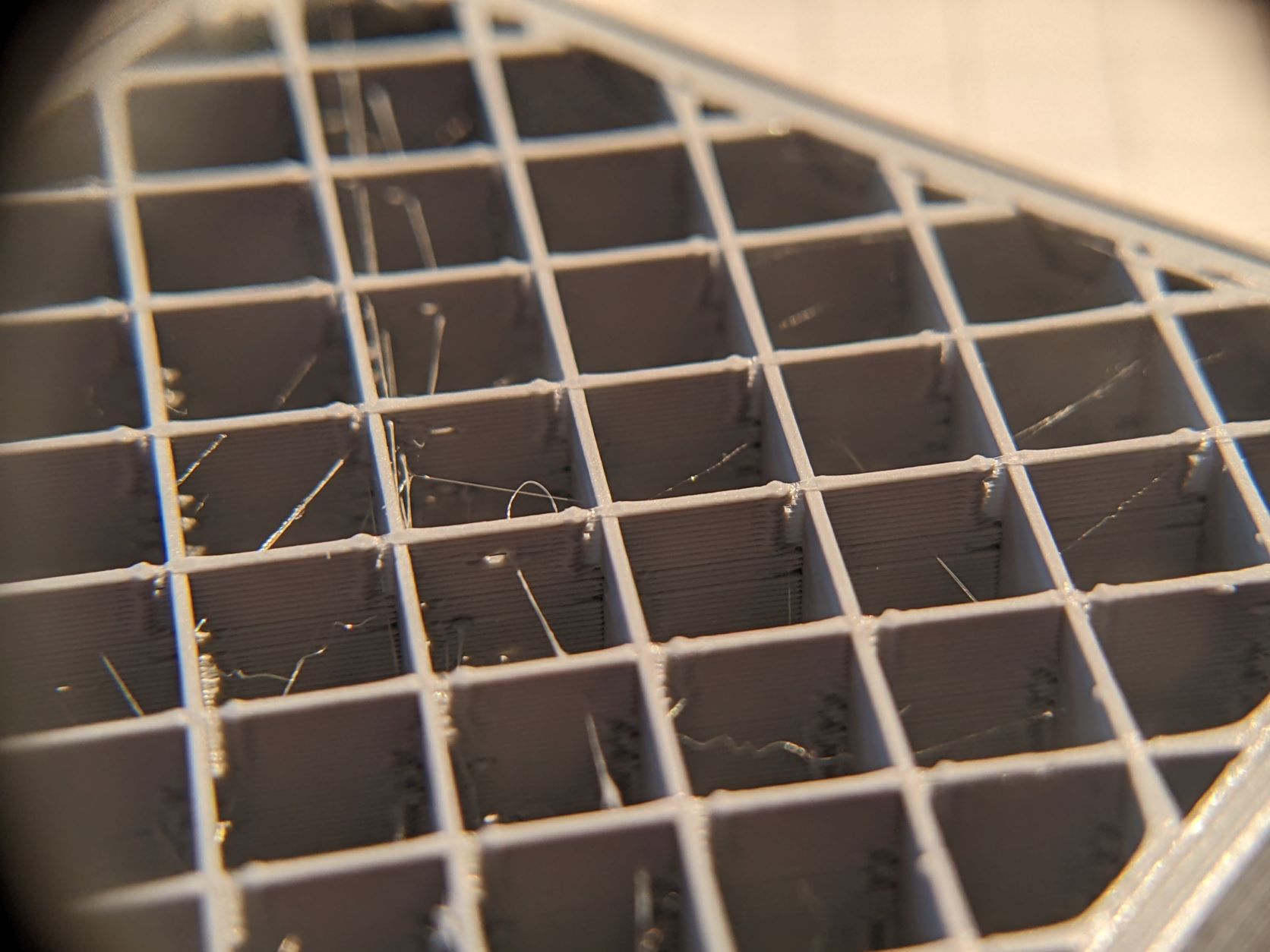

I've found the problem - and it was user error in the slicer

Although I had the slicer set to 0.8mm nozzzle diameter and 0.4mm layers, I had it fixed at 0.45mm extrusion width, so it was trying to place a 'stretched' line of extrusion, and that (apparently) results in a kind of clump-gap flow in general, but when it's in the infill the extrusion it crosses seems to make the clumps clump in a regular pattern.

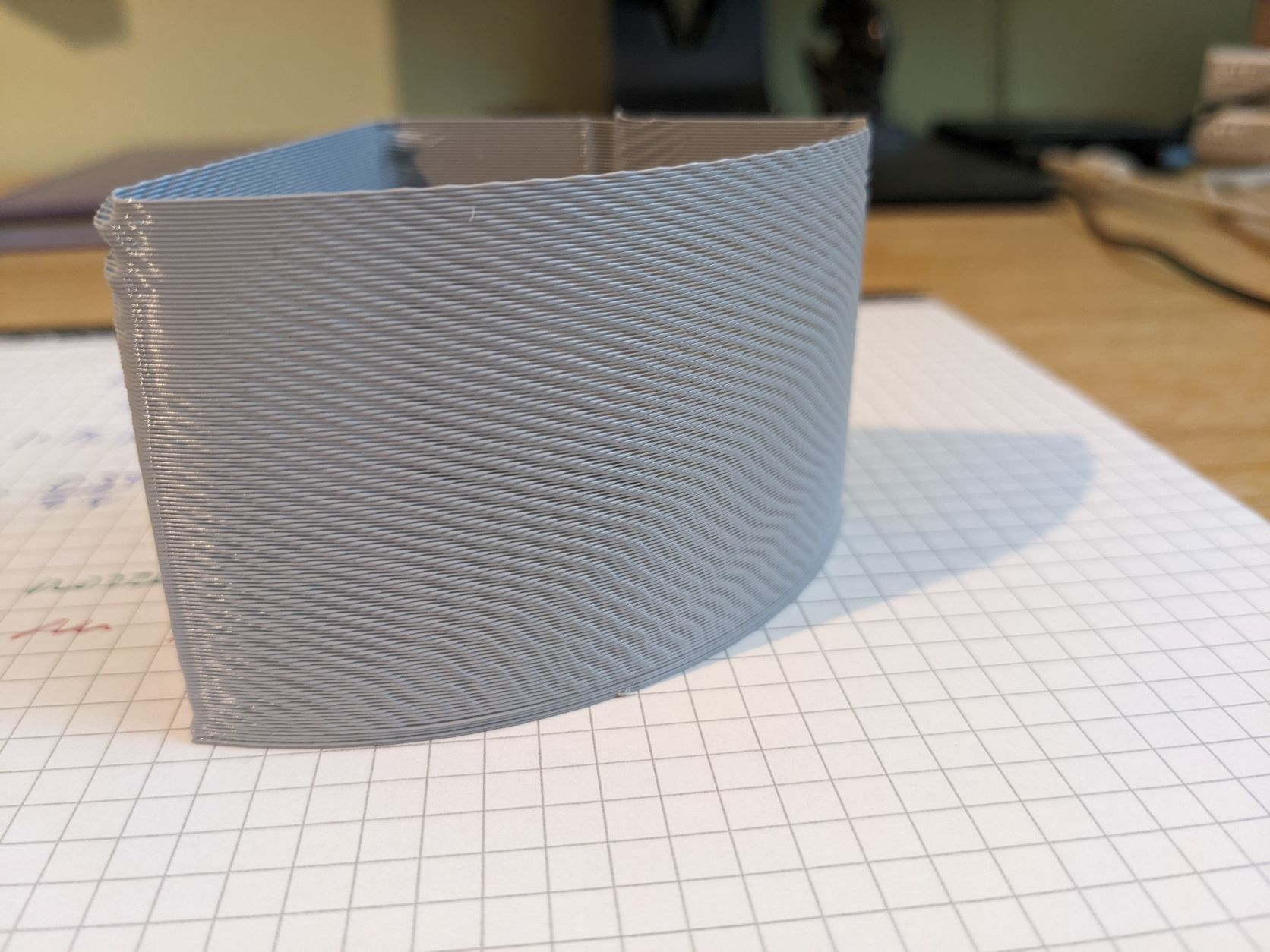

If I do a single line perimeter, no infill it does the same, and I end up with a sort of knitted effect shell:

Having now seen it putting down a proper bead from the nozzle, and the bold thick lines that result, plus the rate it eats filament, I think it would be very obvious that's the problem if I do it again. However, I've never seen a printer with a 0.8mm nozzle under way, so it didn't jump out at me.

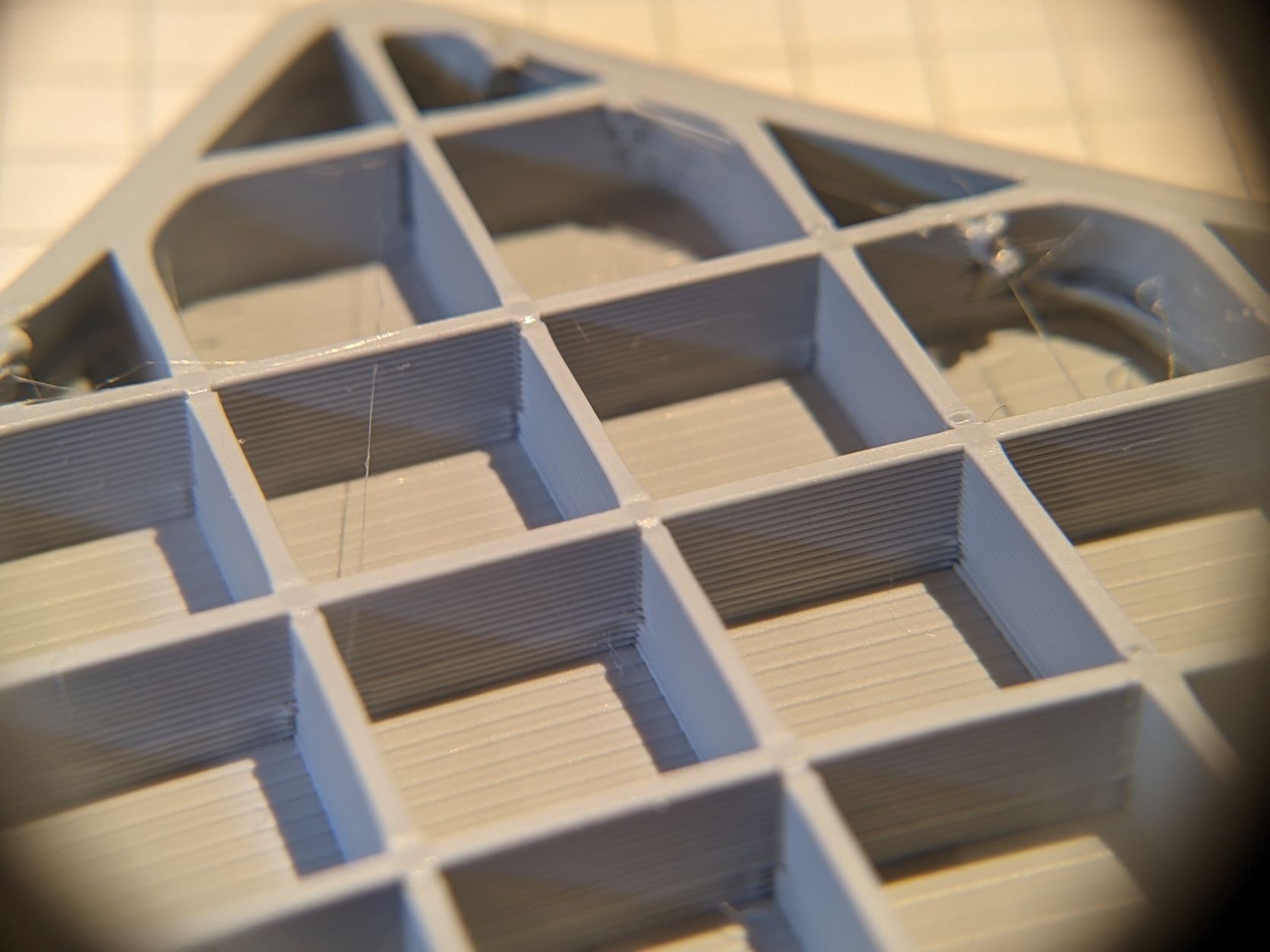

Anyway, infill now behaving itself, and the parts are a good deal chunkier:

Thanks all.

-

@achrn what line width & layer height are you now using on your 0.8mm nozzle for that picture? I've seen something similar on my 0.8mm & 1mm volcano which appeared more often on the first layer. Wondering if I had the same issue...

-

@engikeneer the last picture above (where the fill is OK) is 0.8mm nozzle, 0.3mm layer height, extrusion width 0.9mm.

With 0.4 layer height I've found my printer struggles - some nasty noises from the extruder, and fast infill wasn't staying put on theprevious layer, so at the corners at the ends of runs it was pulling off and then bunching up and tangling. Some more tuning to be done there.

The previous (faulty) effects were 0.8mm nozzle, variously 0.3 and 0.4mm layer height, and (this was the problem) extrusion width 0.45. I was also having terrible trouble with the first layer that was not going down right and needed finessing with babysteps, but I'm back to zero babystepping now - just let it mesh level the bed.

-

@achrn said in strange discontinuous infill:

With 0.4 layer height I've found my printer struggles - some nasty noises from the extruder, and fast infill wasn't staying put on theprevious layer,

That sounds like insufficient heat (or heat transfer), so the plastic is not fluid at the nozzle enough for smooth extrusion?

-

@rjenkinsgb said in strange discontinuous infill:

@achrn said in strange discontinuous infill:

With 0.4 layer height I've found my printer struggles - some nasty noises from the extruder, and fast infill wasn't staying put on theprevious layer,

That sounds like insufficient heat (or heat transfer), so the plastic is not fluid at the nozzle enough for smooth extrusion?

Yes, I thought that was likely. I didn't notice what the temperature graph was showing, but I did have it set at 210, which I think is slightly towards the low end of what the material wants, so it is at least a very possible explanation.

It's a shiny new Revo, so it's 40W, brass block/nozzle/thing and I'm still learning what it can do. I also have a long bowden, which I expect adds to the extruder load and makes pressure advance matter.

-

Figured out my issue.. for some reason I now need to print PLA at 240-250C instead of 190-210C with the same speeds. Not sure why though.. still using the Rapido (HF), still using the same plated copper nozzle. Only change was FW upgrades, but I don't think the thermistor reading is wrong as I can feed it just fine at 200C as always..

My guess right now is that the Verbatim PLA I used got worse towards the inside of the spool. Not sure though why I need 50C more than last week..